A 6 axis load cell is a high-tech tool for precise force measuring. It detects forces and moments in multiple directions at once. These sensors play a crucial role in sectors needing precision and measurements in many directions. They measure forces along the X, Y, and Z axes and torques around these axes. This lets us fully understand the forces involved. Precision load measurement makes them key in fields like manufacturing, aerospace, and robotics.

Key Takeaways

- A 6 axis load cell provides accurate force and moment measurement in multiple directions.

- These sensors are critical in industries requiring high-precision measurements.

- Data from a six-axis weight measuring tool offers comprehensive force analysis.

- Applicable in various fields such as manufacturing, aerospace, and robotics.

- The technology behind load cells ensures precise force measurement for quality and efficiency.

Understanding 6 Axis Load Cells

6-degree-of-freedom force sensors are at the forefront of precision force measurement. They measure forces and torques in many dimensions at once. Unlike traditional technology, 6 axis load cells are crucial in high-precision applications. They measure force across six axes, making them better than standard load cells.

What is a 6 Axis Load Cell?

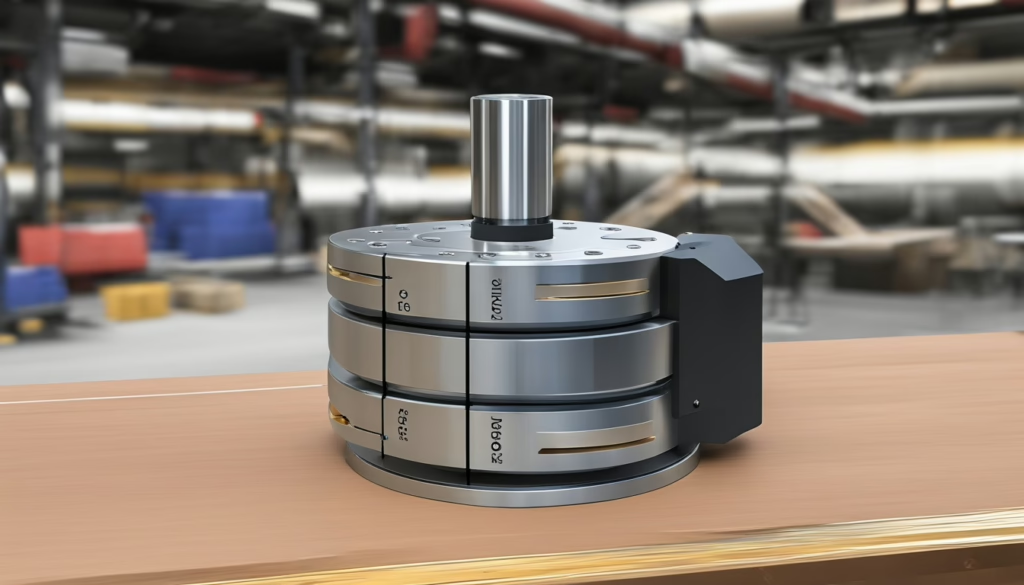

A 6 axis load cell is a high-tech sensor. It measures forces and moments in six directions: X, Y, Z, and their rotational moments. It’s a multi-axis load sensor used in robotics, aerospace, and manufacturing. Unlike standard cells, 6 axis load cells give a full picture of how forces affect a structure.

How Do 6 Axis Load Cells Work?

6 axis load cells use strain gauges to work. They detect mechanical changes when force is applied. These changes turn into electrical signals. This data shows the force from all directions. This accuracy is essential for high-precision tasks.

Main Components of 6 Axis Load Cells

It’s essential to understand a 6 axis load cell’s parts. The main parts are:

- Load Cell Body: It’s the core part that holds the strain gauges and takes on forces.

- Strain Gauges: They measure the mechanical changes from forces. Their placement and tuning are key for correct force measurement.

- Circuitry: These parts process the strains gauge signals into data we can read.

These elements work together to give accurate and detailed force insights. 6 axis load cells offer unmatched precision and deep understanding of force dynamics.

Using 6 axis load cells for precision tasks can change how you collect and analyze data. As this technology gets better, its use in new areas grows.

The Benefits of Precision Force Measurement

Using a precision force measuring tool is key for exact results in many areas. It’s vital in both industrial work and scientific studies. With these devices, operations run smoother and product quality improves.

High Accuracy

A top advantage of precision force measuring gadgets is their accuracy. They use high-accuracy load transducers to minimize errors. This ensures dependable measurements for critical tasks, improving product quality and safety across sectors.

Enhanced Performance

A precision force measuring tool greatly boosts performance. Its accuracy means better process control, leading to top efficiency. By incorporating industrial weighbridge sensors, they enhance capabilities in large-scale operations. This strengthens performance and helps with operational efficiency.

Versatility in Applications

The flexibility of precision force measuring tools is a big plus. They fit many uses, from industrial weighbridges to lab tools. Thanks to high-accuracy load transducer tech, they offer reliable measurements for a variety of challenges. This meets specific needs well.

Types of Multi-Axis Load Sensors

It’s crucial to grasp the different multi-axis load sensors and their unique benefits. These sensors, like the 6 axis load cell, measure forces in several directions. They give detailed data for accurate analysis.

Multi-Directional Load Cells Explained

Multi-axis load sensors measure many force parts, including x, y, and z axes forces. For example, a 6 axis load cell also looks at rotational forces. This process offers a deeper insight into stress and strain in specific uses. Such detail is key in areas needing high precision and force analysis.

Differences Between 3 Axis and 6 Axis Load Cells

Three-axis load cells and six-axis ones differ in measurement scope. A three-axis version measures forces in x, y, and z directions, good for simple tasks. Meanwhile, a 6 axis load cell also gauges moments around these axes for a fuller analysis. This aspect is essential in complex tasks like robot motion studies or tire testing, where knowing rotational forces is a must.

Choosing the Right Load Sensor

Picking the right load sensor depends on task complexity, the environment, and needed accuracy. For complex force measurements in multiple directions, a six-axis load cell is best. The MCS10 multi-axis load sensor from HBM is known for its reliability and precision. It’s great for mechanical engineering, robotics, and structural tests. Plus, it reduces crosstalk and comes with easy-to-use TEDS technology, making it ideal for various critical tasks.

Industrial Applications of 6 Axis Load Cells

Load cell tech plays a crucial role in many fields. It offers accurate load measurement. This boosts performance and efficiency in tough situations.

Manufacturing

In manufacturing, 6 axis load cell applications ensure machines work right. They keep product quality high and waste low. These sensors boost production and keep things consistent.

Aerospace

Aerospace greatly benefits from load cell technology. These sensors test aircraft parts for durability and performance. They ensure materials can handle flight’s tough demands, keeping everything safe.

Robotics

Robotics uses 6 axis load cell applications for smarter machines. Sensors give robots precise control for detailed tasks. This makes robots more capable, improving technology’s reach and efficiency.

Why Choose High-Accuracy Load Transducers?

Choosing a high-accuracy load transducer is key in fields where precision is everything. Devices like the 6 degree of freedom force sensor boost reliability and performance. They provide essential accuracy for safety, quality control, and reducing material waste.

In biomedical research, precise force measuring devices are crucial. They help get accurate, reliable data. Tiny differences in force can mean the difference between success and failure. The high accuracy of these sensors is critical.

The implementation of a high-accuracy load transducer can transform the operational efficacy in various sectors by delivering precise measurements that are vital for advanced manufacturing and engineering processes.

Aerospace, robotics, and industrial automation also gain from the 6 degree of freedom force sensor. These sectors need devices that can carefully measure force and load. This helps drive innovation and tech progress.

Let’s explore a detailed comparison of the advantages offered by these advanced load transducers:

| Characteristic | Traditional Load Sensors | High-Accuracy Load Transducers |

|---|---|---|

| Accuracy | Moderate | High |

| Application Range | Narrow | Wide |

| Material Waste Reduction | Low | High |

| Cost Efficiency | Average | Optimal |

Investing in a precision force measuring device leads to better efficiency and quality. It helps industries meet high standards and encourages innovation.

Load Cell Technology Improvements Over the Years

Over the years, load cell technology has made great advances. These advances come from improvements in material science, modern electronics, and software. Each area has contributed significantly to the way we measure and analyze force today.

Advancements in Material Science

Material science has greatly advanced 6 axis load cell technology. New materials have made sensors more durable and sensitive. This means they can measure loads more precisely, even in tough conditions.

For example, using advanced alloys and composites has made sensors stronger. They can now handle harsh environments but still keep their accuracy.

Integration with Modern Electronics

Modern electronics have transformed load cell technology. This change has made collecting data faster and more efficient. Precision load measurement has seen big improvements.

Digital signal processing and smart sensors now allow for instant data sharing. This makes load cells more reliable and useful in many industries.

Software Enhancements

Software has gotten better, pushing load cell technology forward. Now, advanced algorithms help us understand complex force measurements better. This means users can make smarter, informed choices from their data.

These software updates make sure data isn’t just accurate. They also make sure it’s easy to use for important decisions.

| Key Area | Improvements | Impact on 6 Axis Load Cell |

|---|---|---|

| Material Science | Use of advanced alloys and composites | Enhanced durability and accuracy |

| Modern Electronics | Digital signal processing, smart sensors | Faster data collection, real-time transmission |

| Software Enhancements | Advanced algorithms, analytical tools | Improved data interpretation, actionable insights |

Custom Load Cell Designs for Specialized Needs

We know that standard solutions don’t always work for everyone. That’s why we provide custom load cell design services. Whether you need changes in size, capacity, connectivity, or material, we’ve got you covered. Our custom solutions ensure you get precision load measurement solutions that fit your needs perfectly.

Our expertise spans many industries, allowing us to create load cells that give accurate, reliable readings, no matter the challenge. For instance, we can design a 6 axis load cell specifically for the complex needs of manufacturing or aerospace.

Creating a custom load cell starts with understanding what you really need. We team up with you to come up with a solution that fits right in with your system and boosts its performance and reliability. This way, we ensure that every load cell we make meets your exact needs.

If you need a custom design due to space limits, environmental factors, or unique measurement needs, our experts are ready to help. We focus on precision and personalization to make sure our 6 axis load cells deliver unmatched accuracy and reliability.

Working with XJCSENSOR for Your Load Cell Requirements

Partnering with XJCSENSOR means you get the best precision load measurement solutions. They’re customized for what you need. Our vast experience in making six-axis weight measuring tools ensures top performance and reliability.

Collaborative Design Processes

We value teamwork in our design process at XJCSENSOR. We know every client has unique needs. So, we make sure each precision load measurement tool is made just right.

Our team works closely with you. We offer custom services like changing dimensions, improving performance, and choosing materials. This way, we create solutions that meet your exact needs.

Expertise in Load Cell Manufacturing

XJCSENSOR is skilled in making load cells for many sectors, including robotics, medical, and new energy. We focus on quality. Our advanced tech produces six-axis weight tools that are very accurate and long-lasting.

We do strict testing and use the best materials. We also follow industry guidelines strictly. All this shows our dedication to being the best.

| Feature | Standard Load Cells | Custom Load Cells |

|---|---|---|

| Design Flexibility | Limited | High |

| Performance Optimization | Static Parameters | Client-Specific Adjustments |

| Material Selection | Standard Options | Customized Choices |

Conclusion

The use of the 6 axis load cell has transformed many industries. These sensors are key for precise force measurement in fields like manufacturing and robotics. They offer reliable data, making operations more efficient and high-performing.

Technology in load cells is always advancing. New materials and better electronics are increasing their precision. This means specialized needs across different industries can be met accurately and dependably.

At XJCSENSOR, we aim to push the limits of load cell applications. Our focus on innovation and quality helps us boost efficiency in various sectors. For more on how our load cell amplifiers can upgrade your system, check out our load cell amplifiers page. We are proud to offer cutting-edge technology to meet our customers’ complex needs.