In today’s fast-changing manufacturing world, industrial automation sensors play a key role. They help monitor and control industrial processes in real-time. By using the top industrial automation sensors, factories can improve their efficiency, cut down on downtime, and boost quality. These steps are vital for staying ahead in the market.

At XJCSENSOR, we focus on delivering top-notch, customizable automation solutions for our clients. We know that the right sensors can greatly help manufacturers increase their output and make operations smoother.

Key Takeaways

- Industrial sensors are essential for real-time monitoring and control.

- Choosing the best industrial automation sensors significantly impacts factory performance.

- Automation solutions help optimize production lines and reduce downtime.

- XJCSENSOR specializes in customizable sensor solutions for various industries.

- Maintaining quality control is key for staying competitive.

Introduction to Industrial Automation Sensors

Industrial automation sensors are key to boosting productivity and keeping factories running smoothly. They track and measure things like temperature, pressure, motion, and presence. This real-time data helps industries make better choices, leading to more efficient operations.

Exploring automation technology shows how sensors have grown. From simple mechanical tools to modern digital ones, their development is impressive. Smart sensors have changed the game, making systems that can adjust to new situations.

Knowing the different types of sensors is vital for any factory wanting to get better. The right sensors can cut downtime, lower mistakes, and boost productivity. The right sensor tech can truly change how factories work today.

Understanding Factory Efficiency and Automation

Factory efficiency is key to good manufacturing performance. It looks at how well a factory works, including speed, waste, and energy use. Knowing how these parts work together is important.

Automation is a big help in making factories more efficient. It uses new tech to make things faster and better. This means less mistakes and better tracking of how things are going.

Let’s see how automation changes things:

| Metric | Before Automation | After Automation |

|---|---|---|

| Production Speed (units/hour) | 50 | 100 |

| Waste Reduction (%) | 10 | 3 |

| Energy Consumption (kWh/unit) | 2.5 | 1.2 |

Using smart sensors in automation helps collect better data. This lets factories watch their work closely. They can keep making things better and better, using data to guide them.

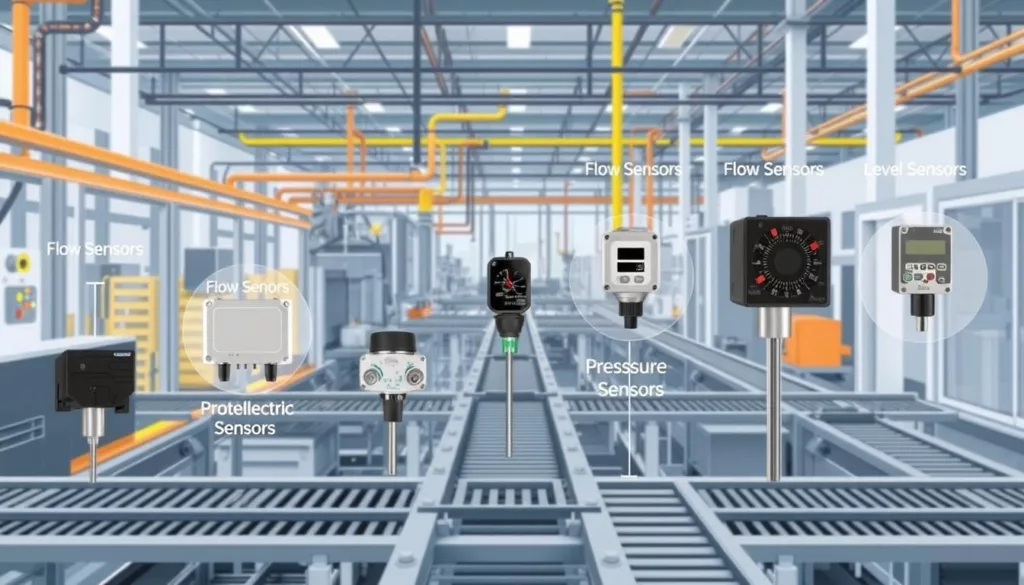

Types of Industrial Automation Sensors

In the world of sensor technology, many types of industrial automation sensors exist. Each one is made for a specific job in different automation tasks. Knowing about these types helps make industrial processes more efficient and reliable. Here’s a quick look at the main sensor types used in factories and industries.

- Proximity Sensors: These sensors find objects without touching them. They’re used a lot in making things and keeping things safe. They make work flow better.

- Photoelectric Sensors: These sensors use light to find objects. They’re key in packing and sorting things. They measure distance well and work with clear objects too.

- Inductive Sensors: They find metal objects. They’re used a lot in making machines work because they watch metal parts all the time.

- Vision Sensors: These sensors take pictures and make choices based on what they see. They help check quality by looking closely at things.

- Ultrasonic Sensors: They measure distance by sending sound waves. They’re great for finding objects in hard-to-see places.

- Laser Sensors: These sensors are very accurate. They’re used for measuring distance and for precise work, like in making things.

Every type of industrial automation sensor plays a big role in making things better. They help make work more efficient and productive. Knowing how they work helps pick the right one for the job.

Best Industrial Automation Sensors for Factory Efficiency

In today’s fast-paced manufacturing world, picking the right industrial automation sensors is key. Many sensors on the market offer special benefits for different needs. Knowing these options helps manufacturers choose wisely to improve their operations.

Overview of Top Sensor Options

Several sensors are vital for better factory performance. Here are some of the most important ones:

- Proximity Sensors: Great for finding objects without touching them, they’re perfect for automating machines.

- Vision Sensors: Crucial for checking product quality, they look at visual data to ensure products are up to standard.

- Inductive Sensors: Detect metal objects with electromagnetic fields, making them essential for automation.

- Photoelectric Sensors: Use light to detect changes, useful in many tasks like packaging and sorting.

Benefits of Each Sensor Type

Knowing what each sensor does helps use them better:

| Sensor Type | Key Benefits |

|---|---|

| Proximity Sensors | Non-contact detection, reduced wear and tear, quick response time. |

| Vision Sensors | Enhanced quality assurance, real-time data analysis, versatility across applications. |

| Inductive Sensors | Durable for harsh environments, reliable performance, minimal maintenance required. |

| Photoelectric Sensors | Flexible installation options, high sensitivity, effective in diverse lighting conditions. |

For industries needing precise solutions, there are customizable options. A top manufacturer, XJCSENSOR, offers versatile force sensors. They provide detailed data for uses like industrial automation and medical devices.

Industrial Proximity Sensors and Their Applications

Industrial proximity sensors are key to better manufacturing. They allow for contactless detection, which means no physical touch. This helps machines last longer and cuts down on repair costs. Knowing how these sensors work helps them fit well in different places.

How Proximity Sensors Enhance Performance

Proximity sensors boost how well things work. They bring:

- Contactless operation: This cuts down on wear and tear, making machines last longer and saving on repairs.

- Fast response times: Quick detection means faster adjustments, speeding up production.

- Versatile sensing capabilities: They work with many materials, fitting into many industrial needs.

Key Features to Look For

When picking proximity sensors, look for these key features:

- Sensing distance: Pick sensors with the right range for your space to ensure they work well.

- Environmental resistance: Check how they handle humidity, temperature, and chemicals to see if they last.

- Compatibility with existing systems: Make sure they fit with your current setup.

Utilizing Photoelectric Sensors in Manufacturing

Photoelectric sensors are key in today’s manufacturing applications. They use light beams to find objects, helping with automation. This method is based on light transmission and reflection, making it reliable for monitoring.

These sensors are vital for better efficiency enhancement. They cut down on errors, keeping product quality high. This leads to more production, less downtime, and less waste.

Photoelectric sensors also fit well in different factory settings. There are many types, like through-beam and diffuse sensors, for various needs. They work well even in tough conditions, unlike older methods.

As companies aim for more productivity, photoelectric sensors are a big help. They improve performance and keep businesses ahead in the changing manufacturing world.

Inductive Sensors: The Hidden Power in Automation

In the world of industrial automation, inductive sensors are key but often overlooked. They are great at finding metallic objects without touching them. This boosts automation performance. Knowing how they work and their common uses in factories helps industries use them better.

Working Principles of Inductive Sensors

Inductive sensors use electromagnetic fields to find metal. When metal enters their zone, it changes the field. This change sends a signal to the sensor, showing the object is there. Key features of inductive sensors include:

- Non-Contact Detection: They don’t need to touch, which cuts down on wear.

- Durability: Built to last in tough industrial settings, they’re reliable for a long time.

- Rapid Response Times: They detect fast, which is key for keeping production high.

Common Use Cases in Factories

Inductive sensors are used in many ways in factories. Here are some examples:

- Positioning: They accurately find where parts are on conveyors.

- Counting: They keep track of how many items go through production lines.

- Quality Assurance: They make sure the right parts are used for assembly.

Adding inductive sensors to automated systems makes things run smoother. They work well in tough places, showing their value in improving automation.

Vision Sensors: A New Frontier in Quality Control

Vision sensors are changing the game in manufacturing. They use advanced imaging to check products, making sure they’re up to standard. This means products are more reliable and consistent.

Using vision sensors has many benefits. They spot defects better, which means fewer mistakes. They also work fast, saving time and boosting efficiency. This helps manufacturers stay ahead while saving money.

Vision sensors are key to better quality control in manufacturing. They make processes smoother and products better. To learn more about different sensors, like torque and force, click here.