In today’s fast-evolving industrial landscape, the demand for high-quality force sensors is key. This article shines a light on the top force sensor makers in the USA. They are known for their innovations in measurement technology.

We will look at key components like load cells, strain gauges, and pressure transducers. These industry leaders offer the Best Force Sensor solutions for various needs. Understanding the role of US force sensors shows their importance in precision measurement.

It also highlights the expertise of these manufacturers. They deliver advanced and reliable sensor technologies.

Key Takeaways

- Discover leading brands in the force sensor market.

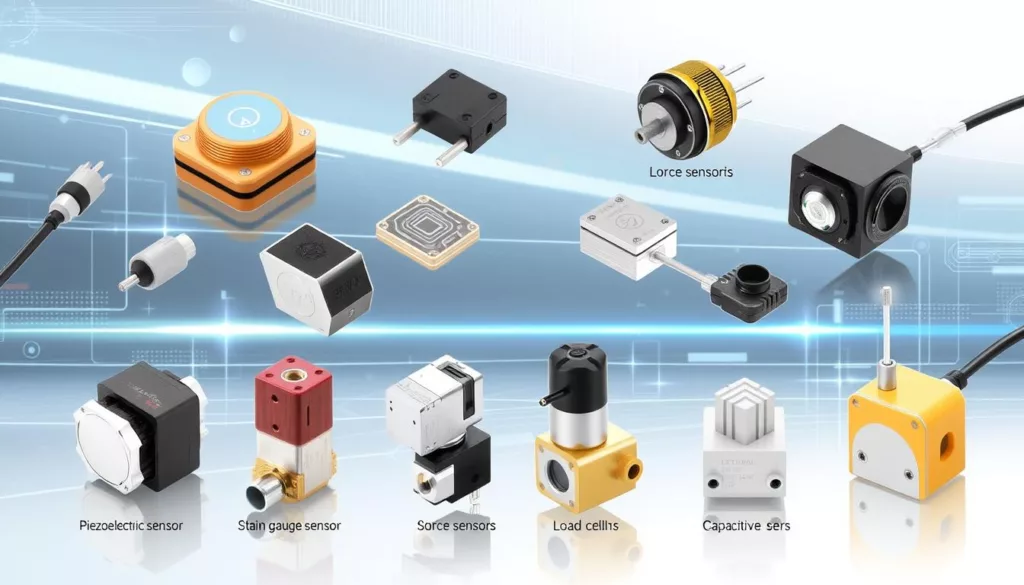

- Learn about various types of force sensors including load cells and strain gauges.

- Understand the importance of precision measurement in industrial applications.

- Explore innovative technologies driving advancements in sensor solutions.

- Gain insights into customer support and services offered by manufacturers.

Introduction to Force Sensors

Force sensors are key devices that turn mechanical force into electrical signals. This lets us measure and analyze with great precision. They are vital in many fields, thanks to their role in force sensing. Load cells and strain gauges, for example, measure force in different ways but aim for the same goal: accuracy.

This technology is a must in many industries. It makes processes more efficient and helps improve quality. So, it’s a big deal in sectors like manufacturing, aerospace, and healthcare.

What Is a Force Sensor?

A force sensor detects and measures the force on an object. It changes the mechanical force into an electrical signal. This makes it possible to monitor and control things accurately.

Load cells are often used in weighing systems. Strain gauges, on the other hand, are key for checking the health of structures.

Applications of Force Sensors

Force sensors are used in many areas, helping various industries. They make processes better and improve quality. Here are some main uses:

- Weight measurement: Load cells give accurate weight readings in industrial scales. This is important for managing inventory.

- Pressure measurements: Pressure transducers check hydraulic systems. They ensure safety and reliability.

- Quality control: Strain gauges are used in load testing. They help check if structures are safe, keeping everyone safe.

Top Force Sensor Manufacturers and Suppliers

In the United States, the field of force sensor technology is filled with key players. A few stand out for their innovative approaches and expertise. These companies offer high-quality solutions for different needs in the industry. Each supplier brings unique capabilities and specializations, providing a wide range of products.

Overview of the Leading Companies

- HBM is known for its robust load cells, which are precise and of high quality. This company focuses on digital sensor technology, improving accuracy in many applications.

- Interface specializes in high-capacity force sensors for tough environments. Their innovations in load cells and torque sensors meet the needs of industries that require precise measurements, even in extreme conditions.

- Futek combines advanced sensor technology with compact designs, appealing to a wide range of applications. Their focus on customization makes them stand out from others.

Specializations in Force Sensor Technology

| Company | Specialization | Key Feature |

|---|---|---|

| HBM | Load Cells | Digital sensor technology for improved accuracy |

| Interface | High-Capacity Sensors | Designed for extreme conditions |

| Futek | Custom Load Cells | Compact and innovative designs |

Understanding Different Types of Force Sensors

Force sensors are key in many industries, giving precise force measurements. Knowing the different types helps us pick the best for each job. Load cells, strain gauges, and pressure transducers are top choices for measuring force.

Load Cells

Load cells are vital in force sensing tech. They turn force into an electrical signal, key for weighing. There are several types, like hydraulic, pneumatic, and strain gauge load cells.

- Hydraulic Load Cells

- Pneumatic Load Cells

- Strain Gauge Load Cells

Each type has its own strengths, fitting various needs in manufacturing and more.

Strain Gauges

Strain gauges are vital for precise strain and stress measurements. They’re used in structural checks and material research. Their small size makes them useful in many fields, from medicine to space tech.

Pressure Transducers

Pressure transducers monitor fluid power systems. They change pressure into electrical signals for instant data. They’re essential in oil, auto, and food industries for smooth operations. Learn more about these sensors at this resource.

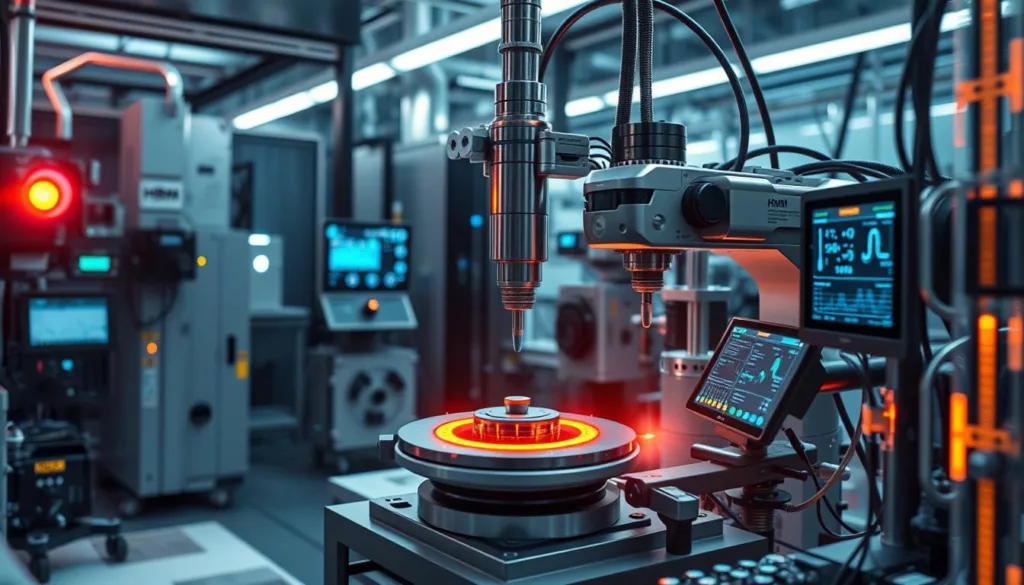

Key Players in the Industry

In the world of force sensors, HBM and Interface are leaders. They focus on quality and innovation. Their products meet the needs of many industries that need precise measurements.

HBM: Innovation and Quality

HBM is known for its innovation in measurement. With over 60 years of experience, they keep improving their technologies, like load cells. Their products are very accurate and reliable, keeping operations safe.

Their quality sensors work well with different systems. They help collect accurate data and track performance.

Interface: Precision Measurement Solutions

Interface is all about precision measurement. They make high-performance load cells and torque sensors. Their products can handle tough environments, making them great for industrial and commercial use.

Interface’s solutions are very accurate. They provide important data for critical processes.

| Feature | HBM | Interface |

|---|---|---|

| Years of Experience | 60+ | Over 50 |

| Specialization | Load Cells | Load Cells, Torque Sensors |

| Target Industries | Aerospace, Automotive, Manufacturing | Energy, Robotics, Transportation |

| Key Product Feature | High Precision | High Reliability |

Emerging Trends in Force Sensor Technology

Force sensor technology is changing fast, thanks to new ideas and a need for better features. The use of IoT in force sensors is a big part of this change. It’s making it easier to collect and use data.

Smart sensors with IoT can talk wirelessly. This lets us watch and analyze things in real-time. It helps make things run better and helps us fix things before they break.

Integration of IoT Technologies

IoT in force sensors is opening up new ways to use them in industry. These smart sensors help a lot:

- Remote monitoring: Sensors send data to us right away, so we can make changes fast.

- Data analytics: We can look at the data to guess when things might break or need fixing.

- Scalability: We can grow systems easily, without much trouble, to meet changing needs.

Advancements in Sensor Materials

New materials for sensors are making them better and more lasting. These materials are light but strong, even in tough conditions. They help a lot:

- Improved accuracy: New materials mean we can measure things more precisely, even in hard places.

- Longevity: These materials make sensors last longer, so we don’t have to replace them as often.

- Flexibility: New designs can fit many uses without losing their effectiveness.

Looking at these new developments in force sensors, we see big changes coming. The mix of IoT and new materials will make things better in many areas. It’s leading to a future that’s more efficient and based on data.

How to Choose the Right Force Sensor

Choosing the right force sensors for your needs is key. You must understand the application needs of your project. Each project has its own set of requirements, like the type of force and the environment. This knowledge helps pick the best sensor for your industrial needs.

Determining Application Needs

First, you need to know what your application needs are. Think about these points:

- The specific type of force measurement required.

- Environmental conditions such as temperature, humidity, and chemicals.

- How well it fits with your current systems or machinery.

Factors to Consider: Accuracy, Range, and Cost

When looking at factors to consider, focus on three main things:

- Accuracy in sensors: For precise measurements, like in quality control, high accuracy is a must. Sensors with better accuracy usually perform better.

- Range: Make sure the sensor can handle the force levels in your application.

- Cost of force sensors: Balance the total cost against your budget. Think about maintenance and how long it lasts, not just the price.

For more on force sensor technology, check out XJCSENSOR. They offer a wide range of force sensors for industrial use.

Customer Support and Service from Manufacturers

Good customer support is key when choosing a force sensor maker. It helps with setup, calibration, and upkeep. This ensures the sensor works well in different situations. Companies like HBM and Interface lead by providing top-notch support.

Importance of Technical Assistance

Technical help is vital for sensor users. It helps get the most out of the investment. From the start to fixing problems, expert support keeps things running smoothly. This teamwork boosts understanding and performance.

Warranties and Product Testing

Sensor warranties show quality and reliability. Before sale, makers test their products thoroughly. Good warranties mean the maker trusts their product and protects your investment. Knowing warranty details helps understand what to expect, as shown by industry sources. Strong quality checks also build trust in the manufacturer.

| Manufacturer | Technical Assistance | Warranties | Product Testing |

|---|---|---|---|

| HBM | Comprehensive technical guidance | 2 years standard warranty | Extensive pre-release performance testing |

| Interface | 24/7 customer service | 3 years warranty on most products | Detailed lab testing protocols |

Innovation in the Force Sensor Market

Recent breakthroughs in torque measurement technology have changed the game for force sensors. These new innovations focus on better precision and reliability. They make it possible to get more accurate readings in many rotational tasks, helping out a lot of industries.

Recent Advancements in Torque Sensors

The world of force sensors has seen big improvements. Key points include:

- Increased Accuracy: New manufacturing methods mean torque sensors give more precise results.

- Improved Responsiveness: Better sensors react faster to changes, helping with quick data collection and analysis.

- Advanced Digital Integration: New models work well with digital systems, making data easier to see and manage.

These advancements in torque sensors are key for modern industrial automation and robotics. They need to be very reliable.

Case Studies of Successful Implementations

Looking at case studies shows how companies use force sensors in their work. Here are some examples:

- Automotive Industry: A big car maker used torque sensors to check assembly. This cut down on mistakes and improved quality.

- Aerospace Sector: An aerospace company used new torque tech to test parts safer. This led to fewer product recalls.

- Robotics: A robotics company added new force sensor tech to their assembly line. It made production faster and more efficient.

These examples show how versatile torque sensors are. They play a big part in boosting productivity and safety in different fields.

Conclusion

The world of force sensors is always changing, thanks to new tech and different needs in industries. This overview shows how important force sensors are in many fields. Top makers in the USA lead by creating accurate and reliable solutions.

Knowing what these top companies can do helps us make better choices when picking sensors. Our last thoughts stress the need to match sensor tech with specific needs. This makes things work better and safer.

Learning about the best makers and what they offer helps businesses get the best sensors. This means they can work more efficiently and effectively.