In precision manufacturing, force sensor technology is key for accurate measurements and reliable operations. It helps engineers and industrial professionals improve production processes. Using advanced sensor solutions can greatly improve precision assembly, leading to better results in the manufacturing chain.

By using force sensor technology in precision manufacturing, we can make our methods more efficient and high-quality. We aim to offer solutions that meet our clients’ specific needs, helping them excel in assembly.

Key Takeaways

- Force sensor technology is essential for accurate measurement in manufacturing.

- Implementing sensor solutions can lead to greater operational efficiency.

- Precision assembly benefits from real-time data and consistent monitoring.

- Customizable force sensors ensure adaptability in various manufacturing environments.

- Understanding the role of sensors enhances quality control measures.

Introduction to Force Sensor Technology

Force sensor technology is key in today’s manufacturing world. It gives exact force readings, making production better. This overview shows how force sensors boost efficiency in many fields.

Force sensors give real-time data, helping find and fix assembly issues. This makes work safer and products better. Companies use them to keep quality high and stay ahead in the market.

Adding force sensors to manufacturing makes processes better and supports quality checks. We’ll look at different types of force sensors and their uses in precision manufacturing next.

The Importance of Precision Manufacturing

Precision manufacturing is key in today’s industry. It boosts product quality and makes operations more efficient. By cutting down on waste and rework, companies save resources and increase profits.

Today’s consumers want high-quality products. To meet this demand, companies must improve their processes. Using advanced tools and methods, like force sensors, helps maintain top-notch quality assurance. This leads to better products for customers.

Choosing precision manufacturing helps companies stay competitive. Investing in the right technology is essential for high-quality standards. This approach not only meets market needs but also sets companies up for success in the long run.

| Benefits of Precision Manufacturing | Description |

|---|---|

| Enhanced Product Quality | Meets or exceeds customer expectations through meticulous standards. |

| Reduced Waste | Minimizes material waste resulting from errors or inefficiencies. |

| Increased Efficiency | Streamlines operations, improving overall productivity. |

| Lower Costs | Reduces rework and material costs, boosting profitability. |

| Competitive Advantage | Positions firms favorably in a crowded marketplace. |

Understanding Force Sensors

Force sensors are key in measurement technology. They turn force or pressure into electrical signals for analysis. These devices are vital for tracking force in many scenarios. Knowing how they work is important for using them well in manufacturing.

Different types of force sensors use different technologies. For example:

- Strain Gauges – Measure how much something bends when force is applied.

- Piezoelectric Sensors – Make an electrical charge when they feel mechanical stress.

- Capacitive Sensors – Notice changes in capacitance when force is applied.

Each type has its own special function for different measurement needs. This makes them versatile in manufacturing. Understanding these mechanics helps use sensors more efficiently, boosting productivity.

| Type of Force Sensor | Principle of Operation | Typical Applications |

|---|---|---|

| Strain Gauge | Measures deformation in a material under stress | Load testing, structural monitoring |

| Piezoelectric Sensor | Generates voltage when pressure is applied | Vibration monitoring, impact sensing |

| Capacitive Sensor | Detects changes in capacitance due to force | Touch applications, pressure mapping |

Types of Force Sensors Used in Manufacturing

Knowing about different force sensors is key for better manufacturing. These sensors turn mechanical force into electrical signals. This makes automation and precision better. Load cells, strain gauges, piezoelectric sensors, and capacitive sensors are the main types used.

Each type has special features for certain jobs.

Load Cells

Load cells are top-notch for weighing things. They change mechanical force into an electrical signal. They are very accurate and stable, giving precise weight readings.

They are used in industrial scales, quality control, and more.

Strain Gauges

Strain gauges measure how much something bends or stretches under force. They change their electrical resistance based on the stretch. They are flexible and fit into many places.

This makes them great for testing stresses in beams, bridges, and more. They are used in aerospace, cars, and building construction.

Piezoelectric Sensors

Piezoelectric sensors use materials that make an electric charge when stressed. They are best for measuring dynamic forces, like vibrations and impacts. They are fast and can detect small forces.

Robots and healthcare use them a lot.

Capacitive Sensors

Capacitive sensors measure force by how close an object is. They are good for not touching things. This makes them perfect for touch screens and cars.

They are also used in gadgets and electronics.

Choosing the right sensor can really help manufacturing. For more on using force sensors in machines, check out this link.

Force Sensor Technology in Precision Manufacturing

Force sensor technology is key in precision manufacturing. It lets us track and analyze forces during production. This gives us important data to make our operations better.

By using this technology, we get insights that help us make better decisions. This leads to better control over our processes. As a result, manufacturers can make fewer mistakes, which makes customers happier.

Our use of force sensor technology keeps us leading in manufacturing innovation. We customize solutions for our customers, showing our dedication to quality. These advanced sensors improve accuracy and help us make products that meet high standards.

Benefits of Utilizing Force Sensors

Using force sensors in manufacturing brings big benefits. It makes processes more efficient and precise. Companies see improvements in several important areas.

Improved Accuracy and Reliability

One key force sensors benefit is better accuracy in measurements. This means fewer errors in production. It ensures products meet exact standards.

The data from these sensors is reliable. This builds trust in the quality of the final products.

Enhanced Quality Control

Force sensors help a lot with quality control. They give real-time feedback on forces during manufacturing. This lets teams spot problems right away.

This makes the production process smoother. It cuts down on waste and failures. The result is a more reliable manufacturing process.

| Benefit | Description | Impact on Manufacturing |

|---|---|---|

| Accuracy | Precise measurement of force applied in processes | Reduced errors in product specifications |

| Reliability | Consistent and dependable data for decision-making | Increased trust in production quality |

| Quality Control | Real-time monitoring for defects and inconsistencies | Enhanced ability to meet quality standards |

Applications of Force Sensor Technology in Manufacturing

Force sensor technology is now key in many manufacturing areas. It boosts precision and efficiency, changing how things are done.

Precision Assembly

In precision assembly, force sensors are essential. They help ensure parts fit together just right. This tech allows for:

- Real-time force measurement during assembly

- Detection of inconsistencies that might lead to defects

- Enhanced control over assembly pressure and alignment

Automotive Manufacturing

In car making, safety and reliability are top priorities. Force sensors help by:

- Monitoring fastening processes to guarantee the correct torque

- Testing components for durability and load capacity

- Facilitating the assembly of high-stakes components such as brakes and frames

Aerospace Engineering

Aerospace engineering needs the highest safety and performance standards. Force sensors help by:

- Assuring the accuracy of structural assemblies

- Enabling rigorous testing of materials under stress

- Supporting the precise assembly of complex systems like avionics and fuselages

Using force sensor technology in these fields shows its wide range of uses. It leads to better quality control and more efficient work.

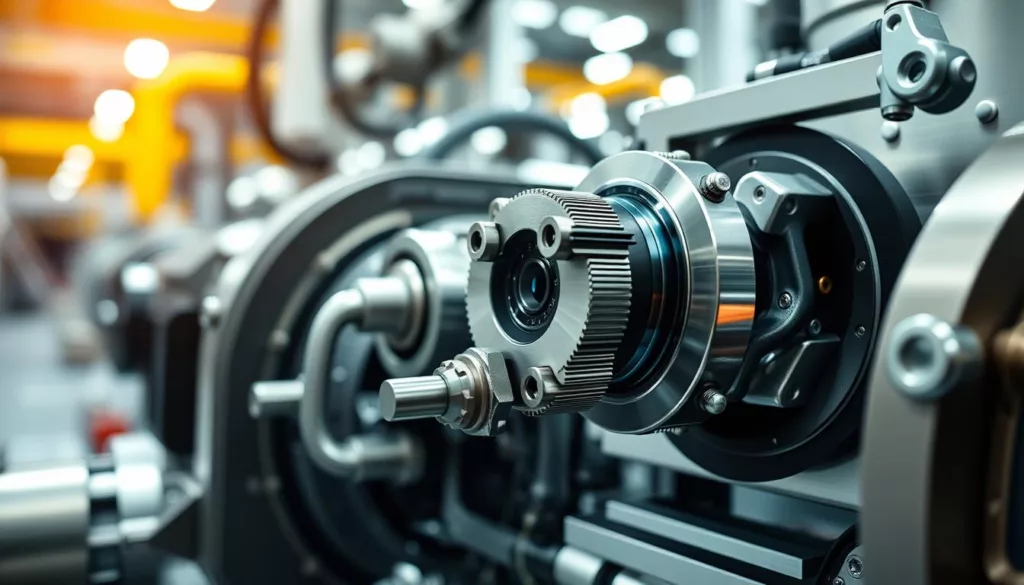

The Role of Torque Sensors

In precision manufacturing, knowing about torque sensors is key for top performance. These sensors measure the rotational force. This helps manufacturers keep up with quality standards. Different types of sensors do this job well, giving important data for machine operation.

Types and Functions

Torque sensors are made in various forms to fit different needs. Here are some common ones:

- Rotary Torque Sensors: Used in rotating machines to measure torque directly on the shaft.

- Static Torque Sensors: For non-rotating tasks, often used for testing and calibration.

- Wireless Torque Sensors: For remote monitoring without cables, making things more flexible.

Impact on Performance

Using torque sensors greatly improves performance. They offer real-time data, which helps in:

- Making machinery more reliable by monitoring torque consistently.

- Boosting safety by stopping over-torquing, which can damage parts.

- Using less energy, as correct torque settings lead to better efficiency.

It’s important for engineers to know about torque sensors. This knowledge helps in choosing the right sensors for manufacturing.

| Sensor Type | Primary Use | Advantages |

|---|---|---|

| Rotary Torque Sensors | Rotating machinery | Direct measurement, real-time data |

| Static Torque Sensors | Testing and calibration | High accuracy, reliable results |

| Wireless Torque Sensors | Remote monitoring | Increased flexibility, reduced clutter |

Piezoresistive Sensors in Precision Applications

Piezoresistive sensors are key in precise fields. They change resistance when pressed, showing exceptional sensitivity. Their design lets them measure accurately in tough places like labs and factories. This makes them a trusted tool for engineers.

The benefits of piezoresistive sensors are many:

- High accuracy for detailed measurements

- Wide operational range, working well in different settings

- Robust construction for harsh conditions

These sensors are used in many areas, like cars, planes, and health care. In each field, they help keep things running smoothly and efficiently.

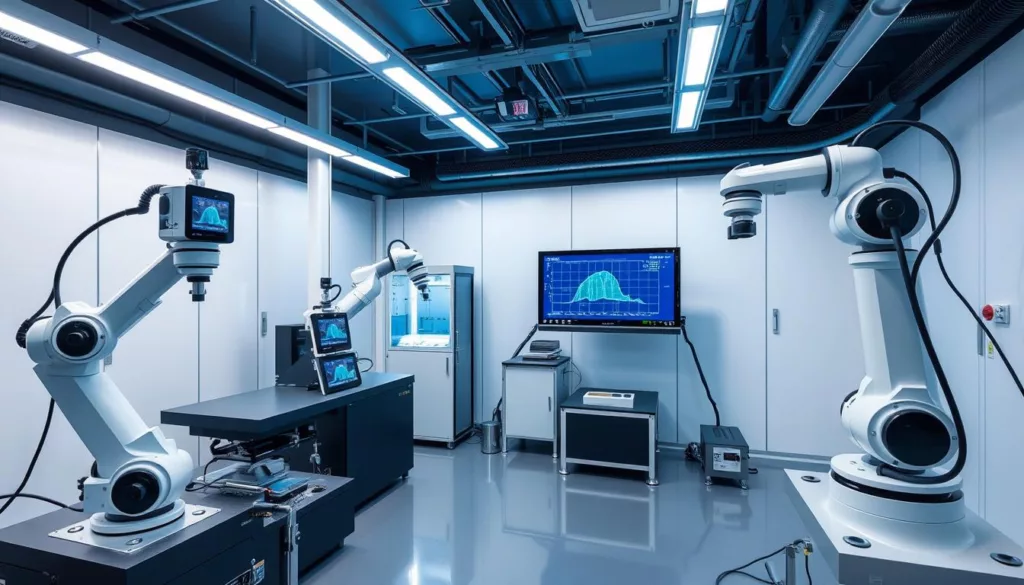

Implementing Force Measurement Systems

Setting up force measurement systems needs careful planning. It’s important to understand how to integrate and calibrate sensors. This ensures the system works well and gives accurate data.

System Integration

Integrating force measurement systems into current manufacturing processes is key. It makes sure sensors talk well with other tools like data systems and control units. Important things to think about include:

- Compatibility: Make sure sensors fit with what you already have.

- Scalability: Plan for growth by designing systems that can expand.

- Data Flow: Keep data moving smoothly between sensors and analysis tools.

Calibration and Maintenance

Calibrating sensors is critical for accurate force measurements. Regular upkeep helps spot and fix any issues. Good calibration steps include:

- Use standard loads for the first calibration.

- Do regular checks as the maker suggests.

- Keep records of calibration for future reference.

To make force measurement systems better, follow a set plan for calibration and upkeep. For more on force sensors, check out this resource.

| Component | Importance | Best Practices |

|---|---|---|

| Force Sensors | Measure applied force accurately | Use high-quality sensors from trusted brands |

| Data Acquisition Systems | Collect and process data from sensors | Ensure compatibility with force sensors |

| Calibration Equipment | Verify sensor accuracy | Regularly check calibration against standards |

Challenges in Force Sensor Technology

Force sensors are key in precision manufacturing. Yet, they face several challenges that affect their performance. It’s vital to tackle these issues to fully utilize their capabilities in manufacturing.

Environmental factors and data interpretation problems are major concerns. These areas need attention to ensure force sensors work well.

Environmental Factors

Environmental conditions greatly impact force sensors. Changes in temperature, humidity, and exposure to contaminants can skew readings or damage the sensors. Key challenges include:

- Temperature Variations: Extreme temperatures can cause calibration drift.

- Moisture: High humidity can corrode sensitive parts.

- Dust and Contaminants: Particles can block sensing elements, causing errors.

Data Interpretation Issues

Interpreting data from force sensors is a challenge. The complexity of raw data can lead to mistakes if not managed correctly. Key hurdles include:

- Signal Noise: External interference can add noise, making analysis hard.

- Calibration Errors: Incorrect calibration can result in wrong readings.

- Data Overload: Too much data can overwhelm systems, slowing down analysis.

| Challenge Type | Specific Issues | Impact |

|---|---|---|

| Environmental Factors | Temperature Variations, Moisture, Dust | Altered Readings, Physical Damage |

| Data Interpretation | Signal Noise, Calibration Errors, Data Overload | Misleading Insights, Analysis Delays |

Future Trends in Force Sensor Technology

Force sensor technology is changing fast, thanks to new ideas and better ways to connect things. Looking ahead, we see big changes that will change how things are made.

Innovations on the Horizon

New force sensors will be more accurate and quick. This is important for many industries. Some big changes include:

- Miniaturization: Smaller sensors that work better in tight spaces.

- Smart Sensors: These will think for themselves, analyzing data right away.

- Wireless Communication: Going wireless makes setup easier and lets things move around more.

Integration with IoT

IoT is changing how force sensors work. By linking sensors to big networks, companies get more data than ever. The main benefits are:

- Remote Monitoring: People can watch operations live, making things more efficient.

- Predictive Maintenance: Sensors can spot problems before they happen, cutting down on downtime.

- Data-Driven Decisions: With better data, companies can make smarter choices, leading to better results.

In summary, the future of force sensor technology looks very different. Companies that focus on these new ideas and IoT will do well.

Conclusion

Exploring force sensor technology in precision manufacturing has opened new doors to success. It makes manufacturing more accurate and reliable. We focus on creating high-quality, custom sensor solutions to meet today’s production needs.

We are committed to helping our clients reach their manufacturing goals. Our experience allows us to offer personalized advice. This way, we can tackle the challenges of force sensor technology together, ensuring top-notch results.

Our dedication to innovation in sensor solutions remains strong. Using force sensor technology boosts manufacturing abilities. This leads to better results and higher efficiency for businesses.