At XJCSENSOR, we’re leaders in custom 3-axis force sensor solutions for industry. Our innovative force sensing technology lets us create sensors that fit specific industrial needs. In today’s fast-paced manufacturing world, precision measurement is key. Our high-quality industrial force sensors help our clients work more efficiently and reliably.

We know each industry has its own hurdles. That’s why we focus on making our customers happy with customizable force sensing solutions. Our dedication to quality and the latest technology makes us a reliable partner for businesses. For more details, check out our official site.

Key Takeaways

- XJCSENSOR specializes in custom 3-axis force sensors.

- Precision measurement is key in modern manufacturing.

- We offer tailored solutions for various industrial needs.

- Our products boost operational efficiency and reliability.

- Quality and innovation are our core values.

Understanding Force Sensing Technology

Force sensing technology is key in many industries. It helps measure force, pressure, and weight with great accuracy. Knowing how it works is important to see its value in today’s world.

What is Force Sensing Technology?

Force sensing technology is about systems that detect and measure forces on objects. It uses industrial force sensors to turn physical forces into electrical signals. These sensors, like strain gauges or piezoelectric materials, give important data for making smart decisions in manufacturing.

The Importance of Force Sensors in Industry

Using force sensing technology makes industries work better and safer. It helps by:

- Improving how processes are controlled

- Reducing risks from too much load

- Making products better by keeping production consistent

- Keeping workers and machines safer

Car, plane, and manufacturing industries need these sensors a lot. They help save money and prevent problems, making them very important in today’s fast-paced market.

Benefits of Custom Force Measurement Solutions

Custom force measurement solutions offer big advantages to many industries. They meet specific needs and improve productivity. This is because they follow individual standards and requirements.

Tailored Solutions for Different Industries

Each industry faces unique challenges. Custom force sensors are made to fit these needs. This means sectors like automotive, aerospace, and manufacturing get sensors that work best for them.

Here are some key sectors that use custom solutions:

- Automotive Manufacturing

- Aerospace Engineering

- Medical Equipment Production

- Structural Testing in Construction

Enhanced Precision and Accuracy

Custom force measurement solutions also boost precision and accuracy. These are key for success. Tailored sensors improve performance and reliability.

Studies show these specialized sensors work well in many areas. Companies see better data and efficiency. This shows how important custom solutions are for success.

Exploring 3 Axis Load Cells

3-axis load cells are a big step forward in force sensing technology. They can measure forces in three dimensions with great precision. These sensors are key in many industries because they help control and measure forces accurately.

How 3 Axis Load Cells Work

3-axis load cells use advanced tech to measure forces in three directions: X, Y, and Z. They have strain gauges that detect when a force is applied. This causes the load cell to deform, sending out a signal that shows the force’s strength and direction.

This real-time data is vital for many fields. It helps ensure safety and quality in industries like automation and construction. Customizable 3 axis force sensors are a big help here, making sure everything runs smoothly and safely.

Applications of 3 Axis Load Cells in Industrial Settings

3-axis load cells are very useful in many areas. Here are some examples:

- Robotics – They help robots control their movements better.

- Aerospace – They check if aircraft structures can handle loads.

- Manufacturing – They watch over assembly and quality control.

- Construction – They measure forces in building materials and structures.

- Research – They help with precise force measurements in experiments.

| Application | Description | Benefits |

|---|---|---|

| Robotics | Force feedback for automation | Increased efficiency and safety |

| Aerospace | Load evaluation in aircraft | Enhanced structural integrity |

| Manufacturing | Quality control in production | Reduction in defects and rework |

| Construction | Measurement of structural loads | Improved safety measures |

| Research | Precision in experimental setups | Accurate data collection |

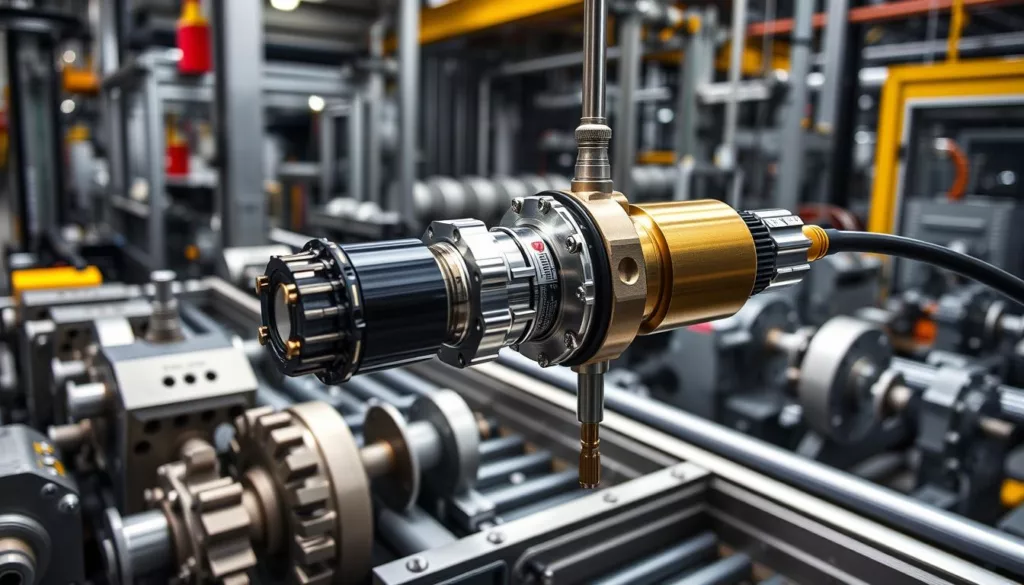

Customizable 3 Axis Force Sensor Solutions for Industry

Our 3 axis force sensor solutions are top-notch because they’re both versatile and strong. We make sure they fit many industrial needs. This means each sensor works well with other systems and performs great.

Features of Customizable Solutions

Our force sensor solutions have some key features:

- Programmability: You can adjust them to fit your needs.

- Robustness: They can handle tough industrial settings.

- Ease of Integration: They’re easy to add to your current systems, cutting down on downtime.

- Scalability: They can grow with your business, supporting upgrades and expansions.

Adapting to Industry-Specific Needs

XJCSENSOR is great at creating custom force measurement solutions for different industries. We work closely with our clients to understand their needs. This way, we make sure our solutions improve performance and meet industry standards.

By focusing on industry-specific needs, we help businesses get the most out of their force sensors. This leads to better efficiency and productivity.

Applications of Multi-Axis Force Sensors

Multi-axis force sensors are key in many industries. They give precise measurements that boost efficiency and function. Knowing how these sensors work helps companies pick the right tech for better performance and reliability.

Industries Utilizing Multi-Axis Force Sensors

Many sectors use multi-axis force sensors. Here’s a list of main industries where they’re used:

- Aerospace: In making planes and spaceships, these sensors check if structures are strong and accurate.

- Automotive: They help test car parts, making them safer and more efficient.

- Manufacturing: These sensors are vital for checking product quality, keeping standards high.

- Robotics: They help robots move safely and carry loads, important for their work.

- Healthcare: In medical tools, they help test and make sure devices work right.

Case Studies of Successful Implementations

Looking at how multi-axis force sensors have made a difference shows their value. Here are some examples:

| Industry | Application | Benefits Achieved |

|---|---|---|

| Aerospace | Wing Stress Testing | Increased safety and reliability of aircraft design |

| Automotive | Crash Testing | Enhanced crash safety ratings and regulatory compliance |

| Manufacturing | Assembly Line Quality Control | Improved product consistency and reduced defect rates |

| Robotics | Load Balancing in Industrial Robots | Optimized performance and reduced wear on components |

| Healthcare | Medical Device Testing | Greater accuracy in medical equipment reliability |

Choosing the Right Industrial Force Sensors

Choosing the right industrial force sensors is key for precise measurements and top performance. Many factors affect the choice of sensors. It’s important for engineers and industrial experts to know these factors well. This helps them make the best choices for their needs.

Factors to Consider in Selection

When picking industrial force sensors, think about these key points:

- Measurement Range: Make sure the sensor can accurately measure the forces in your application.

- Material Compatibility: Check if the sensor’s materials can handle your application’s environment.

- Installation Challenges: Consider how easy it is to add the sensor to your system.

- Output Type: Pick the output type that fits your data collection needs, like analog or digital signals.

- Calibration: Look for sensors with simple calibration to keep accuracy over time.

Comparative Review of Popular Sensors

There are many industrial force sensors, each with its own benefits. Here’s a look at some popular ones:

| Sensor Type | Strengths | Weaknesses |

|---|---|---|

| Load Cells | High accuracy, suitable for various load ranges | Cost can be higher for specialized applications |

| Torque Sensors | Precise torque measurements for dynamic applications | Limited applications outside torque measurement |

| Pressure Sensors | Versatile for fluid dynamics and pressure monitoring | May require specialized mounting systems |

For customizable force sensing solutions, check out XJCSENSOR. They offer tailored solutions that boost your efficiency.

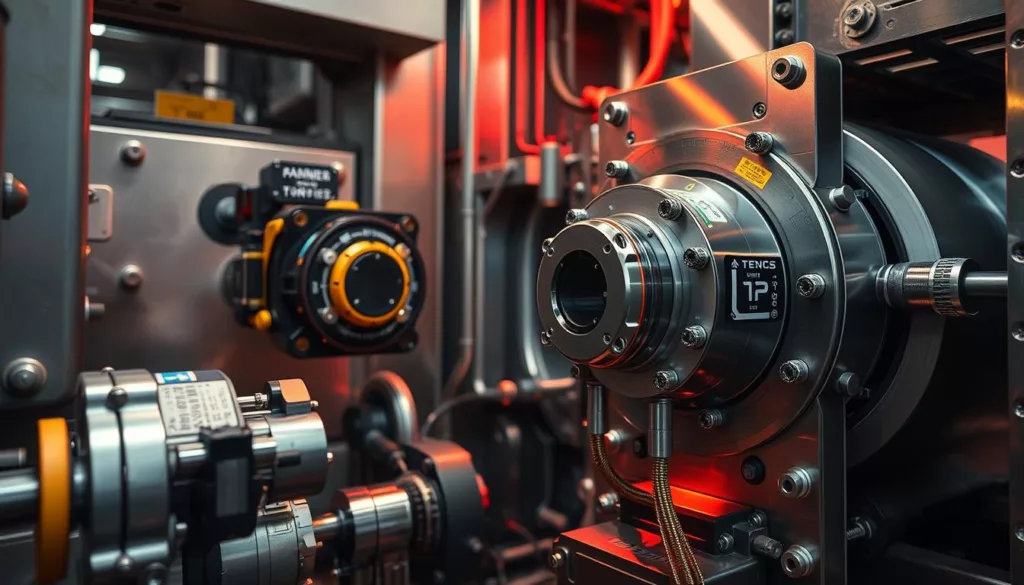

Precision Force Sensors: A Closer Look

In the world of industry, precision force sensors are key. They make operations better by being very accurate and reliable. These sensors use the latest technology to give exact measurements in many situations.

Defining Precision Force Sensors

Precision force sensors are made to measure force very accurately. They are different from regular sensors because they use new materials and technology. This makes them perfect for places that need exact force readings, like in robotics and assembly lines.

Benefits of Using Precision Force Sensors

Using precision force sensors has many benefits:

- Improved Product Quality: They help make products better by giving accurate force measurements. This reduces defects and makes products higher quality.

- Increased Efficiency: With accurate data, processes can be made smoother. This leads to better use of resources and more productivity.

- Enhanced Safety: In places where safety is very important, these sensors give reliable data. This helps prevent accidents and breakdowns.

- Versatile Applications: These sensors work well in many areas, like automation and quality control.

By choosing custom force measurement solutions, industries can get the most out of precision force sensors. This leads to better performance.

| Feature | Standard Force Sensors | Precision Force Sensors |

|---|---|---|

| Accuracy | Moderate | High |

| Response Time | Good | Excellent |

| Durability | Average | High |

| Cost | Lower | Higher |

| Applications | Limited | Wide-ranging |

Understanding the benefits of precision force sensors is key for industries. It helps them improve their measurement skills and work more efficiently.

Industry-Specific Force Transducers

Industry-specific force transducers are key in manufacturing. They turn mechanical force into electrical signals. This is vital for many uses.

Applications in Manufacturing

In today’s factories, these transducers watch over assembly lines and product tests. They make sure force is applied right during assembly. This boosts work efficiency.

They also check the strength and quality of materials. This is important in making sure products are good.

Role in Quality Control Processes

Quality control gets a big boost from these sensors. They check if products meet standards and what customers want. They do this by watching force during making and putting together.

They give real-time data. This helps cut down on waste, makes products more reliable, and improves quality.

Companies wanting to improve their making can learn more about force sensor use in automated systems. Using the right force transducers makes making better, safer, and cheaper.

Why XJCSENSOR is Your Trusted Partner

In the world of force sensing technology, we know how important it is to have solutions that fit your needs. XJCSENSOR is your go-to for customizable 3 axis force sensor solutions. We’re all about creating custom force measurement solutions that meet your specific needs.

Expertise in Custom Solutions

Our team has a lot of experience in making solutions that meet your exact needs. We work closely with you to understand what you need. This way, we can create sensor solutions that make your operations better and more efficient.

Commitment to Quality and Innovation

XJCSENSOR values quality and innovation above all. We use the latest technology to make sure our sensors are reliable and perform well. We’re always looking for new ways to improve our solutions, keeping us at the top of our field.

Trends in Force Sensing Technology

The world of force sensing technology is changing fast. New advancements aim to boost sensitivity, durability, and connectivity. These improvements lead to better, more adaptable force sensing solutions for many industries.

Advancements in Sensor Technology

New materials and tech are changing force sensors. For example, advanced composites make sensors more durable and reliable. Also, making sensors smaller and lighter doesn’t hurt their performance.

Adding IoT features lets us monitor and analyze data in real-time. This makes force sensing solutions not just effective but also smart and quick to respond.

Future Outlook for Force Sensors in Industry

The future of force sensing looks bright as more industries see its value. Experts predict a big rise in demand for smart force sensors. Companies will look for solutions that fit their unique needs.

Advances in machine learning and AI will bring even more precision and control. This will be a big step forward in force measurement.

We’re staying ahead of these changes, always updating our offerings. This keeps us at the top in delivering top-notch force sensing solutions.

Conclusion

In this article, we looked at why customizable 3-axis force sensors are key for industries. They help improve precision and meet different needs across sectors. These sensors are also very flexible, making them useful in many areas.

At XJCSENSOR, we focus on top-notch, custom sensor solutions for our clients. We aim to solve your specific challenges with our innovative and technical skills. This ensures your operations run smoothly and efficiently.

Exploring force sensing technology? Think of XJCSENSOR as your reliable partner. Our expertise in creating custom 3-axis force sensors sets us apart. We can boost your efficiency with sensors made just for you.