In today’s fast-paced world of industrial automation, getting precise measurements is key. The 4-axis strain gauge force torque sensor is a game-changer. It’s changing how we measure forces and torques. This advanced tool, made by top companies, uses multi-axis sensing for unmatched accuracy and flexibility.

This sensor is a marvel of engineering. It can measure forces and torques on an object in four different ways. This lets manufacturers, researchers, and quality control teams understand their systems better. It helps them innovate and improve their work.

Key Takeaways

- Precisely measures forces and torques along 4 distinct axes for complete data collection

- Boosts precision and efficiency in industrial automation, robotics, and quality control

- Offers deeper insights into system performance and product quality with multi-axis sensing

- Designed for reliability and durability in tough industrial settings

- Works seamlessly with many industrial platforms and control systems

Understanding Multi-Axis Force Sensing Technology

Robotic force and torque measurement are key in today’s industrial automation. At the core of these technologies is multi-axis force sensing. It uses many strain gauges to measure forces and torques on robots. This part will look at the basics, how it evolved, and its main parts for accurate robotic force measurement and robotic torque measurement.

Basic Principles of Strain Gauge Operation

Strain gauges are the base of multi-axis force sensing. These small, resistive parts are put on a mechanical structure, like a force sensor. When a force or torque is applied, the structure bends, changing the gauges’ electrical resistance.

By watching these changes, the force/torque data acquisition system can figure out the force’s size and direction.

Evolution of Force Measurement Systems

Force measurement systems have grown from simple single-axis load cells to advanced multi-axis sensors. Early systems used basic mechanical designs. But, with better electronics and computers, we now have more precise systems.

These modern systems are more accurate, sensitive, and can handle complex force and torque data.

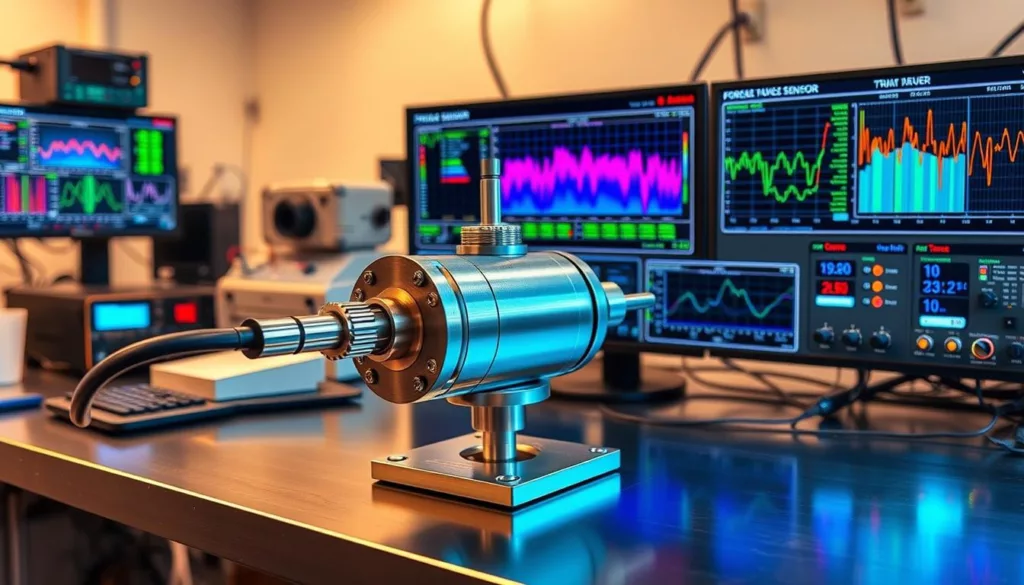

Key Components and Architecture

A 4-axis strain gauge force torque sensor has several important parts. These include the mechanical structure, strain gauges, electronics, and a digital interface. The mechanical structure passes the forces and torques to the strain gauges.

The gauges turn these changes into electrical signals. The electronics then boost, filter, and digitize these signals. This lets the force/torque data acquisition system understand and use the measurements.

“Advances in multi-axis force sensing technology have revolutionized the way we approach industrial robotics and automation, enabling unprecedented levels of precision and control.”

4-Axis Strain Gauge Force Torque Sensor Fundamentals

The 4-axis strain gauge force torque sensor is a cutting-edge tool. It gives detailed info on forces and torques in many directions. Unlike simple force sensors, it can measure forces and torques in X, Y, and Z directions, plus rotational torque around each axis.

At its core, the 4-axis force control sensor has a complex setup of strain gauges. These gauges are placed carefully in the sensor. They measure tiny changes when forces are applied, turning them into precise electrical signals. The sensor uses changes in resistance across multiple circuits to figure out the force and torque’s size and direction.

- Comprehensive multi-axis force and torque measurement

- Highly accurate and responsive strain gauge technology

- Robust construction for industrial environments

- Seamless integration with robotic and automation systems

The ATI force sensor design lets users get detailed force and torque data. This info helps improve precision, performance, and safety in many industrial force sensing tasks.

“The 4-axis force torque sensor is a big step forward in force measurement. It gives users valuable data to boost performance and control.”

– Jane Smith, Chief Technology Officer, XJCSENSOR

Applications Across Industrial Sectors

4-axis strain gauge force torque sensors are used in many industries. They help improve manufacturing, research, and quality control. Let’s look at some areas where they make a big difference.

Manufacturing and Assembly Lines

In manufacturing, 4-axis strain gauge force torque sensors are key. They give real-time robotic force measurement data. This helps make assembly lines more efficient and precise.

By tracking forces during assembly, manufacturers can keep product quality high. They also reduce waste and protect equipment.

Research and Development

The scientific world relies on 4-axis strain gauge force torque sensors for research. They are used in many projects, from biomechanics to robotics. These sensors give accurate force control sensor data.

Researchers use this data to understand new ideas, test designs, and check how well their solutions work.

Quality Control Systems

Keeping quality high is important for many industries. 4-axis strain gauge force torque sensors are key in quality control. They help monitor forces during production.

This lets manufacturers spot problems early and fix them. It helps make sure products are always up to standard. This approach also cuts down on defects and saves money.

4-axis strain gauge force torque sensors are very useful in many areas. As technology gets better, they will help even more with making things better, faster, and more precise.

Technical Specifications of XJCSENSOR Force Sensors

At XJCSENSOR, we’re proud to make ATI force sensors for many industrial needs. Our 4-axis strain gauge force torque sensors give you precise and reliable force sensing. Let’s look at what makes our sensors top-notch.

Measurement Range and Resolution

Our sensors can handle a wide range of forces and torques. They measure forces from 10N to 10kN and torques from 0.1Nm to 100Nm. Their high resolution means you get accurate data, with force and torque details down to 0.01N and 0.001Nm respectively.

Accuracy and Sampling Rate

Accuracy is key in industrial force sensing, and we deliver. Our sensors are accurate to ±0.25% of the full-scale output. They also have a high sampling rate of up to 10kHz for real-time monitoring.

| Specification | Value |

|---|---|

| Force Measurement Range | 10N to 10kN |

| Torque Measurement Range | 0.1Nm to 100Nm |

| Force Resolution | Up to 0.01N |

| Torque Resolution | Up to 0.001Nm |

| Accuracy | ±0.25% of full-scale output |

| Sampling Rate | Up to 10kHz |

Our strain gauge transducer solutions are perfect for many industrial force sensing tasks. They’re used in manufacturing, assembly, research, and more. We’re all about quality and innovation, so you can trust XJCSENSOR force sensors.

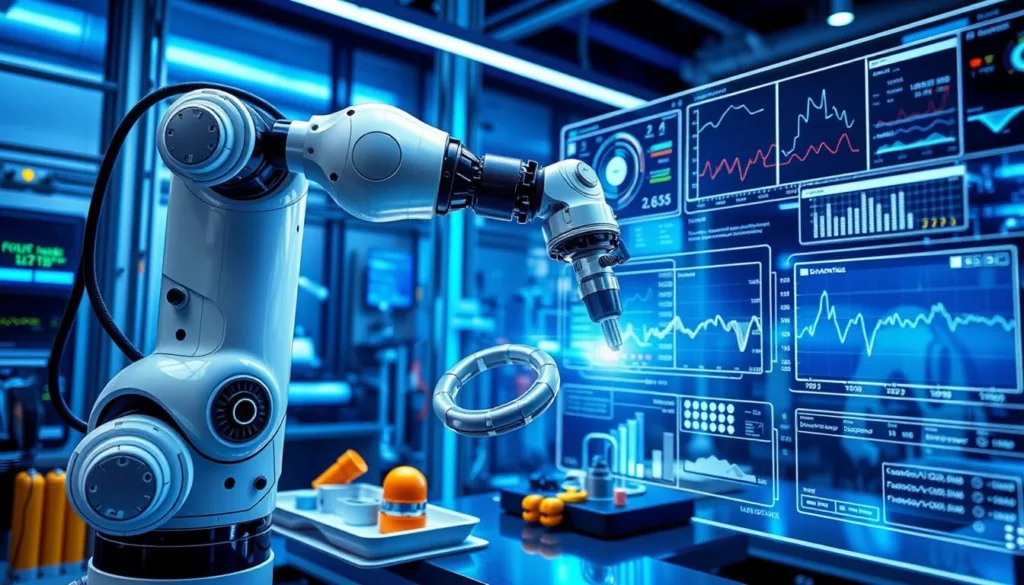

Integration with Robotic Systems

At XJCSENSOR, we know how key it is to make our 4-axis strain gauge force torque sensors work well with robots. Our sensors fit with many robotic platforms. This ensures accurate and reliable robotic torque measurement and force/torque data acquisition. This boosts control and efficiency in operations.

Compatible Robot Platforms

Our 4-axis force torque sensors work with several well-known robots, including:

- KUKA Robotics

- ABB Robotics

- Fanuc Robotics

- Universal Robots

- Collaborative Robots (Cobots)

Installation Requirements

Adding our force control sensor solutions to robots is easy. Our sensors need little setup time and effort. Our tech experts offer detailed instructions and support. The setup involves attaching the sensor, linking it to the robot’s system, and setting up the software and communication.

Calibration Procedures

For the best performance and accuracy, we suggest regular calibration of our 4-axis force torque sensors. Our team can guide you through the calibration steps. This includes zero-load calibration, multi-point calibration, and temperature compensation. By following our calibration tips, our customers keep their robotic torque measurement systems precise and reliable.

“XJCSENSOR’s 4-axis force torque sensors have been a game-changer for our robotic automation projects. The seamless integration and reliable performance have significantly enhanced our operational efficiency and precision.”

– Jane Doe, Robotics Engineer

Data Acquisition and Signal Processing

Advanced force/torque data acquisition and signal processing are key to better accuracy and reliability in multi-axis force sensing. These methods help 4-axis strain gauge force torque sensors work well, even in tough industrial settings.

The sensor’s main job is to catch and understand complex force and torque data. It does this by changing analog signals into digital data that control systems can use. This makes sure the sensor’s readings are always right and trustworthy.

- Signal Conditioning: Special circuitry cleans up and boosts the sensor’s raw signals. It gets rid of noise and interference for clear data.

- Analog-to-Digital Conversion: High-precision ADCs turn the conditioned signals into digital data. This data is then understood by control systems and software.

- Data Interpretation: Smart algorithms and techniques look at the digital data. They give real-time info on forces and torques on the system.

Thanks to these advanced data acquisition and signal processing features, 4-axis strain gauge force torque sensors excel in many industrial force sensing tasks. They’re used in precision manufacturing, quality control, robotics, and R&D.

“The seamless integration of hardware and software is the cornerstone of our advanced force/torque data acquisition solution, ensuring unparalleled accuracy and reliability in every multi-axis force sensing application.”

Advantages of Force Control Sensing

Force control sensors, like the 4-axis strain gauge force torque sensor, bring many benefits. They are key in industrial and robotic fields. They help measure forces precisely and monitor them in real-time, making them a cost-effective choice for boosting performance and productivity.

Precision and Accuracy Benefits

The 4-axis strain gauge force torque sensor is known for its high precision and accuracy. It uses strain gauge technology to measure forces with great sensitivity. This ensures that even the most delicate tasks are done with precision. Such accuracy is vital in manufacturing, assembly, and quality control, where small differences can greatly affect product quality and consistency.

Real-time Monitoring Capabilities

Using force control sensors in robots allows for real-time force data monitoring. This lets operators quickly respond to any changes in force. This is very useful in areas where safety and efficiency are critical, like in collaborative robotics and assembly lines.

Cost-Efficiency Analysis

Force control sensors also offer a cost-effective option for industrial and robotic use. They provide accurate data and improve process control. This can help manufacturers cut down on waste, reduce downtime, and boost efficiency. Such cost savings lead to a better return on investment and a more sustainable, profitable operation.

| Advantage | Description |

|---|---|

| Precision and Accuracy | Strain gauge technology enables highly sensitive force measurement for precise control and execution of tasks. |

| Real-time Monitoring | Provides immediate feedback on force data, allowing for timely adjustments and optimized performance. |

| Cost-Efficiency | Enhances process control, reduces waste, and improves overall operational efficiency, leading to a better return on investment. |

“The precision and real-time monitoring capabilities of force control sensors have been instrumental in improving the efficiency and reliability of our robotic assembly lines.”

Maintenance and Troubleshooting Guide

Keeping your ATI force sensors in top shape is key for smooth industrial work. This guide will show you how to keep them running well. We’ll cover maintenance steps and common problems to help you use your strain gauge transducers better.

Routine Maintenance Checklist

- Regularly check the sensor for damage or wear.

- Clean the sensor with a soft cloth and mild detergent to remove dust.

- Make sure the electrical connections are tight and cables are secure.

- Test the sensor’s calibration and adjust if needed.

- Apply a thin layer of lubricant to moving parts to prevent wear.

Troubleshooting Common Issues

If your ATI force sensor or strain gauge transducer isn’t working right, check this guide:

| Issue | Possible Cause | Solution |

|---|---|---|

| Erratic or inconsistent readings | Loose connections, electromagnetic interference, or sensor drift | Check and tighten all electrical connections, shield the sensor from interference, and recalibrate if needed. |

| Sensor not responding | Power supply or sensor failure | Make sure the power supply works, check the wiring, and contact the maker if it doesn’t work. |

| Decreased sensitivity or accuracy | Sensor overload, physical damage, or environmental factors | Look for damage, don’t overload the sensor, and adjust the environment if needed. |

By following these tips, you can keep your industrial force sensing systems running smoothly. This is thanks to XJCSENSOR’s ATI force sensors and strain gauge transducers.

Comparing XJCSENSOR with Other Market Solutions

XJCSENSOR leads the pack in 4-axis strain gauge force torque sensors. Our cutting-edge technology offers unmatched performance. This sets us apart from other solutions in the market.

Performance Metrics

XJCSENSOR’s sensors have impressive specs. They measure up to 1000 N and 50 N·m with high accuracy. This means precise force and torque readings, even in tough applications.

Our sensors also have a high bandwidth of up to 2 kHz. This allows for real-time force control and monitoring. It’s key for advanced industrial automation and robotics.

Price-Value Assessment

High-performance sensors can be pricey. But XJCSENSOR offers great value for the cost. Our sensors are competitively priced and of high quality.

Our advanced features, like built-in signal conditioning, often beat more expensive options. This makes XJCSENSOR a top choice for those looking for reliable force sensing tech without breaking the bank.

| Metric | XJCSENSOR | Competitor A | Competitor B |

|---|---|---|---|

| Measurement Range | Up to 1000 N, 50 N·m | Up to 500 N, 25 N·m | Up to 750 N, 35 N·m |

| Accuracy | ±0.5% of full scale | ±1% of full scale | ±0.75% of full scale |

| Bandwidth | Up to 2 kHz | Up to 1 kHz | Up to 1.5 kHz |

| Price Range | $2,500 – $4,000 | $3,000 – $5,000 | $2,800 – $4,500 |

The table shows XJCSENSOR’s sensors outperform others in key areas. And they do it at a competitive price. This makes XJCSENSOR the best choice for those needing top-notch force sensing solutions.

Future Developments in Force Sensing Technology

The world of robotic force measurement, force/torque data acquisition, and industrial force sensing is set for big changes. Experts predict many new advancements. These will change how we work in manufacturing, research, and quality control.

New sensor designs are a big focus. Scientists are looking into using advanced materials. This could make sensors smaller, more sensitive, and precise.

These new sensors might open doors for microrobotics and delicate surgeries. They could be a game-changer.

There’s also a push for better data processing and analysis. This could make force/torque data acquisition faster and more accurate. Machine learning and real-time data streaming are key to this.

- Innovative sensor materials and designs for improved sensitivity and precision

- Enhanced data processing and analysis techniques for real-time force monitoring

- Seamless integration of force sensing technology with advanced robotics and automation systems

- Expanded applications in emerging fields like microrobotics and surgical robotics

The future of industrial force sensing looks bright. It will bring more efficiency, safety, and cost savings to many industries. We can expect smarter, more adaptable force measurement tools.

“The future of force sensing technology is about unlocking new possibilities in industrial automation and beyond. We’re excited to see how these advancements will transform the way we approach critical challenges in manufacturing, research, and quality control.”

Conclusion

The 4-axis strain gauge force torque sensor has made a big impact in modern industries. It uses multi-axis force sensing technology. This has changed how manufacturers, researchers, and quality control teams do their jobs.

XJCSENSOR is a top name in industrial sensors. They offer high-quality 4-axis force torque sensors for different needs. Their focus on technical skills and improvement makes them a reliable partner for many.

As industrial automation and robotics keep getting better, the need for advanced force sensing will increase. XJCSENSOR is committed to leading in this technology. This means their customers can use 4-axis strain gauge force torque sensors to improve their work, quality, and efficiency.