In the world of industrial automation, precise force and torque measurements are key. They help improve manufacturing, product quality, and robotic safety. This guide explores force torque sensors in detail, covering their technology, uses, and impact on industries.

Force torque sensors are vital in today’s factories. They let manufacturers track and manage forces and torques during important tasks. These sensors boost efficiency, safety, product reliability, and save costs. Knowing how these sensors work helps professionals achieve better precision, productivity, and innovation.

Key Takeaways

- Industrial automation force torque sensors are essential tools for optimizing manufacturing processes and ensuring product quality.

- These sensors enable precise monitoring and control of forces and torques, contributing to improved safety, reliability, and cost savings.

- Comprehensive understanding of force torque sensor technology, applications, and integration is critical for industrial automation professionals.

- Advancements in sensor design and performance are driving the evolution of precision force measurement capabilities.

- Integrating force torque sensors with robotic systems enhances automation capabilities and drives innovation in manufacturing.

Understanding Industrial Automation Force Torque Sensors

In the world of industrial automation, force torque sensors are key. They measure and interpret mechanical forces and torques. These sensors are vital for robotic force sensing, helping with precise control in many manufacturing and assembly tasks.

Basic Principles and Components

Force torque sensors work on basic principles of force measurement. Known as load cells, they use different technologies to turn mechanical forces into electrical signals. These signals are then analyzed by industrial control systems.

The main parts include strain gauges, piezoelectric elements, or capacitive sensing elements. These parts respond to forces, creating an output that shows the measured loads.

Key Operating Mechanisms

Force torque sensors work in different ways, depending on their technology. Strain gauge-based sensors measure forces by seeing how a part deforms. Piezoelectric sensors create an electrical charge when stressed mechanically.

Capacitive force sensors notice changes in capacitance due to force. This makes them very accurate and sensitive in measuring forces.

Sensor Architecture Overview

The design of force torque sensors varies based on the application. Single-axis sensors are best for forces in one direction. Multi-axis force transducers can handle forces and torques in many directions. This gives detailed data for complex robotic systems and industrial tasks.

| Sensor Type | Measurement Capabilities | Key Applications |

|---|---|---|

| Single-Axis Sensors | Measure forces in a single direction | Assembly, testing, and quality control tasks |

| Multi-Axis Force Transducers | Detect forces and torques in multiple dimensions | Robot force sensing, industrial automation, and advanced manufacturing |

“Precise force measurement is essential for the success of industrial automation and robotic systems. Force torque sensors provide the critical data needed to ensure accurate control and optimal performance.”

Applications Across Manufacturing Industries

At XJCSENSOR, we know how important robotic assembly force control and automated quality control forces are. They help make manufacturing more efficient and precise. Our force torque sensors are used by leaders in many industries to improve their processes and quality.

In the car industry, our sensors help robots assemble parts perfectly. This ensures cars are built without any mistakes. In electronics, our sensors help check the quality of products, making sure they are always the same.

Our sensors are also used in aerospace, medical devices, and food processing. They make these industries better by saving money and making things safer. XJCSENSOR is a key partner in making these industries more efficient.

| Industry | Application | Benefits |

|---|---|---|

| Automotive | Robotic assembly force control | Precise component integration, seamless vehicle assembly |

| Electronics | Automated quality control forces | Consistent product quality, reduced defects |

| Aerospace | Precision manufacturing | Enhanced safety, improved efficiency |

| Medical Devices | Delicate assembly and testing | Consistent product quality, regulatory compliance |

| Food Processing | Automated packaging and handling | Increased productivity, reduced waste |

At XJCSENSOR, we aim to give our clients the best force torque sensing solutions. This helps them lead in their fields. Our technology makes their work more efficient, safe, and of high quality.

“XJCSENSOR’s force torque sensors have been a game-changer in our production process. The level of precision and control they provide is unmatched, allowing us to consistently deliver the highest-quality products to our customers.”

– Production Manager, Automotive Manufacturer

Types of Force Torque Sensors in Industrial Settings

In the world of industrial automation, force torque sensors are key for precise control and measurement. They come in different types, each for specific needs in manufacturing. Let’s look at the main types of force torque sensors used in industry.

Single-Axis Sensors

Single-axis force torque sensors are the simplest and most common in industrial automation. They measure force or torque along one axis. This is useful for load monitoring, material testing, and controlling robotic arms. Their simplicity and low cost make them a favorite among manufacturers.

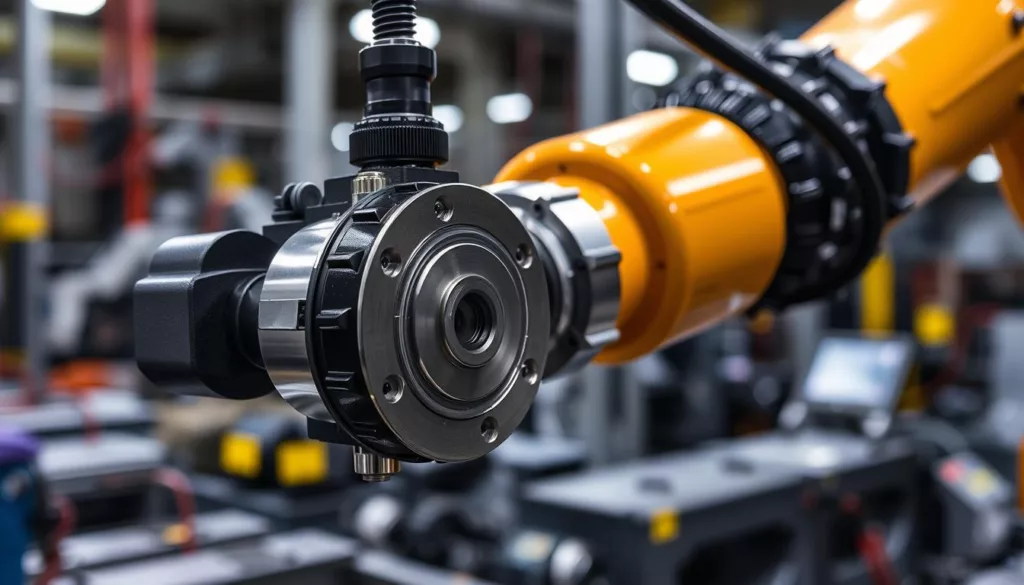

Multi-Axis Force Transducers

Multi-axis force transducers can measure force and torque in multiple directions at once. These advanced sensors are vital for tasks like robotic assembly and press fitting. They offer detailed insights into forces, helping with more accurate monitoring and control.

Specialized Application Sensors

- Miniature Force Sensors: Made for tight spaces, these sensors are great for medical device testing and micro-assembly.

- Precision Force Measurement Sensors: These sensors are very accurate and sensitive. They’re needed for tasks like material testing and robotic force-feedback.

- Explosion-Proof Sensors: These sensors are designed for dangerous environments. They ensure safe operation in industries like oil and gas, mining, and chemical processing.

Knowing about the different force torque sensors helps professionals in industrial automation choose the right one. Whether it’s for single-axis monitoring, multi-dimensional analysis, or special needs, there’s a sensor for every application.

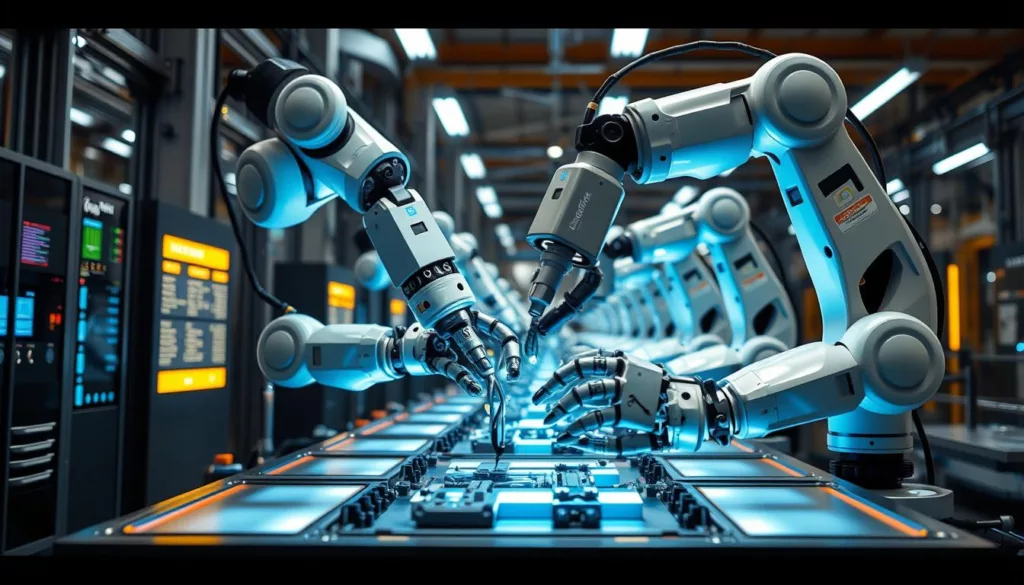

Integration with Robotic Systems

Force torque sensors are key in robot force sensing and robotic assembly force control. They help robots do complex tasks with great precision and flexibility. These sensors give robots the feedback they need to handle tough environments and change as needed.

Adding force torque sensors to robots makes them smarter and more in control. They let robots:

- Feel and react to unexpected touches

- Change how they hold things for delicate parts

- Find the best paths for faster work

- Feel like they have a sense of touch

- Use advanced control for better accuracy

This teamwork is a game-changer in many areas, like robotic assembly, handling materials, checking quality, and making things with precision. With force torque sensors, robots can handle new situations, move through complex spaces, and do tasks with unmatched accuracy and consistency.

“The integration of force torque sensors unlocks a new level of control and intelligence for robotic systems, enabling them to adapt and excel in a wide range of industrial applications.”

Precision Force Measurement Technologies

In the world of industrial automation, precision force measurement is key for top performance and safety. XJCSENSOR explores the advanced tech behind these vital sensors. They show how these technologies boost the accuracy and dependability of force-torque sensors.

Strain Gauge Technology

Strain gauge sensors work by changing electrical resistance when force is applied. They use thin metallic parts that bend under load, changing their electrical properties. This lets them measure forces very accurately in many applications.

Capacitive Sensing Methods

Capacitive force sensors use changes in electrical capacitance due to material deformation. This method is very sensitive, repeatable, and stable over time. It’s a top pick for tough industrial settings.

Optical Force Detection

Optical force detection is becoming more popular in industrial automation. It turns mechanical forces into light signals. This method is precise and doesn’t need electrical connections, making it safer in dangerous places.

| Technology | Principle | Key Advantages |

|---|---|---|

| Strain Gauge | Electrical resistance changes | High accuracy, wide range |

| Capacitive Sensing | Capacitance variations | Sensitivity, repeatability, stability |

| Optical Force Detection | Optical signal conversion | Immunity to EMI, improved safety |

These cutting-edge force measurement technologies, with XJCSENSOR’s know-how, offer the precise, dependable, and strong force-torque sensor solutions needed in industrial automation. By knowing what each tech can do, makers can pick the best one for their needs.

Quality Control and Force Monitoring Solutions

The world of industrial automation is changing fast. Force torque sensors are now key for keeping product quality high and making manufacturing better. They help with automated quality control forces and precision robotic force monitoring. This means they give real-time data to help manufacturers stay top-notch.

Companies use force torque sensors to get more precise and controlled. These sensors track forces and torques during different stages of making things. This lets them spot any problems or changes from what’s expected.

With the data from these sensors, makers can make smart choices fast. They can find and fix issues that could hurt product quality. This way, they avoid waste, cut down on expensive fixes, and keep delivering quality goods to customers.

- Real-time data collection and analysis for automated quality control

- Precise force monitoring to maintain optimal manufacturing processes

- Early detection of issues to prevent costly production errors and rework

- Improved overall efficiency and consistency in manufacturing operations

Force torque sensors are helping leaders in industrial automation reach new heights in quality and efficiency. As technology gets better, these sensors will become even more important for making things better.

“Automated quality control forces and precision robotic force monitoring are essential for maintaining the highest standards in modern manufacturing.”

XJCSENSOR’s Advanced Force Torque Sensor Solutions

At XJCSENSOR, we’re proud of our wide range of industrial automation sensor systems and force-torque sensor technology. Our products are designed to meet the needs of today’s manufacturing industries. They offer precision, reliability, and top-notch performance.

Product Range Overview

We offer a variety of single-axis, multi-axis, and specialized sensors for different industrial needs. Whether you need precise force measurement, advanced robotic control, or quality monitoring, we have the right sensor for you.

- Single-Axis Force Sensors: These sensors accurately detect force along one axis. They’re perfect for applications needing precise load measurement and monitoring.

- Multi-Axis Force Transducers: Our multi-axis force transducers measure forces and torques in multiple dimensions. They offer enhanced control and feedback for robotic systems and complex machinery.

- Specialized Sensors: Our range includes sensors for unique industrial environments. This includes high-temperature, explosion-proof, or hygienic applications, ensuring seamless integration into your operations.

Technical Specifications

Our force torque sensor solutions are engineered to the highest standards. They use advanced technologies and strict quality control measures. Our sensors have industry-leading accuracy, repeatability, and reliability. They ensure consistent, dependable performance in demanding industrial settings.

| Specification | Performance Range |

|---|---|

| Measurement Range | 0.1 N to 100 kN |

| Accuracy | ±0.1% to ±0.5% of full scale |

| Repeatability | ±0.05% to ±0.1% of full scale |

| Operating Temperature | -40°C to +120°C |

Implementation Cases

Our force torque sensor solutions have been successfully used in many industries. This includes robotics, automotive, aerospace, and medical device manufacturing. By using our sensors, our clients have seen better process control, improved quality assurance, and increased efficiency.

“XJCSENSOR’s force torque sensors have been a game-changer for our robotic assembly line. The precision and responsiveness of their technology have allowed us to optimize our processes and reduce costly errors.”

Installation and Calibration Best Practices

Adding precision force measurement sensors to industrial systems needs careful attention. At XJCSENSOR, we offer detailed guides to help your sensors work their best. This ensures reliable data and boosts productivity in your manufacturing.

Proper Sensor Placement

Where you place sensors is key for accurate force readings. Our experts suggest these steps for installing industrial automation sensors:

- Find the exact spot where you need to measure force or torque.

- Securely attach the sensor, avoiding any interference or movement.

- Make sure the sensor is correctly aligned with the force direction.

- Keep the sensor away from vibrations or environmental factors that could affect readings.

Calibration Procedures

Calibrating force torque sensors keeps measurements accurate over time. Here’s how we recommend calibrating:

- Set up a controlled test area with known forces or torques.

- Run multiple tests to check sensor linearity and hysteresis.

- Adjust settings like zero offset and sensitivity to match standards.

- Keep records of calibration settings and plan for regular recalibration.

| Calibration Interval | Recommended Frequency |

|---|---|

| Single-Axis Force Sensors | Every 6 months |

| Multi-Axis Force Torque Transducers | Every 3 months |

| Specialized Application Sensors | Varies by usage, at least annually |

By sticking to these precision force measurement and industrial automation sensor systems guidelines, your XJCSENSOR sensors will give you reliable, consistent, and accurate force data. This is vital for your critical manufacturing needs.

“Proper installation and calibration are the keys to unlocking the full precision force measurement and industrial automation sensor systems of force torque sensors.”

Maintenance and Troubleshooting Guidelines

Keeping industrial automation force torque sensors in top shape is key for precise robotic systems and manufacturing. XJCSENSOR suggests a detailed maintenance and troubleshooting plan to ensure these sensors work well.

Regular Maintenance Procedures

Here are the main steps for regular maintenance:

- Check the sensor housing and connectors for damage or wear

- Clean the sensor and mounting points to remove debris

- Make sure the sensor is calibrated as the maker suggests

- Look over the electrical connections and wiring for any issues

- Watch for any unusual changes in the sensor’s performance data

Common Issues and Solutions

Force torque sensors sometimes face common problems. Quick troubleshooting and fixing are needed. Here are some typical issues and how to solve them:

| Issue | Possible Cause | Solution |

|---|---|---|

| Inaccurate force/torque readings | Sensor calibration drift, overload, or damage | Recalibrate the sensor or replace if necessary |

| Unstable or fluctuating sensor output | Electrical interference, loose connections, or environmental factors | Ensure proper shielding, tighten connections, and isolate from sources of interference |

| Sensor communication failures | Wiring issues, incompatible control systems, or software configuration problems | Check wiring, verify controller compatibility, and troubleshoot software settings |

Calibration Schedules

Keeping sensors accurate needs regular calibration. The schedule depends on the sensor’s use, environment, and application importance. XJCSENSOR advises:

- Calibrate annually for general industrial use

- Calibrate every 6 months for precision robotic systems

- Calibrate before critical operations or after damage

By sticking to these maintenance, troubleshooting, and calibration tips, users can keep their sensors reliable and accurate. This supports precision and efficiency in manufacturing and robotics.

Future Trends in Force Torque Sensing Technology

The world of industrial automation is changing fast. Force-torque sensor technology is getting a big boost. Companies like XJCSENSOR are leading the way with new solutions for today’s factories.

One big change is making force-torque sensors smaller. This lets them fit into tiny robots and machines. They’re also getting more precise and tough, making them useful in many places.

Another exciting trend is adding wireless to these sensors. This lets data flow easily, making it easier to fix problems and check on things from afar. It makes factories work better and faster.

Lastly, combining these sensors with AI and machine learning is a game-changer. This mix helps predict when things might break, improves how things are made, and makes smarter choices. It’s all about making factories more productive and perfect.