In today’s fast-changing world of industrial automation, motion control sensors are key. They help make manufacturing processes more efficient, precise, and quick. This is driving the Fourth Industrial Revolution, or Industry 4.0. XJCSENSOR leads in providing innovative motion control sensors. They help automate and optimize many industrial areas.

This guide dives into the basics, uses, and future of motion control sensors in industrial automation. Knowing about different sensors and their abilities helps professionals and engineers choose the best for their needs.

Key Takeaways

- Motion control sensors are key for efficient, precise, and quick manufacturing in Industry 4.0.

- XJCSENSOR is a top provider of customized sensor solutions for automation and optimization in various sectors.

- Understanding motion control sensors is vital for making smart choices in industrial automation.

- Motion control sensors are essential for the Fourth Industrial Revolution, boosting innovation and efficiency in manufacturing.

- Choosing the right motion control sensor requires knowing the specific needs of different industrial applications.

Understanding Motion Control Sensors in Modern Industrial Automation

The world of industrial automation is changing fast, thanks to new motion detection technologies. At the center of these changes are motion control sensors. They help machines, processes, and data work together smoothly in factories. We’ll look at how motion detection works, the parts of motion control systems, and their role in Industry 4.0.

Basic Principles of Motion Detection

Motion detection sensors catch and understand the movement of things in factories. They use different technologies like infrared and ultrasonic to track movement. This helps them provide important data for better workflows, safety, and efficiency in automation systems.

Key Components of Motion Control Systems

- Sensing Elements: These are the heart of the system, detecting and measuring movement with tools like proximity sensors and encoders.

- Control Units: These are the brains, using microprocessors and PLCs to make sense of the data and control the system.

- Actuators: They’re the movers, turning signals into action with mechanical or electromechanical devices.

- Communication Interfaces: These are the messengers, making sure all parts of the system can talk to each other.

Role in Industry 4.0

Motion detection is key to the Industry 4.0 movement. It gives detailed, real-time data on how well equipment and processes are doing. This data is vital for making factories smarter, more connected, and efficient. It’s all about making factories more productive, flexible, and quick to respond.

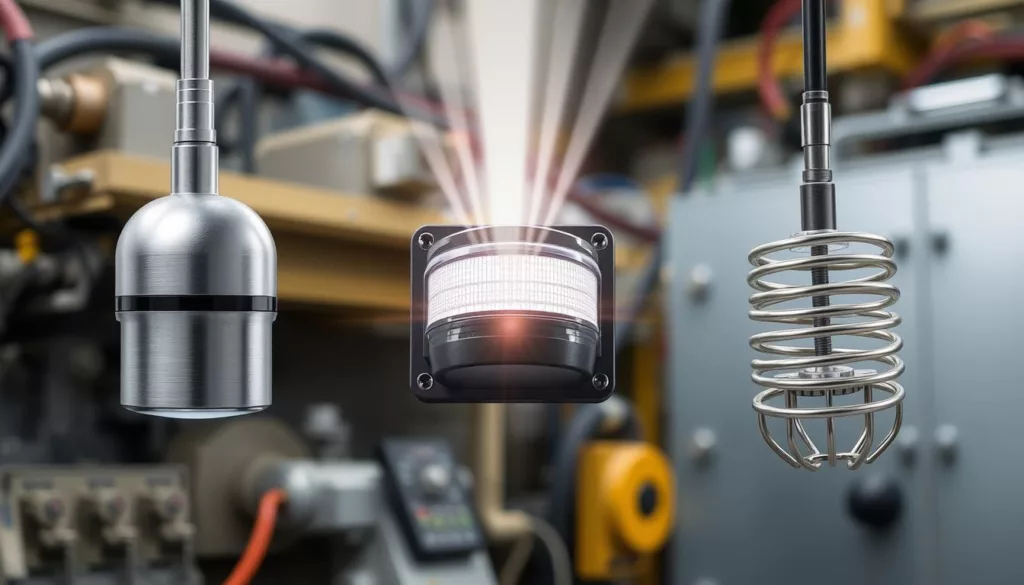

Types of Motion Control Sensors for Automation Applications

In the world of industrial automation, motion control sensors are key. They help make systems precise, efficient, and smart. Three main types are proximity sensors, photoelectric sensors, and inductive sensors. They are versatile and used in many places.

Proximity Sensors: These sensors use electromagnetic fields or capacitive tech to find objects without touching them. They’re great for tasks like robotic picking, material handling, and checking assembly lines. Proximity sensors are fast and reliable, perfect for busy automation settings.

Photoelectric Sensors: These sensors use light to detect objects. They’re good for long-range sensing, counting objects, and checking positions. This makes them essential in packaging, material handling, and quality control.

Inductive Sensors: These sensors find metallic objects using electromagnetic induction. They’re tough and work well in dirty, wet places. Inductive sensors are used in machine tools, conveyor belts, and metalworking.

Knowing what each sensor can do helps automation experts choose the best ones. This improves processes, boosts productivity, and ensures reliable work in Industry 4.0.

Industrial Proximity Sensors: Applications and Benefits

Industrial proximity sensors are key in today’s automation systems. They help detect objects, materials, and movements with great precision. The most common types are inductive sensors, capacitive sensors, and magnetic sensors. Each has its own strengths and uses in the industrial world.

Inductive Proximity Sensors

Inductive inductive sensors use an electromagnetic field to find metallic objects. They’re perfect for places where you don’t want to touch things, like in machines and assembly lines. These sensors are reliable, quick, and can handle tough environments.

Capacitive Proximity Sensors

Capacitive sensors can spot both metal and non-metal things by changing the electrostatic field. They’re great for checking levels, finding objects, and keeping an eye on things in food, packaging, and plastics. They’re good at finding different materials, making them useful in many areas.

Magnetic Proximity Sensors

Magnetic sensors find ferromagnetic objects by sensing magnetic fields. They’re used in motor control, knowing where things are, and when they’ve stopped. They work well in tough places and don’t get affected by dust, water, or shakes.

These sensors bring many benefits to industries. They help control processes better, make things safer, work more efficiently, and cut down on downtime. By using these sensors, companies can make their work better, improve product quality, and be more innovative.

Photoelectric and Vision Sensing Technologies

In the world of industrial automation, photoelectric sensors and vision sensors are key. They help detect motion and monitor positions accurately. These advanced optical sensing tools use light and images to improve safety, efficiency, and quality in many manufacturing areas.

Photoelectric sensors work by sending and receiving light to find objects. They can be set up in different ways to fit various industrial needs. They’re great for detecting objects, counting them, and measuring small movements. This makes them essential for today’s automated systems.

Vision sensors, on the other hand, use complex algorithms to process images. These photoelectric sensors can check product quality, recognize patterns, and track positions with great accuracy. Adding vision sensors to production lines helps ensure products are made consistently, spots defects, and boosts productivity.

| Sensor Type | Key Applications | Advantages |

|---|---|---|

| Photoelectric Sensors |

|

|

| Vision Sensors |

|

|

Using photoelectric and vision sensors, automation experts can improve their work. They can make products better, work more efficiently, and increase productivity. As we move towards more intelligent and data-driven manufacturing, these optical sensing technologies will be even more important in Industry 4.0.

“Photoelectric and vision sensors are the eyes and ears of modern industrial automation, enabling precise motion control, quality inspection, and process optimization.”

Advanced Motion Control Sensors for Precision Manufacturing

In the world of precision manufacturing, advanced motion control sensors are key. They help make sure products are made consistently and to a high standard. These electronic devices give precise measurements and real-time data. This helps manufacturers improve their processes and reach new heights of precision.

High-Speed Motion Detection

One big leap in motion control sensors is detecting fast movements accurately. XJCSENSOR has made big strides in this area. Their technology can track quick, tiny movements, which is vital for precision manufacturing. This means even the most challenging production tasks are done with perfect precision, leading to flawless products every time.

Micro-Movement Sensing

XJCSENSOR also shines in detecting tiny movements. These sensors can spot the smallest changes, helping manufacturers control their work with unmatched accuracy. This is very important in industries where small differences can greatly affect the quality of the final product, like in precision manufacturing.

Quality Control Applications

Advanced motion control sensors have changed the game in quality control for precision manufacturing. They give real-time data and insights. This lets manufacturers watch their production lines closely and quickly spot and fix any problems. This level of control is key to keeping quality and consistency at the highest levels in precision manufacturing.

| Feature | Benefit |

|---|---|

| High-Speed Motion Detection | Enables precise monitoring and control of rapid, micro-scale movements, essential for demanding precision manufacturing processes. |

| Micro-Movement Sensing | Allows for the detection of the smallest movements, critical for industries where small changes can affect product quality. |

| Quality Control Applications | Provides real-time data and insights, enabling manufacturers to closely monitor production lines and maintain the highest standards of quality and consistency. |

By using XJCSENSOR‘s advanced motion control sensors, precision manufacturing companies can achieve unmatched accuracy, efficiency, and quality control. This gives them a big advantage in today’s fast and demanding industrial world.

“XJCSENSOR’s innovative motion control sensors are game-changers in the precision manufacturing industry, empowering us to push the boundaries of what’s possible in terms of product quality and consistency.”

XJCSENSOR’s Innovation in Motion Control Technology

At XJCSENSOR, we aim to lead in sensor innovation and offer customized solutions for our clients. Our knowledge in XJCSENSOR technology has helped us create top-notch motion control sensors. These sensors are changing what’s possible in the field.

Our main innovation is a high-speed motion detection system. It tracks and responds to fast movements with unmatched precision. This technology has greatly improved quality control for our customers in precision manufacturing.

Our engineers have also developed micro-movement sensing. This lets us detect the smallest changes in position or orientation. Such fine control is key for applications where small adjustments greatly affect product quality.

| Feature | Benefit |

|---|---|

| High-speed motion detection | Enables real-time response and optimization in fast-paced industrial environments |

| Micro-movement sensing | Provides unparalleled precision for critical quality control and process monitoring applications |

| Customized sensor solutions | Tailored to meet the unique requirements of each customer’s application |

Our innovation is driven by understanding our customers’ needs and a commitment to excellence. With XJCSENSOR, you get leading solutions from a team of experts who are passionate about your success.

“XJCSENSOR’s cutting-edge motion control sensors have been a game-changer for our manufacturing operations. The level of precision and responsiveness they provide has significantly improved our efficiency and product quality.”

Integration Challenges and Solutions in Sensor Implementation

Adding motion control sensors to industrial systems can be tricky. XJCSENSOR is here to help with installation issues and maintenance. We guide our customers through the tough parts of sensor setup.

Common Installation Issues

Getting sensors to work right starts with where and how you install them. Some big problems include:

- Sensors not being straight because of uneven surfaces or shaking

- Signals getting messed up by nearby electrical stuff

- Bad cable paths causing signal loss

- Sensors not being protected enough in tough environments

Troubleshooting Guidelines

XJCSENSOR offers detailed guides to fix these problems. Our team suggests a step-by-step plan:

- Make sure sensors are placed right and won’t move

- Look for and block out electrical interference

- Check cables for damage or interference

- Make sure the sensor housing can handle the environment

Maintenance Best Practices

Keeping sensors in good shape is key for them to work well over time. XJCSENSOR recommends these maintenance tips:

| Practice | Description |

|---|---|

| Periodic Inspections | Regularly check for physical damage, wear, and proper functioning. |

| Calibration Checks | Verify sensor accuracy and recalibrate as needed to maintain precision. |

| Cleaning and Lubrication | Keep sensors free from dirt, debris, and apply appropriate lubricants. |

| Firmware Updates | Install the latest software updates to enhance performance and security. |

By tackling installation problems and following our maintenance tips, XJCSENSOR ensures our clients get the most out of their sensors. This makes integrating motion control technology into their systems smooth and reliable.

Future Trends in Motion Control Sensors

The world of industrial automation is changing fast. Sensor trends are leading the way in motion control. New technologies like the Internet of Things (IoT) and artificial intelligence (AI) are making sensors smarter.

IoT is making motion control sensors work together seamlessly. This lets them collect data in real-time and predict when they need maintenance. It helps manufacturers work better, cutting down on downtime and making things more efficient.

AI is also changing the game in motion control. It’s improving quality control and making manufacturing more precise. AI helps spot defects faster and makes production smoother.

- Advancements in sensor precision and reliability to meet the demands of high-speed and micro-movement applications.

- Increased integration of sensor networks and cloud-based data analytics for complete process monitoring.

- Emergence of self-calibrating and self-learning sensor systems to adapt to changing environmental conditions.

The future of motion control sensors looks bright. They will make things more efficient, improve quality, and be more flexible. Companies that adopt these new technologies will be at the forefront of change.

“The future of motion control sensors lies in their seamless integration with advanced technologies, empowering manufacturers to achieve new levels of operational excellence.”

Environmental Considerations and Sensor Selection

As industrial automation grows, picking the right motion control sensors is key. We must think about how the environment affects their work. This ensures sensors work well in tough industrial places.

Industrial Environment Factors

Industrial settings can be very hard on sensors. Things like extreme temperatures, chemicals, and vibrations can harm them. It’s important to pick sensors that can handle these challenges.

Durability and Protection Standards

- Ingress Protection (IP) ratings show how well sensors resist dust, liquids, and more.

- Standards for shock and vibration help sensors last in busy industrial areas.

- Temperature ratings tell us how hot or cold a sensor can handle.

Cost-Benefit Analysis

Choosing motion control sensors means balancing cost, performance, and durability. While top sensors might cost more upfront, they save money in the long run. A detailed cost-benefit analysis helps find the best value.

“Choosing the right motion control sensors for your industrial environment is a critical decision that can have far-reaching impacts on productivity, efficiency, and profitability.”

Conclusion

In this article, we’ve looked at how motion control sensors are key in today’s industrial automation. They help with everything from basic motion detection to advanced precision manufacturing. These sensors are essential for improving efficiency, quality, and innovation in many industries.

XJCSENSOR has become a leader in sensor engineering. We’ve created advanced solutions that meet our customers’ specific needs. Our focus on technical excellence and understanding industry challenges has helped us deliver customized systems. These systems increase automation efficiency and boost productivity.

The future of industrial automation looks bright, thanks to advancements in motion control sensors. With the rise of Industry 4.0, there’s a growing need for these technologies. XJCSENSOR is dedicated to leading the way. We’re investing in research and development to bring new sensor solutions to the market. These solutions will help our customers stay competitive and ahead of the curve.