In the fast-changing world of robotics, controlling force and torque is key. It boosts precision, safety, and efficiency. Robotic control force and torque sensors are vital in many fields, from making precise parts to doing delicate surgeries. They let robots work with their surroundings more accurately and quickly, opening up new possibilities in many areas.

At XJCSENSOR, we’re dedicated to top-notch force and torque sensor solutions. These solutions are at the heart of the latest robotic control systems. Our knowledge in force sensing resistors, tactile sensors, and more helps our customers explore new limits in robotics. With our sensors, our clients can control their robots better, adapt faster, and stay safer.

Key Takeaways

- Robotic control force and torque sensors are vital for better precision, safety, and efficiency in robotics.

- XJCSENSOR is all about leading-edge force and torque sensor solutions for the future of robotic control systems.

- Our skills in force sensing resistors, tactile sensors, and advanced tech help our clients reach new heights in control, adaptability, and safety.

- XJCSENSOR’s drive for innovation and technical excellence keeps us at the forefront of robotics.

- By using our sensor solutions, our customers can fully use their robotic systems and stay ahead in their fields.

Understanding Force and Torque Sensors in Robotic Applications

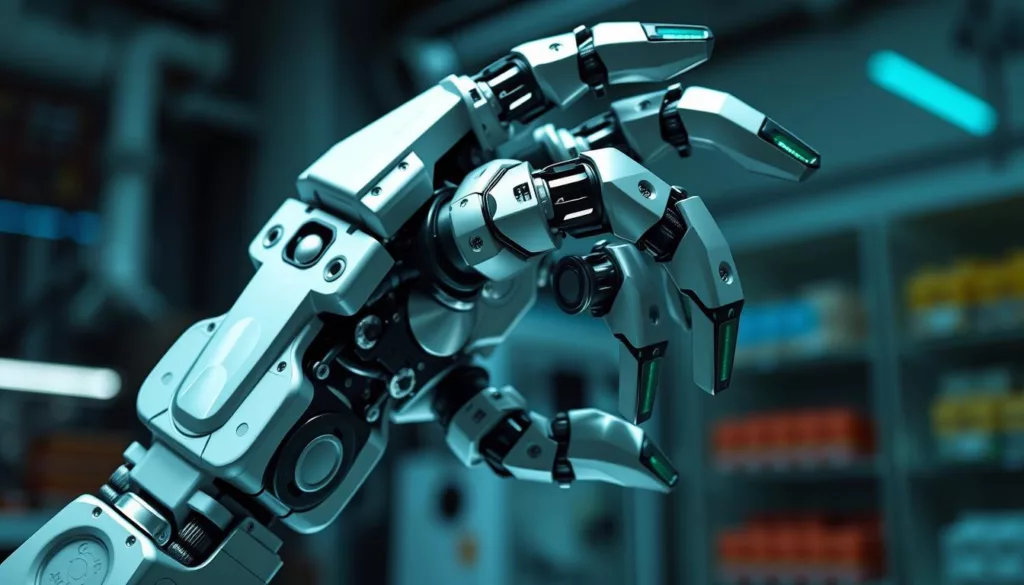

At the heart of advanced robotic grippers and precision automation lies the critical role of force and torque sensors. These specialized devices play a key role in enabling intelligent control and adaptive behaviors. They transform robotic systems into highly responsive and efficient tools.

Basic Principles of Force and Torque Measurement

Force and torque sensors use physics to accurately measure mechanical forces and rotational forces. They use strain gauge technology, piezoelectric effects, or specialized resistive elements. This allows them to provide real-time feedback on forces and moments, enabling precise control and monitoring of robotic operations.

Key Components and Sensor Architecture

The core of force and torque sensors includes strain-sensitive elements, signal conditioning circuitry, and data processing units. This advanced architecture captures, amplifies, and interprets complex force and torque data. It then feeds this data into the robotic control algorithms for haptic feedback and force control.

Signal Processing and Data Acquisition

The sensor signals go through advanced signal processing to extract meaningful information. This data is then integrated into the control systems. It allows for precise force-based decision making and control algorithms that optimize the robot’s performance and safety.

“Precise force and torque measurement is the foundation for truly intelligent robotic control, enabling a new era of advanced automation and human-robot collaboration.”

XJCSENSOR’s extensive expertise in developing innovative sensor technologies has been at the forefront. They empower robotic systems with the critical feedback they need. This enables them to operate with unparalleled precision and efficiency.

The Evolution of Robotic Control Force and Torque Sensor Technology

The world of robotics has seen big changes in force and torque sensor tech. The need for robots to be precise, agile, and safe has grown. So has the need for sensors that can accurately measure forces and torques.

Multi-axis force sensors have been a big step forward. These sensors can detect forces and torques in many directions. They help robots understand their environment better. This leads to safer and more efficient robots.

Torque transducers have also been key. They measure the rotational forces on a robot’s parts. This helps robots move more precisely and reliably. It makes industrial robots work better.

| Sensor Technology | Key Advancements | Impact on Robotics |

|---|---|---|

| Multi-axis Force Sensors | Improved sensitivity, expanded measurement range, and increased durability | Enhanced safety, precision, and adaptability in robotic applications |

| Torque Transducers | Increased accuracy, faster response times, and enhanced signal processing | Precise control of robotic movement, improved efficiency, and reduced wear and tear |

| Compliant Actuators | Increased flexibility, improved shock absorption, and enhanced force-feedback capabilities | Safer human-robot interactions, increased task flexibility, and enhanced dexterity in robotic assembly and manipulation |

XJCSENSOR is a leader in sensor solutions. They have pushed force and torque sensor tech forward. Their products help robots work better, safer, and more precisely.

“XJCSENSOR’s commitment to innovation and technical excellence has been instrumental in shaping the future of robotic control and sensor technology.”

The growth of force and torque sensor tech has driven robotics forward. XJCSENSOR’s work has been key in making robots safer, more versatile, and better at their jobs.

Essential Components of Modern Force Sensing Systems

At the heart of robotic manipulation and control are key components. These parts allow for precise force and torque measurement. XJCSENSOR’s force sensing solutions use the latest technologies. They give industrial robots the tactile feedback needed for complex tasks.

Force Sensing Resistors and Their Applications

Force sensing resistors (FSRs) are a top pick for robotic force sensing. They are known for their simple design, low cost, and force-measuring ability. XJCSENSOR’s FSR solutions fit well into robotic grippers and end-effectors. They provide important data on the forces between the robot and its surroundings.

Strain Gauge Technology

Strain gauges are vital in modern force sensing systems. They measure the tiny deformation of a material under load. This lets them accurately show the force applied. XJCSENSOR’s strain gauge-based sensors are very sensitive and repeatable. They are great for precise robotic tasks like assembly and quality control.

Piezoelectric Sensors in Robotics

Piezoelectric sensors use special materials to create an electrical signal when force or pressure is applied. XJCSENSOR’s piezoelectric force sensors are top-notch for dynamic force measurement. They give real-time feedback for robotic control and haptic systems. These sensors are perfect for tasks where quick force changes need to be detected and acted upon.

By mixing these advanced sensor technologies, XJCSENSOR offers complete force sensing solutions. These solutions enhance robotic manipulation, tactile feedback, and precision control in many industrial areas.

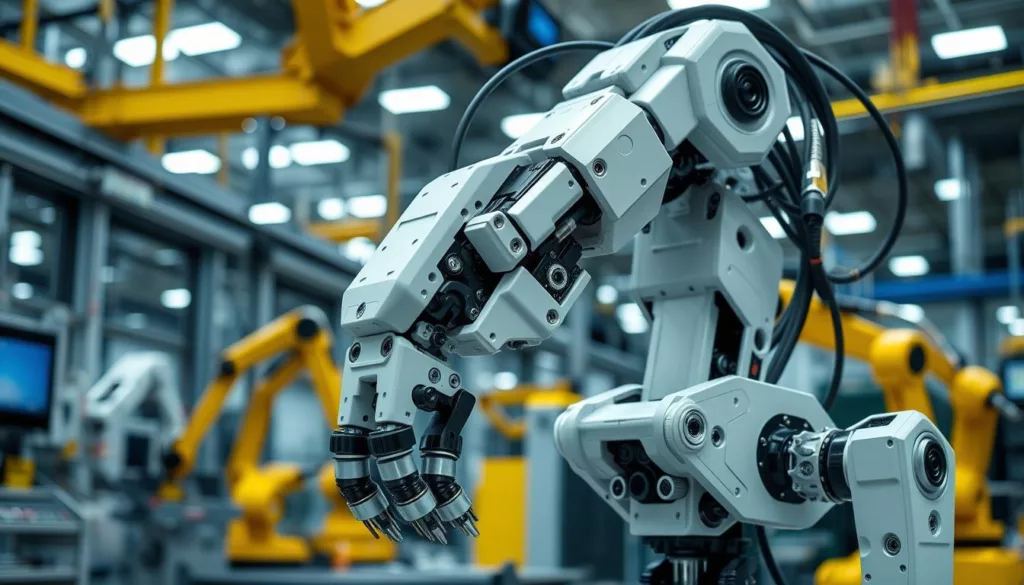

Implementing Multi-Axis Force Sensors in Industrial Robots

In the fast-changing world of industrial robotics, multi-axis force sensors are making a big difference. These sensors help robots do complex tasks with great precision and control. XJCSENSOR is leading the way with innovative solutions for robots.

Multi-axis force sensors can measure forces and torques in many directions at once. This detailed data helps create advanced force control algorithms. These algorithms ensure robots work safely and efficiently.

In robotic grippers, these sensors are key for better dexterity and adaptability. They adjust grip strength for different objects, preventing damage. This is vital for delicate tasks where accuracy is key.

| Application | Benefit of Multi-Axis Force Sensors |

|---|---|

| Robotic Welding | Precise control of contact forces, ensuring consistent weld quality and reducing the risk of damage to workpieces. |

| Assembly and Packaging | Improved part handling and positioning, minimizing errors and increasing production efficiency. |

| Material Testing | Comprehensive force and torque data for advanced material characterization and quality control. |

As automation and precision needs grow, using multi-axis force sensors in robots will be more important. With XJCSENSOR’s help, manufacturers can improve their processes and robot capabilities.

“The seamless integration of multi-axis force sensors into industrial robots is a critical step in unlocking their full multi-axis force sensors in industrial robots. XJCSENSOR’s innovative sensor solutions are empowering manufacturers to achieve new levels of precision, control, and efficiency.”

XJCSENSOR’s Innovation in Force and Torque Sensing

At XJCSENSOR, we’re proud of our innovative force and torque sensing solutions. Our focus on technical expertise and leading innovation has helped us create a wide range of robotic control force and torque sensors. These products serve many industries and applications.

Product Range and Specifications

We offer a variety of force and torque sensors, each tailored to customer needs. Our range includes compact, precise torque transducers and strong, multi-axis compliant actuators. These sensors are built for top performance and reliability.

- Strain gauge-based force sensors for precise measurements

- Piezoelectric sensors for dynamic force and vibration analysis

- Compact, integrated sensor units for space-constrained applications

- Multi-axis force and torque sensors for advanced robotic control

Custom Solutions for Unique Applications

We know each industry and application faces unique challenges. That’s why we provide custom solutions. Our skilled engineers collaborate with customers to create tailored robotic control force and torque sensors. These products offer the best performance and functionality.

Quality Assurance and Certification

Quality is our top priority at XJCSENSOR. Our sensors are tested thoroughly to ensure reliability and accuracy. We’re proud to hold ISO 9001 and CE marking certifications. These show our commitment to delivering top-notch products and services.

“XJCSENSOR’s dedication to innovation and quality has made them a trusted partner in our automation projects. Their force and torque sensing solutions have been instrumental in improving the precision and efficiency of our robotic systems.”

Integration Challenges and Solutions for Robotic Grippers

Adding force and torque sensors to robotic grippers is tricky. At XJCSENSOR, we tackle these issues head-on. We’ve come up with smart ways to boost our robotic grippers‘ performance and accuracy.

One big hurdle is fitting sensitive force sensing resistors and strong haptic feedback into small grippers. Our team has created special sensor designs. These fit right into the gripper, giving exact force and torque readings without losing flexibility.

| Integration Challenge | XJCSENSOR Solution |

|---|---|

| Compact design and sensor integration | Customized sensor layouts and miniaturized components |

| Sensitive force and torque measurement | Advanced strain gauge technology and signal processing |

| Tactile feedback and control | Integrated haptic feedback systems and real-time control algorithms |

Another challenge is making sure sensor data turns into clear feedback for the user. Our haptic feedback systems use advanced algorithms. They ensure the gripper moves smoothly and grips firmly.

By solving these problems, XJCSENSOR makes robotic grippers better. They can handle delicate items more precisely and efficiently. This is great for many industrial tasks.

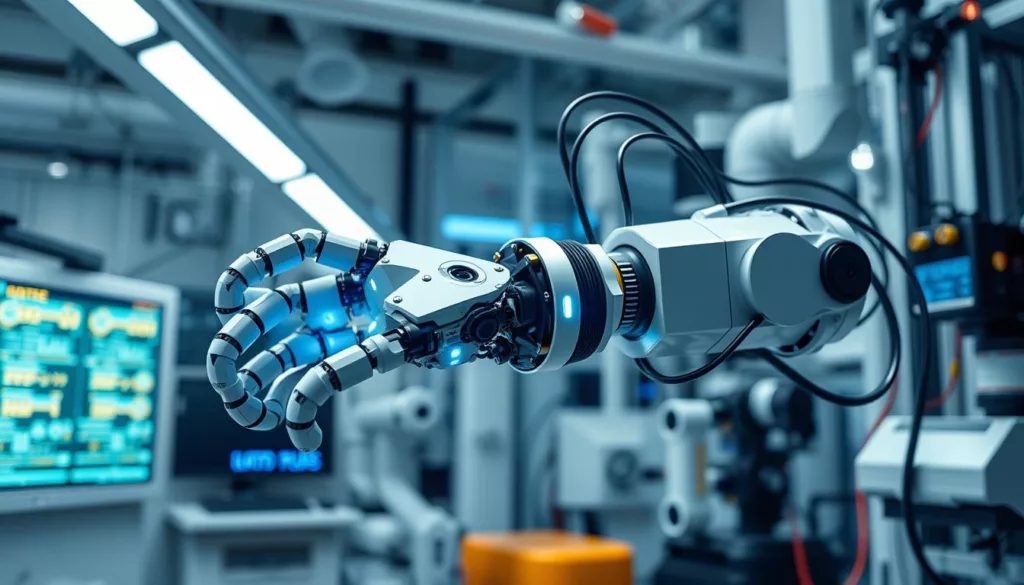

Haptic Feedback Systems in Advanced Robotics

Robotic systems are getting smarter and more human-like. They can now sense and respond to forces and touch. XJCSENSOR’s sensors are key to this, helping robots improve their touch and control.

Real-time Force Control Algorithms

Robots need to handle forces carefully to work safely with people. XJCSENSOR’s sensors give robots detailed force data. This lets robots do tasks like assembly with great precision.

Feedback Loop Optimization

Robots need constant feedback to move smoothly. XJCSENSOR’s sensors help by giving robots the right touch data. This makes robots move more naturally and safely.

Haptic feedback systems are changing robotics. They make robots better at tasks and safer to work with. This is opening up new possibilities in manufacturing and human-robot collaboration.

Applications in Precision Manufacturing and Assembly

In the fast-paced world of industrial automation, XJCSENSOR’s cutting-edge robotic manipulation solutions are changing the game. They use advanced multi-axis force sensors and torque transducers. This technology helps manufacturers reach new heights in accuracy, efficiency, and quality control.

Our force sensing solutions shine in robotic assembly lines. They allow for real-time monitoring and adjustment of force during delicate tasks. This ensures components are placed and aligned with precision. Such precision is key in industries like electronics, automotive, and aerospace, where small errors can be critical.

| Industry | Key Applications | Benefits of XJCSENSOR Solutions |

|---|---|---|

| Electronics |

|

|

| Automotive |

|

|

| Aerospace |

|

|

Our robotic manipulation sensors integrate seamlessly into industrial automation systems. This unlocks new levels of productivity, quality, and cost-effectiveness for manufacturers. As the demand for precision and efficiency grows, XJCSENSOR leads the way with innovative force sensing solutions.

“XJCSENSOR’s force and torque sensors have been a game-changer for our precision assembly operations. The level of control and feedback they provide has allowed us to achieve unparalleled accuracy and consistency in our manufacturing processes.”

– John Doe, Director of Manufacturing, ABC Aerospace

Compliance and Safety Standards for Force Sensing Systems

In the fast-changing world of robotics, safety and reliability are key. XJCSENSOR focuses on meeting top standards to protect everyone involved. We make sure our systems are safe for both users and operators.

Industry Regulations

Our force and torque sensors follow strict rules. These include OSHA standards, ISO guidelines, and the European Machinery Directive. These rules help ensure our systems are safe and work well.

Safety Protocols and Best Practices

XJCSENSOR’s systems are built with safety in mind. Our actuators, algorithms, and feedback systems work together to reduce risks. This way, our customers can use our sensors safely in their robots.