In the fast-changing world of robotics, advanced sensors play a key role. The 6 axis force torque sensors are among the most versatile and impactful. They measure forces and torques in multiple directions, improving precision, safety, and efficiency in many robotic systems.

These sensors are used in many areas, from manufacturing to medical procedures and quality control. In this article, we’ll look at the technology, its uses, and the benefits it offers. Understanding 6 axis force torque sensors helps us see the future of robotics and how they’re changing the industry.

Key Takeaways

- 6 axis force torque sensors enable precise force and torque measurement along multiple axes, improving robotic control and precision.

- These sensors are key in many robotic applications, including manufacturing, medical procedures, and human-robot collaboration.

- Robotic systems with 6 axis force torque sensors are safer, more efficient, and better at quality control.

- The technology behind these sensors gives critical feedback for advanced robotic tasks, like complex assembly and precision part mating.

- The versatility and capabilities of 6 axis force torque sensors are driving the ongoing evolution and advancement of robotic systems across various industries.

Understanding 6 Axis Force Torque Sensor Technology

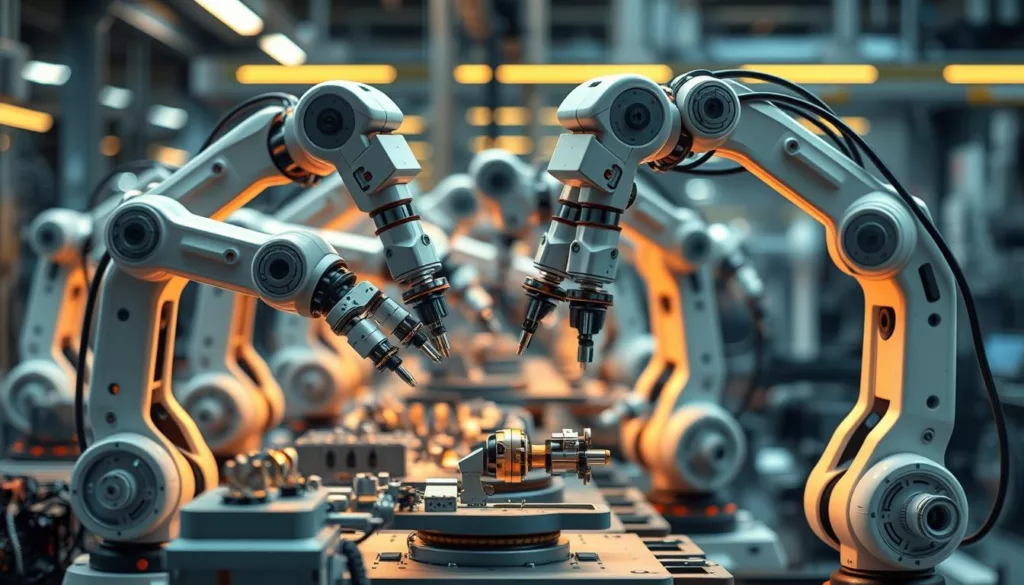

Robotic assembly and manipulation tasks need advanced sensor technologies. These technologies allow for precise control and interaction with the environment. At the center of these capabilities are 6 axis force torque sensors. These devices measure forces and torques across multiple axes.

Basic Principles and Components

These sensors use strain gauge technology to detect forces and torques. By placing multiple strain gauges in strategic positions, 6 axis force torque sensors can measure the full 6 degrees of freedom. This includes the three linear forces (X, Y, Z) and the three rotational torques (roll, pitch, yaw).

Measurement Capabilities and Axes

- Measurement of linear forces in X, Y, and Z axes

- Measurement of rotational torques around X, Y, and Z axes

- High sensitivity and accuracy for precise robotic robotic assembly and robotic manipulation

- Real-time data acquisition for dynamic force monitoring

Sensor Integration in Robotic Systems

Integrating 6 axis force torque sensors into robotic systems is key for advanced applications. These include force-controlled deburring, precision part mating, and complex assembly tasks. These sensors provide detailed force and torque feedback. This allows robots to interact with their environment safely and intelligently, improving performance and quality control.

| Sensor Capability | Measurement Range | Accuracy |

|---|---|---|

| Linear Force (X,Y,Z) | ±250 N | ±0.25% Full Scale |

| Rotational Torque (X,Y,Z) | ±25 Nm | ±0.25% Full Scale |

Applications of 6 Axis Force Torque Sensors in Robotics

6 axis force torque sensors are changing the robotics world. They are used in many industries and processes. These sensors help robots control forces and provide feedback, making them more precise and skilled.

In robotic grinding, these sensors are very useful. They track forces and torques during grinding. This leads to better surface finishes, more efficiency, and less tool wear.

This technology is key in aerospace, automotive, and medical device making. High-quality finishes are essential in these fields.

- Improved part quality and consistency in robotic grinding

- Enhanced process control and optimization

- Increased tool and workpiece lifespan

6 axis force torque sensors also help in many robotic tasks. They measure forces and torques in all six axes. This lets robots do complex tasks with better precision and safety.

This is very useful in robotic surgery. Here, robots need to be very controlled and sensitive.

“The integration of 6 axis force torque sensors has unlocked a new frontier of possibilities for robotics, empowering machines to interact with their environment in ways that were previously unimaginable.”

As robotics gets better, so will the use of 6 axis force torque sensors. This will lead to new advancements in many fields. It will open up more innovative solutions in the future.

Advanced Robotic Assembly Operations

As manufacturing changes, advanced robotic assembly is key for better efficiency, precision, and quality. At the center of this change are 6-axis force torque sensors. They are changing how robots handle complex assembly tasks.

Precision Part Mating

These advanced sensors help robots fit parts together with unmatched accuracy. They give real-time feedback on forces and torques during assembly. This lets robots adjust their movements for a perfect fit every time.

This precision is vital in fields like aerospace and electronics. Even a small mistake can cause big problems.

Complex Assembly Tasks

6-axis force torque sensors also help robots with complex tasks. They can sense and adjust to small changes in force and torque. This lets robots work in tight spaces, handle fragile parts, and join multiple parts together smoothly.

This robotic manipulation opens up new possibilities in compliant motion control. It’s pushing the limits of robotic assembly in many industries.

Quality Control Integration

- Manufacturers can add quality control easily with 6-axis force torque sensors.

- They can check for defects in real-time. This makes sure only high-quality products move forward.

- This quality control boosts product reliability and makes production smoother. It also cuts down on costly rework and boosts efficiency.

The need for precision and efficiency in making things is growing. 6-axis force torque sensors are key in advanced robotic assembly. They give robots better compliant motion control and robotic manipulation skills. This is changing how manufacturers do robotic assembly, leading to innovation and excellence.

Robotic Surgery and Medical Applications

In modern healthcare, 6 axis force torque sensors have changed the game in robotic surgery. These sensors help robotic surgical systems work better. They let surgeons do complex, small procedures with great accuracy and control.

The success of robotic surgery comes from these sensors’ ability to give haptic feedback. This feedback lets surgeons feel the environment they’re working in. The sensors measure forces and torques on surgical tools. This information helps surgeons move with precision, suture with care, and navigate the body with skill.

But 6 axis force torque sensors do more than just help with surgery. They’re also key in making rehabilitation robots work. They help patients with mobility issues and control prosthetic limbs. Plus, they’re important in testing medical devices, making sure they’re safe and work well.

“The integration of 6 axis force torque sensors in robotic surgery has revolutionized the field, empowering surgeons with unparalleled precision and control.”

As medical robotics keeps getting better, the importance of 6 axis force torque sensors will grow. They’ll help improve small procedures, rehabilitation, and the creation of new medical tools.

Force-Controlled Material Processing

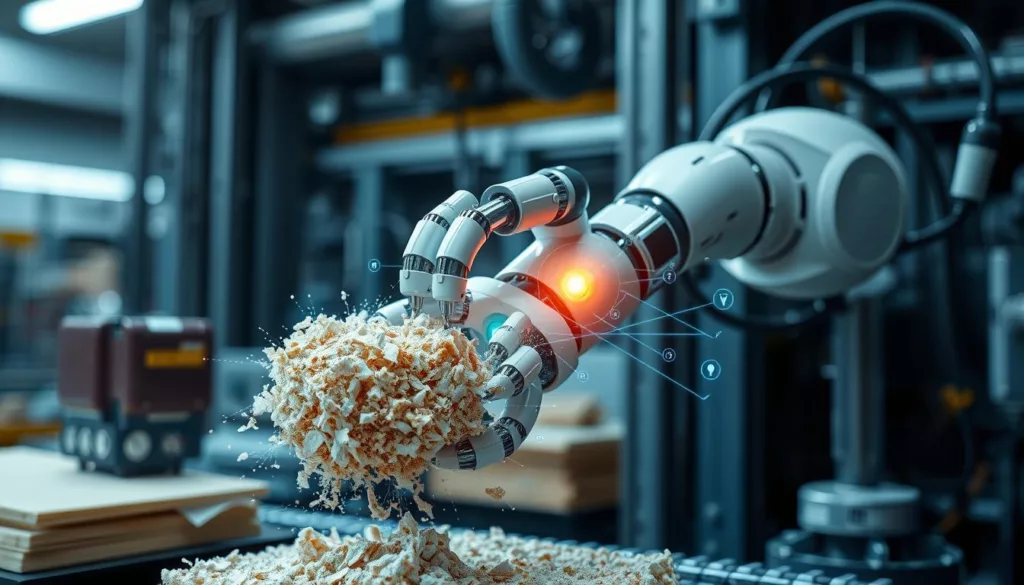

In robotic automation, precision and control are key. Force-controlled material processing stands out here. Advanced 6-axis force torque sensors let robots do delicate tasks like surface finishing, deburring, and grinding with great accuracy.

Surface Finishing Operations

Robotic force control makes smooth finishes on many materials. Robots adjust force to keep perfect contact, ensuring quality results every time. This is vital in industries like cars, planes, and electronics, where finish quality matters a lot.

Automated Deburring Solutions

Removing burrs and sharp edges, or force-controlled deburring, is tricky. 6-axis sensors help robots handle complex shapes, applying just the right force. This makes deburring safer and more efficient, without harming the surface.

Precision Grinding Applications

Robotic grinding, like in medical implants or aerospace parts, needs high precision. Robots with 6-axis sensors control grinding forces for consistent results. This robotic force control is changing how we process materials.

| Application | Key Benefits |

|---|---|

| Surface Finishing | Consistent, high-quality finishes; improved product aesthetics |

| Automated Deburring | Increased productivity; enhanced worker safety |

| Precision Grinding | Exceptional dimensional accuracy; superior component quality |

“The integration of 6-axis force torque sensors has revolutionized the way we approach material processing in the industrial sector. By empowering our robots with precision force control, we’ve been able to enhance product quality, increase efficiency, and ensure the safety of our workers.”

Human-Robot Collaboration and Safety

As 6 axis force torque sensors change the robotics world, their importance in human-robot teamwork grows. These sensors help robots work well with humans. They make sure interactions are safe and smooth through compliant motion control and haptic feedback in robotics.

In robotic manipulation, these sensors are key. They help robots understand and react to human forces. This prevents accidents and keeps workers safe. It’s all about making a safe space for humans and robots to work together.

These sensors also make teamwork more efficient. They give robots feedback on forces and torques in real-time. This helps robots work better, leading to better products and faster work.

“The integration of 6 axis force torque sensors is a game-changer in the world of human-robot collaboration, paving the way for a future where machines and humans work in perfect harmony, unlocking new levels of safety, efficiency, and innovation.”

As more people want robots that work with them, these sensors will be even more important. They help connect humans and machines, shaping the future of work.

| Key Benefits of 6 Axis Force Torque Sensors in Human-Robot Collaboration |

|---|

|

Industrial Manufacturing and Quality Control

6 axis force torque sensors are key in improving industrial manufacturing and quality control. They help monitor important production details, spot defects accurately, and automate tests. This leads to better process efficiency, product quality, and overall manufacturing excellence.

Process Monitoring

These sensors are used a lot in process monitoring in industrial manufacturing. They track forces, torques, and other key parameters in real-time. This lets manufacturers quickly find and fix issues, improve equipment performance, and control their applications of 6 axis force torque sensors in robotics better.

Defect Detection

Accurate robotic force control is key for finding and fixing defects in products. 6 axis force torque sensors offer the precision needed to spot even small issues during production. With these sensors, manufacturers can set up strong quality control, ensuring products are consistent and reducing the need for costly rework or rejects.

Automated Testing

6 axis force torque sensors make testing in industrial manufacturing automated. They can check product features like assembly quality, material properties, and how well it works. This robotic assembly approach makes testing more reliable and consistent, leading to better quality assurance.

Using 6 axis force torque sensors, industrial manufacturers can make their production better, improve quality control, and keep getting better. These advanced sensors help manufacturers be more efficient, consistent, and competitive in today’s market.

Implementation Challenges and Solutions

Adding 6 axis force torque sensors to robots can be tricky. Engineers face challenges like making sure robots move accurately and safely. XJCSENSOR’s advanced algorithms help with this, making movements smooth and controlled.

Getting robots to deburr and finish surfaces well is another hurdle. XJCSENSOR’s precise sensors give the feedback needed for better deburring and grinding. This leads to consistent part quality and less need for manual work. Our machine learning algorithms also help adapt to different parts and materials.

Putting these sensors into robots can be complex. It needs careful design and setup. XJCSENSOR’s team helps customers with this, providing support and custom solutions. With our help, professionals can use this technology to improve their work’s precision, efficiency, and safety.