In today’s fast-changing industrial world, precision and reliability in torque measurement are key. Manufacturers in many fields, like cars, planes, green energy, and medical devices, need sensors that fit their specific needs. These new sensor technologies are changing how we check, analyze, and improve our important processes. This leads to better efficiency, safety, and productivity.

At the heart of this change are top makers like XJCSENSOR. They focus on creating solutions that solve their clients’ unique problems. With their advanced engineering, latest measurement methods, and deep understanding of customer needs, they help manufacturers reach new heights in performance and control.

For example, medical devices need better sensitivity, green energy needs to work in tough conditions, and fast industrial processes need real-time data. Customizable torque sensors let businesses explore new chances for growth and innovation. By working with experts, manufacturers can get solutions that not only meet their needs but also prepare them for the future, helping them succeed in a tough market.

Key Takeaways

- Customizable torque sensors are changing industrial processes across many sectors, bringing new precision, reliability, and efficiency.

- Top makers like XJCSENSOR lead in creating custom torque sensing solutions for unique needs.

- Customization helps businesses solve specific problems and find new chances for growth and innovation.

- Working with experts ensures manufacturers get the latest and most advanced torque sensing technologies.

- Precision torque measurement, custom torque solutions, and industrial torque monitoring are big benefits of these sensor technologies.

Understanding the Fundamentals of Industrial Torque Sensing

High-accuracy torque sensing is key in many industrial processes. It ensures equipment works well and products are of high quality. Let’s dive into the basics of torque measurement and the parts of modern torque sensors.

Basic Principles of Torque Measurement

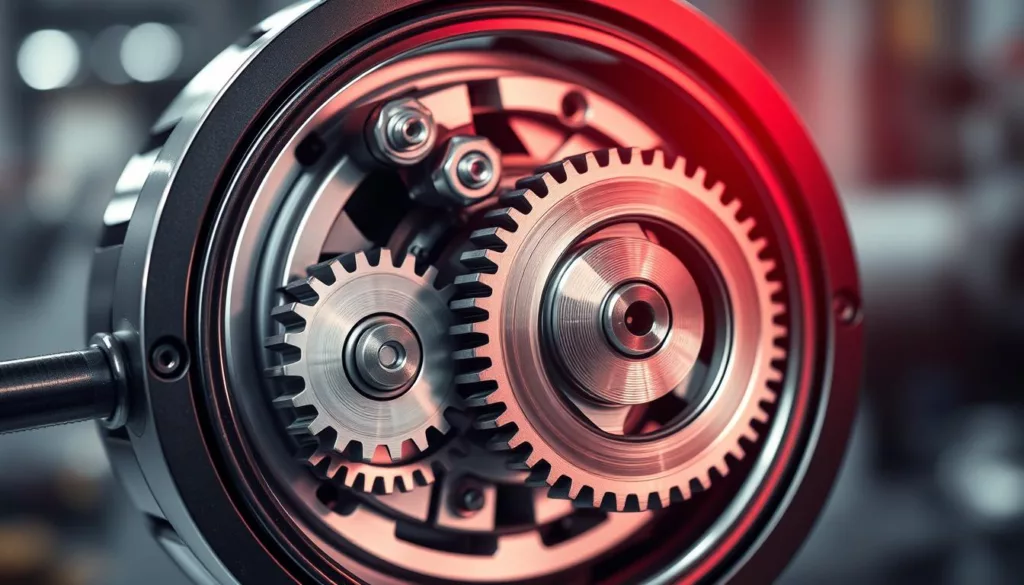

Torque is the rotational force in many industrial fields. It’s used in machinery, power transmission, robotics, and automation. Torque sensors use advanced tech to turn this force into electrical signals. This lets us monitor and control important processes with precision.

Key Components of Modern Torque Sensors

- Strain Gauge: This part changes the applied torque into an electrical signal.

- Sensor Body: It’s the strong outer part that keeps the inside safe and makes mounting easy.

- Signal Conditioning Electronics: These parts make the raw signal better by amplifying and filtering it. They also change it into a format that’s easy to use.

Signal Processing and Data Output Methods

Modern torque sensors use smart signal processing for accurate measurements. They do things like convert analog signals to digital, filter out noise, and use algorithms to improve the signal. The data can then be sent out in different ways, like analog signals, digital bus protocols, or wirelessly, based on what’s needed.

| Signal Processing Technique | Benefit |

|---|---|

| Analog-to-Digital Conversion | Enables seamless integration with digital control systems and data acquisition |

| Digital Filtering | Reduces noise and improves signal quality for high-accuracy torque measurements |

| Advanced Algorithms | Enhances measurement precision and reliability through advanced signal processing |

Knowing how industrial torque sensing works helps us see its value. It shows how high-accuracy torque sensing and customized torque transducers meet the needs of different industries and tasks.

Advantages of Application-Specific Torque Sensors in Manufacturing

In today’s fast-changing manufacturing world, application-specific torque sensors play a key role. They offer many benefits that help improve production and efficiency.

One major advantage is their high accuracy and precision. Made for each industry’s needs, these sensors give reliable measurements. This leads to better control and quality in processes.

- Improved Process Efficiency: Application-specific torque sensors give precise torque data. This helps manufacturers refine their processes, cutting down on waste and boosting output.

- Enhanced Reliability: Custom sensors are built to handle specific conditions and demands. This makes equipment more reliable and available for use.

- Increased Productivity: Adding bespoke torque instrumentation to production lines reduces downtime. It also speeds up troubleshooting and maintenance, leading to more productivity and profit.

Also, these sensors help improve safety and follow regulations. They are made to meet specific standards and needs of industries.

“Customized torque sensors have been instrumental in optimizing our manufacturing processes, ensuring we consistently meet our quality and efficiency targets.”

As manufacturers aim to lead, using application-specific torque sensors and bespoke torque instrumentation is essential. These tailored solutions help companies achieve better performance, reliability, and cost savings in their operations.

Customizable Torque Sensors for Unique Industry Needs

In the world of industrial automation, a one-size-fits-all approach doesn’t work. At XJCSENSOR, we know each industry and application has its own needs. That’s why we offer flexible torque sensing systems and industry-tailored torque technology for our clients.

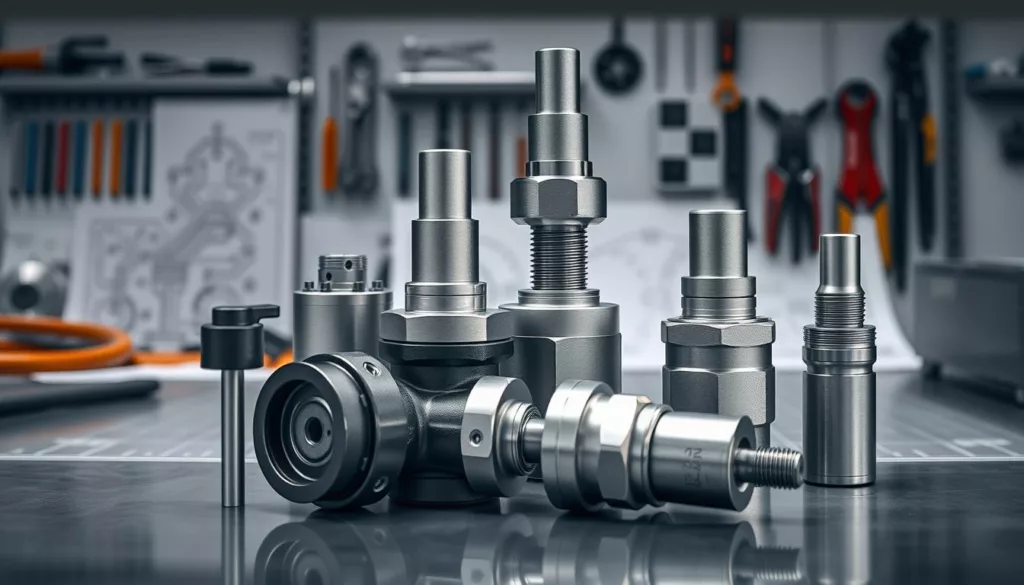

Tailoring Sensors to Specific Applications

Our team works closely with clients to find the exact needs for their application. Whether it’s high-speed machinery, automotive production, or textile manufacturing, we can create a custom torque sensor. Our solution ensures top performance and reliability.

Customization Parameters and Options

We offer many customization options to fit your industrial needs. From size and mounting to signal output and environmental resistance, we’ve got you covered. Our advanced manufacturing lets us tailor the sensor to your exact needs, making it a perfect fit.

Integration Capabilities with Existing Systems

Seamless integration is essential when adding new sensor technology. We focus on compatibility to ensure a smooth transition. Whether it’s integrating our flexible torque sensing systems into automation networks or retrofitting industry-tailored torque technology into legacy machinery, our support and expertise help. This streamlines the installation and maximizes your investment.

“The customization options and integration capabilities offered by XJCSENSOR have been instrumental in ensuring our torque sensing needs are met with precision and reliability.”

– John Doe, Manufacturing Engineer

High-Precision Measurement Technologies in Modern Torque Sensing

In the fast-changing world of industrial automation, precise torque measurement is key. XJCSENSOR leads in developing top-notch torque sensing tech. They aim for high accuracy and reliability.

XJCSENSOR deeply understands the basics of precision torque measurement. Their team has created new sensor designs. They use advanced materials and signal processing for high-accuracy torque sensing in different industries.

| Sensor Technology | Measurement Accuracy | Applications |

|---|---|---|

| Strain Gauge Torque Sensors | ±0.1% of full scale | Automotive testing, industrial machinery, material research |

| Magnetoelastic Torque Sensors | ±0.25% of full scale | Powertrain systems, robotics, medical devices |

| Optical Torque Sensors | ±0.05% of full scale | Aerospace, wind turbines, high-precision manufacturing |

XJCSENSOR uses advanced sensors to give customers the precision torque measurement they need. This helps them improve production, quality, and innovation.

“The key to unlocking the full precision torque measurement lies in the ability to precisely measure and control critical parameters like torque. Our innovative sensor technologies empower our customers to achieve new levels of efficiency, quality, and performance.”

XJCSENSOR stays ahead in high-accuracy torque sensing tech. They keep exploring new ways to improve precision, reliability, and adaptability. Their mission is to provide customized, cutting-edge solutions for success in today’s competitive world.

Design Considerations for Bespoke Torque Instrumentation

Creating customized torque transducers and bespoke torque instrumentation requires careful thought. Our team of experts focuses on material selection, environmental conditions, size, and mounting needs. They also consider performance specifications and tolerances to meet your specific needs.

Material Selection and Environmental Factors

The right materials for a torque sensor are key, as they must handle the environment it’s in. Temperature, humidity, corrosive elements, and vibration can affect its performance and life. Our engineers pick the best materials, coatings, and protective measures for your customized torque transducers.

Size and Mounting Requirements

The size and mounting of bespoke torque instrumentation are tailored to fit your space and needs. We design with your machinery, equipment, or systems in mind. This ensures a smooth and secure fit, making installation easier.

Performance Specifications and Tolerances

Precision is essential for custom torque sensing solutions. We work with you to set the exact performance specs, like measurement range and accuracy. We test and check our customized torque transducers to make sure they meet your standards.

XJCSENSOR addresses these key design factors to create bespoke torque instrumentation that fits your needs perfectly. Our engineering skills and innovative methods ensure top performance, reliability, and durability.

Industry-Specific Applications and Case Studies

At XJCSENSOR, we know each industry faces its own challenges with industrial torque monitoring. That’s why we offer application-specific torque sensors tailored to meet our clients’ needs in various sectors.

In the automotive world, our torque sensors are key to ensuring quality and performance in powertrain parts. They help monitor torque levels during assembly and testing. This has boosted production efficiency and cut down on warranty claims for automakers.

“XJCSENSOR’s tailored torque sensors have been a game-changer for our operations. The level of precision and reliability they provide has been instrumental in maintaining the high standards our customers expect.”

In aerospace, our industrial torque monitoring solutions track fastener torque during aircraft assembly and maintenance. This has improved safety, reduced costly rework, and ensured regulatory compliance for our customers.

Across the energy sector, from wind turbine gearbox monitoring to oil and gas pipeline valve control, our application-specific torque sensors have shown their value. They help optimize efficiency and reduce downtime.

No matter the industry, XJCSENSOR is dedicated to providing customized torque sensing solutions. We help our customers overcome their unique challenges and reach their operational goals.

Advanced Features of Flexible Torque Sensing Systems

As the need for custom torque technology grows, makers look for flexible torque sensing systems with new features. These systems offer digital interfaces and real-time monitoring. They change how industries measure and control torque.

Digital Interface Options

Today’s torque sensors have many digital interface options. They make it easy to connect with control systems and data platforms. You can use Modbus, CANbus, and Ethernet for smooth communication.

Real-time Monitoring Capabilities

Systems that monitor in real-time give insights into machinery and processes. They track torque data to spot issues and plan maintenance. This leads to better uptime and lower costs.

Data Analysis and Reporting Tools

Flexible torque systems come with advanced data tools. They turn raw data into useful information. With analytics and reports, industries can make better decisions and improve control.

The role of flexible torque sensing systems in industry is vital. They help manufacturers become more efficient and reliable. This sets them up for success in their markets.

“The integration of advanced features in our torque sensing solutions has been a game-changer for our customers, enabling them to achieve unprecedented levels of control, efficiency, and data-driven decision-making.”

Maintenance and Calibration of Custom Torque Sensors

Keeping your custom precision torque measurement solutions accurate and reliable is key. At XJCSENSOR, we offer detailed advice on how to maintain and calibrate your high-accuracy torque sensing tools. This helps them work better and last longer.

It’s important to regularly care for and recalibrate your sensors. This keeps your torque data reliable. Our experts suggest these steps:

- Set up a maintenance plan to clean, check, and service your sensors as the maker advises.

- Do regular recalibration checks to make sure your sensor’s precision torque measurement is spot on. Make any needed tweaks.

- Fix any problems, like signal drift or outside interference, that could affect your high-accuracy torque sensing quality.

Being proactive with sensor upkeep and calibration ensures your custom torque tools keep giving you precise, consistent, and accurate readings. Our team is ready to help you keep your tailored solutions in top shape.

“Proper maintenance and calibration are the keys to unlocking the full precision torque measurement of your custom torque sensors.”

Future Trends in Customizable Torque Sensing Technology

The industrial world is changing fast, and so is the need for new torque sensing tech. Companies and engineers want sensors that fit their unique needs. XJCSENSOR is leading the way, making torque measurement better for industries.

Emerging Technologies and Innovations

Big changes are happening in torque sensing, thanks to new tech like IoT and AI. XJCSENSOR’s sensors will use these advancements for real-time monitoring and smart decisions. This means better control and insights for those working in industry.

Industry 4.0 Integration Prospects

Industry 4.0 is changing how factories work, and XJCSENSOR’s tech is ready for it. Their sensors will help make production more efficient and automated. With Industry 4.0, XJCSENSOR’s solutions will help industries work better, produce more, and use equipment more effectively.