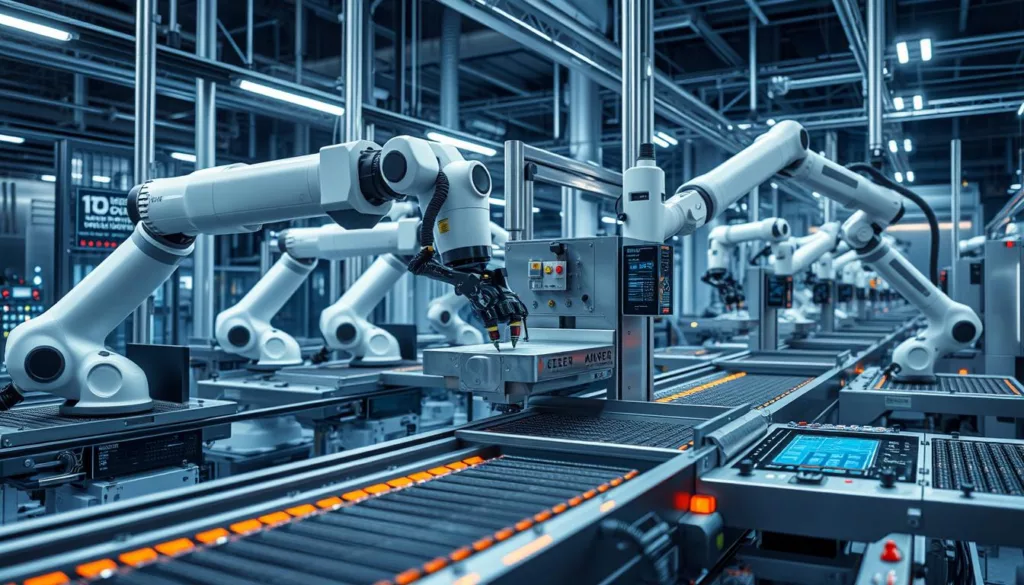

The demand for smart sealing solutions in industries keeps growing. We lead in sensor technology and see the need for automated sealing sensors. They improve production and maintain seal integrity in various uses. Our focus on innovation and quality helps us create advanced sealing solutions.

Smart sealing technology boosts efficiency and quality. It does this through precise monitoring and control. This article will discuss how these sensors are changing industries. They play a vital role in modern industrial practices.

Key Takeaways

- Automated sealing sensors significantly enhance production efficiency.

- These sensors ensure the integrity of seals in various applications.

- Intelligent sealing technology is instrumental in quality control.

- Advanced sealing solutions are tailored to meet industry-specific needs.

- The adoption of innovative sensor technology is crucial for modern operations.

Understanding Automated Sealing Sensors

Automated sealing sensors are key in many industries to make sure seals are reliable and of high quality. They use smart technology to keep an eye on and manage the sealing task. This helps in making operations efficient and ensuring the quality of products.

What is an Automated Sealing Sensor?

An automated sealing sensor is a modern tool that checks if seals are present, good, and intact. These seal integrity sensors make smart sealing systems better, reducing waste and making sure products meet the needed quality. With the help of real-time data, these sensors let manufacturers be more accurate in what they do.

How Automated Sealing Sensors Work

Automated sealing sensors work by watching different factors when sealing. They use smart technology to see how seals form, find problems, and give quick feedback. This careful watch helps fix any quality issues fast, making sure packaging is never weak. Also, using these systems makes companies more productive and keeps quality high.

Businesses can get better at controlling their sealing tasks by looking into advanced sensor options. XJCSENSOR offers solutions that can greatly improve control and efficiency.

Benefits of Intelligent Sealing Technology

Intelligent sealing technology is key in today’s manufacturing. It boosts performance and meets strict standards. Many companies find increased production efficiency and better product quality with it.

Increased Efficiency in Production

This technology makes operations smoother. Processing times are faster, cutting down on delays. Automated systems adjust to changes in production. This ensures things run smoothly and increased production efficiency is achieved.

Enhanced Seal Integrity and Quality Control

Seal integrity is crucial for production. Intelligent solutions monitor and check the sealing, helping with quality control in sealing applications. They spot issues in real time. This stops product failures and leads to enhanced seal integrity. It makes products reliable and safe.

| Benefit | Description |

|---|---|

| Efficiency | Reduces production time and accelerates operational processes. |

| Cost Savings | Minimizes resource waste, leading to lower production costs. |

| Quality Assurance | Real-time monitoring enhances the integrity of seals, preventing defects. |

| Adaptability | Ability to adjust to changing production demands, ensuring smooth operations. |

For reliable solutions, look into XJCSENSOR’s technology. It shows how crucial precision is in industry.

Applications of Advanced Sealing Solutions

Advanced sealing solutions are useful in many areas, like packaging, pharmaceuticals, and food. Every sector has special requirements that these technologies meet well. They keep products safe and meet strict industry rules.

Packaging Industry Use Cases

In packaging, these solutions make production much better. They help avoid leaks and keep items sealed from factory to store. Here are some uses:

- Sealing of plastic and glass containers.

- Integration with automated packaging lines for improved throughput.

- Quality control measures that prevent tampering and maintain freshness.

Pharmaceutical and Food Industry Implementations

In the pharmaceutical and food sectors, advanced sealing is crucial. It must follow tough rules, making it necessary for safety. Here’s how it helps:

- Protecting sensitive medications from contamination.

- Ensuring food safety by preventing spoilage and bacterial growth.

- Facilitating traceability and batch monitoring through adaptive sealing technologies.

Features of Smart Sealing Systems

Smart sealing systems are changing how industries operate. They bring together key features for better efficiency. These include improving productivity and ensuring the seals meet high-quality standards. Let’s look at three important features of smart sealing technology.

Real-Time Monitoring Capabilities

Real-time monitoring stands out as a top feature of smart sealing systems. Engineers can watch the sealing process as it happens. This lets them spot and fix issues fast, keeping things running smoothly. Highlights are:

- Instant alerts for seal failure or anomalies

- Continuous feedback on seal integrity

- User-friendly dashboards displaying live data

Integration with Existing Production Lines

Being able to integrate with production lines is key for businesses. Smart sealing systems fit right into current setups without big changes. The upsides are:

- Minimized downtime during implementation

- Smooth operation alongside pre-existing machinery

- Improved overall efficiency due to synchronized operations

Data Analytics and Reporting Functions

Data analytics in sealing technology greatly aids in making decisions. Smart systems analyze data to give insights for action. This ensures:

- Detailed reports on sealing performance

- Identification of trends and potential areas for improvement

- Support for strategic planning and resource allocation

| Feature | Description | Benefits |

|---|---|---|

| Real-Time Monitoring | Continuous tracking of sealing processes | Quick anomaly detection and adjustments |

| Integration with Production Lines | Seamless incorporation into existing setups | Minimized downtime and improved efficiency |

| Data Analytics | Analysis of data for actionable insights | Performance reports and trend identification |

Automated Sensor for Sealing Applications

Choosing the right sensors is crucial in automated sealing processes. Making the correct selection ensures systems work perfectly, leading to superior sealing. By understanding your operational needs, you can pick sensors that boost both performance and reliability.

Choosing the Right Sensor for Your Needs

Selecting the ideal automated sensor involves several important factors. Consider the sensor’s range, sensitivity, and how well it fits with your setup. These attributes significantly affect how well your sensor will work.

- Operational Environment: Think about the conditions where the sensors will work. Temperature changes and exposure to chemicals can impact their efficiency.

- Type of Sealing Application: Different sealing methods might need specific sensors. Knowing if you need them for vacuum sealing, pressure sealing, or other types helps narrow down your options.

- Integration Capabilities: Ensure the sensors can be easily integrated with your current machines. This makes them work better and cuts down setup time.

- Customization Needs: Look into customizing sensors to better meet your needs. Custom solutions can improve your sealing process’s efficiency.

Let’s compare several types of sensors and their uses:

| Sensor Type | Features | Best Use Cases |

|---|---|---|

| Capacitive Sensors | Sensitive to material changes, non-contact detection | Perfect for sensitive materials and environments |

| Laser Sensors | High precision, long-range detection | Ideal for high-speed production lines |

| Ultrasonic Sensors | Utilize sound waves, versatile detection | Effective for various types of sealing processes |

Digital Sealing Monitoring: A Game Changer

Digital sealing monitoring is changing the game in sealing processes. It makes sealing more accurate and efficient. By using advanced monitoring technology, businesses see big improvements in different areas.

How Digital Monitoring Improves Efficiency

With digital sealing monitoring, companies see what’s happening in their sealing processes in real-time. The main advantages are:

- Immediate feedback: Quick data on sealing lets companies adjust right away, cutting down waste.

- Predictive maintenance: Spotting seal issues early means fewer delays, keeping things running smoothly.

- Enhanced accuracy: High-tech sensors keep seal quality consistent, boosting production efficiency.

These benefits lead to less spending and more work getting done. Digital sealing monitoring is becoming essential for modern manufacturing.

Case Studies of Digital Sealing Monitoring Success

Companies using digital sealing monitoring are seeing big benefits. One top packaging company saw sealing defects drop by 30%. These successes show how different industries can become more efficient.

Looking at case studies, we see how catching problems early helps. These cases prove that careful monitoring makes production smoother. They also show why it’s smart to use new tech solutions.

To learn more about sensors that bring better control and accuracy, check out innovative sensor technologies. This could lead to better results in many fields.

Automated Seal Verification Techniques

Effective seal checks are key in keeping product quality high and customers happy. There are many ways to verify seals, each suited for different tasks. Picking the right method for your business is very important.

Comparative Analysis of Verification Methods

| Verification Technique | Description | Advantages | Limitations |

|---|---|---|---|

| Visual Inspection | Manual or automated visual checks for seal integrity. | Cost-effective and straightforward. | Subject to human error; inconsistent results. |

| Pressure Testing | Measuring internal pressure to confirm seal effectiveness. | Provides quantitative data for assessment. | Requires specific equipment; time-consuming. |

| Leak Testing | Detecting leaks using air or liquid pressure methods. | Highly accurate; sensitive to minor leaks. | Can be expensive; requires skilled operators. |

| Automated Seal Verification Systems | Real-time monitoring using sensors for seal detection. | Increases efficiency; minimizes human error. | Initial investment cost; reliance on technology. |

Best Practices for Implementing Seal Verification

To deploy seal verification well, using the best methods is crucial. Here are some tips:

- Conduct a thorough assessment of existing processes to determine needs for automated seal verification.

- Select the most appropriate verification technique based on product specifications and production volume.

- Integrate automated systems with existing production lines to streamline operations.

- Train staff on the importance of verification techniques and how to utilize equipment effectively.

- Regularly review and update verification protocols to ensure compliance with industry standards.

Cutting-Edge Sealing Technology Trends

Keeping up with the latest in sealing technology is key for manufacturers. This knowledge helps improve production. Adopting new sealing technologies makes processes more efficient and reliable. It also helps them meet industrial changes.

Innovations in Sealing Technology

New sensor technologies have changed how seals work. These sensors offer real-time data, improving monitoring and sealing quality. By using these new technologies, manufacturers see big gains in efficiency. Important advances include:

- Smart diagnostics enabling proactive maintenance.

- Data-driven insights for continuous improvement.

- Versatile sensor models for diverse industrial applications.

The Future of Automated Sealing Solutions

The future looks promising for automated sealing. Industry standards are evolving, with a focus on precision and reliability. Bringing in advanced technologies will make manufacturing smoother. Key future trends are:

- Increased automation through AI and machine learning.

- More robust systems capable of self-calibration.

- Enhanced connectivity among various production equipment.

By focusing on these advanced solutions, automated sealing becomes more efficient and dependable. This meets the changing needs of industries.

Conclusion

Automated sealing sensors make industrial sealing much better. They make the process faster and more reliable. These smart tools are changing the way we seal packages and check quality.

With these advanced sensors, we meet our clients’ changing needs. This improves efficiency and results. Smart technology is becoming key in boosting performance.

We’re proud to offer top-notch sensor solutions like those from XJCSENSOR. They show our commitment to leading in the industry. For more on our custom solutions, check out XJCSENSOR.