The field of healthcare is always changing, and custom surgical robotics sensor development plays a big role. We focus on advancing this technology. This ensures that surgeries done with robots are precise and accurate.

This article talks about the important parts of surgical robot sensors, including how they are made. We’ll see how these sensors help make surgeries safer for patients. With new sensor technology, we’re showing why precise sensors are crucial for robot surgeries and how they make medical procedures better.

Let’s dive deep into this topic, looking at what’s new and what challenges we face in making sensors for robotic surgery.

Key Takeaways

- Understanding the role of custom sensors in surgical robotics.

- The importance of precision in enhancing surgical outcomes.

- Current trends and future directions in sensor technology.

- Insights into regulatory compliance during the manufacturing process.

- Strategies for collaborating with medical professionals to tailor sensors effectively.

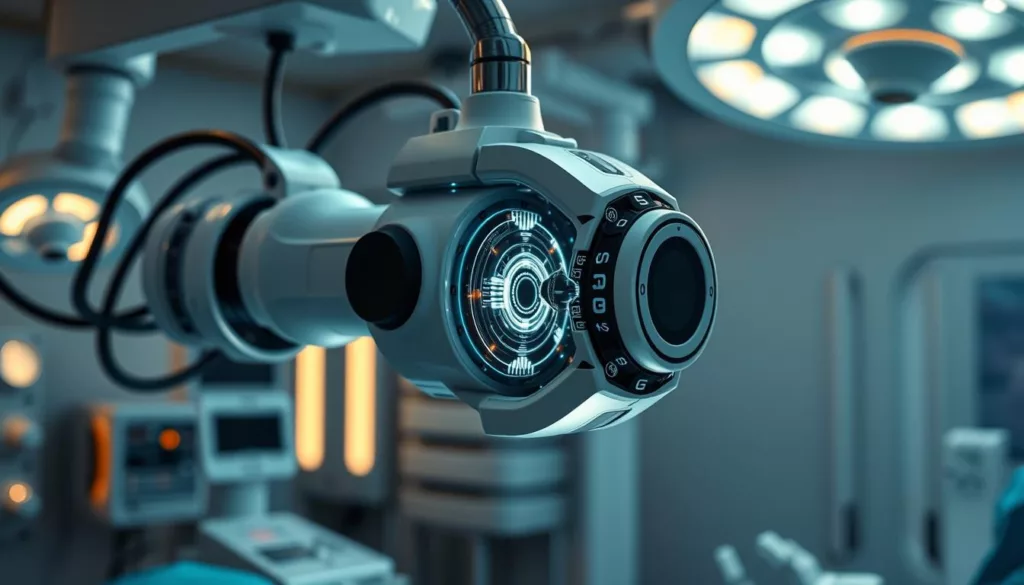

Introduction to Surgical Robotics Sensors

Surgical robotics sensors are key to making robotic surgeries safer and more efficient. They include force sensors, imaging systems, and motion sensors. These improve the robots’ precision and functionality. They’re crucial because they give real-time feedback, leading to less invasive surgeries and shorter recovery times for patients.

Definition and Importance

The term surgical robotics sensors covers a range of technologies aimed at better surgical results. These sensors monitor various factors. This ensures surgeons have the right information during surgery. Sensor tech in robotic surgery has changed the way surgeries are done, making things safer and improving outcomes.

Current Trends in Surgical Robotics

Nowadays, there’s a shift towards smart sensors that work with data analytics and connectivity. This moves robotic surgery forward. Better syncing of robotic systems improves their function. As the need for precision grows, companies are creating new, exact solutions. XJCSENSOR is leading in custom sensor design and manufacturing.

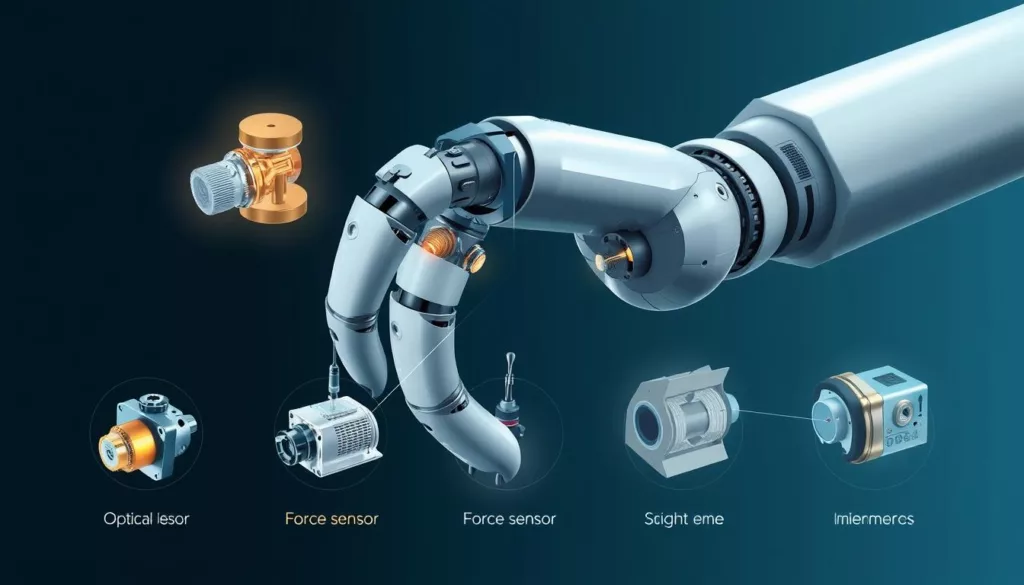

Key Components of Surgical Robotics Sensors

In the world of surgical robotics, knowing the kinds of sensors is crucial. They help make surgeries more precise and effective. Each sensor type offers unique, accurate information needed for complex surgeries.

Types of Sensors Used

Surgical robotics use various sensors for better accuracy and safety. These include:

- Pressure sensors

- Accelerometers

- Image sensors

These sensors collect real-time data, aiding surgeons in making informed decisions. For further details on sensor technology, check out XJCSENSOR.

Integration with Surgical Systems

Integrating sensors into surgical robots allows for smooth system communication. It improves workflows and gives surgeons vital information during the operation. This makes robotic-assisted surgeries more efficient.

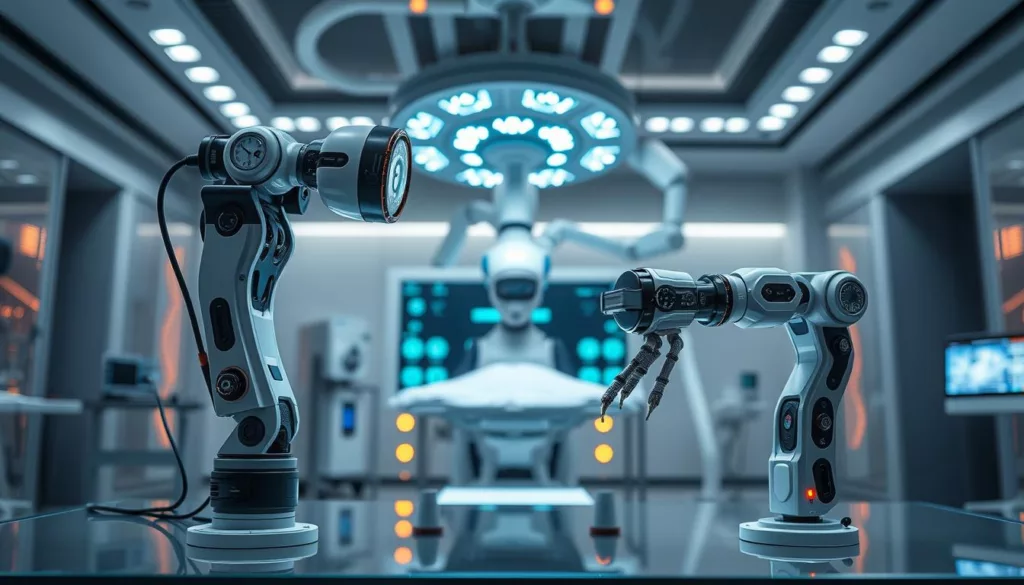

Importance of Precision and Accuracy

In microsurgery, precision sensors are critical. Even a small error can cause big problems, highlighting the need for accuracy. Surgical robots must be precise and accurate for the surgery to succeed. Creating advanced sensors that enhance safety and effectiveness is a key focus.

The Development Process of Custom Sensors

Developing custom sensors for surgical robotics is complex but vital. Each sensor must be precise for specific surgeries. This ensures they meet the high standards of medical professionals and stick to industry rules.

Stages of Development

The journey of creating custom sensors goes through many steps:

- Research and Conceptualization: We focus on the unique needs of robotic surgery.

- Design: Our team works on detailed designs that ensure the sensors work well.

- Prototyping: We build early models to test our ideas.

- Testing and Refinement: These models are thoroughly tested to improve their quality.

- Production: The final sensors are made. They follow the rules for medical sensors.

Role of Prototyping

Prototyping is crucial for sensor design in robotic surgery. It lets developers test if their designs will work on a large scale. Each prototype undergoes strict tests. This makes sure they perform well in surgery.

Compliance with Regulatory Standards

Following the rules for medical sensors is a must for us. We stick closely to FDA guidelines. This ensures our sensors are safe for patients and work well in hospitals. This dedication to quality and rules wins the trust of medical experts. It helps our products succeed.

Manufacturing Capabilities for Surgical Sensors

We have strong manufacturing abilities for surgical sensors. Our methods use advanced robotic techniques to keep quality top-notch. We rely on the latest technologies. These make our production efficient and our sensors accurate.

Technologies Used in Manufacturing

Many technologies support our manufacturing steps, including:

- Additive manufacturing: Enables intricate designs and rapid prototyping.

- Precision CNC machining: Delivers exceptional accuracy for each component.

- Advanced robotics: Enhances production speed and consistency.

Quality Control Measures

Quality control is crucial in making sensors. We follow strict quality checks throughout our manufacturing. This includes:

- Regular inspections and testing of raw materials.

- In-process quality checks to ensure compliance with design specifications.

- Final validation tests to confirm performance and reliability.

Scalability and Customization Options

Our setup is ready for big orders and custom requests. We can manage large amounts and make sensors as needed. We work closely with health professionals to create custom solutions. We quickly adapt to new market needs for special sensors.

- Flexible production runs tailored to particular surgical applications.

- Cohesive partnerships with healthcare providers for bespoke solutions.

- Rapid response to emerging market demands for specialized sensors.

Customization Options for Surgical Sensors

Customization is key in making surgical sensors. Each surgery has its own needs. Our goal is to tailor sensors to surgical needs. This ensures they meet the challenges faced in different operations. By working closely with doctors, we improve our sensors. This makes them more effective for medical use.

Tailoring to Surgical Procedures

Our custom surgical robotics sensors need to adapt. Different surgeries require specific features, like more precision or special feedback. This is done through careful design. The design process focuses on surgical needs. This leads to better results for both patients and healthcare providers.

Collaborating with Medical Professionals

We believe in collaborating in sensor design with doctors. This ensures our sensors are both innovative and practical. By holding workshops and talking regularly, we get valuable feedback. This guides our design, making solutions that meet surgery needs.

Case Studies of Custom Solutions

Our custom sensors have proven successful in case studies. One example is working with leading surgical teams. We created sensors that improved robotic surgery systems. This allowed for more precise control. It highlights our ability to solve specific challenges.

For details on our sensor technology, visit XJCSENSOR’s medical applications.

| Case Study | Objective | Outcome |

|---|---|---|

| Robotic Surgery Partnership | Enhance precision | Improved surgical accuracy by 30% |

| Injection Pumps | Optimize medication delivery | Reduced patient recovery times |

| Ventilator Integration | Enhance monitoring | Increased patient safety during procedures |

Testing and Validation of Surgical Sensors

Testing surgical sensors well is key for their reliability and performance. We work hard to make sure these sensors are top-notch and meet the needed standards. By checking their effectiveness and safety, we make sure they work well in real surgeries.

Importance of Rigorous Testing

Thorough testing finds any issues in surgical sensors before they’re used on patients. This careful checking reduces risks in surgeries, protecting patients. It also builds trust with doctors who use our sensors.

Methods of Validation

We use different ways to make sure our sensors are up to par:

- Simulation Testing: Analyzing performance under various scenarios.

- Mechanical Endurance Testing: Evaluating durability through repeated use.

- Usability Assessments: Gathering feedback from surgical teams to refine user experience.

Each approach helps us fully understand how our sensors will work in surgeries.

Real-World Application Scenarios

Using our sensors in real surgeries gives us important feedback. This helps us make our sensors better and more innovative. Working with surgeons helps us find and fix specific challenges, improving future surgery tech.

| Validation Method | Purpose | Outcome |

|---|---|---|

| Simulation Testing | Performance analysis under varied conditions | Identification of potential design flaws |

| Mechanical Endurance Testing | Evaluation of sensor durability | Assurance of long-term reliability |

| Usability Assessments | Feedback from surgical teams | Improvement of user interface and functionality |

We’re dedicated to maintaining our focus on quality and reliability in surgeries through these processes.

Future Trends in Surgical Robotics Sensors

The world of surgical robotics is changing fast, with major innovations. These changes are shaping what’s next for robotic surgery. Sensor technology and computational methods are getting better, making new things possible in the clinic.

Advancements in Sensor Technology

New sensor technologies are making devices more accurate and reliable. Key progress includes:

- Improved miniaturization methods that allow sensors to be integrated seamlessly into surgical instruments.

- Enhanced biocompatibility of sensors, which reduces the risk of complications during procedures.

- Innovative wireless technologies that enable real-time data transmission without cumbersome connections.

The Role of Artificial Intelligence

AI is becoming crucial for surgical sensors, helping with data analysis and decisions in real time. Machine learning can handle lots of sensor data, which results in:

- More accurate predictive analytics that improve surgical outcomes.

- Automation of routine tasks, allowing surgeons to concentrate on critical decisions.

- Enhanced pattern recognition capabilities that assist in identifying anomalies during procedures.

Predictions for the Industry

The future of surgical robotics will see more AI and advanced sensors. This will make surgeries more efficient. What we can expect includes:

- Greater use of tele-surgery, enabled by improved sensor feedback and AI analysis.

- Development of smart surgical tools that adapt to different surgical environments in real time.

- Increased focus on patient data integration, leading to highly customized surgical approaches.

Challenges in Development and Manufacturing

Making surgical sensors involves complex steps. It requires careful attention and knowledge. We’ll look into the technical issues, rules for medical devices, and market needs for these sensors.

Technical Challenges

Integrating various technologies is a big challenge in making surgical sensors. It’s key to make sure different systems work well together. This often means a lot of testing to get everything functioning as one.

Regulatory and Compliance Obstacles

Following strict rules for medical devices is tough. It means dealing with detailed regulations that can slow things down. Manufacturers must do a lot of testing and keep up with changing standards.

Addressing Market Demands

To meet what people want from surgical sensors, it’s crucial to keep checking on what users need and new tech developments. Talking with healthcare experts helps make sure products meet today’s standards. Staying ahead of new trends is key to bringing out successful sensor innovations.

| Challenge Category | Description | Impact on Development |

|---|---|---|

| Technical | Integration of diverse technologies and interoperability | Increased development time and complexity |

| Regulatory | Compliance with stringent medical device regulations | Longer approval processes and potential for delays |

| Market | Constantly evolving user needs and preferences | Need for ongoing research and innovation |

Conclusion and Call to Action

We’ve shown how important custom surgical robotics sensors are in making surgeries better. We’ve talked about how developing and making high-quality sensors is key. These steps are important for surgeries to be efficient and for helping patients more.

We really believe in working together on making new medical sensors. This means teams of engineers, doctors, and researchers should share ideas. Sharing helps make better surgical sensors. By sharing, we can make surgery tech that truly helps doctors and patients.

If you need custom sensor solutions, please get in touch for a consultation. Our team is ready to offer advice and create new solutions. We aim to improve surgical robotics to help patients recover better.