The oil pressure sensor is a small yet mighty component crucial to engine performance and longevity. Acting as the engine’s silent communicator, this device monitors oil pressure and warns drivers of potential issues. Maintaining an optimal oil pressure level is pivotal, as it ensures engine lubrication, reduces wear and tear, and ultimately extends the life of the vehicle.

Understanding the Oil Pressure Sensor

What is an Oil Pressure Sensor?

An oil pressure sensor is a device integrated into a vehicle’s engine system that monitors and measures the pressure of engine oil. The readings are relayed to the dashboard or control system, where they can inform the driver if the oil pressure drops below safe levels. Without this critical feedback, drivers could unknowingly operate a vehicle under low oil pressure conditions, leading to costly repairs or engine failure.

Why is an Oil Pressure Sensor Important?

Oil is the lifeblood of your engine, and the oil pressure sensor serves as its guardian. When oil pressure drops, it can result in inadequate lubrication, causing excessive friction among engine components. This sensor provides early warnings, helping drivers address minor issues before they escalate into major mechanical problems.

Functions of an Oil Pressure Sensor

Monitoring Oil Pressure in Real-Time

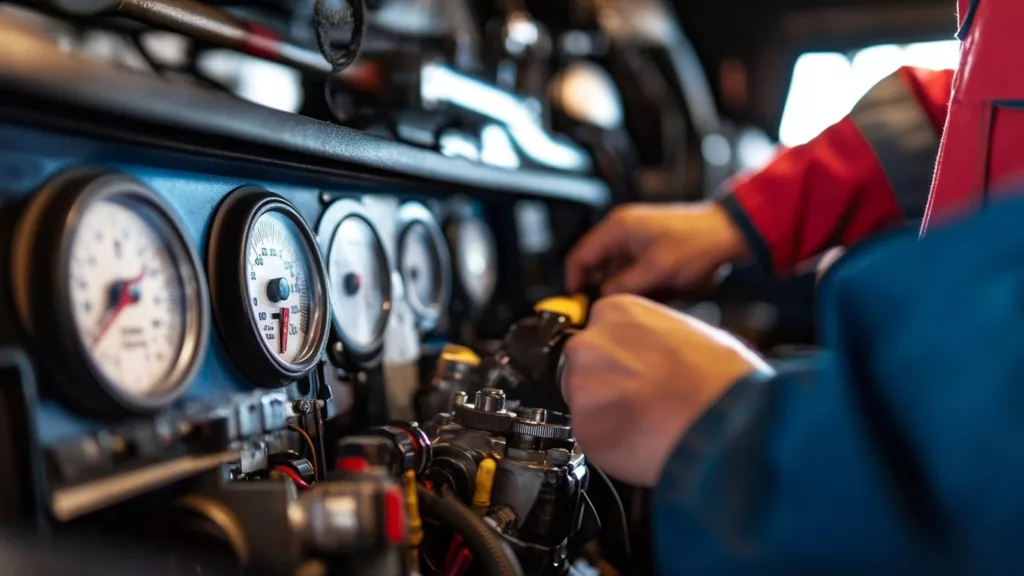

The primary role of an oil pressure sensor is to provide real-time data on the engine’s oil pressure. Modern vehicles often display this information as a gauge on the dashboard, allowing drivers to monitor fluctuations during operation.

Preventing Engine Damage Through Alerts

Should the oil pressure fall below optimal levels, the oil pressure sensor triggers a warning light or buzzer. This early detection can save drivers from catastrophic engine failure, ensuring prompt action is taken.

Types of Oil Pressure Sensors

Switch-Type Oil Pressure Sensors

Switch-type sensors function on a binary system, where they activate a warning light once the pressure falls below a set threshold. These sensors are cost-effective and widely used in older vehicles.

Analog Oil Pressure Sensors

Analog sensors offer continuous readings, presenting the pressure level on a gauge. These are ideal for enthusiasts and professionals seeking detailed data on oil pressure performance.

Digital Oil Pressure Sensors

Modern vehicles often employ digital oil pressure sensors. These devices interface directly with a car’s onboard diagnostic system, offering enhanced precision and compatibility with advanced vehicle systems.

Installation and Compatibility

Common Vehicles Using Oil Pressure Sensors

Oil pressure sensors are standard in passenger vehicles, commercial trucks, and high-performance cars. Their use isn’t limited to automobiles; they are also employed in industrial machinery and marine engines.

Installation Best Practices

Installing an oil pressure sensor requires precision. Ensuring a secure connection to the engine block and using manufacturer-recommended torque values can prevent leaks and inaccurate readings. Professionals recommend replacing the sensor during routine oil changes for best results.

How the Oil Pressure Sensor Works

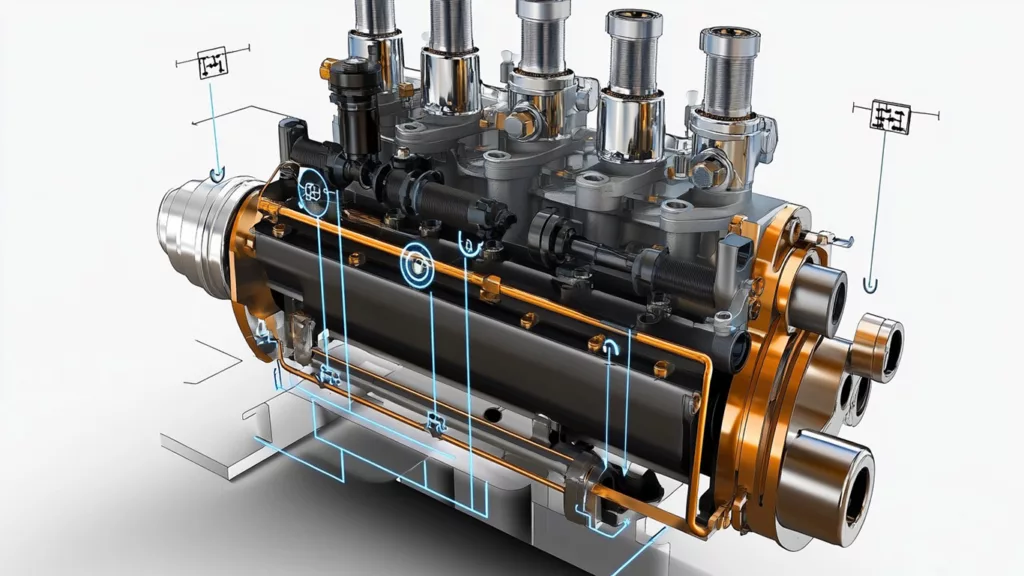

Core Components of an Oil Pressure Sensor

The sensor comprises a diaphragm that reacts to oil pressure changes, converting mechanical pressure into electrical signals. These signals are interpreted by the vehicle’s ECU (Electronic Control Unit), which alerts the driver if anomalies are detected.

The Role of Oil Pressure Signals in Diagnostics

Mechanics rely on the data provided by oil pressure sensors for diagnostics. A consistent drop in pressure might indicate leaks, pump malfunctions, or even internal engine wear.

Common Issues and Troubleshooting

Symptoms of a Faulty Oil Pressure Sensor

A faulty oil pressure sensor may cause inaccurate readings, dashboard warning lights, or even engine stalling. Regular inspection can help identify these problems early.

Diagnosing Oil Pressure Sensor Problems

Technicians use diagnostic tools to assess the sensor’s performance. These tools measure resistance, ensuring the sensor is functioning correctly within its specified range.

Steps to Fix or Replace an Oil Pressure Sensor

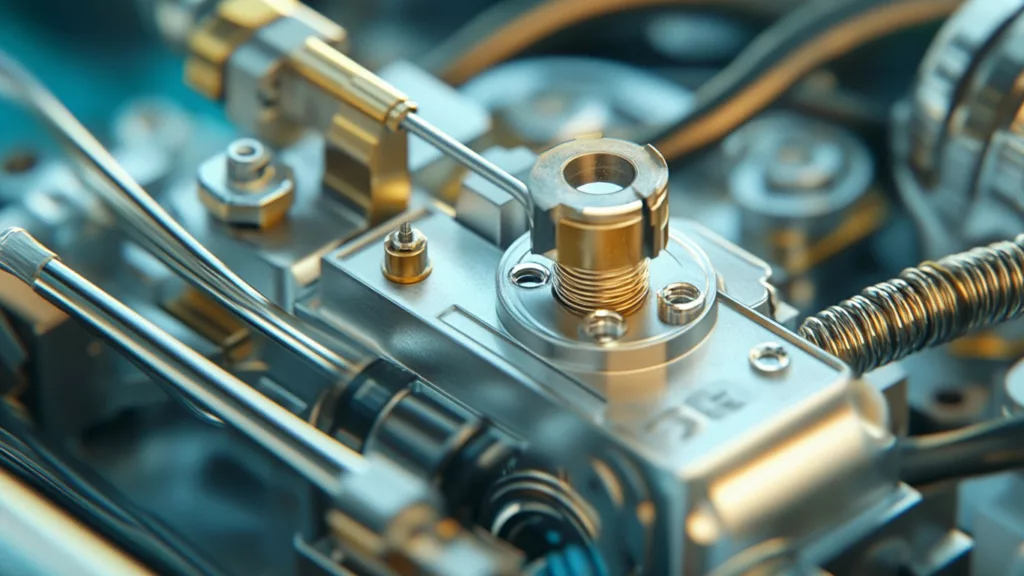

Replacing an oil pressure sensor involves disconnecting the battery, unscrewing the old sensor, and installing a new one with appropriate thread sealant. Always consult the vehicle’s manual or a certified mechanic for proper procedures.

FAQs

How long does an oil pressure sensor last?

What happens if you ignore a faulty oil pressure sensor?

Can I drive with a broken oil pressure sensor?

Is it expensive to replace an oil pressure sensor?

How do I know if my oil pressure sensor needs calibration?

What oil pressure level is considered safe?

Conclusion

The oil pressure sensor is a vital component that safeguards your engine’s health. From providing real-time alerts to preventing costly damages, this small device plays a big role in ensuring optimal vehicle performance. Whether you’re a car enthusiast or an everyday driver, understanding how this sensor works, its maintenance, and its troubleshooting is crucial for peace of mind on the road. Always prioritize timely inspections and quality replacements to keep your engine running smoothly for years to come.