Introduction to Force Sensors

Force sensors are critical components in various industrial and mechanical applications, helping to measure force, torque, and load in different systems. Among the many types of force sensors, torque cells stand out as specialized devices designed to measure rotational force, making them essential in fields like automotive engineering, robotics, and manufacturing.

Understanding Torque Cells

What is a Torque Cell?

A torque cell is a sensor used to measure the twisting force (torque) applied to a rotating or stationary system. These sensors provide crucial data in mechanical testing, ensuring optimal performance and efficiency in motors, gears, and industrial machinery.

How Torque Measurement Works

Torque measurement is based on the principle of detecting strain in a rotating shaft or mechanical component. A torque sensor typically uses strain gauges or piezoelectric elements to detect deformation and convert it into an electrical signal that represents torque values.

Types of Torque Sensors

Different types of torque sensors cater to various applications, each designed to measure torque in specific environments.

Rotary Torque Sensor

- Measures torque in rotating systems

- Commonly used in engines, motors, and powertrains

- Provides real-time data for performance optimization

Inline Torque Sensor

- Installed within a drive shaft or coupling

- Offers high accuracy in torque measurement

- Ideal for quality control in manufacturing

Shaft Torque Sensor

- Mounted directly on a rotating shaft

- Measures dynamic torque without disrupting the system

- Used in mechanical testing and machine diagnostics

Dynamic Torque Sensor

- Designed for measuring torque in moving components

- Essential for monitoring load changes in high-speed machinery

- Used in aerospace, robotics, and industrial automation

Torque Transducers and Their Applications

What is a Torque Transducer?

A torque transducer is a device that converts torque into an electrical signal, similar to a torque sensor but with added capabilities like wireless data transmission and enhanced precision.

Common Industrial Applications

- Automotive industry:Engine and drivetrain testing

- Aerospace engineering:Aircraft component stress analysis

- Manufacturing:Quality control in assembly lines

- Robotics:Ensuring smooth and precise movement in robotic arms

How Torque Cells Work

Working Principles of Torque Measurement

A torque cell functions by detecting strain in a mechanical structure subjected to torque. The deformation changes the resistance in the sensor’s strain gauge, which is then converted into an electrical signal for measurement.

Factors Affecting Accuracy

- Temperature fluctuations

- Misalignment of the sensor

- Electrical interference from surrounding equipment

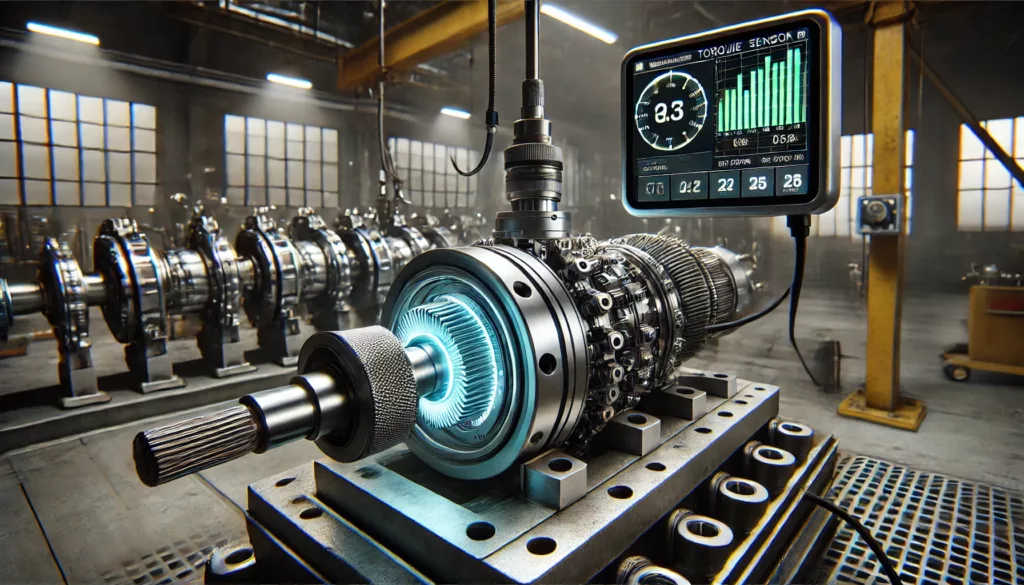

Rotary Torque Sensors: How They Work and Where They Are Used

Working Mechanism

A rotary torque sensor is attached to a rotating shaft and continuously measures torque while the component is in motion. This type of sensor is essential for monitoring real-time performance in motors and power transmission systems.

Applications in Automotive and Aerospace Industries

- Evaluating engine performance

- Testing gearboxes and drive systems

- Measuring efficiency in aircraft turbines

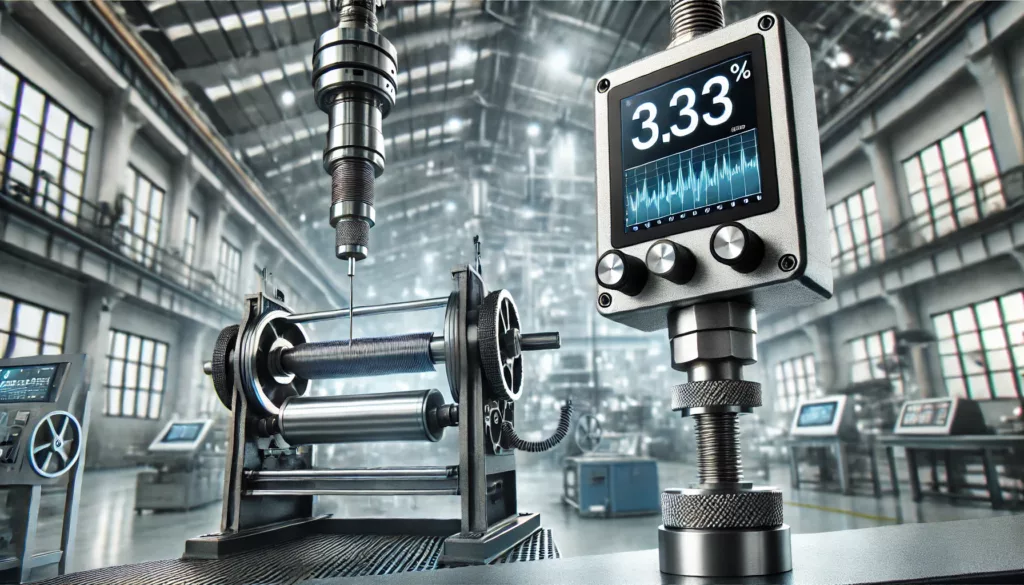

Inline Torque Sensors for Precision Measurement

How Inline Torque Transducers Operate

Inline torque transducers are integrated into a mechanical system and measure torque directly from the shaft or coupling, providing highly accurate data.

Key Benefits and Uses

- Precise torque measurement for quality control

- Used in robotics for motion control

- Helps optimize mechanical efficiency in industrial processes

Motor Torque Sensors: Ensuring Optimal Performance

Importance in Electric Motors

A motor torque sensor is crucial for monitoring torque output in electric and combustion motors. It helps prevent overloading and enhances efficiency.

How Motor Torque Sensors Improve Efficiency

- Detecting energy losses in the system

- Optimizing performance through real-time feedback

- Preventing mechanical failures by monitoring stress levels

Dynamic Torque Sensors: Measuring Torque in Motion

Features of Dynamic Torque Transducers

- Measures fluctuating torque in high-speed applications

- Provides real-time data on mechanical stress

- Used in complex systems like aircraft engines and industrial machines

Common Applications

- Monitoring wind turbine performance

- Measuring torque fluctuations in heavy machinery

- Testing high-speed motor components

Torque Load Cells vs. Other Force Sensors

Differences Between Torque Load Cells and Standard Force Sensors

- Torque load cells measure rotational force, while standard force sensors measure linear force

- Torque sensors are used in mechanical systems with rotating parts, while force sensors are used in static applications

How to Choose the Right Torque Sensor

Factors to Consider When Selecting a Torque Transducer

- Measurement range and accuracy

- Environmental conditions and temperature stability

- Data transmission requirements (wired vs. wireless)

Installation and Calibration of Torque Sensors

Best Practices for Accurate Readings

- Proper alignment of the sensor with the rotating shaft

- Regular calibration to maintain precision

- Avoiding electrical interference from other devices

Common Applications of Torque Cells

Torque cells are widely used in industries such as:

- Automotive:Engine performance testing

- Aerospace:Aircraft stress analysis

- Manufacturing:Quality control in machinery production

- Robotics:Ensuring smooth motion in robotic arms

Advantages and Limitations of Torque Sensors

Benefits of Torque Sensors

- High accuracy and real-time measurement

- Helps prevent mechanical failures

- Enhances efficiency in industrial processes

Potential Drawbacks

- Sensitive to temperature changes

- Requires precise installation for accurate readings

- Higher cost compared to standard force sensors

Innovations in Torque Measurement Technology

Wireless Torque Sensors

- Eliminates the need for complex wiring

- Enables remote monitoring of torque values

Smart Torque Measurement Solutions

- AI-powered analysis for predictive maintenance

- Integration with IoT for real-time performance tracking

Conclusion

Torque cells and transducers are essential tools for measuring rotational force in various industrial applications. From automotive and aerospace to robotics and manufacturing, these sensors provide critical data to improve efficiency, ensure safety, and optimize mechanical performance. With advancements in wireless and smart sensor technology, torque measurement is becoming even more accurate and accessible for future applications.