Introduction

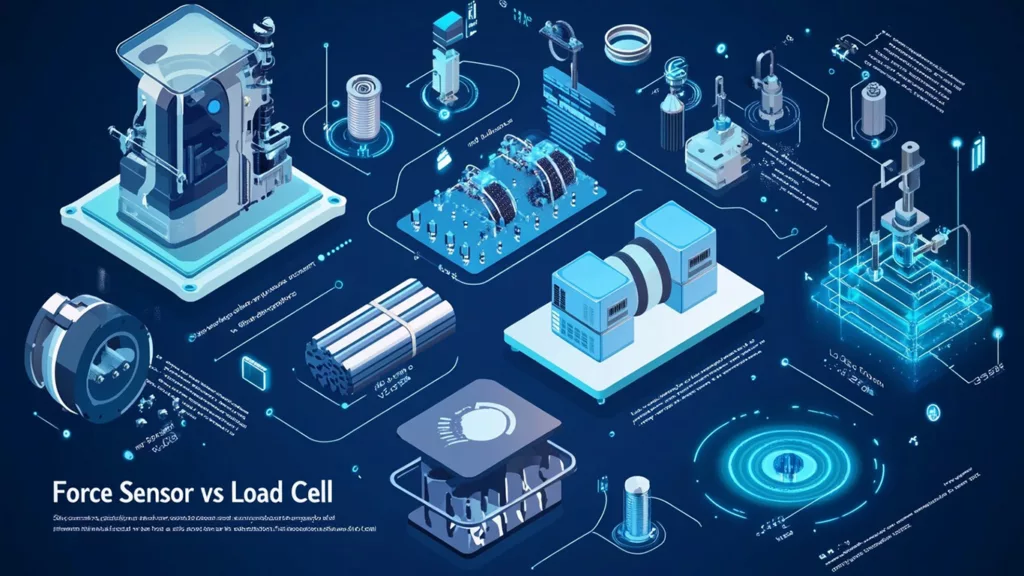

Understanding the nuances between a force sensor vs load cell can make or break the success of your application. Whether you’re involved in industrial automation, robotics, or medical device development, choosing the right force measurement tool is critical. Let’s clear the fog and help you make an informed decision.

Force Sensor vs Load Cell

Although often used interchangeably, force sensors and load cells are not the same. Both devices measure force, but they differ in sensitivity, design, application, and construction.

What is a Force Sensor?

A force sensor is a device that detects and measures physical force by converting it into an electrical signal. Force sensors are often more compact and flexible in design, suited for low-capacity, high-precision tasks like touchscreens or robotic hands.

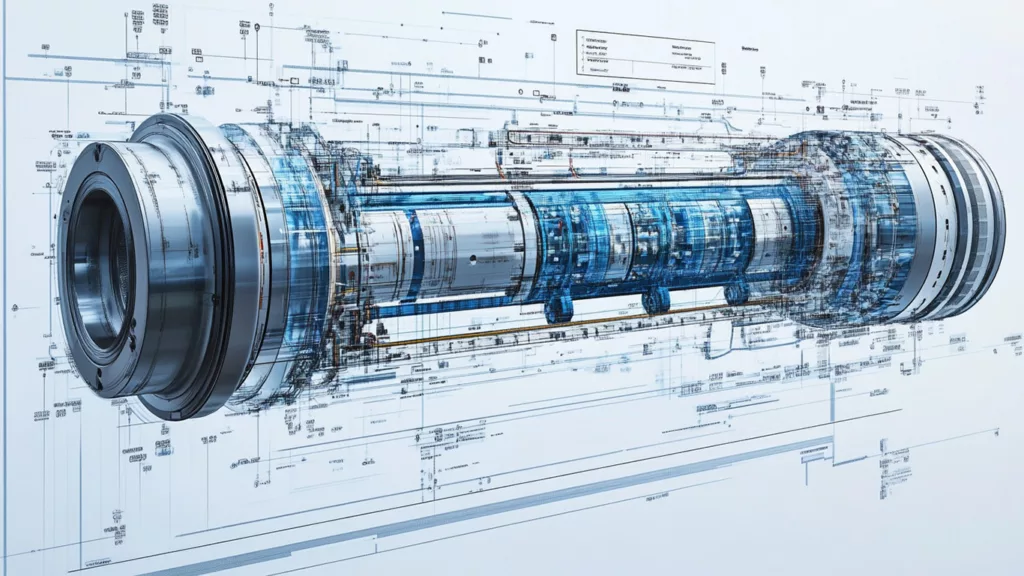

What is a Load Cell?

A load cell is a specific type of force sensor designed to measure weight or load. Commonly used in weighing scales and industrial machines, load cells are built for high-capacity, highly accurate measurements over a broader range.

How Force Sensors Work

Force sensors typically use materials that deform under pressure. This deformation changes an electrical property—such as resistance or capacitance—allowing the sensor to quantify the applied force.

How Load Cells Operate

Load cells, particularly strain gauge load cells, operate by measuring strain in an elastic element. When force is applied, the strain gauges change resistance proportionally, and the device calculates the corresponding load.

Force Sensor Types

- Capacitive Force Sensors

- Resistive Force Sensors

- Piezoelectric Force Sensors

- Optical Force Sensors

Each offers unique advantages, such as high sensitivity or immunity to electromagnetic interference.

Load Cell Types

- Hydraulic Load Cells

- Pneumatic Load Cells

- Strain Gauge Load Cells

- Capacitive Load Cells

Each is suited for different environments and measurement ranges.

Material Differences

Force sensors often use flexible polymers or silicon, while load cells are generally built from stainless steel or aluminum, enhancing their durability in rugged conditions.

Precision and Accuracy

Load cells usually offer superior precision for larger forces, whereas force sensors excel in applications demanding sensitivity to very slight changes.

Response Time Comparison

Force sensors usually have faster response times, making them ideal for dynamic applications where real-time feedback is critical.

Cost Differences

Force sensors are typically less expensive, but their cost can escalate with highly sensitive versions. Load cells, while pricier, justify the investment with their robust performance.

Force Range Capability

Load cells are designed to handle massive forces, sometimes reaching into tons. Force sensors are typically used for lower-force applications.

Environmental Factors

Load cells are rugged and often weather-sealed. Force sensors, although durable, might require additional casing for outdoor use.

Size and Portability

Force sensors are smaller, lighter, and easier to integrate into compact systems. Load cells tend to be bulkier but highly stable.

Ease of Installation

Force sensors offer plug-and-play simplicity. Load cells might require professional installation to ensure precision and calibration.

Calibration Needs

Both devices require periodic calibration, but load cells need it more often, especially in heavy-duty industrial applications.

Industries Using Force Sensors

- Robotics

- Consumer Electronics

- Medical Devices

Industries Using Load Cells

- Manufacturing

- Aerospace

- Automotive

Force Sensor Applications

From smartphones to prosthetic limbs, force sensors are critical in making devices smarter, more intuitive, and human-like.

Load Cell Applications

Load cells shine in weighbridges, tension measurement systems, and cargo scales, ensuring logistics and manufacturing processes remain accurate and efficient.

Pros and Cons of Force Sensors

Pros:

- High sensitivity

- Lightweight and small

- Quick response

Cons:

- Limited force range

- Sensitive to environmental factors

Pros and Cons of Load Cells

Pros:

- High capacity

- Durable

- Extremely accurate

Cons:

- Larger size

- Higher cost

Choosing Between Force Sensor vs Load Cell

Choosing between a force sensor vs load cell boils down to your specific application needs. Need high precision for tiny forces? A force sensor is your go-to. Need to weigh heavy loads in an industrial setting? A load cell will serve you better.

FAQs

What is more accurate, a force sensor or a load cell?

Can a load cell be used as a force sensor?

Which is cheaper: a force sensor or a load cell?

Are load cells better for industrial applications?

Can force sensors handle environmental stress?

Is calibration difficult for load cells?

Conclusion

Both force sensors and load cells are indispensable in modern technology. Understanding their differences ensures that you select the right device for your needs. Whether you need a compact, sensitive sensor or a heavy-duty, robust load cell, making an informed choice ensures better performance and longevity.

Clear Call-to-Action (CTA):

Ready to elevate your automation game?

XJCSENSOR is a premier sensor manufacturer specializing in custom and wholesale sensor solutions. Our products serve industries like industrial automation, robotics, automotive, 3C electronics, packaging automation, agricultural machinery, medical devices, and beyond.

Contact us today for more information, explore our wide range of products, or follow us on social media to stay updated with the latest sensor technologies!