Choosing the Right Force Sensor Manufacturer Matters

In today’s ultra-competitive, tech-driven world, the right force sensor can mean the difference between groundbreaking success and frustrating failure. But here’s the kicker — your project’s success isn’t just about the sensor itself. It’s about how to choose the right force sensor manufacturer for your project. A reliable partner will ensure top-notch quality, seamless integration, and unparalleled support. Conversely, a poor choice could sabotage even the best-laid plans. So, how do you ensure you’re picking the best? Grab a cup of coffee — we’re diving deep.

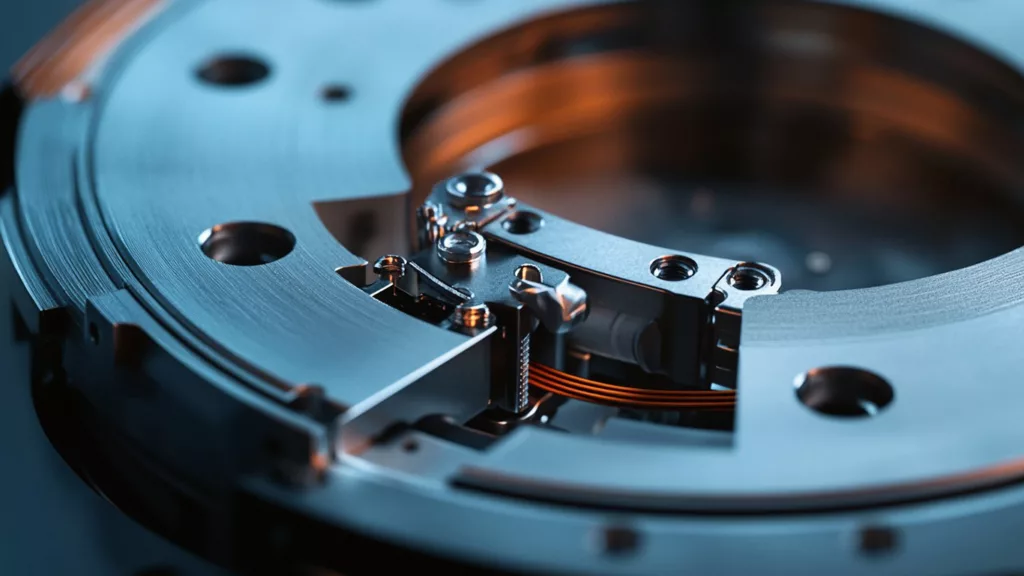

What is a Force Sensor?

Force sensors, also known as load sensors or force transducers, are devices designed to measure the magnitude of forces. These forces can be compression, tension, torque, or pressure. Whether it’s a robotic arm ensuring precision or a car seat detecting passenger presence, force sensors play silent yet crucial roles.

Why Selecting the Right Manufacturer is Critical

Imagine having a Rolls Royce engine but with low-grade fuel. Disastrous, right? That’s exactly what happens when top projects are paired with substandard manufacturing. Selecting the right force sensor manufacturer guarantees that the product specifications, endurance, and performance align with your project’s needs.

Common Applications of Force Sensors

Force sensors are woven into the fabric of modern innovation:

- Automotive safety systems

- Medical devices and prosthetics

- Industrial robotics

- Consumer electronics

- Aerospace mechanisms

- Agricultural automation

Key Qualities to Look for in a Force Sensor Manufacturer

When considering how to choose the right force sensor manufacturer for your project, keep your radar tuned for:

- Proven engineering expertise

- State-of-the-art manufacturing facilities

- Stringent quality control processes

- Transparent communication

Evaluating Manufacturer’s Technical Capabilities

Capabilities aren’t always evident from fancy websites. Ask hard questions:

- Can they produce miniature sensors?

- What’s their tolerance for high-stress environments?

- How do they test each unit?

A technically adept manufacturer won’t shy away from detailed discussions.

Importance of Customized Force Sensor Solutions

No two projects are identical. A great manufacturer offers customization:

- Size adjustments

- Different force ranges

- Specific mounting options

- Environmental sealing

Customization shows a willingness to walk the extra mile.

How Material Choices Impact Sensor Performance

Materials matter more than you’d think! Stainless steel offers durability; aluminum ensures lightweight precision. Knowing a manufacturer’s material options and why they choose certain ones is a glimpse into their depth of expertise.

Assessing Technological Advancements in Manufacturing

Manufacturers embracing smart production, AI diagnostics, and predictive maintenance capabilities are leaps ahead. When you wonder how to choose the right force sensor manufacturer for your project, think innovation.

Why Compliance Matters

Certifications like ISO 9001 or RoHS aren’t just fancy stickers. They represent:

- Quality commitment

- Regulatory adherence

- Environmental responsibility

A manufacturer flaunting these badges is serious about excellence.

Importance of a Broad Product Portfolio

A manufacturer with only one sensor type? Big red flag. Choose a provider with a diversified lineup:

- Load cells

- Torque sensors

- Strain gauge-based designs

- Customized solutions

Breadth often equals depth.

Understanding Lead Times and Delivery Reliability

You can’t afford production delays. Probe their track record:

- Average lead times

- Emergency production capabilities

- Inventory management systems

Reliable timelines save reputations.

Role of After-Sales Service in Your Decision

A relationship doesn’t end post-sale. Great manufacturers provide:

- Installation assistance

- Troubleshooting guidance

- Maintenance advice

Good after-sales service = insurance for your investment.

Balancing Cost with Quality

Everyone wants a bargain, but in force sensors, cheap often equals nasty. Transparent pricing tied to robust quality builds trust. Sometimes, paying a little more upfront saves mountains later.

How Industry Experience Shapes Reliability

Experience means wisdom born from mistakes, innovation from necessity, and robustness from real-world testing. Favor manufacturers with seasoned footprints in your industry.

Reading Between the Lines of Reviews

Testimonials tell you a story. However, look deeper:

- Consistency of praise

- Specific success stories

- Problem-solving capabilities

Authentic feedback beats polished brochures.

Importance of International Presence

A global footprint often signals stability and adaptability. Local reps, service centers, and diverse shipping options can make your life a lot easier.

How Research-Driven Companies Deliver Better Products

R&D investment is a crystal ball into a company’s future-readiness. It demonstrates a commitment to:

- Continuous improvement

- Technology leadership

- Solving tomorrow’s challenges

Ensuring Durability and Accuracy

Reliable manufacturers boast rigorous testing:

- Lifecycle tests

- Environmental stress screening

- Repeatability assessments

It’s not enough to function; the sensor must endure.

Understanding Warranty Coverage and Terms

Warranties reflect confidence. Check:

- Duration

- What’s covered

- Replacement or repair policies

A rock-solid warranty builds peace of mind.

Why Transparent Communication is Essential

During your project, clear, honest, and fast communication can save days, dollars, and disasters. Choose manufacturers who listen, clarify, and act swiftly.

Choosing a Partner that Grows with Your Needs

Your project today might be a product line tomorrow. Partner with a manufacturer capable of scaling:

- Higher volume orders

- Additional customization

- Global distribution

Eco-Friendly Manufacturing in Sensor Production

Sustainability isn’t a luxury anymore; it’s a necessity. Ask about:

- Eco-friendly materials

- Energy-efficient facilities

- Recycling programs

Every green initiative counts.

Mistakes to Avoid When Choosing a Force Sensor Manufacturer

Common blunders include:

- Focusing only on cost

- Ignoring certification proof

- Overlooking service support

- Choosing based only on proximity

Stay sharp to avoid these missteps.

Building a Long-Term Partnership

Choosing a manufacturer isn’t a one-off transaction. It’s the beginning of a relationship. Look for someone who thinks like a partner, not just a supplier.

FAQs About Choosing the Right Force Sensor Manufacturer

What should I prioritize when choosing a force sensor manufacturer?

How important are certifications like ISO for sensor manufacturers?

Can a smaller manufacturer offer better customization than a big brand?

Is it risky to source sensors from overseas manufacturers?

How do I verify a manufacturer’s reputation?

Should cost be a primary factor in selection?

Wrapping Up: Secure Your Project’s Success

In conclusion, learning how to choose the right force sensor manufacturer for your project isn’t rocket science — but it does require diligence, clarity, and strategic thinking. Prioritize expertise, innovation, and a solid support system. Your project’s success hinges on the tiny, powerful forces measured by these crucial components.

Clear Call-to-Action (CTA):

Ready to elevate your projects with world-class force sensor solutions?

At XJCSENSOR, we specialize in manufacturing customized, wholesale force sensors trusted across industries like industrial automation, robotics, automotive, 3C electronic automation, packaging automation, agricultural machinery, and medical equipment. Contact us today to explore premium sensors tailored to your needs. Partner with XJCSENSOR for innovative solutions that drive success!

Related Reading

- Custom vs. Standard Force Sensors: Which One Do You Need?

- Top 5 Force Sensor Manufacturers in 2025 (And Why XJCSENSOR Leads)

- What Makes a High-Precision Force Sensor?