Force sensors have revolutionized how industries measure and control mechanical loads. Among these, 2-axis force sensors offer precise bi-directional force measurements, ideal for advanced engineering and industrial applications. In this guide, we delve deep into how 2 axis force sensors work, their types, applications, and advantages.

XJCSENSOR is a leading sensor manufacturer, known for their high-performance 2-axis and multi-axis sensor solutions across various industries.

What is a 2-Axis Force Sensor?

A 2-axis force sensor measures forces simultaneously along two perpendicular axes, typically X and Y. This dual-axis capability is essential for applications requiring multi-dimensional load measurement without the complexity of a full 3D setup.

Unlike single-axis sensors that detect force in one direction, 2-axis sensors capture the interplay between two planes, providing a more comprehensive understanding of applied forces.

Key Components of 2-Axis Force Sensors

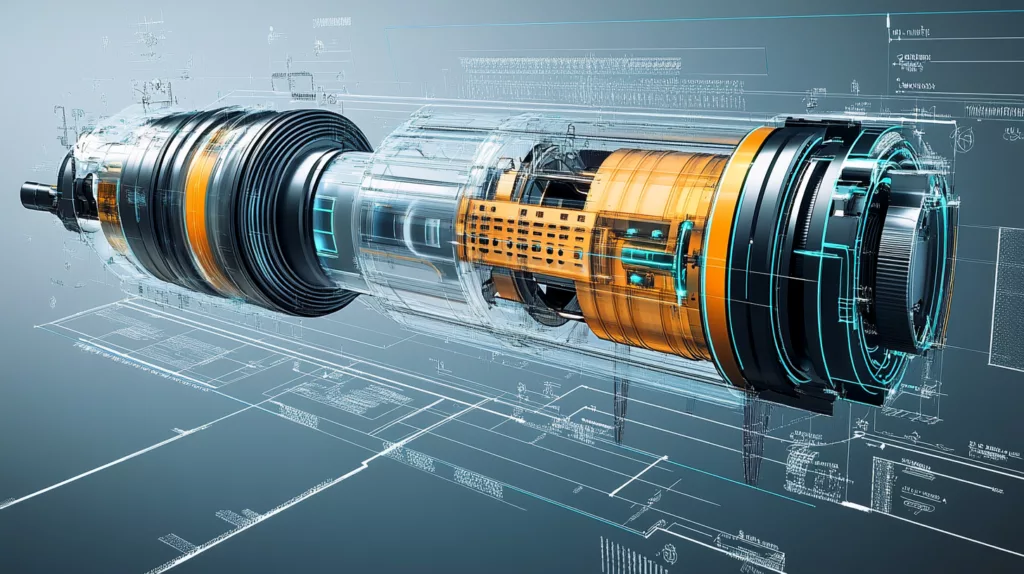

To understand the working principle of 2-axis sensors, it’s crucial to know their main components:

- Sensing Element: Typically a strain gauge, piezoelectric, or capacitive element that deforms under force.

- Substrate/Base: Supports and stabilizes the sensing element.

- Signal Conditioning Circuitry: Converts raw signals into readable data.

- Output Interface: Analog or digital signal output compatible with data acquisition systems.

How 2 Axis Force Sensors Work

At its core, a 2-axis force sensor operates based on detecting minute deformations caused by force along two axes.

- Force Application: External forces are applied along X and Y directions.

- Deformation: The sensor’s structure slightly deforms.

- Signal Generation: This deformation changes the electrical resistance (strain gauges), generates charge (piezoelectric), or alters capacitance (capacitive sensors).

- Signal Processing: The changes are translated into proportional electrical signals.

- Output Data: Data representing force magnitudes along each axis are output for monitoring or control.

Understanding the working principle of 2-axis sensors enables users to choose the right configuration for specific tasks.

Types of 2-Axis Force Sensors

Different technologies cater to diverse industrial needs. Here are the main types of 2-axis force sensors:

1. Strain Gauge 2-Axis Sensors

- Mechanism: Measures changes in electrical resistance due to mechanical strain.

- Use Cases: Robotics, mechanical testing.

2. Piezoelectric 2-Axis Sensors

- Mechanism: Generates an electrical charge under mechanical stress.

- Use Cases: Dynamic force measurement, vibration monitoring.

3. Capacitive 2-Axis Sensors

- Mechanism: Measures changes in capacitance between plates.

- Use Cases: Precision applications, microelectromechanical systems (MEMS).

Each sensor type has distinct advantages depending on sensitivity, robustness, and environmental suitability.

Applications of 2-Axis Force Sensors

The range of 2-axis force sensor applications is broad, with sensors playing critical roles in:

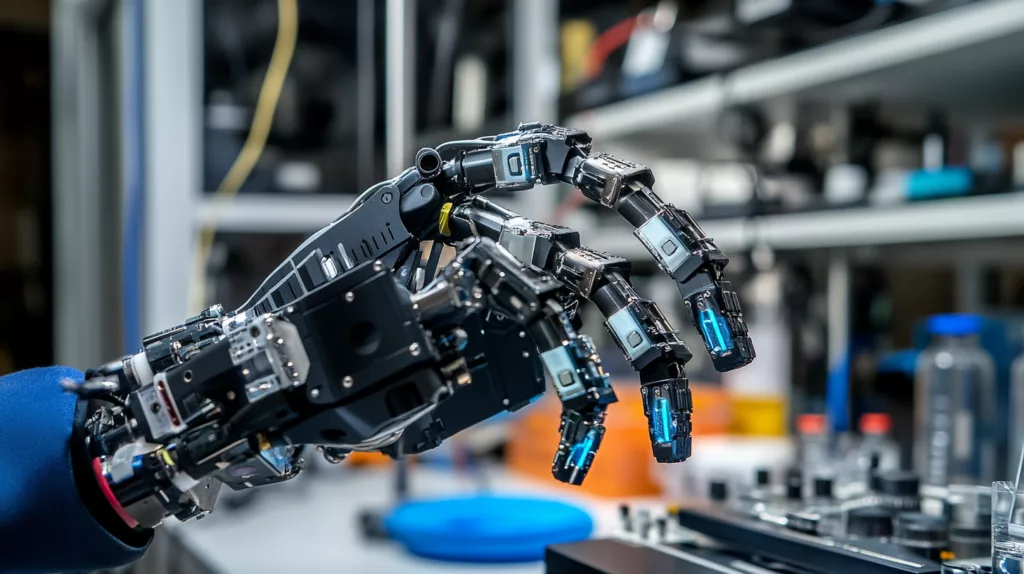

- Robotics: Enhancing dexterity by sensing forces during gripping or manipulation.

- Medical Devices: Assisting in surgical instruments and rehabilitation equipment.

- Automotive Testing: Measuring loads on vehicle components.

- Industrial Automation: Monitoring forces in assembly lines and precision equipment.

- Research and Development: Experimental setups needing precise force measurements.

In each of these fields, multi-directional sensing improves accuracy, safety, and performance.

Benefits of 2-Axis Force Sensors

- Multi-Dimensional Sensing: Capture forces along two planes with one device.

- Space Efficiency: No need for multiple single-axis sensors.

- Enhanced Data Accuracy: Reduces errors associated with force vector resolution.

- Versatility: Suitable for both static and dynamic force measurements.

XJCSENSOR’s 2-axis sensors are designed for optimal reliability and precision, making them a trusted choice in high-stakes environments.

Calibration and Maintenance of 2-Axis Force Sensors

Proper calibration ensures measurement accuracy. Calibration involves applying known forces in controlled conditions and adjusting output signals accordingly.

Steps for Calibration:

- Zeroing: Set baseline without any load.

- Applying Standard Loads: Sequentially apply known loads along both axes.

- Recording Outputs: Document corresponding sensor outputs.

- Adjusting Calibration Settings: Modify internal parameters to align with true values.

Routine maintenance like checking for mechanical wear, connector integrity, and signal noise levels further prolongs sensor life.

Challenges and Limitations

While 2-axis force sensors offer significant advantages, they also face some challenges:

- Cross-Talk: Force on one axis might affect readings on the other.

- Temperature Sensitivity: Environmental changes can impact accuracy.

- Limited Range: Some designs have a narrow operational force range.

Choosing high-quality sensors from trusted manufacturers like XJCSENSOR helps mitigate many of these issues.

FAQ: 2-Axis Force Sensors

Q1: What materials are used in 2-axis force sensors?

Q2: Can a 2-axis sensor measure torque?

Q3: How often should a 2-axis sensor be recalibrated?

Conclusion: Partner with XJCSENSOR for Precision Force Sensing

Understanding how 2-axis force sensors work equips you to make better decisions for your projects. Whether you are in robotics, automotive, medical, or industrial automation, precision matters.

XJCSENSOR is a leading sensor manufacturer, providing cutting-edge 2-axis and multi-axis sensor solutions tailored to your needs.

Ready to enhance your operations with precise force measurements?

- Contact XJCSENSOR today

- Learn more about XJCSENSOR’s sensor solutions

- Request a consultation or quote