Modern industries—from robotics to aerospace—demand highly precise and responsive tools for measuring force. Among the most advanced sensing technologies available today are 3 axis force sensors, also known as triaxial force sensors. These devices can detect and measure force components simultaneously along the X, Y, and Z axes.

As XJCSENSOR is a leading manufacturer of advanced sensor technologies, understanding How 3 Axis Force Sensors Work can help engineers, technicians, and product developers implement more accurate control and feedback systems in a wide array of applications.

What Is a 3 Axis Force Sensor?

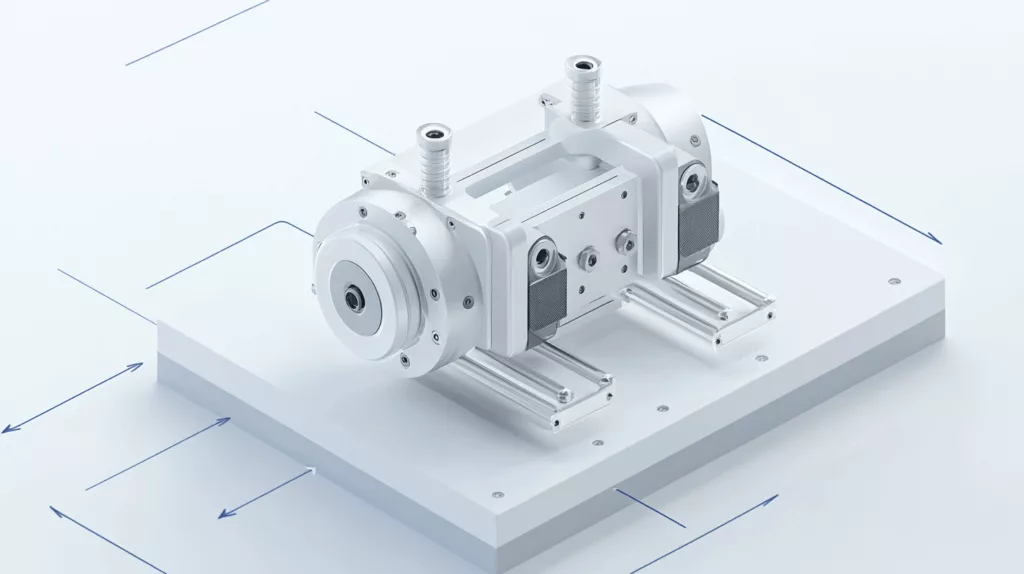

A 3 axis force sensor is a highly sensitive device engineered to measure forces in three perpendicular directions—typically referred to as the X, Y, and Z axes. This capability enables it to capture comprehensive data on how force is applied to an object or surface.

Key Features of Triaxial Force Sensors:

- Measures forces along three axes simultaneously

- High precision and stability

- Compact and durable design

- Suitable for dynamic and static force measurement

These sensors are commonly used in robotics, automation, aerospace testing, biomechanics, and industrial equipment calibration.

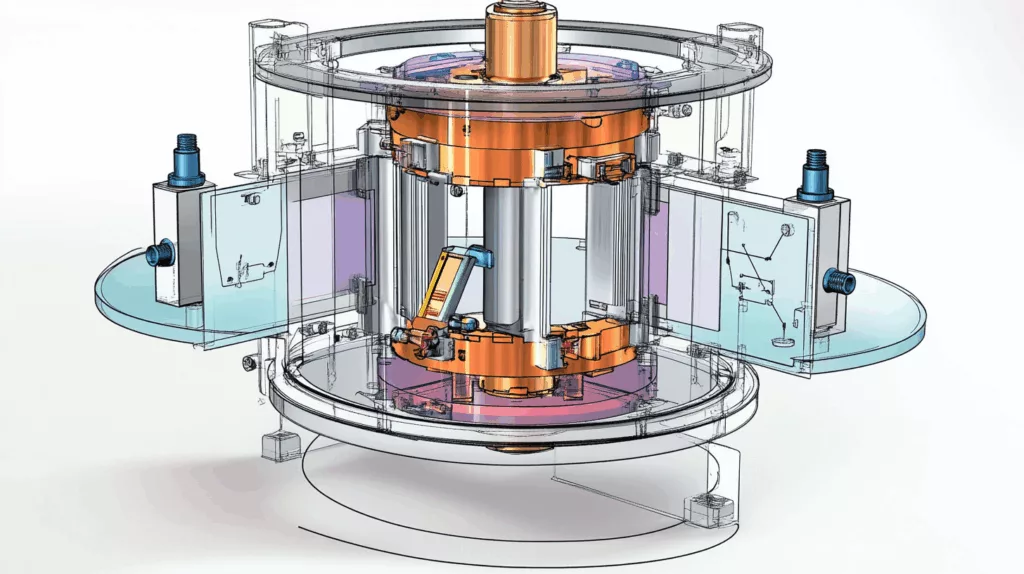

The Working Principle of 3 Axis Force Sensors

At the heart of a 3 axis force sensor is a multi-axis load cell, which converts applied mechanical forces into electrical signals using strain gauge technology or piezoelectric elements.

Components and Design

- Sensing Element (Load Cell): Often constructed with specialized alloys to ensure structural stability and sensitivity.

- Strain Gauges or Piezoelectric Crystals: Embedded in each axis to detect deformation or pressure.

- Signal Conditioner: Amplifies and digitizes the analog signals from each axis.

- Output Interface: Transmits data to a display or control system, typically via analog, USB, or Ethernet.

How Forces Are Measured

When force is applied to the sensor:

- The internal structure experiences strain (micro-deformation).

- Strain gauges detect the deformation on each axis.

- Each axis outputs a voltage proportional to the applied force.

- The sensor’s electronics process and combine the data into readable force vectors.

Applications of 3 Axis Force Sensors

The versatility of triaxial force sensors makes them indispensable across multiple sectors.

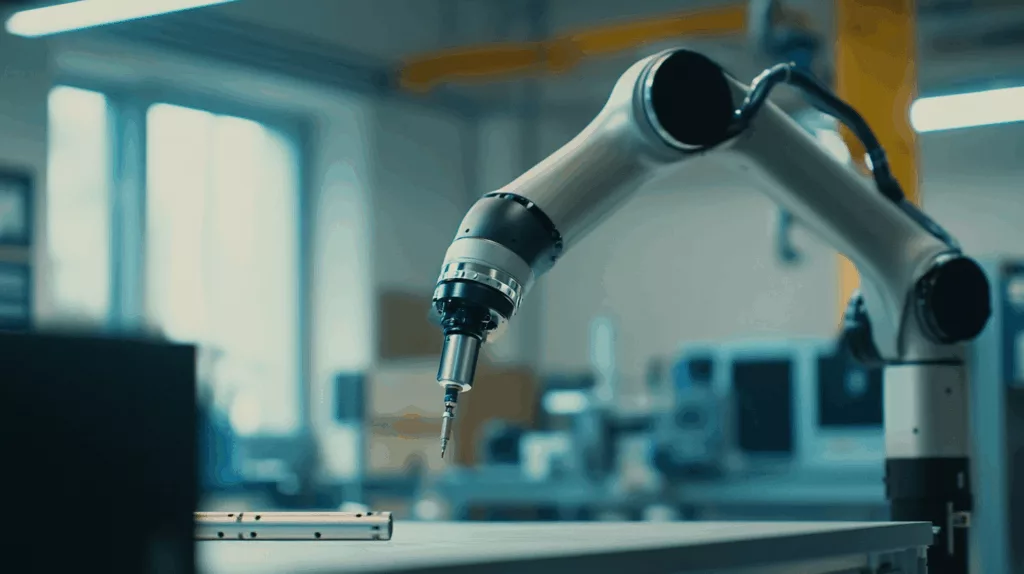

Robotics and Automation

- Ensures precision in robotic gripping and manipulation

- Enables force feedback in collaborative robots (cobots)

- Monitors tool wear and process forces in CNC machining

Aerospace and Defense

- Simulates and measures aerodynamic loads

- Tests materials and components under multi-directional forces

Medical and Biomechanics

- Analyzes joint movements and gait forces

- Integrates into prosthetics for real-time force monitoring

Automotive and Transportation

- Tests crash forces and component durability

- Evaluates steering and braking performance

Benefits of Using Triaxial Force Sensors

- High Sensitivity: Detects subtle variations in force application.

- Multidirectional Analysis: Offers a full vector view of how forces interact.

- Compact and Integrated: Can be embedded in small-scale systems.

- Improved Safety and Accuracy: Reduces errors in high-stakes environments.

FAQs About 3 Axis Force Sensors

Q1: Can 3 axis force sensors be customized for specific applications?

Yes, many manufacturers like XJCSENSOR offer customizable sensor solutions to fit specific dimensional, load, and environmental requirements.

Q2: Are these sensors suitable for harsh environments?

Many triaxial sensors are built with protective enclosures and rugged materials, making them ideal for industrial or outdoor use.

Q3: What’s the difference between a 3 axis sensor and a 6 axis force/torque sensor?

A 3 axis sensor measures force in three directions, while a 6 axis sensor also measures torque (rotational force) about each of those three axes.

Final Thoughts: Why Choose a 3 Axis Force Sensor?

Understanding how 3 axis force sensors work reveals why they’re a cornerstone in precision force measurement. Their ability to capture real-time, multidirectional data makes them crucial in advancing technologies that demand high responsiveness and safety.

If you’re seeking reliability and high-performance sensing, XJCSENSOR’s advanced triaxial force sensors stand out with their robust engineering and industry-grade quality. Whether you’re in R&D, manufacturing, or medical tech, integrating the right sensor can dramatically elevate your system’s performance.

Explore XJCSENSOR’s full range of 3 axis force sensors and take your application to the next level.