Learning about 3 axis force sensors is key for many professionals. They are used in fields like manufacturing and healthcare. These devices help measure forces with great precision, guiding important decisions and new ideas.

We will explore how these sensors work. We’ll show their importance and the benefits of using them in different systems.

This guide will talk about the different types of force sensors. We’ll look at their main parts and their role in various areas. By the end, you’ll know how these sensors work and their value in your projects.

Key Takeaways

- 3 axis force sensors measure vector forces across three dimensions.

- Understanding force sensor technology is critical for accurate data collection.

- Precision force measurement is crucial in industries such as robotics and medical fields.

- Knowing the components of a force sensor helps in effective integration into existing systems.

- Advancements in technology enhance the efficiency of force sensors.

- Real-time data provided by these sensors can significantly improve decision-making processes.

Understanding Force Sensors

Force sensors are key in engineering and automation. They detect and measure the force on objects. This is crucial in many fields, from making things to robotics.

What Are Force Sensors?

Force sensors turn force into electrical signals. They come in two types: mechanical and electronic. Mechanical ones use physical changes to measure force. Electronic ones use advanced tech for better accuracy and speed.

How Do They Function?

Force sensors work by changing physical force into an electrical signal. When force is applied, the sensor changes shape. This change is then turned into an electrical signal.

This signal is vital for controlling and monitoring processes. It shows how well force measurement technology works today.

Types of Force Sensors

Knowing about the different types of force sensors is key for industrial use. There are mainly two kinds: mechanical and electronic force sensors. Each has its own role and benefits, making them useful in various ways. We’ll dive into these categories and see why 3 axis force sensors stand out.

Mechanical Force Sensors

Mechanical force sensors work by changing shape when force is applied. They include:

- Bending beams

- Load cells

- Spring-based sensors

These sensors are tough and reliable. They’re great for places where things need to last a long time. Their design also makes them affordable for many industries.

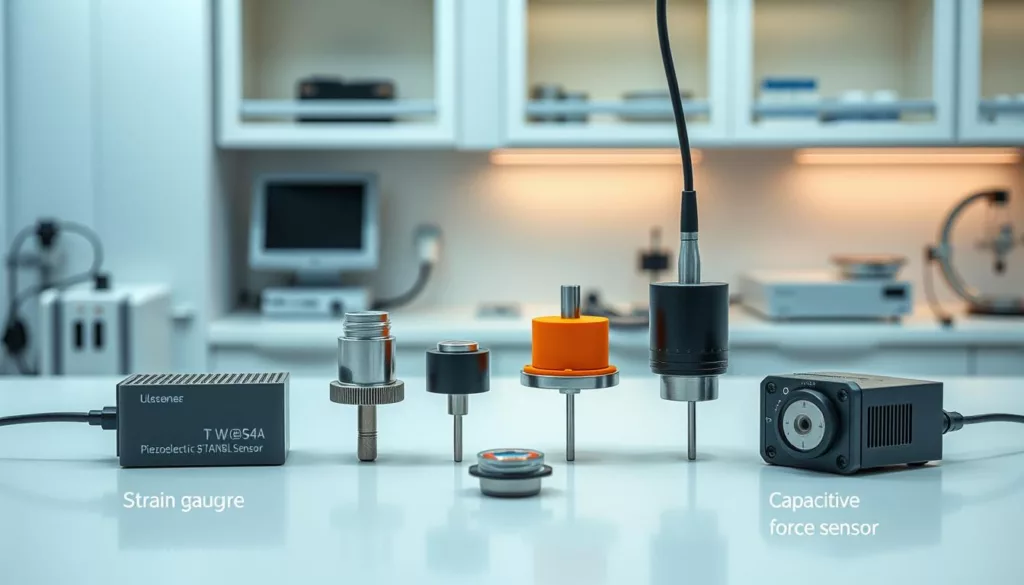

Electronic Force Sensors

Electronic force sensors use circuits to sense force changes. They’re more precise and sensitive. Examples are:

- Strain gauge sensors

- Capacitive sensors

- Piezoelectric sensors

These sensors can send signals electronically. This means they can send data in real-time. This is a big plus in today’s tech world.

3 Axis Force Sensors vs. Other Sensors

3 axis force sensors are special because they measure force in three directions. This is different from regular sensors that only measure in one direction. Here’s a table showing the main differences:

| Feature | 3 Axis Force Sensors | Conventional Sensors |

|---|---|---|

| Measurement Dimensions | Three dimensions | One dimension |

| Data Output | Multi-directional | Single-directional |

| Applications | Complex applications (robotics, aerospace) | Simpler applications (weight measurement) |

| Cost | Higher initial investment | Generally lower cost |

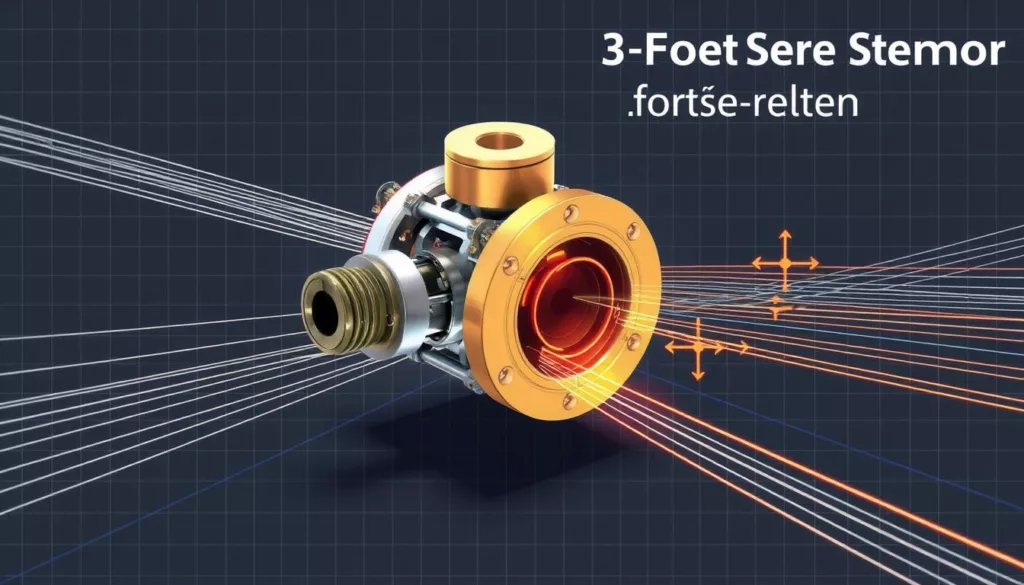

How Does a 3 Axis Force Sensor Work?

Exploring a 3 axis force sensor means looking at how it works and its parts. We’ll dive into the science of measuring force and how each part helps the sensor perform well.

The Working Principle of 3 Axis Force Sensors

Force sensors measure force in three directions: X, Y, and Z. This lets them analyze forces fully. They use special parts to turn force into electrical signals. This way, they can accurately detect and process forces, helping in many fields.

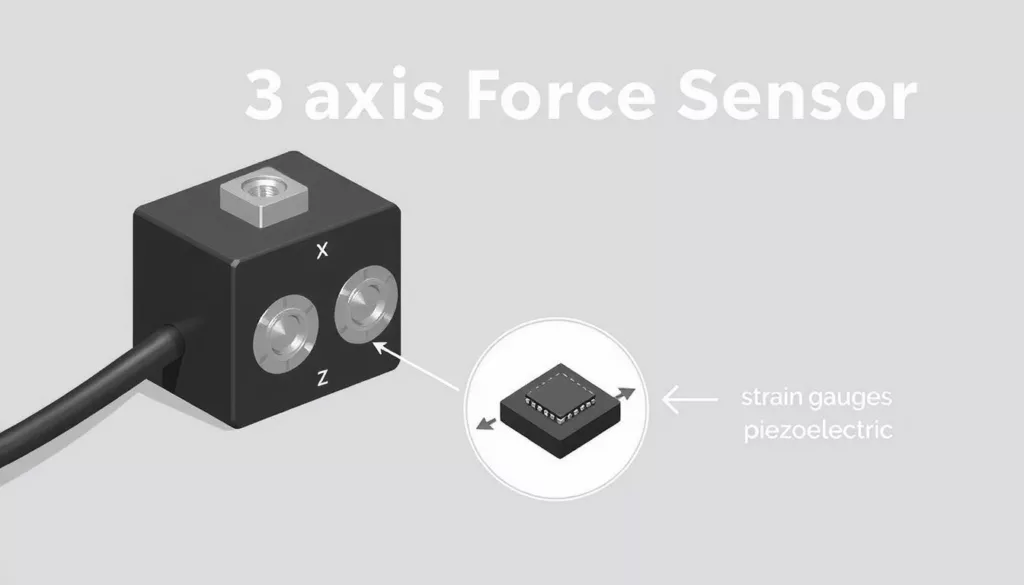

Components of a 3 Axis Force Sensor

The success of a 3 axis force sensor comes from its parts. Key components are:

- Strain Gauges: These measure how much something bends; they change their resistance with stress, showing the force applied.

- Load Cells: These are the main force-measuring parts. They turn force into electrical signals that can be measured.

- Microcontrollers: These parts take the signals from strain gauges and load cells. They turn these signals into data we can understand.

Together, these parts make the sensor reliable and important in many uses.

Force Sensor Technology

In recent years, force sensor technology has grown a lot. This growth is thanks to new advancements that make these sensors better and more useful. We’ll look at the new features that are changing how we measure and track force in many industries.

Advancements in Force Sensor Technology

Several important advancements have driven the growth of force sensing technology:

- Smart Sensors: Smart sensors use intelligent algorithms for real-time monitoring and analysis. This makes them more accurate in many uses.

- Miniaturization: Making sensors smaller has allowed them to fit into tighter spaces. This doesn’t hurt their ability to work well.

- Enhanced Data Processing: Better data processing means faster and more reliable results. This makes measuring easier and more efficient.

Applications of Force Sensing Technology

Force sensors are used in many areas, showing their big impact:

- Automated Systems: In robotics and automation, force sensors are key. They help machines interact and control their environment precisely.

- Load Testing: In construction and manufacturing, force sensors are vital. They help check if structures can hold their weight and loads.

- Quality Assurance: On production lines, these sensors check the force used in making and packaging products. This keeps quality high.

Components of a 3 Axis Force Sensor

Understanding a 3 axis force sensor’s parts is key to knowing how it works. Each part is crucial for the sensor to measure forces accurately in three dimensions.

Strain Gauges

Strain gauges are vital in a 3 axis force sensor. They pick up on strain from applied forces, turning mechanical changes into electrical signals. The quality of these signals affects the sensor’s performance, showing the force it feels.

Load Cells

Load cells are the heart of force measurement in these sensors. They change mechanical force into a signal that can be measured. With strain gauges, they make the sensor more sensitive and precise, handling different force levels well.

Microcontrollers

Microcontrollers are important for handling data from the sensor’s parts. They take the signals from strain gauges and load cells and turn them into useful data. This data can be used in many ways, thanks to the microcontrollers’ ability to connect with other systems.

Force Measurement Technology Explained

Understanding force measurement technology is key to making sense of sensor data. We’ll look at two important areas: how sensors process signals and the need for calibration to ensure accuracy.

Signal Processing in Force Sensors

Force sensors send out raw signals that need to be refined. Different techniques are used to improve these signals. The main steps are:

- Filtering: This removes unwanted noise and frequencies, giving us true force readings.

- Averaging: Averaging multiple readings makes the data more accurate and consistent.

- Amplification: Sometimes, signals are too weak and need to be amplified for analysis.

These steps help in better signal processing, leading to more accurate data and better performance in various applications.

Calibration Techniques

Calibration is vital for keeping force sensors accurate. Regular checks ensure sensors work as expected and give reliable readings. Here are some common calibration methods:

- Static Calibration: This involves applying known forces to set a baseline for comparison.

- Dynamic Calibration: Tests how sensors handle quick changes in force, simulating real-world use.

- Software Calibration: Uses software to adjust sensor outputs based on set parameters, making calibration easier.

Force Sensor Applications

Force sensors are used in many areas. They help measure force, making things safer and more efficient. This is true in different places, improving how things work and keeping people safe.

Industrial Applications

In factories, force sensors are key. They help make production better by:

- Real-time monitoring of loads to avoid machine breakdowns.

- Checking product quality to meet standards.

- Making machines work better, saving time and effort.

- Helping robots place parts accurately.

Medical Applications

In healthcare, force sensors are vital. They help keep patients safe and well cared for. They are used for:

- Tracking vital signs through force data.

- Improving prosthetics for better comfort.

- Testing how the body reacts in exams.

Robotics and Automation

Force sensors make robots better at working with people. They offer:

- Better touch feedback for robots to understand their surroundings.

- More flexible programming for different tasks.

- Safe actions in unexpected situations.

Benefits of 3 Axis Force Sensors

3 axis force sensors do more than just measure. They offer advanced features that are key in many fields. Their precision and accuracy in measuring forces across different axes are unmatched. This makes the data they collect reliable for making important decisions.

Precision and Accuracy

3 axis force sensors are known for their precision and accuracy. They measure forces in multiple directions, unlike single-axis sensors. This means more consistent data, which is crucial in fields like robotics, aerospace, and structural testing. Accurate force measurements are vital for safety and performance.

Real-Time Data Collection

Another big plus of 3 axis force sensors is their ability to collect data in real-time. This lets users analyze and act on changes quickly. It’s especially useful in manufacturing and quality control. Fast responses to data can boost efficiency and productivity.

Conclusion

We’ve looked into how 3 axis force sensors work and their many uses. These devices are key in many fields, helping to measure things accurately. This makes work more efficient.

These sensors are used in many places, like factories, hospitals, and robotics. They help improve how things work and meet today’s engineering needs.

At XJCSENSOR, we help you use 3 axis force sensors well. We offer the support you need to make your work more precise and effective.