3 axis force sensors have changed robotics, making tasks more precise and efficient. At XJCSENSOR, we see their value in many fields like manufacturing, healthcare, and logistics. These sensors help robots work better and give important feedback.

We will explore how these sensors help robots get better. We’ll also look at how engineers use them in robot technology.

Key Takeaways

- 3 axis force sensors greatly enhance the precision of robotic tasks.

- They play a vital role in various sectors, improving overall operational efficiency.

- Feedback capabilities lead to better control in robotics force sensing applications.

- Integration techniques greatly influence the performance of sensor technology in robotics.

- Continuous innovation in this field promises further advancements in robotic applications.

Introduction to 3 Axis Force Sensors

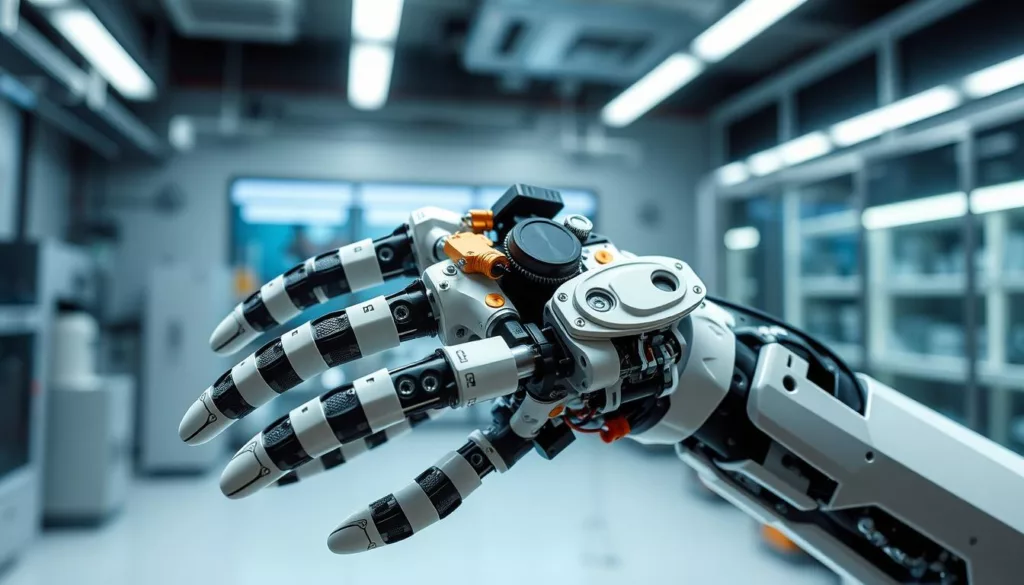

In robotics, 3 axis force sensors are key. They measure forces along three axes: X, Y, and Z. This is vital for robots to understand their surroundings.

These sensors turn mechanical forces into electrical signals. This lets robots get feedback in real-time. It’s important for robots to adapt to their environment.

Using these sensors in robots boosts their control and precision. They help robots handle objects better. This is critical for tasks needing great skill.

XJCSENSOR makes top-notch 3 axis force sensors for robots. Our focus on innovation and quality improves robot performance.

Understanding Robotics Force Measurement Tools

In robotics, precision is key. Robotics force measurement tools are essential for achieving high accuracy and stability. They help robots understand their interactions with the environment. This is important for tasks like gripping, lifting, and assembly.

Using tools like 3 axis force sensors boosts robotics’ capabilities. These sensors give robots real-time feedback on their forces. This allows robots to adapt and work more safely and efficiently.

Knowing how these tools work helps engineers make robots better. In fields like manufacturing, healthcare, and services, using force measurement tools can lead to big improvements. It drives innovation and makes operations better.

| Feature | Benefit |

|---|---|

| Real-time Force Feedback | Enables immediate adjustments in robotic behavior to ensure safety and efficiency |

| 3 Axis Measurements | Allows for detailed force assessments in all directions, boosting task accuracy |

| Enhanced Stability | Reduces the risk of mechanical failure or accidents during operation |

| Data-Driven Decisions | Supports informed adjustments based on precise measurements |

Applications of 3 Axis Force Sensors in Robotics

3 axis force sensors are key in robotics, boosting efficiency and precision. They give robots the feedback needed for better movements. This makes them essential in many fields.

Enhancing Precision in Robotic Tasks

Adding 3 axis force sensors makes robots more precise. This is critical in places like assembly lines, where small changes can greatly improve quality. Robots can adjust their actions on the fly, ensuring parts are placed perfectly.

This precision not only makes operations more consistent. It also raises productivity in factories.

Impact on Robotics Force Control Systems

These sensors change how robots work with their environment. They help robots adapt to different loads, improving performance and reducing mistakes. The sensors allow robots to adjust their actions based on feedback.

This flexibility makes workflows smoother. Robots can avoid damaging products and machines, making them last longer.

Force Feedback Sensors in Robotics

In robotics, force feedback sensors are a game-changer. They give robots the ability to feel and adjust to forces they meet. This makes robots better at working with humans, where being quick and smart is key.

Benefits of Force Feedback in Robotic Applications

Force feedback sensors in robotics offer many benefits:

- Enhanced Dexterity: Robots can do complex tasks better, thanks to real-time feedback.

- Reduced Risk of Damage: Robots can avoid hurting themselves or breaking parts.

- Improved Safety Measures: Robots can check how they’re doing, making operations safer.

Companies like XJCSENSOR are leading the way in force feedback tech. They’re changing how robots work. To learn more, check out force feedback sensors in robotics.

| Benefit | Description |

|---|---|

| Enhanced Dexterity | Improves precision in tasks requiring delicate movements. |

| Reduced Risk of Damage | Prevents harm to delicate components and enhances overall system longevity. |

| Improved Safety | Allows robots to operate safely in environments with human interaction. |

Integrating Force Sensors in Robotic Applications

Adding force sensors to robots involves many technical steps. It’s important to place sensors right to get the right force readings. This makes sure the robot works well.

Calibration is key in this process. It makes sure the sensors give accurate data. This data helps the robot know what’s happening around it. Robots need to be very precise in their actions.

XJCSENSOR is great at making this work. Our team works with engineers to make sure the sensors work perfectly. This makes robots more reliable and effective.

Using force sensors in robots can give companies a big advantage. It’s all about how well the sensors work and how the robot responds. With better sensors, robots can do more and adapt faster in different fields.

Benefits of 3 Axis Force Sensors in Robot Technology

3 axis force sensors make robots better in many ways. They help robots control their actions more precisely. This is key for tasks that need exact force feedback, making robots safer and more efficient.

These sensors also help robots handle different weights better. They keep track of forces, letting robots adjust quickly. This is important in changing situations.

Another big plus is saving energy. Robots use less power because they measure forces accurately. This means they last longer and use less energy overall.

In short, 3 axis force sensors make robots work better, safer, and longer. They are key for improving productivity and quality. For more on these sensors, check out XJCSENSOR’s website.

Challenges in Implementing Force Sensing Technology for Robots

Using force sensing technology in robots comes with many challenges. One big one is calibrating the sensors. It’s key to get the force data right for the robot to work well.

Dealing with lots of data is another problem. Force sensors make a lot of data, and we need smart software to sort it out. This can be tough, even for big companies.

External factors like electromagnetic noise can mess with the sensors. This can make the robot think it’s doing something it’s not. We need to find ways to keep these problems away.

Getting robots to understand and use force feedback is hard too. We need better control systems to make sense of the sensor data. At XJCSENSOR, we’re working hard to solve these problems. We want to help industries use force sensing technology successfully.

| Challenge | Description | Potential Solutions |

|---|---|---|

| Sensor Calibration | Ensuring accurate sensor readings to reflect true force measurements. | Regular calibration cycles and advanced calibration tools. |

| Data Complexity | Difficulty in analyzing large volumes of data for actionable insights. | Investing in powerful analytics software and training. |

| External Interference | Impact of environmental factors on sensor performance. | Shielding and filtering technologies to reduce interference. |

| Feedback Interpretation | Challenges in creating robots that can process and respond to feedback. | Developing advanced control systems and algorithms. |

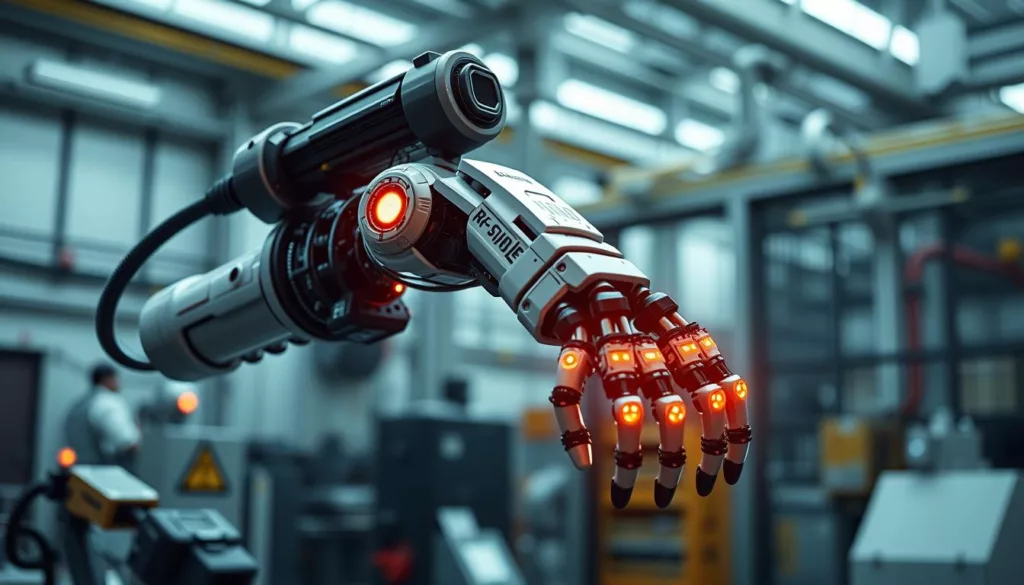

Future Trends in Robotics Force Sensing Applications

Robotics technology is getting better, and future trends in robotics force sensing applications are getting a lot of attention. New ideas in machine learning and artificial intelligence are changing force sensors. They will help systems make better decisions with real-time force feedback.

Miniaturization is making force sensors smaller and more versatile. Companies like XJCSENSOR are leading the way. They create advanced, precise sensors for industries like cars, planes, and gadgets.

- Distributed sensing systems will help robots move and interact smarter with their surroundings.

- Better data processing means robots will respond faster and more accurately in tough situations.

- Robust sensors will work well even in harsh conditions, keeping performance steady.

These future trends in robotics force sensing applications mark a big change. Robots will talk and work in new ways. This will help businesses work more efficiently and precisely than ever before.

Conclusion

3 axis force sensors are key in robotics, making robots more precise and controlled. They help robots get feedback, which is vital for their work. This technology makes robots more efficient and adaptable, changing how we do things in many industries.

The quality of these sensors is critical for robotics to work well. Working with top companies like XJCSENSOR, experts can find the right sensors for their projects. This teamwork is key to making robotics work as planned.

We’re looking forward to bringing more innovative solutions to robotics. This will help robots perform better and smarter. Learn more about new sensor technologies and how they can improve your robotic projects.