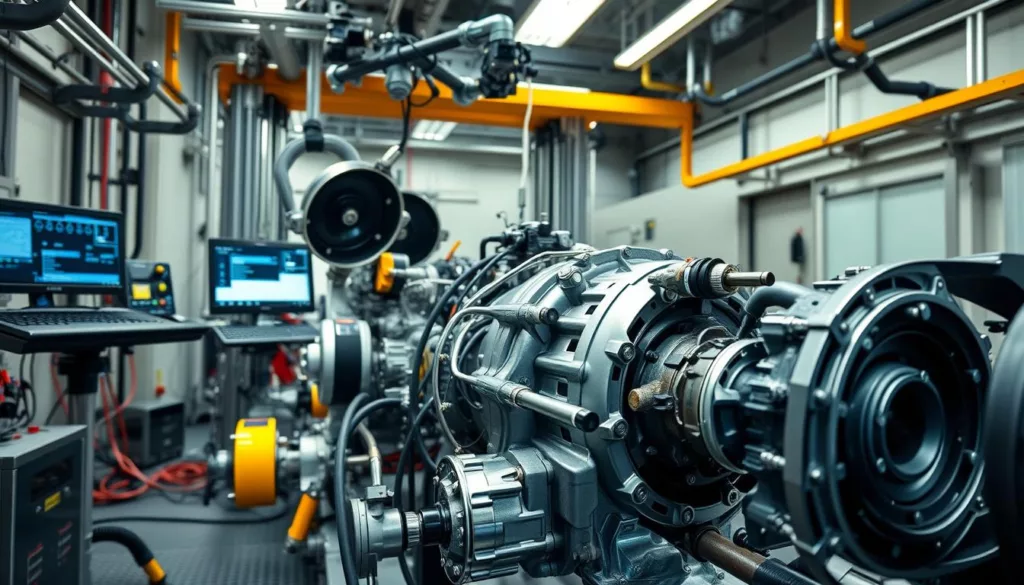

In the world of car engineering, torque sensors are key for better car performance, safety, and new ideas. They help in many car tests, like checking engine power and electric car parts. These sensors are vital for measuring and understanding the torque forces that affect how cars work and feel.

The uses of torque sensors in cars cover many areas. Each one helps make cars better, more efficient, and safer. With the exact data from these sensors, car engineers can improve engine power, check car parts, and test how cars move. They also make sure cars meet high quality standards during development.

Key Takeaways

- Torque sensors are essential tools for optimizing vehicle performance and safety in automotive testing

- These sensors enable precise measurement and analysis of critical torque forces across a wide range of applications

- Automotive engineers leverage torque sensor data to enhance engine performance, validate drivetrain components, and assess vehicle dynamics

- Rigorous quality control and durability testing are facilitated by the insights provided by torque sensors

- The integration of torque sensors is critical for the development and validation of modern electric vehicles

Understanding Torque Sensors in Modern Automotive Testing

Torque sensors are key in the car world. They help test how well cars perform and their parts. These sensors measure the force or torque on car systems. This gives important data to engineers and researchers.

Basic Principles of Torque Measurement

Torque sensors work by measuring twisting force on a shaft. They use strain gauges to detect small changes in material. This lets them know how much force is applied and in which direction.

Types of Automotive Torque Sensors

- Optical Torque Sensors: Use light to measure twisting, giving high precision.

- Magnetoelastic Torque Sensors: Detect changes in magnetic fields to sense torque.

- Resistive Torque Sensors: Use strain gauges to measure resistance changes, a cost-effective option.

Key Components and Functions

Automotive torque sensors have key parts like the sensing element and data systems. These work together to capture and send torque data. This helps engineers understand how cars perform and behave.

| Component | Function |

|---|---|

| Sensing Element | Turns torque into an electrical signal, like voltage or resistance change. |

| Signal Conditioning | Boosts, filters, and processes raw signals for accurate data. |

| Data Acquisition | Gets the processed signals and turns them into digital data for analysis. |

Using torque sensor tech in car tests helps engineers. They learn more about car dynamics, power, and performance. This leads to safer, more efficient, and reliable cars.

Applications of Torque Sensors in Automotive Testing

Torque sensors are key in the world of car testing and development. They give important insights into how cars perform and use energy. This helps engineers make their designs better.

One area where torque sensors excel is in engine performance testing and validation. They measure crankshaft torque to analyze an engine’s power, efficiency, and how it responds. This info is key for tweaking engine settings for better performance.

Torque sensors also help a lot in transmission efficiency testing. They track torque through the drivetrain to find where power is lost. This helps improve gear shifting and makes transmissions more efficient. It’s important for making transmissions that use less fuel and perform better.

| Application | Key Benefits |

|---|---|

| Engine Performance Testing | Analyze power output, efficiency, and response characteristics |

| Transmission Efficiency Testing | Identify power loss, optimize gear synchronization, and enhance overall efficiency |

| Drivetrain and Powertrain Testing | Evaluate torque transfer, efficiency, and durability across the entire powertrain system |

| Vehicle Dynamics and Handling Assessment | Assess steering, suspension, and brake system performance for improved handling and stability |

Torque sensors are also important in drivetrain and powertrain testing. They give detailed info on torque, efficiency, and durability. This is vital for making drivetrain parts that last and perform well.

Also, torque sensors help in vehicle dynamics and handling assessment. They check how steering, suspension, and brakes work. This info is key for making cars handle better and feel more stable.

As cars keep getting better, the use of torque sensors will grow. These tools are essential for improving car performance, efficiency, and safety.

Engine Performance Testing and Validation

Torque sensors are key in testing and validating engine performance. They give insights into powertrain efficiency. This includes analyzing crankshaft torque, testing transmission efficiency, and verifying power output. These tools help engineers improve engine performance and ensure it works well.

Crankshaft Torque Analysis

Torque sensors measure crankshaft torque accurately. This helps analyze an engine’s power delivery. It’s important for adjusting combustion, finding imbalances, and checking mechanical efficiency.

By monitoring torque, engineers can fine-tune engine settings. This includes adjusting ignition timing and fuel injection for better performance.

Transmission Efficiency Testing

Torque sensors in transmissions check power transmission efficiency. This is key for evaluating gear and bearing performance. It helps find ways to improve powertrain efficiency.

Installing torque sensors in cars is vital for this testing. It ensures the drivetrain works well.

Power Output Verification

Measuring engine power output is critical for validating performance. Torque sensors, with speed sensors, give the needed data. This data is key for checking engine performance and optimizing power delivery.

It helps ensure the vehicle meets design specifications. This is important for quality and performance.

| Application | Torque Sensor Measurement | Benefit |

|---|---|---|

| Crankshaft Torque Analysis | Precise measurement of crankshaft torque | Optimize combustion parameters, identify imbalances, and validate mechanical efficiency |

| Transmission Efficiency Testing | Assess power transmission efficiency in gears, bearings, and other components | Identify areas for improvement and enhance overall powertrain efficiency |

| Power Output Verification | Measure engine power output in conjunction with speed sensors | Benchmark performance, optimize power curves, and ensure design specifications are met |

“Torque sensors are essential for unlocking the full engine performance. They give precise data for optimizing powertrain efficiency. This leads to better products for the market.”

Drivetrain and Powertrain Testing Solutions

In the world of car engineering, torque sensors are key. They help check how well drivetrain and powertrain systems work. These sensors give important info on how power moves in a vehicle. This helps engineers make their designs better for torque sensing for vehicle dynamics analysis and better performance.

One big use of torque sensors is checking automotive torque sensor quality assurance. They measure torque in different parts of the drivetrain. This lets engineers find where power is lost and make it better. This way, they can make cars more fuel-efficient and cut down on emissions.

| Drivetrain Component | Torque Sensor Application | Benefit |

|---|---|---|

| Gearbox | Transmission efficiency testing | Optimized gear ratios and lubrication |

| Differential | Torque distribution analysis | Improved traction and handling |

| Driveshaft | Torsional vibration monitoring | Enhanced driveline durability |

Using advanced torque sensing for vehicle dynamics analysis helps car makers. It makes sure their systems work well. This way, they can keep making cars better and better.

“Accurate torque measurement is the foundation for optimizing drivetrain efficiency and vehicle dynamics. Our torque sensors enable engineers to make data-driven decisions that elevate the performance and reliability of modern automotive systems.”

Vehicle Dynamics and Handling Assessment

In the world of car testing, torque sensors are key. They help check how a car moves and handles. These sensors give important info on the car’s steering, suspension, and brakes. This info helps make cars better to drive, more comfortable, and safer.

Steering System Analysis

Torque sensors are important for checking a car’s steering. They measure the force on the steering wheel. This helps engineers make the steering better, so drivers can control the car easily.

Suspension Load Testing

Torque sensors also check a car’s suspension. They watch the torque at the suspension points. This info helps make the ride smoother, the car more stable, and better in corners.

Brake System Evaluation

Torque sensors are used to test a car’s brakes too. They measure the torque in the brakes. This helps find problems and make the brakes work better, for safety and control.

By using torque sensors, car engineers learn more about how a car moves and handles. This leads to making cars that are safer, better to drive, and more refined.

Torque Sensor Integration in Electric Vehicle Testing

The car industry is quickly moving towards electric vehicles (EVs). Torque sensors are key in testing and improving EVs. They help make EVs run better and use less energy.

In testing EV powertrains, torque sensors are used to check motor and drivetrain performance. They measure the motor’s torque, giving insights into power, efficiency, and how fast the car responds. This info helps make the car’s controls better, giving drivers a smoother ride.

Torque sensors are also important for testing EV batteries. They measure the torque sent to the wheels, showing how well the battery and power system work. This data helps improve battery life, charging, and braking, making the car go further and be more eco-friendly.

Also, torque sensors help check EV regenerative braking systems. They measure braking torque, helping engineers find the best mix of regenerative and friction braking. This improves how well the car recovers energy and drives.

Torque sensors are becoming more important in electric vehicle testing. They give vital data on how EVs perform, helping engineers and makers make them better. This leads to more efficient and green cars for the future.

Quality Control and Durability Testing

At the heart of reliable car performance are key components that go through tough quality control and durability tests. Torque sensors are key in this, giving vital data for torque sensor calibration for cars and torque sensor data acquisition in vehicles.

Component Lifecycle Analysis

Engineers study the life of each part to understand its long-term performance and durability. Torque sensors measure forces and stresses on important parts. This helps spot where parts might fail and improve designs for longer life.

Reliability Testing Protocols

- Comprehensive reliability testing makes sure car parts can handle real-world driving.

- Torque sensors are part of these tests to watch how powertrain, suspension, and steering systems do under different loads.

- This data helps makers create strong, high-performance parts that meet or beat standards.

Performance Benchmarking

Torque sensors are key in setting performance standards for car parts and systems. They measure torque data to check efficiency, quickness, and overall performance. This lets engineers keep improving and innovating.

| Test Parameter | Torque Sensor Application | Benefit |

|---|---|---|

| Powertrain Efficiency | Measure driveline torque and power output | Optimize for maximum energy efficiency |

| Suspension Dynamics | Analyze suspension loads and wheel forces | Enhance ride quality and handling |

| Braking Performance | Evaluate brake system torque and response | Ensure reliable, high-performance braking |

By using torque sensor insights, car makers can create products of top quality, durability, and performance. This is key in today’s competitive market.

Data Acquisition and Analysis Methods

In the world of torque monitoring in cars, getting and analyzing data is key. Advanced methods help engineers understand how cars perform and find ways to make them better.

High-precision sensors are used to measure torque accurately in real-time. These sensors have advanced digital signal processing. They capture detailed info about the forces on the engine, drivetrain, and chassis.

- Data Acquisition Strategies: Automotive engineers use various methods to collect torque data. This includes wireless sensor networks, on-board data loggers, and cloud-based platforms. These ensure data is collected and integrated smoothly across different systems.

- Data Analysis Techniques: The torque data is then analyzed thoroughly. Engineers use statistical tools, machine learning, and visualization techniques. This helps them spot patterns, find anomalies, and gain insights for design improvements and performance optimization.

| Data Acquisition Approach | Key Advantages | Potential Applications |

|---|---|---|

| Wireless Sensor Network | Flexibility, Scalability, Real-time Monitoring | Engine Performance Testing, Drivetrain Efficiency Analysis |

| On-board Data Logging | Robust, Autonomous, Complete Data Capture | Vehicle Dynamics and Handling Assessment, Durability Testing |

| Cloud-based Data Management | Remote Access, Centralized Storage, Advanced Analytics | Fleet-wide Performance Monitoring, Predictive Maintenance |

By combining data acquisition and analysis, automotive engineers gain valuable insights. This leads to continuous improvement in torque monitoring and sensor installation in cars. It ensures vehicles perform well, are reliable, and meet the industry’s demands.

“Effective data acquisition and analysis are the cornerstones of automotive engineering excellence, empowering us to push the boundaries of vehicle performance and innovation.”

Real-time Monitoring and Calibration Techniques

Keeping torque sensors accurate is key in car testing. We look at how to monitor and calibrate them in real-time. This ensures they work well during tests. Our team uses strong calibration and optimization to fix errors fast, giving reliable torque readings for better cars.

Sensor Calibration Procedures

Calibrating sensors right is the first step to good torque readings. Our skilled technicians use top-notch tools and methods to check sensor performance. This careful work helps us spot and fix any issues, making sure sensors give consistent, accurate data.

Performance Optimization Methods

Improving torque sensor performance is a constant task in car testing. Our engineers use smart algorithms and models to tweak sensor settings. This boosts sensitivity, linearity, and precision. We keep an eye on sensor behavior and adjust as needed, ensuring top data quality, even in tough tests.

Error Detection and Correction

Quickly finding and fixing errors is vital for accurate torque readings. Our advanced systems watch sensor outputs closely, alerting us to any problems. When we spot issues, our team acts fast, recalibrating or adjusting sensors to keep the test running smoothly.