In today’s fast-paced industrial world, accurately measuring axial force and torque is key. It ensures product quality, boosts process efficiency, and keeps equipment reliable. XJCSENSOR, a top name in sensor tech, offers a wide range of solutions for these critical measurements. This guide will dive into XJCSENSOR’s advanced axial force and torque measurement tools. We’ll look at the basic principles, cutting-edge sensor tech, and top-notch data systems to help industrial pros do their best work.

Key Takeaways

- Discover the basic principles of force and torque detection, enabling you to select the right measurement solutions for your applications.

- Explore XJCSENSOR’s advanced load cell and torque sensor technologies, designed to deliver superior performance and reliability.

- Learn about the integration of strain gauges in measurement systems and the techniques for ensuring long-term stability and temperature compensation.

- Understand the benefits of rotary torque transducers and their versatile applications across diverse industries.

- Gain insights into XJCSENSOR’s multi-component force sensor technology and its capabilities for combined force and torque measurements.

Understanding the Fundamentals of Force and Torque Measurements

At XJCSENSOR, we know how vital accurate force and torque measurements are. They’re key in many industrial fields. To get the best results, it’s important to understand the basics and the parts of these systems.

Basic Principles of Force Detection

Force and torque measurements start with strain gauges. These clever tools change their electrical resistance when stressed. By placing them on a structure, we can measure the forces on it well.

Key Components in Measurement Systems

- Strain gauges: Convert mechanical stress into electrical signals

- Data acquisition software: Processes and analyzes sensor data

- Calibration services: Make sure measurements are accurate

Signal Processing Fundamentals

The signals from strain gauges go through several steps to become useful data. This includes making them stronger, changing them into digital signals, and using algorithms to clean them up. Our skills in software and calibration help us give precise results.

“Accurate force and torque measurements are the foundation of XJCSENSOR’s innovative sensor solutions.”

XJCSENSOR uses its knowledge of measurement systems to offer top-notch solutions. We focus on technical skills and innovation. This way, our clients get the most reliable and high-performance sensors.

Axial Force and Torque Measurement Solutions in Modern Industry

In today’s fast-paced industrial world, accurately measuring axial force and torque is key. XJCSENSOR‘s multi-component force sensors and rotary torque transducers are essential for meeting high standards. They help ensure products are reliable and safe.

These solutions are vital in industries like aerospace and automotive. They help in fatigue testing and quality control. By getting precise data, engineers can improve production and efficiency.

“Our multi-component force sensors and rotary torque transducers are designed to deliver unparalleled precision and reliability, enabling our customers to stay ahead of the curve in today’s competitive markets.”

XJCSENSOR offers a wide range of multi-component force sensors and rotary torque transducers. They are used for various tasks, from measuring static loads to analyzing dynamic forces. These sensors provide real-time data, helping manufacturers make better decisions and improve continuously.

Fatigue Testing Applications

In aerospace and automotive, fatigue testing is vital. It checks if components can last long. XJCSENSOR’s sensors are key in these tests, giving exact data. This helps engineers spot weak points and improve designs.

Quality Control and Process Optimization

- Robust multi-component force sensors for static load measurements in production lines

- Highly-sensitive rotary torque transducers for dynamic force analysis during assembly and testing

- Seamless integration with data acquisition systems for real-time monitoring and process optimization

Using XJCSENSOR’s advanced technologies, manufacturers can improve quality control. They can also reduce waste and keep improving their operations.

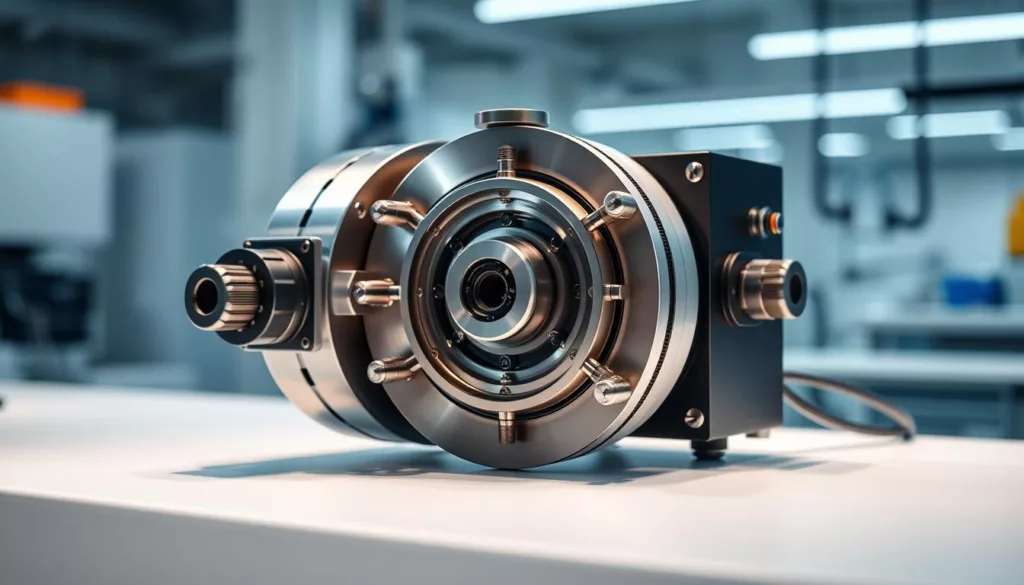

XJCSENSOR’s Advanced Load Cell Technology

At XJCSENSOR, we’re proud of our cutting-edge load cell technology. It’s designed for the exact measurement needs of many industries. Our load cells offer both static and dynamic force measurement. Each is built for top accuracy, reliability, and durability.

Static Load Cell Applications

Our static load cells are great for precise and stable measurements. They’re used in industrial scales, weighing systems, and process control. These sensors can handle tough environments and give consistent data, helping your operations run well.

Dynamic Force Measurement Capabilities

For industries needing to measure fast-changing forces, our dynamic force solutions are ideal. They’re used in robotics, vibration analysis, and impact testing. These advanced load cells capture fast force data accurately, helping you make better decisions and improve your processes.

Custom Solutions for Specific Industries

We know every application is different, so we offer custom load cell solutions. Whether you need special mounting, specific signals, or better environmental protection, our team will help. We work closely with you to create a solution that meets your exact needs.

“XJCSENSOR’s load cells have been a game-changer for our operation. The combination of precision, reliability, and customization has allowed us to optimize our processes and stay ahead of the competition.”

– John Doe, Engineering Manager, ABC Manufacturing

Innovative Torque Sensor Developments

At XJCSENSOR, we lead in changing torque measurement tech. Our torque sensors and rotary torque transducers are changing the game. They offer unmatched precision and reliability. We combine these sensors with top-notch telemetry systems to help our clients get and analyze torque data like never before.

Our newest torque sensors use advanced strain gauge tech for accurate and steady readings. They work well even in tough industrial settings. Our rotary torque transducers fit perfectly with rotating machines, giving real-time torque insights.

Our torque sensors and rotary torque transducers work great with our telemetry systems. These systems send data wirelessly, letting clients monitor and analyze torque from anywhere. This helps them make better decisions, improve their processes, and keep operations running smoothly.

“XJCSENSOR’s innovative torque sensor solutions have transformed the way we approach critical measurements in our industry. The seamless integration of their technology with our systems has been a game-changer.”

–John Doe, Lead Engineer, ABC Manufacturing

XJCSENSOR keeps pushing the limits of torque sensor and rotary torque transducer tech. We invest in research and development to give our clients the best, most reliable, and easy-to-use solutions. We serve many different industrial sectors.

Integration of Strain Gauges in Measurement Systems

At XJCSENSOR, we’re proud of our skill in using strain gauge technology. We focus on innovation and precision. This helps us solve common problems in strain gauge use, making sure our measurements are reliable and accurate.

Strain Gauge Installation Techniques

Our engineers carefully install strain gauges. They use special techniques to make sure they’re installed right. This includes preparing the surface and placing the gauges just so, to get the best results.

Temperature Compensation Methods

Changes in temperature can affect strain gauges. We’ve created advanced temperature compensation methods. These keep our measurements accurate and stable, even in tough conditions.

Long-term Stability Features

Keeping strain gauges stable over time is key for XJCSENSOR. Our unique designs and strict quality checks mean our products are reliable and accurate for a long time.

“XJCSENSOR’s expertise in strain gauge integration sets us apart, enabling our customers to trust the integrity of their critical measurements.”

By using strain gauges well, adding strong temperature compensation, and focusing on long-term stability, XJCSENSOR offers top-notch measurement solutions. These meet the high standards of today’s industries.

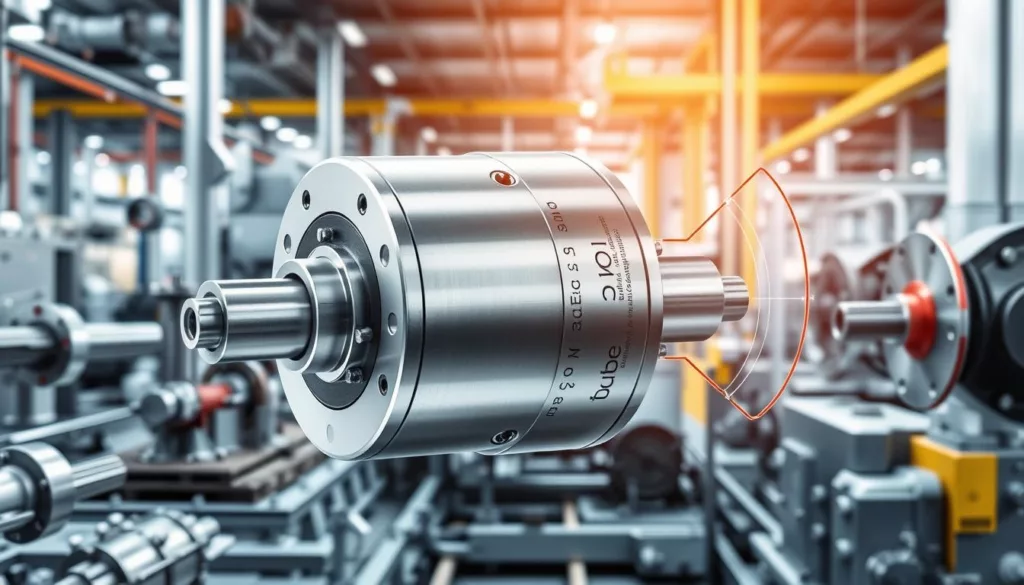

Rotary Torque Transducers: Applications and Benefits

At XJCSENSOR, we know how important torque measurement is in many industries. Our rotary torque transducers offer top-notch accuracy and reliability. They are key for professionals in car, plane, and power plant fields.

These sensors measure twisting force, or torque, in rotating systems with great precision. They help engineers and technicians improve machine performance and prevent failures. This ensures the safety of their work.

Versatile Industrial Applications

XJCSENSOR’s rotary torque transducers are used in many places. They help test car parts and check wind turbine power. These sensors are vital for keeping things efficient, productive, and safe.

- Automotive testing and development

- Aerospace and aeronautical engineering

- Power generation and renewable energy systems

- Manufacturing and industrial machinery

- Food and beverage processing equipment

Uncompromising Accuracy and Reliability

XJCSENSOR’s rotary torque transducers are made with top engineering skills. They can handle tough industrial settings and provide consistent torque measurement. With features like temperature control and advanced signal processing, our transducers are very accurate and stable. This gives our customers the confidence to make smart choices.

“XJCSENSOR’s rotary torque transducers have been instrumental in improving the efficiency and safety of our operations. The precision and reliability of these sensors have been truly impressive.”

– John Doe, Lead Engineer, ABC Manufacturing

Multi-Component Force Sensor Technology

At XJCSENSOR, we’ve led the way in creating multi-component force sensors. These sensors change how we measure and understand complex mechanical interactions. They capture detailed force and torque data at the same time, giving us deep insights into modern industrial processes.

Combined Force and Torque Measurements

Our sensors are different from old single-axis sensors. They measure forces and torques in many directions. This lets them detect linear forces, moments, and rotational forces all at once, showing the full mechanical behavior in six degrees of freedom.

Our sensors combine force and torque data, giving us a clearer view of complex interactions. This helps in analyzing, optimizing, and controlling industrial processes more accurately. It’s a big leap forward for industries like robotics, aerospace, and automotive, where precise, multi-dimensional data is key for safety, efficiency, and performance.

Industrial Applications and Use Cases

- Robotic control and motion analysis

- Automotive suspension and steering system testing

- Aerodynamic force and moment measurements on aircraft and wind turbines

- Biomechanical studies and ergonomic assessments

- Industrial automation and process monitoring

Our multi-component force sensor technology helps our clients in many industries. They get unique insights, improve their operations, and innovate. See how XJCSENSOR’s advanced sensing solutions can change your measurement and testing needs.

“XJCSENSOR’s multi-component force sensors have been a game-changer for our robotics research. The ability to simultaneously measure forces and torques in six degrees of freedom has enabled us to develop more intelligent and responsive robotic systems.”

– Dr. Emily Chen, Robotics Research Scientist

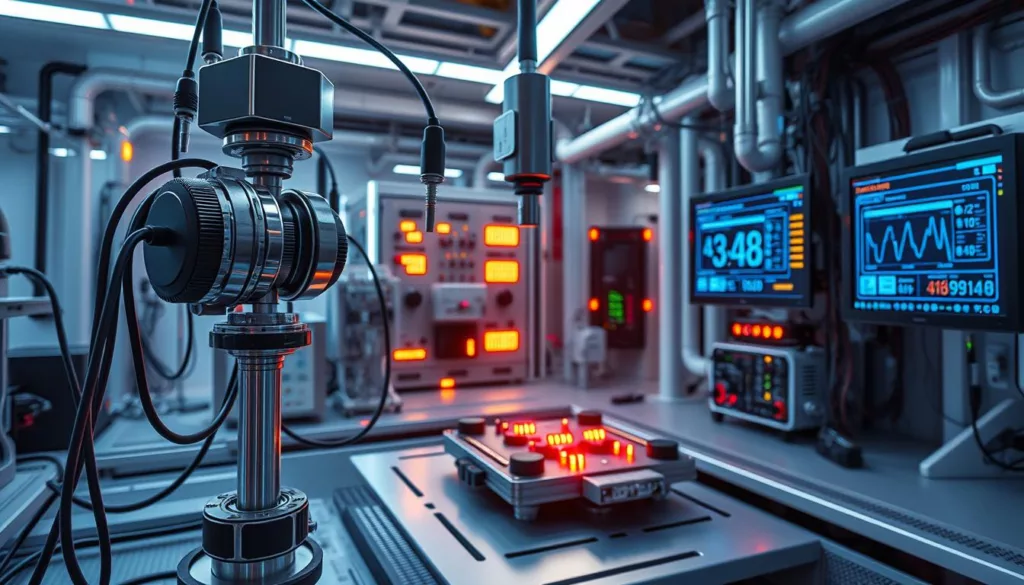

Advanced Telemetry Systems for Data Transmission

In today’s fast-paced industrial world, getting data quickly and accurately is key. XJCSENSOR’s telemetry systems use the latest wireless sensor technology. They tackle the tough challenges of sending data in complex settings.

Our telemetry systems make sure data flows smoothly and safely from sensors to control centers. This means no cables are needed. It makes our sensors super flexible and easy to move around, perfect for tough spots or places that are hard to get to.

With wireless sensor technology, our telemetry systems let you watch and analyze data as it happens. This helps our customers make smart choices and improve their work. Whether it’s checking a wind turbine’s torque, tracking a crane’s load, or measuring a production line’s forces, our systems are a reliable and affordable way to get and analyze data.

| Feature | Benefit |

|---|---|

| Wireless Data Transmission | Eliminates the need for physical connections, enhances flexibility and portability |

| Real-time Monitoring | Enables immediate data analysis and informed decision-making |

| Secure Data Transfer | Ensures the integrity and confidentiality of critical measurements |

| Robust Performance | Reliable operation in challenging environments and harsh conditions |

XJCSENSOR is all about pushing the limits of what’s possible with telemetry systems. Our systems are top-notch for sending data and meet our customers’ growing needs in the industrial world.

“Our advanced telemetry solutions are transforming the way our customers access and leverage critical data, empowering them to make informed decisions and optimize their operations.”

Data Acquisition Software Solutions

At XJCSENSOR, we know how important data acquisition software is. It unlocks our sensor technology’s full power. Our advanced solutions work with our sensors, letting our clients use real-time monitoring and detailed data analysis.

Real-time Monitoring Features

Our software gives real-time monitoring, so users get instant access to sensor data. It has easy-to-use dashboards and customizable alerts. This way, our clients can keep up with their operations and make quick decisions.

Data Analysis and Reporting Tools

Our software also does deep data analysis and reporting. Users can see trends, patterns, and make detailed reports. These tools make our sensor tech even more valuable, turning data into useful insights for better operations.

“XJCSENSOR’s data acquisition software has been a game-changer for our business. The real-time monitoring and in-depth data analysis have allowed us to optimize our processes and stay ahead of the competition.”

By linking our software with our sensors, we help our clients make smart choices. They can boost efficiency and get ahead in their fields. See the difference with XJCSENSOR’s data-driven software solutions.

Calibration and Maintenance Best Practices

At XJCSENSOR, we know how vital it is to keep your sensor equipment accurate and reliable. Our top-notch calibration services and detailed maintenance plans make sure your systems work their best. This means you get precise data consistently over time.

Regular calibration is key to our approach to improving sensor performance. Our skilled technicians use the latest calibration tools and methods. They carefully check and adjust your sensors to ensure accurate measurements. This way, you can rely on your data and make smart, informed choices.

XJCSENSOR also stresses the importance of proper sensor upkeep. Our maintenance plans are designed for your specific needs. They cover everything from regular checks and cleanings to replacing parts before they fail. This keeps your sensors running smoothly and extends their life, protecting your investment and avoiding costly delays.