Load cells are key in precise weight measurement. They are vital in many fields, from making things to moving goods. They help us measure weight accurately, last long, and protect against too much weight.

Load cells are great at accurate weight measurement. They can spot tiny changes in force. This is super important in places like food and medicine, where quality and rules depend on it.

Load cells are also durable. They can handle tough conditions and lots of use. This means they work well for a lot of tasks and don’t need much fixing, saving money and time.

Another big plus is overload protection. It keeps the system safe from too much weight. This is really helpful in places where unexpected weight can be dangerous.

Key Takeaways

- Load cells provide highly accurate weight measurement, ensuring reliable and consistent results.

- Robust and durable construction of load cells enables long-lasting performance and minimal maintenance.

- Overload protection feature in load cells safeguards the weighing system and its surroundings from possible damage.

- Load cells are versatile and suitable for a wide range of industries and weighing applications.

- The precise and reliable nature of load cells makes them essential components in modern weighing systems.

Understanding Load Cells and Their Functionality

At the heart of accurate weight measurement technology are load cells. These devices turn mechanical force into electrical signals. This makes it possible to collect precise data in many industrial settings. Knowing how load cells work is key to using them well in weighing systems.

What Are Load Cells?

Load cells are the main parts of weighing systems. They change physical force into electrical signals. They use strain gauge technology to measure how much they bend and turn this into a signal.

This lets load cells accurately show the weight or force on them. They are the base of reliable weight measurement.

How Do Load Cells Work?

Load cells have many parts that work together to measure weight. When force is applied, it bends the load cell’s parts. Strain gauges then measure this bending and turn it into electrical signals.

These signals are then made stronger by the load cell’s electronics. This makes the output easy for weighing or control systems to understand.

| Key Load Cell Components | Function |

|---|---|

| Strain Gauges | Convert mechanical deformation into electrical signals |

| Amplifiers | Boost the electrical output to a usable level |

| Analog-to-Digital Converters (ADCs) | Convert the analog electrical signals into digital data |

| Microprocessors | Interpret the digital data and provide the final weight measurement |

By understanding load cell functionality and how its parts work, we see their importance. They are key to accurate weight measurement technology in many industries.

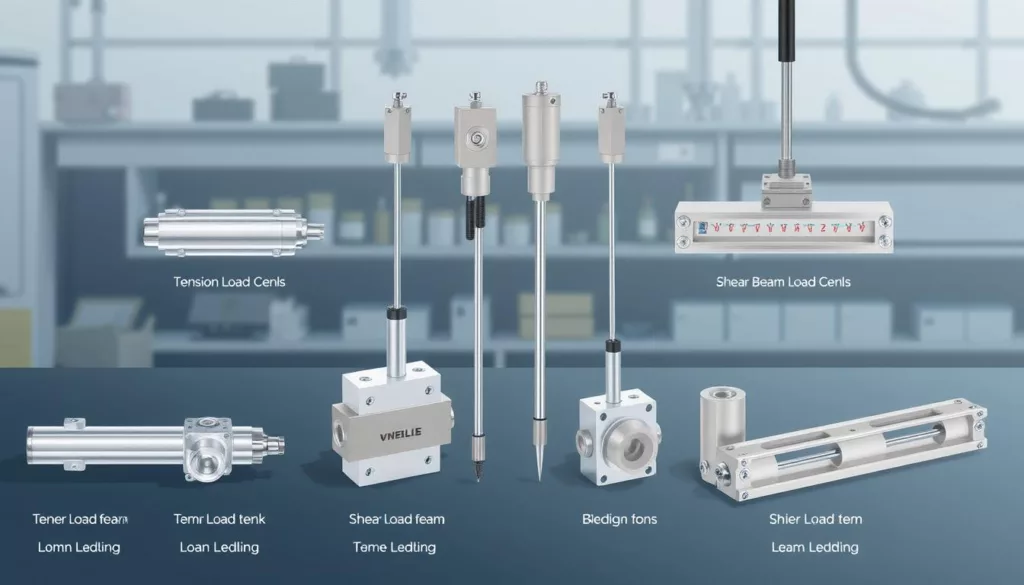

Different Types of Load Cells Available

There are many types of load cells for different weighing needs. Knowing what each type does is key to picking the right one. Let’s look at compression, tension, and shear beam load cells.

Compression Load Cells

Compression load cells measure forces that push down. They’re great for scales and systems where the load is on top. They’re strong and reliable, used in many industries.

Tension Load Cells

Tension load cells measure forces that pull up. They’re perfect for crane scales and bridges. They’re accurate for lifting and pulling forces.

Shear Beam Load Cells

Shear beam load cells measure both push and pull forces. They’re used in many scales and systems. Their design makes them versatile for different applications.

| Load Cell Type | Measurement Principle | Common Applications |

|---|---|---|

| Compression Load Cells | Measures compressive forces | Platform scales, floor scales, and other weighing systems with direct downward load |

| Tension Load Cells | Measures tensile forces | Crane-based weighing, suspension bridges, and other applications with suspended loads |

| Shear Beam Load Cells | Measures both compressive and tensile forces | Industrial scales, hopper scales, and other applications with side-applied loads |

Knowing about load cell types helps you choose the best for your needs. This ensures your system works well and accurately.

“The choice of load cell type is critical in ensuring the performance and reliability of your weighing system.”

Advantages of Load Cells Over Traditional Weighing Methods

Load cells are a top choice for accurate weight measurement and reliable weighing systems. They offer many benefits over traditional methods. This makes them ideal for various industries and uses.

Increased Accuracy

Load cells are known for their high accuracy. They use advanced strain gauge technology for precise measurements. This is key in industries like pharmaceuticals, food processing, and manufacturing, where small weight changes matter a lot.

Enhanced Reliability

Load cells are also very reliable. They can handle tough environments and heavy loads without breaking. This means you can trust the weight measurements they give, reducing errors and equipment failures.

| Characteristic | Traditional Weighing Methods | Load Cells |

|---|---|---|

| Accuracy | Moderate | Excellent |

| Reliability | Variable | Consistently High |

| Durability | Limited | Robust and Long-lasting |

| Maintenance Requirements | Frequent | Minimal |

The table shows the main differences between traditional methods and load cells. Load cells clearly outperform in accuracy, reliability, durability, and maintenance needs.

“The use of load cells has revolutionized the way we approach accurate weight measurement in our industry. The consistency and precision they provide have been instrumental in improving our overall process efficiency.”

– John Doe, Operations Manager at ABC Manufacturing

Using load cells can make weight measurements more accurate and reliable. This leads to better process control, improved product quality, and more efficient operations.

Applications of Load Cells in Various Industries

Load cells are key in many industries. They help ensure quality, efficiency, and precision. These devices are used in food and beverage, pharmaceutical, and manufacturing sectors. They show their value in many commercial and industrial uses.

Food and Beverage Industry

In the food and beverage world, load cells are vital. They help keep quality high and production smooth. They check the weight of containers and ingredients, making sure products are consistent.

They also help in mixing and blending. This ensures the right amounts of ingredients for each product.

Pharmaceutical Sector

The pharmaceutical industry needs accurate and reliable load cells. They are used at every stage of drug making. From weighing raw materials to checking finished products, load cells are essential.

They help keep records accurate and follow rules. This ensures drugs are safe and work well.

Manufacturing and Industrial Use

In manufacturing and industry, load cells are vital. They handle industrial applications and commercial measurement tasks. They measure weights in assembly lines and quality checks.

They also help in warehousing and logistics. Load cells weigh pallets and containers, making shipping easier.

Load cells are essential in many fields. They boost efficiency, quality, and productivity. As technology grows, so will the use of load cells, making them even more important.

Factors to Consider When Choosing a Load Cell

When picking a load cell for your weighing system, several key factors come into play. These factors ensure the load cell fits your application’s needs and works accurately.

Capacity and Range

First, figure out the weight capacity and range you need. Think about the maximum weight your application will handle. Choose a load cell that can safely manage this weight and offers the precision you need. A load cell that’s too small or too large can affect your system’s accuracy and reliability.

Environmental Conditions

The environment where the load cell will operate is critical. Consider factors like temperature, humidity, vibration, and chemical exposure. Load cell selection criteria must include an evaluation of these environmental factors. This ensures the load cell can perform well in its conditions without losing accuracy or durability.

Accuracy and Sensitivity

The accuracy and sensitivity needed vary by application. For example, industries like pharmaceuticals or food processing require very precise measurements. Think about your system’s intended use and choose a load cell that matches your needs for accuracy and sensitivity.

| Criteria | Considerations |

|---|---|

| Capacity and Range | – Anticipated maximum weight – Required measurement precision |

| Environmental Conditions | – Temperature range – Humidity levels – Vibration and shock resistance – Exposure to chemicals or contaminants |

| Accuracy and Sensitivity | – Industry-specific requirements – Desired level of measurement precision |

By carefully considering these factors, you can find the best load cell for your system. This ensures your system performs well, reliably, and offers long-term value.

Integration of Load Cells into Weighing Systems

Companies are looking to make their weighing systems more accurate and reliable. They find that adding load cells is key. Load cells are easy to add to systems, making upgrades simple.

Compatibility with Existing Equipment

Load cells work well with many types of equipment. They fit on scales, balances, and industrial systems. This makes it easy to update systems without big changes.

Calibration Process

Calibration is vital for load cells to work right. It adjusts the load cell to match a known weight. This step is important for industries that need exact weights, like food and pharmaceuticals.

Calibrating load cells involves a few steps:

- Place the load cell in the system.

- Use a known weight to adjust the load cell.

- Check the system’s accuracy by testing it often.

Following these steps ensures that load cells work well together. This means consistent and reliable measurements for businesses.

| Compatibility Factors | Considerations |

|---|---|

| Platform Type | Scales, balances, industrial weighing systems |

| Mounting Requirements | Compression, tension, or shear beam load cells |

| Electrical Interfaces | Analog, digital, or wireless connections |

| Calibration Protocols | Standardized procedures for accurate measurements |

“By seamlessly integrating load cells into our weighing systems, we have been able to achieve unparalleled accuracy and reliability, ensuring our operations run smoothly and efficiently.”

– Jane Doe, Manufacturing Engineer

Maintenance and Care Tips for Load Cells

Keeping your load cells in good shape is key to their long-term performance. By following a few simple steps, you can extend their life and keep them accurate. This is important for your weighing systems.

Regular Inspection Procedures

Regular checks are the first step in load cell care. We suggest looking over your load cells monthly for damage, wear, or corrosion. Also, do calibration checks often to make sure they’re measuring right.

- Visually inspect load cells for cracks, dents, or other physical damage

- Check for signs of corrosion or environmental wear and tear

- Perform calibration checks according to the manufacturer’s recommendations

- Maintain detailed maintenance logs to track inspection and calibration history

Common Issues and Troubleshooting

Load cells can face problems that might affect their work. By tackling these issues quickly, you can avoid downtime and keep your system running smoothly. Here are some common problems and how to fix them:

- Zero Drift: If the load cell’s zero reading changes, try recalibrating it. Also, check for mechanical or environmental factors that might be causing the issue.

- Sensitivity Loss: If the load cell’s sensitivity drops, look at the electrical connections. Check for damage and consider replacing the load cell if needed.

- Unstable Readings: Fluctuating readings might be due to electrical noise, vibrations, or bad installation. Make sure the load cell is properly shielded, grounded, and isolated.

By sticking to these maintenance and troubleshooting tips, you can keep your load cells working well. This will help avoid costly downtime and keep your weighing systems accurate.

Innovations in Load Cell Technology

The world of load cell technology is changing fast. New advancements bring more precision and connectivity. Wireless load cells and smart IoT-enabled systems are leading this change. They are changing how we measure force in many industries.

Wireless Load Cells

Wireless load cells are making a big impact in the weighing industry. They get rid of the need for cables and make setup easier. These sensors use radio frequency or Bluetooth to send data without wires.

This makes them flexible and useful in many areas. They are great for industrial use and even in medical devices. They offer convenience and easy setup.

Smart Load Cells with IoT Capabilities

The future of load cells is all about IoT. Smart load cells have advanced sensors and wireless tech. They are part of IoT-enabled systems that monitor data in real-time.

These systems also do predictive maintenance and let you access data from anywhere. They help industries work better, be more efficient, and make smarter choices with precise data.

| Feature | Wireless Load Cells | IoT-Enabled Load Cells |

|---|---|---|

| Connectivity | RF or Bluetooth | Wireless, Cloud-based |

| Data Transmission | Real-time wireless data transfer | Continuous data monitoring and analysis |

| Flexibility | Easy installation, no physical connections | Remote access and control |

| Optimization | Streamlined weighing processes | Predictive maintenance, process optimization |

As more industries use these new technologies, load cell use will grow a lot. This will help companies be more precise, efficient, and make better decisions with data.

“The integration of IoT and smart technology into load cell systems is a game-changer, allowing us to unlock new levels of performance and data insights that were previously unattainable.”

Cost-Effectiveness of Load Cells in Weighing Systems

Load cell technology is changing the game for effective weighing solutions. It offers cost-effective weighing solutions that are precise and reliable. This helps businesses save money in the long run and work more efficiently.

Long-term Savings

At first, load cell systems might seem more expensive than old methods. But, their durability and accuracy save a lot of money over time. They need less maintenance and replacement, which means big savings on labor and parts.

Reduced Operational Costs

- Improved efficiency in production, logistics, and inventory management processes

- Reduced waste and product loss due to precise weight measurements

- Enhanced data accuracy for better decision-making and cost optimization

- Seamless integration with automated systems for streamlined operations

| Metric | Traditional Weighing | Load Cell-based Weighing |

|---|---|---|

| Accuracy | ±0.5% | ±0.1% |

| Maintenance Frequency | Monthly | Yearly |

| Operational Efficiency | Moderate | High |

Investing in load cell technology can save businesses money in the long run. It boosts their operational efficiency and gives them a competitive edge in the market.

“Load cell-based weighing systems have revolutionized the way we approach industrial and commercial weighing. The precision, reliability, and cost-effectiveness of this technology are unparalleled.”

Future Trends in Load Cell Usage

The demand for precise and efficient weighing systems is on the rise. This is making the future of load cell technology look very promising. One big trend is the growth of automated weighing systems. These systems use advanced load cells for easy, hands-free measurements in many industries.

Growth in Automated Weighing Systems

Automated weighing solutions, driven by new load cell technology, are becoming more popular. They are used in manufacturing, logistics, and food processing. These systems combine load cells with computer systems for real-time data and precise monitoring.

By automating weighing, businesses can work better, make fewer mistakes, and be more efficient. This helps them improve their overall performance.

Focus on Sustainability and Eco-friendliness

The load cell industry is also moving towards sustainable and eco-friendly solutions. Companies are working on load cells that use less energy and are made from green materials. This supports the global push for greener technologies and helps address environmental issues in different sectors.