In today’s competitive manufacturing world, quality, efficiency, and cost are key to success. Tension sensors are changing the game, bringing many benefits to the industry. They are making manufacturing operations more effective and efficient.

Tension sensors are vital in modern manufacturing. They monitor and control web-based processes in real-time. This includes textiles, paper, foils, films, and more. By managing tension, these sensors help maintain quality and boost efficiency.

This article will show you the many benefits of using tension sensors in manufacturing. We’ll cover how they improve quality, reduce costs, and enhance efficiency. Discover how these sensors can transform your operations.

Key Takeaways

- Tension sensors provide real-time monitoring and control of web-based manufacturing processes.

- They enable manufacturers to maintain optimal process conditions and improve product quality.

- Tension sensors can lead to cost reduction, resource optimization, and enhanced production efficiency.

- These sensors contribute to improved process control, automation capabilities, and data-driven decision making.

- Utilizing tension sensors can result in material waste reduction and greater sustainability in manufacturing.

Understanding Tension Sensors and Their Role in Modern Manufacturing

Tension sensors are key in today’s manufacturing. They help improve how things are made and the quality of products. These tools let makers check and control tension levels. This helps them work better and make products that are consistent and top-notch.

Basic Principles of Tension Measurement

Tension sensors find out how much force is on a material like a web or wire. They do this as it goes through a making process. By knowing this, makers can make sure the material is treated right. This lowers the chance of mistakes, waste, and damage to machines.

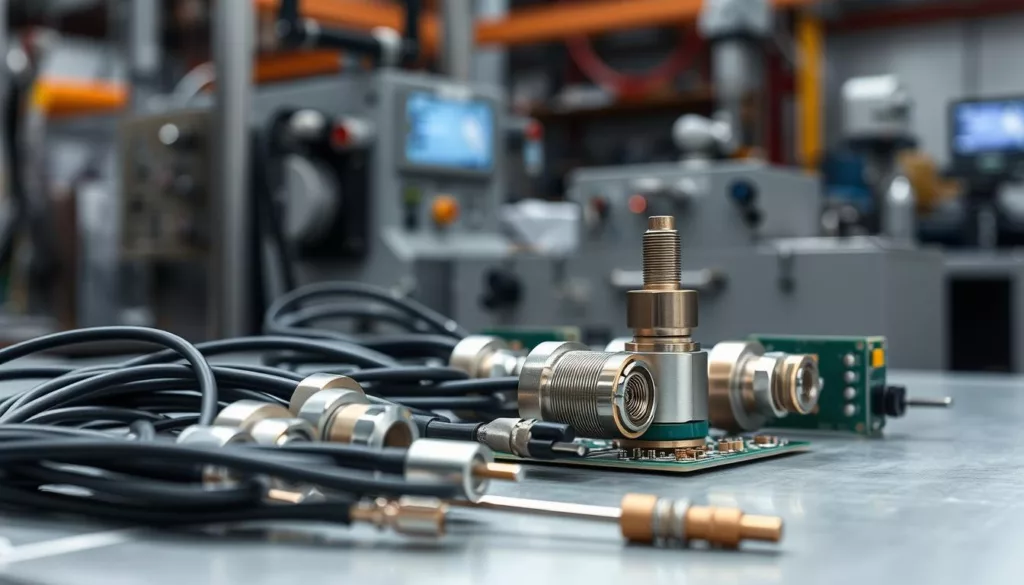

Types of Tension Sensors Available

- Load cells: Measure the force or weight acting on a surface, providing precise tension data.

- Dancer rollers: Detect changes in material tension by monitoring the position of a freely-moving roller.

- Strain gauges: Measure the deformation of a material to determine the tension being applied.

- Optical sensors: Utilize light-based technology to non-invasively monitor tension without physical contact.

Key Components and Installation Requirements

Good tension sensor systems have sensors, processing units, and control parts. Putting them in right and calibrating them is key. This makes sure the tension is measured right. This helps make things faster and better in the making process.

| Tension Sensor Component | Purpose |

|---|---|

| Sensing element | Directly measures the tension force |

| Signal processing unit | Converts the sensor’s output into a usable data signal |

| Control interface | Allows for monitoring, adjustment, and integration with other systems |

“Accurate tension measurement is the foundation for achieving enhanced product quality and increased production efficiency in modern manufacturing.”

Benefits of Using Tension Sensors in Manufacturing

Tension sensors bring many benefits to modern manufacturing. They help improve production efficiency and quality. These sensors monitor tension levels in real-time, making machines work better and products better too.

One big plus of tension sensors is keeping product standards consistent. They watch tension levels and alert when they change. This helps manufacturers fix quality issues fast, keeping output reliable.

Also, tension sensors help with advanced control and automation. They work well with current systems, using smart control and feedback. This boosts equipment effectiveness and cuts down on unplanned stops.

Another great thing is less material waste and better sustainability. By controlling tension, manufacturers use materials better, cutting down on scrap. This saves money and helps the environment.

Tension sensors give manufacturers valuable data for better decisions. They help spot trends, solve problems, and plan for maintenance. This makes operations more reliable and productive over time.

“Tension sensors have been instrumental in taking our manufacturing processes to new levels of efficiency and quality. The real-time monitoring and optimization capabilities have truly transformed the way we operate.”

– Jane Doe, Production Manager, ABC Manufacturing

Enhanced Production Quality Through Real-Time Monitoring

In today’s manufacturing world, enhanced product quality is essential, not just a bonus. Tension sensors are key, helping to monitor production in real-time. They make sure products meet high standards consistently.

Maintaining Consistent Product Standards

Companies place tension sensors along the manufacturing line. This lets them keep an eye on material and product tension. They can spot and fix any quality issues right away, keeping quality high.

Detecting Quality Issues Before They Escalate

Tension sensors serve as an early alert system. They warn of quality problems before they start. This way, manufacturers can fix issues early, avoiding defects and waste.

Quality Assurance Automation

- Tension sensors work with automated quality control systems, making checks easier and faster.

- These systems can adjust the process on the fly, ensuring products are always up to standard.

- This automation boosts quality and makes the whole process more efficient.

Using tension sensors, manufacturers can reach new heights in enhanced product quality. This is thanks to real-time monitoring and improved process control. This approach not only saves money but also builds customer trust and strengthens the brand.

Cost Reduction and Resource Optimization

Manufacturers looking to cut costs and boost profits can benefit from tension sensors. These sensors are key in reducing material waste, boosting production efficiency, and improving machine performance. All these help save a lot of money.

Tension sensors keep an eye on tension levels in manufacturing. This helps cut down on material waste. It’s good for the planet and saves money for businesses. It also means better use of raw materials, fewer product flaws, and higher production rates.

Also, tension sensors give real-time data to improve production efficiency. They spot problems early, keeping product quality high and avoiding costly stops. This leads to more products made and better machine performance.

“Tension sensors are a game-changer in modern manufacturing, helping us reduce material waste, maximize efficiency, and optimize our production processes. The cost savings and improved profitability are truly transformative.”

Adding tension sensors to automated systems is a smart move for manufacturers. It brings real benefits like a competitive edge, better sustainability, and top-notch operations.

Improved Process Control and Automation Capabilities

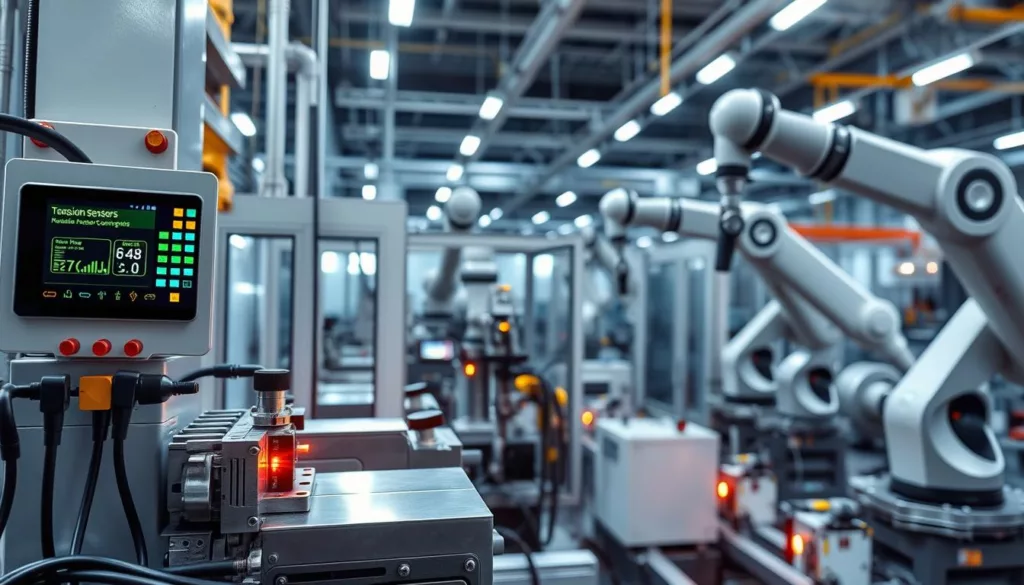

Tension sensors are key in making manufacturing better. They work with current systems to give valuable data. This helps manufacturers make their production more efficient and control their processes better.

Integration with Existing Manufacturing Systems

Adding tension sensors to current systems is a big step. They can fit into old equipment easily. This makes it easier and cheaper to use their advanced features.

Advanced Control Algorithms and Feedback Loops

Tension sensors use smart algorithms and feedback loops. They watch and adjust the process in real time. This keeps product quality high and reduces downtime or defects.

This smart way of controlling the process boosts production efficiency. It also makes the whole operation better.

Remote Monitoring and Control Features

“The ability to remotely monitor and control our manufacturing processes has been a game-changer for our business. Tension sensors have provided us with the insights and control capabilities we need to streamline our operations and make data-driven decisions.”

Remote monitoring and control with tension sensors make things even better. Managers and engineers can check and change important settings from anywhere. This lets them make quick decisions and solve problems fast.

This level of control makes the manufacturing process more efficient and flexible.

Preventing Equipment Downtime and Maintenance Benefits

Adding tension sensors to manufacturing can greatly help avoid equipment downtime and improve maintenance. These sensors are key in preventive maintenance. They help manufacturers spot and fix problems before they cause big issues or stop production.

Tension sensors watch the tension in important parts and warn of upcoming problems. This lets manufacturers plan maintenance ahead of time. This way, they keep machine performance at its best and cut down on unplanned stops. It makes production more efficient and helps equipment last longer.

Also, tension sensors help find the main reasons for frequent maintenance needs. This lets manufacturers fix the real problems, not just the symptoms. It saves money by reducing material waste from failures and makes maintenance smoother.

“Integrating tension sensors into our manufacturing processes has been a game-changer in terms of reducing downtime and optimizing our maintenance practices. The real-time data has allowed us to anticipate issues and address them proactively, leading to significant improvements in our overall operational efficiency.”

– John Smith, Plant Manager at ABC Manufacturing

| Benefit | Impact |

|---|---|

| Preventive Maintenance | Early detection of problems, so we can fix them before they cause big issues or stop production. |

| Optimized Machine Performance | Keeping an eye on and adjusting tension levels to ensure quality and productivity stay high. |

| Reduced Material Waste | Less equipment failures and waste, making our manufacturing more sustainable and cost-effective. |

Using tension sensors helps manufacturers make their equipment more reliable and last longer. This leads to better preventive maintenance, optimized machine performance, and less material waste.

Material Waste Reduction and Sustainability Impact

Tension sensors in manufacturing are changing the game for the environment. They help cut down on waste and make production greener. This is thanks to their ability to monitor material tension accurately.

Optimizing Material Usage

Tension sensors give real-time info on material strain. This lets manufacturers tweak their methods for better material use. It’s all about using less and wasting less, making production more efficient.

Environmental Benefits and Compliance

Using less material thanks to tension sensors is good for the planet. It means less raw material needed, which cuts down on carbon emissions and energy use. Plus, it helps companies follow environmental rules better.

Cost Savings Through Waste Reduction

There’s also a big financial win from using tension sensors. With less waste, companies save money on raw materials and disposal. This boosts their bottom line and makes them more profitable.

| Key Benefits | Description |

|---|---|

| Optimized Material Usage | Tension sensors provide real-time data to fine-tune processes and reduce raw material consumption. |

| Environmental Sustainability | Decreased material demand leads to a lower carbon footprint and improved compliance with sustainability regulations. |

| Cost Savings | Waste reduction directly translates to lower operational expenses and enhanced profitability. |

By using tension sensors in manufacturing, companies can cut down on waste. This boosts their green efforts and saves money. It’s a win-win for the planet and their bottom line.

Data-Driven Decision Making and Performance Analytics

In the fast-paced world of manufacturing, data is key to getting better and staying ahead. Tension sensors are essential for this, helping companies use real-time data for data-driven insights, improved process control, and optimized machine performance.

By using sensor data, companies can see their production in new ways. They can spot trends and problems early. This lets them make smart choices, improve their work, and boost quality and productivity.

- Enhanced Process Control: Tension sensors give constant updates on material tension. This improved process control means better product quality, less waste, and fewer defects.

- Performance Optimization: Sensor data helps find ways to make machines work better. This includes the best tension settings, when to do maintenance, and how to save energy. It all adds up to more efficiency, less downtime, and better equipment use.

- Predictive Maintenance: By watching sensor data, companies can see when equipment might fail. This lets them fix things before they break, saving time and money. It also helps machines last longer.

Tension sensor data is changing the game in manufacturing. It helps companies make smarter choices, control their processes better, and make machines work their best. This leads to growth and staying competitive.

“Tension sensors are the unsung heroes of data-driven manufacturing, providing the critical insights that drive continuous improvement and innovation.”

Industrial Applications and Success Stories

Tension sensors in manufacturing are not just ideas. They have been used in real-world settings across many industries. By looking at case studies and success stories, we learn how these sensors boost production efficiency and quality.

Case Studies from Various Industries

In the automotive world, a top car maker used a cutting-edge tension monitoring system. This system helped them control material tension better. As a result, they cut down on waste, made products more consistent, and sped up production. This led to a 15% increase in production efficiency.

In the textile field, a big fabric maker used tension sensors to improve weaving. They kept an eye on and adjusted tension to reduce defects and maintain quality. This effort led to a 12% jump in first-pass yield and a 20% cut in downtime.

Implementation Challenges and Solutions

- One big challenge is fitting tension sensors into existing systems. Companies have overcome this by teaming up with sensor makers. Together, they create custom solutions that use Industry 4.0 tech and smart algorithms.

- Another issue is making sure sensors are placed and set up right for accurate readings. Getting help from skilled sensor techs and following best practices is key.

- It’s also important to train operators and maintenance teams well. Companies that focus on user education and support see better results in the long run.

Real-world examples and insights show the real benefits of tension sensors for manufacturers. They help improve efficiency, quality, and sustainability. By tackling common problems and using top-notch expertise, companies can fully benefit from these advanced technologies.

Conclusion

The use of tension sensors in manufacturing has changed the game. They improve product quality, control processes better, and make operations more efficient. These advanced sensors are key for industries wanting to lead in a competitive world.

Tension sensors help keep product standards consistent and automate quality checks. They allow for real-time monitoring and adjustments of critical processes. This leads to lower costs, better resource use, and less waste, making manufacturing more sustainable and profitable.

As Industry 4.0 keeps growing, tension sensors will play a bigger role. They help make data-driven decisions and improve performance. By working with current systems, they offer insights for better process improvements and planning. The future looks bright for tension sensors in changing how industries produce, ensure quality, and excel in operations.