The manufacturing world is changing fast. Advanced automation technologies are key to staying ahead. Torque sensors are at the center of these changes. They help improve precision, quality, and efficiency in many industries.

In this guide, we’ll look at the many advantages of using torque sensors. We’ll share our knowledge of sensor technology to help you understand their value.

Key Takeaways

- Torque sensors enhance precision and control in automated processes, enabling optimal performance

- Accurate torque measurements facilitate quality assurance and minimize production variations

- Torque monitoring features improve equipment safety and provide overload protection

- Real-time data integration and analysis enable process optimization and predictive maintenance

- Torque sensor implementation can lead to significant energy savings and cost reductions

Understanding Torque Sensors and Their Role in Modern Automation

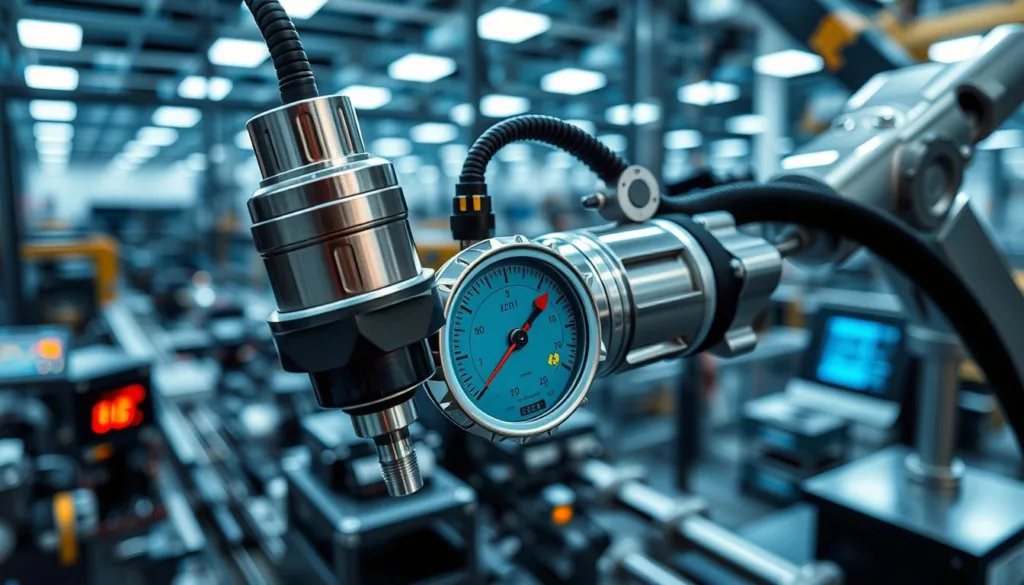

Torque sensors are key in industrial automation. They help engineers and manufacturers measure twisting forces on machinery. Knowing how they work and their parts is essential for their use.

Basic Principles of Torque Measurement

Torque measurement is about twisting force, or torque measurement principles. These sensors measure rotational forces. They give insights into how machines work.

Types of Torque Sensors in Industrial Applications

There are many types of torque sensors for different needs. They range from strain gauge to optical and electromagnetic. Choosing the right one depends on the application.

Key Components and Functionality

Every sensor has special parts that work together. These parts are key to measuring torque well. The design of these parts affects the sensor’s performance.

| Sensor Type | Measurement Range | Accuracy | Durability |

|---|---|---|---|

| Strain Gauge Torque Sensor | 0.1 to 1,000 N-m | ±0.1% to ±1% of full scale | Suitable for harsh environments |

| Optical Torque Sensor | 0.01 to 100 N-m | ±0.1% to ±0.5% of full scale | Immune to electromagnetic interference |

| Electromagnetic Torque Sensor | 0.1 to 10,000 N-m | ±0.2% to ±1% of full scale | High-speed and high-torque applications |

Knowing about torque sensors helps us use them better in automation. This leads to more efficiency and quality in many industries.

Benefits of Using Torque Sensors in Automation

Adding torque sensors to automated systems brings many benefits. It changes how industries work and boosts productivity. These advantages of torque sensors go beyond just measuring accurately. They open up new ways for automation benefits and industrial sensor applications.

One key benefit is precise process control. Torque sensors help keep critical components at the right settings. This means less variation in production and better quality. This precision is key in many industrial sensor applications, like assembly and packaging.

- Improved quality assurance through accurate torque measurement

- Enhanced equipment safety and protection against overloads

- Real-time data monitoring for process optimization

Torque sensors are also vital for predictive maintenance strategies. They help spot problems early, before they get worse. This way, manufacturers can fix issues quickly, cutting down on downtime and boosting efficiency.

The perks of torque sensors in automation go beyond just being more productive. They help save energy and cut costs by using power more wisely. The investment in torque sensors can pay off big time, making it a smart choice for modern factories.

In short, torque sensors in automation offer many benefits. They improve process control, quality, safety, and maintenance. They also help save energy and money. By using these industrial sensor applications, manufacturers can reach new heights of productivity and savings.

Precise Torque Measurement for Enhanced Production Control

Accurate torque measurement is key in today’s automation. It’s the base for better production control and quality. Precise torque measurement helps makers set up their equipment right. This leads to less variation in production and better quality products.

Achieving Optimal Torque Settings

With top-notch torque sensors, makers can set the right torque levels for their machines. This makes the machines work better and last longer. It also saves money and boosts productivity.

Minimizing Production Variations

Keeping torque measurement consistent is vital for tight production control. Torque sensors give real-time data. This lets operators spot and fix any issues fast. It cuts down on waste, rework, and downtime.

Quality Assurance Through Accurate Measurements

Using precise torque sensors in making helps with strict quality assurance. Makers can check if their products meet high standards. This ensures every product is reliable and performs well.

“Accurate torque measurement is the backbone of effective production control, empowering manufacturers to optimize equipment, minimize variations, and deliver consistently high-quality products.”

Advanced torque sensing technology opens up new ways for better production. It brings more efficiency, quality, and savings. It also pushes for ongoing improvement in operations.

Equipment Safety and Overload Protection Features

In the world of industrial automation, equipment safety is key. Torque sensors are vital for safety and protecting against overloads. They watch torque levels in real-time, spotting problems early to avoid damage and downtime.

Torque sensors help prevent overloads. If a machine gets too much torque, the sensor alerts or stops it. This keeps equipment and workers safe.

Also, torque sensors aid in maintenance. They track data to show when parts need fixing. This leads to safer and more reliable equipment.

| Safety Feature | Description |

|---|---|

| Overload Detection | Sensors detect excessive torque levels and trigger alerts or automatic shutdowns to prevent equipment damage. |

| Preventive Maintenance | Continuous torque monitoring enables early identification of wear and tear, allowing for proactive maintenance scheduling. |

| Torque Limiting | Sensors can be integrated with control systems to limit torque and prevent overloading of critical components. |

Torque sensors help keep equipment safe and workers healthy. They prevent expensive failures and ensure a safe work environment. This is key for a productive and safe industrial setting.

“Torque sensors are the unsung heroes of industrial safety, proactively protecting valuable equipment and ensuring the well-being of our workforce.”

Real-Time Data Monitoring and Process Optimization

At XJCSENSOR, we know how important real-time data monitoring is in automation. Torque sensors are key in giving insights to improve your industrial processes. They help us find new ways to be more efficient and productive.

Data Collection and Analysis

Our torque sensors capture precise, real-time measurements. They can be easily added to your data analytics system. With advanced algorithms and machine learning, we turn this data into useful insights. This lets you adjust your processes, spot problems, and make smart decisions.

Integration with Industrial IoT Systems

We make it easy to connect your torque sensors with Industrial IoT systems. This gives you a complete view of your operation. You can track important performance indicators and get alerts for any issues.

Performance Tracking and Reporting

Tracking and reporting performance is key for lasting improvements. Our solutions offer detailed reporting. This lets you see trends, find ways to improve, and show the results to others. With this insight, you can make better decisions and keep improving your processes.

Discover the full power of your automation with XJCSENSOR’s torque sensors. Improve your production control, quality assurance, and reach new levels of excellence.

“Integrating real-time torque data into our operations has empowered us to make data-driven decisions that have significantly improved our productivity and cost-effectiveness.”

– John Doe, Manufacturing Manager

Implementing Predictive Maintenance Strategies

In the fast-paced world of automation, predictive maintenance is changing the game. It helps industries run better and make their equipment more reliable. At the core of this strategy are torque sensors, which give vital information about how well automated systems are working.

By watching torque data in real-time, companies can spot when equipment might fail. This lets them fix things before they break down. It makes equipment more reliable and cuts down on maintenance costs by avoiding unexpected stops and costly fixes.

Predictive Maintenance Techniques

- Trend analysis of torque data to identify patterns and anomalies that indicate possible issues

- Predictive algorithms that use sensor data to forecast equipment failures and plan maintenance

- Integrated IoT systems that collect, analyze, and report on torque data for proactive maintenance decisions

Using these predictive maintenance methods, companies can greatly improve equipment reliability, reduce maintenance costs, and boost their overall efficiency. The insights from torque sensors help leaders make smart choices that keep their automated systems running well for longer.

“Predictive maintenance strategies, powered by torque sensors, are revolutionizing the way industries approach equipment maintenance, leading to improved reliability and substantial cost savings.”

As predictive maintenance keeps getting better, torque sensors will be key in shaping the future of automation and efficiency. By taking this proactive step, companies can stay ahead and get the most out of their automated systems.

Energy Efficiency and Cost Savings Through Torque Monitoring

Using torque sensors in your automation can lead to big energy savings and cost cuts. They help you control power use and lower expenses. This boosts your return on investment (ROI).

Power Consumption Optimization

With accurate torque measurement, you can spot where to cut power use. Keeping torque levels right helps avoid waste and keeps your gear running smoothly. This cuts energy bills and helps the planet.

Reducing Operating Costs

- Prevent equipment damage and unplanned downtime through early detection of torque-related issues.

- Streamline maintenance schedules by monitoring real-time torque data, leading to proactive interventions and reduced repair costs.

- Optimize production workflows and enhance process control, ultimately driving down operational expenditures.

ROI Analysis of Torque Sensor Implementation

Doing a detailed ROI analysis shows the financial gains of using torque sensors. They save on energy, maintenance, and boost production. This makes the investment in torque monitoring worth it in the long run.

“Implementing torque sensors has allowed us to achieve a 15% reduction in our energy consumption and a 20% decrease in overall operating costs. The ROI analysis clearly showed the significant financial benefits of this investment.”

By using torque monitoring, you can save energy, cut costs, and improve your ROI. As a leader in sensor tech, we’re here to help your business thrive.

Quality Control and Process Validation

At XJCSENSOR, we know how important quality control assurance and process validation are. They keep manufacturing consistency high in industrial settings. Our torque sensors help make sure products meet top standards.

Our torque sensors help manufacturers keep their quality high. They make sure machines work right and catch problems early. This keeps manufacturing consistency strong.

- Ensuring optimal torque settings for machinery and equipment to minimize variations in output quality

- Validating production processes through continuous monitoring and data analysis

- Identifying and addressing possible issues before they get worse, keeping manufacturing consistency steady

Our sensors give accurate data in real-time. This helps manufacturers make smart choices and keep their products top-notch. By using our solutions, they can be sure their products are of the highest quality.

“Torque sensors are key to our goal of making products better. They give us the data we need to improve our processes and keep our output consistent and reliable.”

– [Name, Title] at [Company]

At XJCSENSOR, we’re all about helping our customers improve their quality control assurance and process validation. Our advanced torque measurement tech helps them keep their products at the highest quality and consistency.

Conclusion

We’ve seen how torque sensors change the game in automation. XJCSENSOR’s torque sensors are key, giving exact feedback in real-time. This boosts production control, keeps equipment safe, and saves energy.

As tech gets better, torque sensors will play an even bigger role. They help with better process checks and maintenance plans. They also lead to deeper insights and improvements in many industries. By choosing top-notch torque sensors, companies can lead the way in performance, cost-cutting, and green operations.

To wrap it up, using torque sensors in automation is essential for success today. These tools help manufacturers achieve higher precision, safety, and efficiency. This sets them up for growth and staying competitive in a fast-changing market.