When it comes to compact, accurate, and robust force measurement, nothing quite matches the efficiency of the button load cell. This small but mighty component plays a pivotal role in high-precision industries, where space constraints collide with the need for reliability. From robotic arms in manufacturing lines to surgical instruments in hospitals, button load cells are transforming how we measure and interact with applied forces.

Let’s dive deep into the nuts and bolts of this force-sensing marvel.

Introduction to Button Load Cell

The button load cell is not a new entrant in the sensor market, but its rising popularity across industries marks its evolutionary significance. Unlike bulkier load cells, button versions are discreet and capable of measuring large forces within a confined space. They thrive where space, aesthetics, or integration needs are tight.

This trend is driven by the relentless push toward miniaturization in robotics, medical devices, consumer electronics, and automotive systems—where every millimeter counts. Manufacturers are continually investing in refining button load cell designs to make them smarter, smaller, and stronger.

What is a Button Load Cell?

A button load cell is a compression force sensor that comes in a compact, button-like shape. It typically measures force applied vertically onto its surface. The sensor converts mechanical force into an electrical signal using strain gauge technology embedded inside its body.

These sensors are especially valuable in applications requiring discreet force monitoring. Their low-profile build and all-metal construction ensure they deliver both sensitivity and durability, even in environments exposed to vibrations or moisture.

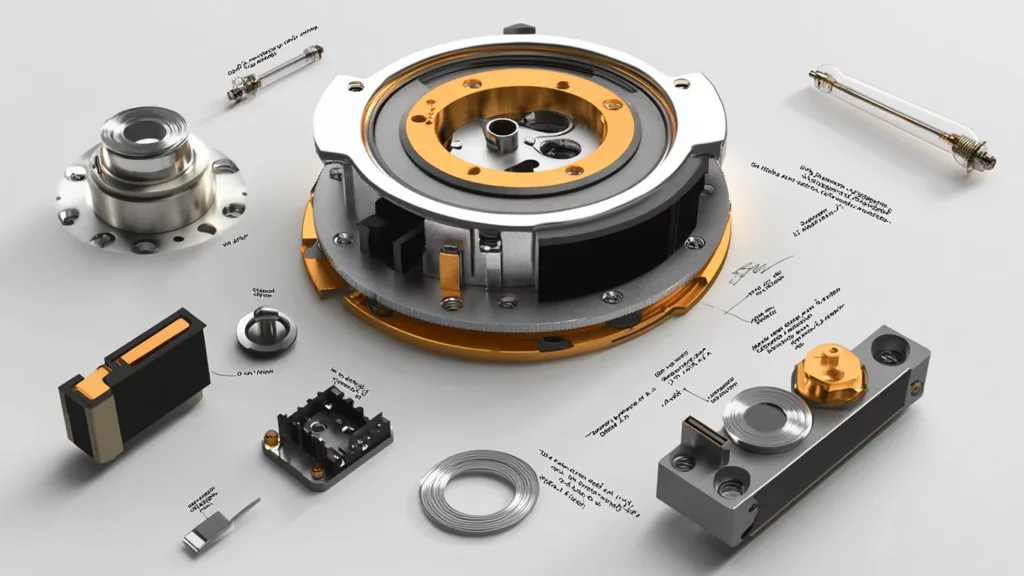

Core Components of a Button Load Cell

Several crucial parts make up a high-functioning button load cell:

- Strain Gauges: These are bonded to the internal structure and respond to deformation when a load is applied.

- Load Cell Housing: Commonly made of stainless steel or aluminum for strength and corrosion resistance.

- Wiring/Cabling: Designed to resist EMI and physical wear, often shielded or customized per industry needs.

Together, these components create a harmonized system capable of lasting millions of cycles while maintaining peak accuracy.

Types of Button Load Cells

Depending on application and design, button load cells are available in multiple types:

- Compression Only: The most common, suited for vertical force detection.

- Tension and Compression: Dual-purpose cells for dynamic load testing.

- Low Profile: Designed for integration in tight or hidden compartments.

- Subminiature: Perfect for precision industries like electronics and medicine.

Every type serves a purpose, and choosing the right one hinges on your application and environment.

Miniature and Micro Button Load Cells

If you think regular button load cells are small, micro versions will astound you. These are specifically engineered for ultra-compact applications such as implantable devices or smart tools used in cleanrooms.

Despite their size, they don’t compromise on performance. Some offer capacities of up to 500 N in packages as tiny as a fingernail.

Working Mechanism of Button Load Cell

When force is applied on the sensor’s top surface, it compresses the internal structure slightly. The strain gauges deform, changing their electrical resistance. This resistance variation is converted to a voltage signal, which is further processed and interpreted as a measurable force.

It’s this elegant simplicity that makes button load cells so reliable.

Materials Used in Button Load Cell

Material choice defines performance. Here are the most commonly used:

- Stainless Steel: High durability, corrosion resistance, ideal for harsh environments.

- Aluminum Alloy: Lightweight and cost-effective, great for portable devices.

- Titanium: Used in aerospace and biomedical applications for strength-to-weight ratio.

Each offers distinct advantages depending on the specific end-use.

Load Capacity Ranges in Button Load Cell

From measuring a few grams to several tons, button load cells cover a broad range. Typical ranges include:

| Load Capacity | Application |

| 0–50 N | Medical tools |

| 100–1000 N | Robotics, testing rigs |

| 5–50 kN | Structural analysis, heavy machinery |

Choose wisely. Overloading can damage the sensor or reduce its accuracy over time.

Accuracy and Repeatability Factors

A key highlight of button load cells is their high repeatability and accuracy, which stems from precise manufacturing and signal calibration.

- Linearity: Deviation from the ideal curve.

- Hysteresis: Variation in output during loading vs unloading.

- Creep: Signal drift under constant load.

Look for sensors with low error margins (≤0.1%) if precision is critical.

Signal Conditioning in Button Load Cell

To ensure accuracy, raw signals from the strain gauge are conditioned using:

- Amplifiers to boost weak voltage signals.

- Filters to remove noise.

- A/D Converters for digital processing.

Some modern versions offer built-in signal conditioning, minimizing the need for external modules.

How Button Load Cell Differs from Other Load Cells

Here’s a quick contrast:

| Parameter | Button Load Cell | Beam Load Cell | S-Type Load Cell |

| Size | Very Compact | Medium | Large |

| Load Direction | Vertical Compression | Bending | Tension & Compression |

| Application | Embedded Systems | Scales, Hoppers | Crane, Tensile Testing |

In essence, button load cells thrive where space and sensitivity intersect.

Key Applications of Button Load Cell

You’ll find button load cells in:

- Medical Devices

- Factory Automation

- Aerospace Testing

- Consumer Electronics

- Agricultural Robotics

Their adaptability is unmatched.

Use of Button Load Cell in Robotics

Robots use these sensors to:

- Monitor grip force

- Prevent overloading

- Enhance feedback loops

Precision and responsiveness are key benefits here.

Integration in Medical Equipment

In the healthcare sector, button load cells are integrated in:

- Prosthetics

- Surgical forceps

- Rehabilitation devices

Their biocompatibility and accuracy save lives, literally.

Why Industries Prefer Button Load Cell

- Tiny Footprint

- High Accuracy

- Durability

- Customizable Output

These features make them a top choice for advanced industrial systems.

How to Choose the Right Button Load Cell

Keep these in mind:

- Load capacity

- Output signal type

- Connector format

- Temperature and IP ratings

Consult with engineers or suppliers to match application needs precisely.

Calibration and Maintenance Tips

- Calibrate annually

- Avoid overloads

- Clean connectors

- Store in dry, dust-free conditions

Proper care equals extended lifespan.

Common Issues and Troubleshooting

- Zero Drift: Recalibrate

- Noise in Output: Check for EMI

- No Signal: Inspect cabling and connectors

- Inconsistent Readings: Examine mounting conditions

Most issues stem from misalignment or harsh environmental exposure.

Mounting and Installation Guide

- Ensure flat mounting surface

- Use correct torque

- Shield cables from vibration and heat

- Prevent off-center loading

Proper installation equals optimal performance.

Button Load Cell in Harsh Environments

Look for:

- IP67 or IP68 Ratings

- Shock Resistance

- Temperature Range (-40°C to +120°C)

Suitable for mining, marine, and manufacturing.

Wireless and Digital Button Load Cell

Modern units include:

- Bluetooth & Wi-Fi

- Plug-and-play modules

- Smart calibration via apps

They streamline integration into digital ecosystems.

Future Trends in Button Load Cell Technology

Expect:

- Self-calibrating sensors

- Machine Learning integration

- Wireless mesh networks

- Miniaturization below 5mm

Innovation is just getting started.

Real-World Case Studies

- Medical Robotics: A Chinese hospital implemented button load cells in robotic surgery arms, improving precision by 30%.

- Automotive Testing: OEMs use them in crash test dummies for real-time force analytics.

- Packaging Automation: Smart packaging lines use these for product weight confirmation.

Buying Tips for Button Load Cell

- Choose certified suppliers

- Look for ISO compliance

- Ask about custom options

- Review real use-case testimonials

A reliable sensor starts with a trusted source.

XJCSENSOR’s Custom Button Load Cell Solutions

XJCSENSOR specializes in custom, high-precision button load cells designed for industrial, medical, and robotic applications. Whether you’re automating a factory or developing next-gen wearable tech, our team provides tailored sensors engineered to fit your needs.

FAQs

What is a button load cell used for?

Button load cells are used to measure compression forces in tight spaces, especially in robotics, medical equipment, and automation.

How accurate are button load cells?

High-quality button load cells offer accuracy levels as tight as ±0.1% of full scale, depending on calibration and use conditions.

Can button load cells measure tension?

Most are designed for compression, but dual-mode versions do exist for both tension and compression.

Are button load cells waterproof?

Some are IP-rated (e.g., IP67 or IP68), making them suitable for wet or harsh environments.

What’s the lifespan of a button load cell?

With proper use, they can last several million cycles, often outliving the equipment they’re integrated into.

Can I get a custom-designed button load cell?

Yes, suppliers like XJCSENSOR provide tailored solutions based on your specifications.

Conclusion

Button load cells have carved a niche for themselves in a world demanding precision, compactness, and resilience. With innovations pushing their boundaries further, these little giants are finding their way into ever more advanced technologies. For businesses aiming to stay at the cutting edge of force sensing, investing in a high-quality button load cell is not just a choice—it’s a necessity.

Clear Call-to-Action (CTA)

XJCSENSOR is a leading sensor manufacturer providing customized wholesale sensor solutions. Our button load cells are widely applied in robotics, automation, medical devices, and more.

👉 Explore our button load cell products now.

📞 Contact us today for a custom quote or expert consultation.

🔗 Follow us on social media for the latest innovations in sensor technology!