Capacitive touch sensors are a cornerstone of modern user interfaces, seamlessly integrated into smartphones, tablets, and other touch-enabled devices. But their applications extend beyond touch detection. A growing question among engineers, scientists, and technology enthusiasts is whether a capacitive touch sensor can be used to measure force. The answer is both fascinating and complex, requiring an understanding of how these sensors work and how their principles can be adapted to measure force.

Understanding Capacitive Touch Sensors

How Do Capacitive Touch Sensors Work?

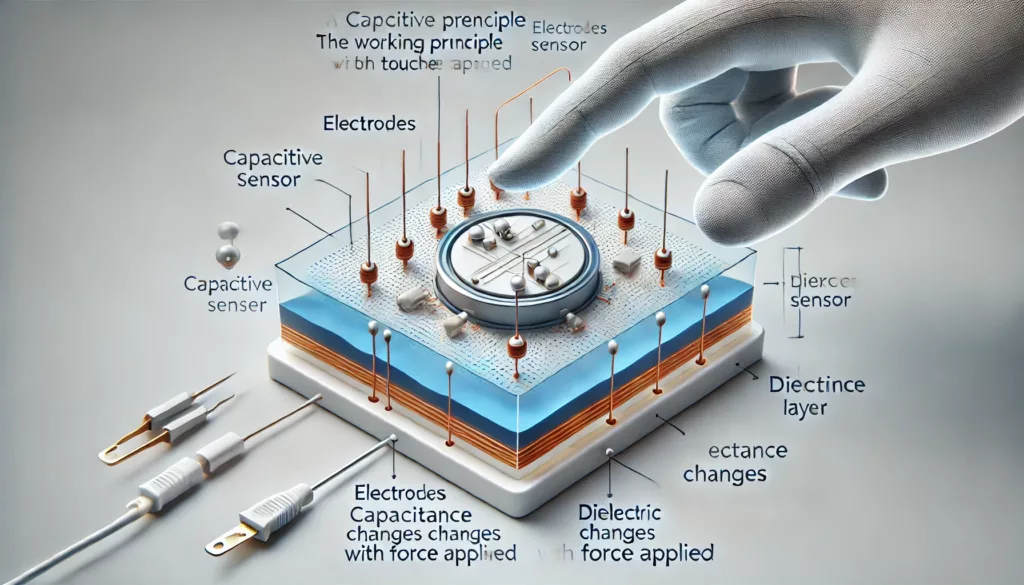

Capacitive touch sensors operate by detecting changes in capacitance. Capacitance is a property of a capacitor—a device that stores electrical charge—defined by the proximity and properties of conductive materials. In a capacitive touch sensor, when a conductive object like a finger comes close to or touches the surface, it alters the local capacitance, which is detected and processed.

Components of Capacitive Touch Sensors

- Electrode Layers: Arranged in a grid, these form the sensing area.

- Dielectric Material: Acts as an insulator between electrodes, influencing capacitance.

- Controller Chip: Processes signals and determines touch location or pressure.

Principles of Measuring Force with Capacitive Sensors

Force and Capacitance Relationship

Capacitive sensors can indirectly measure force by detecting deformation or changes in the distance between electrodes. When a force is applied to a surface, it compresses the dielectric material, altering the capacitance. This relationship can be mathematically modeled to calculate the force.

Factors Influencing Accuracy

- Material Elasticity: A stiffer material may limit measurable changes.

- Sensor Design: Electrode placement and dielectric thickness are critical.

- External Interference: Noise and temperature changes can affect readings.

Applications of Capacitive Sensors for Force Measurement

Smartphone and Tablet Displays

Modern devices use capacitive sensors to detect pressure levels, enabling features like 3D Touch, which differentiates between light taps and firm presses.

Medical Devices

Capacitive sensors are incorporated into wearables and diagnostic tools to monitor subtle pressure changes, such as in blood pressure cuffs or tactile feedback systems.

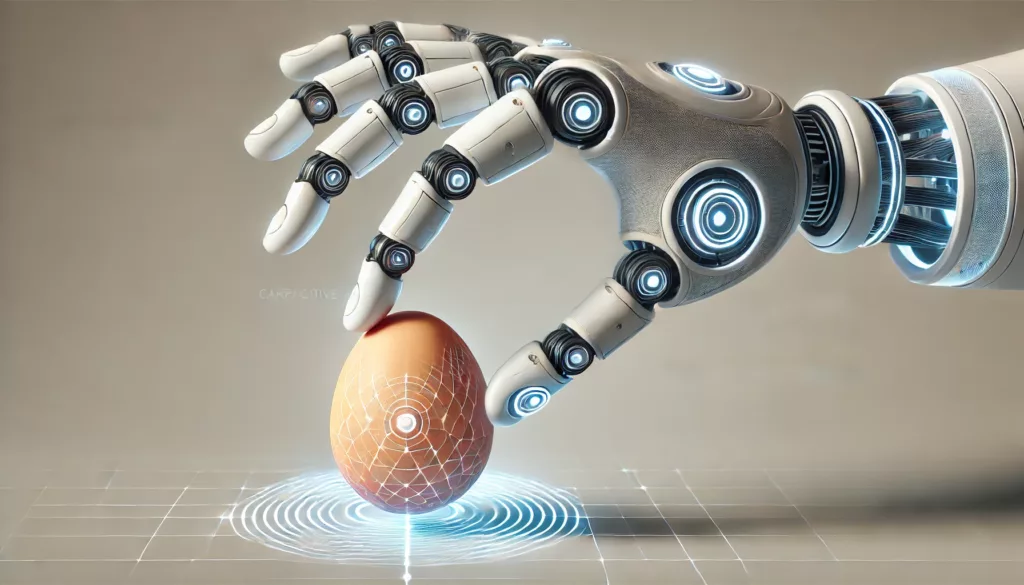

Robotics and Automation

In robotics, capacitive force sensors enable precise manipulation of objects by detecting grip force, ensuring delicate handling.

Advantages of Using Capacitive Sensors for Force Measurement

High Sensitivity

Capacitive sensors are extremely responsive to minute changes, making them ideal for detecting small forces.

Durability and Low Maintenance

With no moving parts, capacitive sensors are less prone to wear and tear compared to traditional mechanical force sensors.

Integration with Touch Interfaces

Combining touch detection and force measurement reduces the need for additional hardware, streamlining device design.

Limitations and Challenges

Limited Force Range

Capacitive sensors are typically designed for small-scale force detection. Measuring high forces may require modifications or alternative technologies.

Nonlinear Response

The relationship between force and capacitance is often nonlinear, necessitating complex algorithms for accurate measurement.

Environmental Sensitivity

Changes in temperature, humidity, or electromagnetic interference can impact sensor performance.

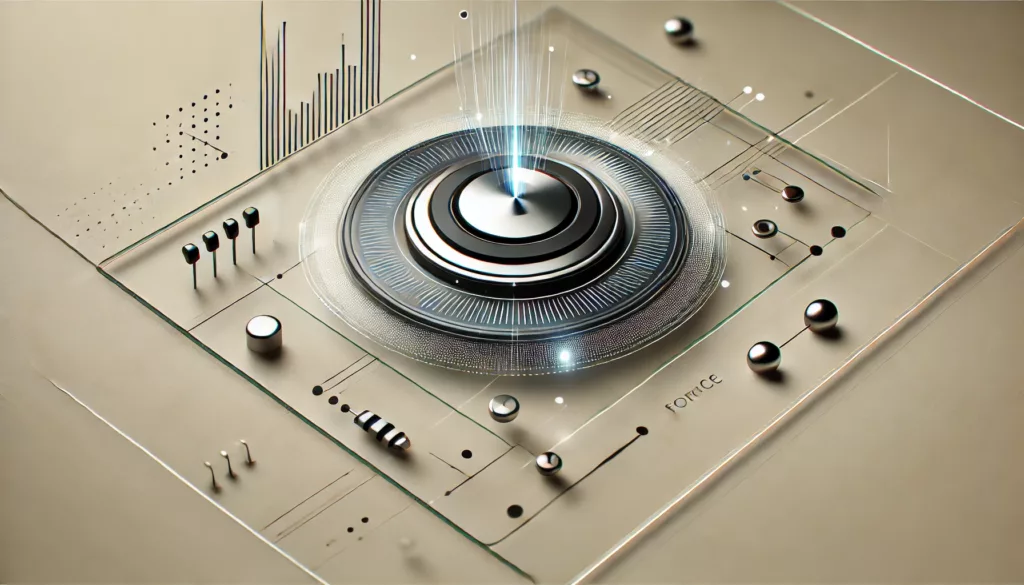

Enhancing Capacitive Sensors for Force Measurement

Innovative Materials

Using advanced elastomers or piezoelectric materials as dielectrics can improve force sensitivity and range.

Signal Processing Techniques

Implementing machine learning algorithms can help filter noise and linearize force measurements.

Hybrid Systems

Combining capacitive sensors with other technologies, like resistive or piezoelectric sensors, enhances accuracy and versatility.

Future Prospects of Capacitive Sensors in Force Measurement

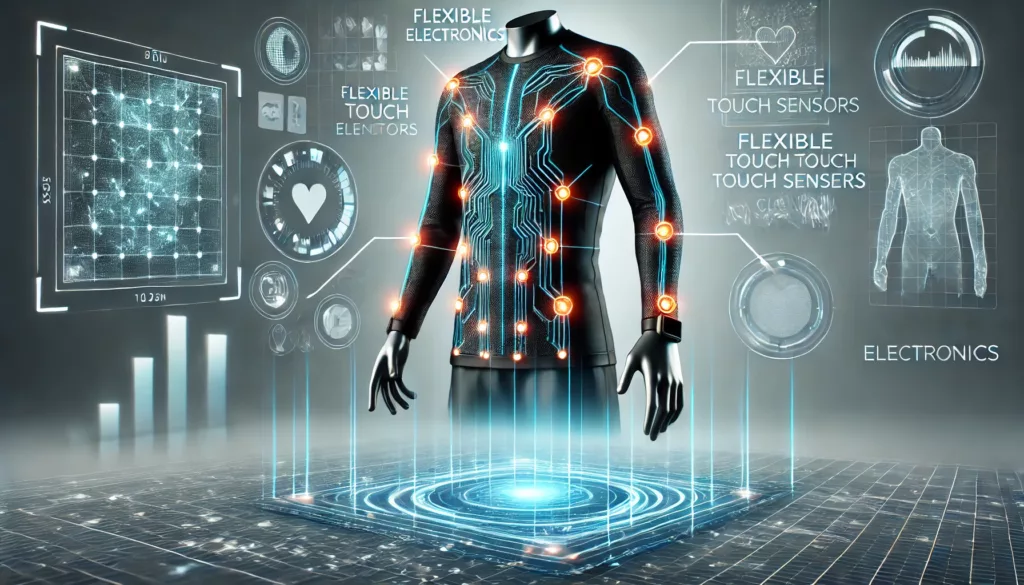

As technology advances, the potential for capacitive sensors to revolutionize force measurement continues to grow. Emerging trends include integrating these sensors into flexible electronics, wearable devices, and human-computer interaction systems.

FAQs

Can capacitive touch sensors detect small forces?

What industries benefit from capacitive force measurement?

Are capacitive sensors better than resistive sensors for measuring force?

How accurate are capacitive sensors in measuring force?

Can environmental factors affect capacitive sensors?

Are capacitive sensors expensive to use for force measurement?

Conclusion

So, can a capacitive touch sensor be used to measure force? The answer is a resounding yes. Although not originally designed for this purpose, advances in materials, design, and processing have unlocked their potential to serve as effective force sensors. Their high sensitivity, durability, and integration capabilities make them a promising solution for modern applications. Whether in consumer electronics, healthcare, or robotics, capacitive touch sensors are poised to redefine how we perceive and measure force.