In the world of automation, picking the right load cell is key. This guide will help you understand what to look for. We’ll cover the types of load cells, important specs, and practical tips. You’ll learn how to choose the best load cell for your needs.

Key Takeaways

- Learn about the different types of load cells and their unique features to find the right one for your application.

- Check the load cell’s capacity, accuracy, and environmental ratings to make sure it fits your needs.

- See how load cells are used in automation, like in manufacturing, packaging, and quality control.

- Understand the importance of installing, calibrating, and integrating load cells with your systems correctly.

- Know how to handle common load cell problems and maintenance to keep it working well for a long time.

Introduction to Load Cells

Load cells are key for precise weight measurement in many industrial settings. They turn force or pressure into an electrical signal. This makes it possible to get accurate data and control processes.

Their role in automation is huge. They help make sure things run smoothly, products are of high quality, and everything is reliable. This is true for many manufacturing and material handling tasks.

What is a Load Cell?

A load cell has a sensitive part that reacts to force or weight. When a load is put on it, this part changes shape. This change is then turned into an electrical signal.

This signal can be used to show the weight or force on a digital screen. There are many types of industrial load cells. Each one is made for different needs and places.

Importance in Automation

In industrial automation, load cells are very important. They help make sure things are accurate and reliable. They are used in many places, like scales, packaging lines, and quality control stations.

Load cells help automation work better. They make sure things are done right, consistently, and can be tracked. This helps increase productivity, cut down on waste, and improve product quality.

“Load cells are the unsung heroes of industrial automation, quietly ensuring that critical processes run with the utmost precision and reliability.”

If you work in manufacturing, logistics, or any field that needs accurate weight measurement, you should know about load cells. They are key to improving your automation and staying competitive.

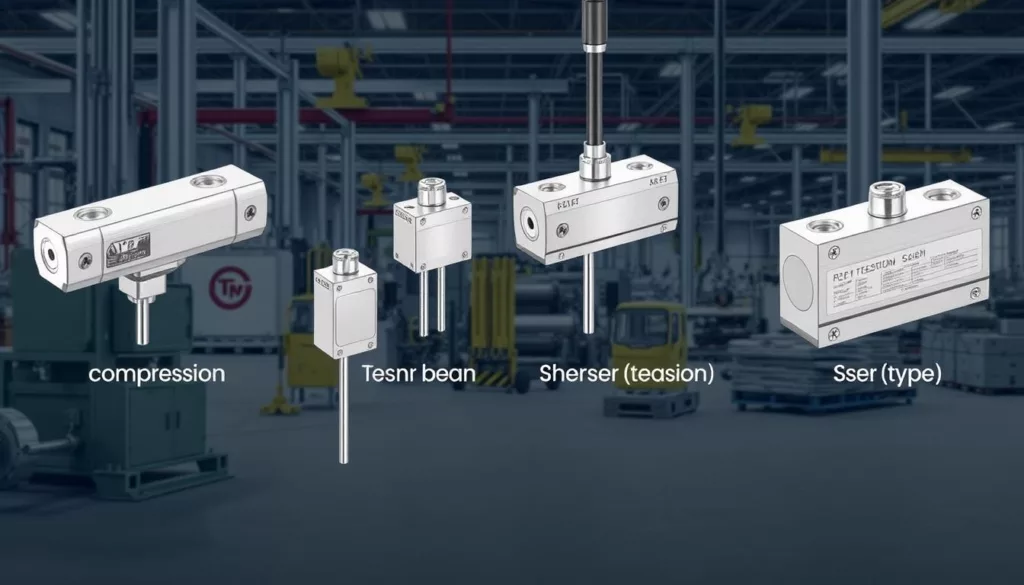

Types of Load Cells

Choosing the right load cell is key for your automation needs. There are four main types: compression, tension, shear beam, and S-type. Each has its own strengths and fits different applications based on your needs.

Compression Load Cells

Compression load cells measure forces that push down. They’re great for weighing platforms, hopper scales, and vehicle scales. These load cells are tough and reliable, perfect for heavy-duty use.

Tension Load Cells

Tension load cells measure forces that pull or hang. They’re used in crane scales, overhead weighing systems, and force measurement setups. These load cells are accurate and sensitive, ideal for precise measurements.

Shear Beam Load Cells

Shear beam load cells measure forces applied sideways or horizontally. They’re good for platform scales, weighing hoppers, and other non-vertical applications. These load cells are compact and easy to install in tight spaces.

S-type Load Cells

S-type load cells, or “S-beam” or “S-type force transducers,” measure both compressive and tensile forces. They’re used in truck scales, floor scales, and force measurement setups. This versatility makes them a popular choice.

Knowing the different types of load cells and their features is important. Consider the load direction, environment, and performance needs. This ensures your chosen load cell meets your application’s demands for reliable, precise measurements.

“The right load cell can make all the difference in the accuracy and reliability of your automation system.”

Key Specifications to Consider

When picking a load cell for your project, look at several important specs. These ensure the device works as you need it to. Key areas to check are capacity, accuracy, resolution, and environmental ratings.

Capacity and Range

The load cell’s capacity is how much weight it can handle. Picking the right capacity is key for accurate and safe measurements. If you choose too little, it might get damaged. Too much, and it might not be as precise.

Accuracy and Resolution

Accuracy shows how close the measurement is to the real value. It’s usually a percentage of the full range. Resolution is the smallest change the load cell can spot. For precise work, high accuracy and resolution are vital for load cell accuracy for automation.

Environmental Ratings

The load cell must stand up to things like temperature, humidity, and vibration. Ratings like IP and NEMA tell you if it’s good for certain conditions. The right load cell capacity automation rating means it will last longer and work better.

“Selecting the right load cell specifications is essential for ensuring accurate and reliable measurements in your automation system.”

By looking at these specs carefully, you can find the best load cell for your project. This ensures it works well, reliably, and accurately.

Load Cell Applications in Automation

Load cells are versatile sensors used in many automated industrial processes. They are key in manufacturing, packaging, and quality control. These tools help improve efficiency, accuracy, and reliability.

Manufacturing

In manufacturing, load cells are vital for monitoring and controlling processes. They measure the weight of materials, work-in-progress, and finished products. This helps manage inventory, ensure quality, and reduce waste.

Packaging

Accurate packaging is critical for product integrity and meeting regulations. Load cells measure the weight of items and containers. This ensures correct fill levels and consistent package weights.

Quality Control

Load cells are essential in quality control systems. They measure critical parameters in manufacturing and packaging. This helps detect defects, identify weight issues, and perform inspections.

Companies use load cells to boost productivity and reduce errors. They are vital in manufacturing, packaging, and quality control. Their versatility makes them indispensable in many industrial applications.

| Application | Load Cell Use | Benefits |

|---|---|---|

| Manufacturing | Material handling, weight monitoring | Optimized inventory, consistent product quality, minimized wastage |

| Packaging | Fill level measurement, package integrity verification | Accurate fill levels, detection of overfilling/underfilling, consistent package weights |

| Quality Control | Defect detection, weight anomaly identification, inline inspections | Improved product quality, reduced errors, higher process reliability |

Factors Influencing Load Cell Selection

When picking the right load cell for your automation needs, several key factors matter. Knowing these will help you make a smart choice. This ensures your application works its best.

Application Requirements

The specific needs of your application are key in choosing the right load cell. Important things to look at include:

- Capacity and range: It’s vital to find the right load capacity and range for accurate readings.

- Accuracy and resolution: Knowing how precise and sensitive you need it will help pick the best load cell.

- Mounting and installation: It’s important to consider the physical needs of your system.

Environmental Conditions

The environment where the load cell will be used affects its performance and life. When choosing the right load cell for automation, think about:

- Temperature: Load cells may face extreme temperatures, so they might need special features to handle it.

- Humidity and moisture: Pick a load cell that can handle water well in damp or wet places.

- Vibration and shock: Load cells in areas with lots of vibration or impact need to be strong and durable.

Budget Constraints

The budget you have is also important in load cell selection criteria. While quality and performance are key, finding a balance with cost is essential. You want to find a solution that meets your needs without breaking the bank.

“Choosing the right load cell is vital for your automation project’s success. By carefully looking at application needs, environmental factors, and budget, you can get the best performance and value.”

Importance of Calibration

Calibration is vital in load cell automation for accurate measurements. It adjusts the load cell’s output to match a known value. This ensures precise and consistent readings. Proper calibration keeps the load cell’s accuracy and integrity, affecting your automation system’s performance.

What is Calibration?

Calibration compares the load cell’s output to a known weight or force. It adjusts the sensor’s settings to match this reference value. This process is key for accurate measurements in process control, quality assurance, and inventory management.

Frequency of Calibration

- Load cells need calibration every 6-12 months or as the manufacturer suggests.

- The calibration frequency also depends on the load cell’s environment, usage, and application importance.

- Regular calibration keeps the load cell accuracy for automation high. It ensures reliable measurements over time.

Impact on Accuracy

Proper load cell calibration automation boosts your measurement system’s accuracy. Calibrated load cells offer precise and consistent readings. This leads to better process control, quality assurance, and inventory management.

Ignoring calibration can cause inaccurate measurements. This can lead to product defects, material waste, and lost productivity.

“Calibrating your load cells regularly is key for your automation system’s accuracy and integrity. It’s a simple yet critical step that greatly impacts your operational efficiency and profitability.”

Integration with Automation Systems

When adding load cells to an automation system, it’s key to match them with the right controllers and communication protocols. This ensures everything works smoothly and efficiently. Knowing these details helps you set up load cells correctly, improving your automated workflows.

Compatibility with Controllers

Load cells need to work well with your system’s controllers. Look for load cells that fit with PLCs, industrial computers, or other automation tools. Check the input/output signals, electrical needs, and what the maker offers in terms of integration.

Communication Protocols

For load cell data to reach your system, you need the right communication protocols. You can use analog signals like 4-20mA or 0-10V, digital ones like Modbus or EtherNet/IP, or even wireless options like Wi-Fi or Bluetooth. Pick the best one for your system and setup for smooth data flow.

Data Management Solutions

- It’s important to link load cell data with your system’s data management tools. This lets you use the technology to its fullest.

- This might mean connecting with ERP systems, MES, or special tools for data display and reports.

- With this setup, you can collect, store, and analyze load cell data. This gives you insights to improve your automated processes and make better decisions.

By focusing on these key areas of load cell integration, your system can fully benefit from this technology. This leads to better control over your processes, higher quality, and more efficiency in your operations.

| Compatibility with Controllers | Communication Protocols | Data Management Solutions |

|---|---|---|

| – PLC compatibility – Industrial computer integration – Electrical specifications alignment |

– Analog signals (4-20mA, 0-10V) – Digital protocols (Modbus, EtherNet/IP, PROFINET) – Wireless connectivity (Wi-Fi, Bluetooth) |

– ERP system integration – MES data integration – Custom data visualization and reporting |

Load Cell Installation Best Practices

Proper load cell mounting automation is essential for accurate results. Following best practices can extend your system’s life and improve its precision. Let’s look at the important steps for installing load cells correctly.

Mounting Techniques

Mounting load cells accurately is critical for precise measurements. The mounting surface should be clean, flat, and sturdy. Load cells can be mounted in different ways, like bolting, welding, or using adhesives.

When choosing a mounting method, consider the environment, material, and expected forces. This ensures the best fit for your needs.

Alignment Considerations

Aligning the load cell correctly is vital for accurate measurements. It must be placed in the right direction, with the sensing axis aligned with the force applied. Misalignment can cause errors and inconsistent data.

Use precision tools and follow the manufacturer’s guidelines for the best results. This ensures your load cell works at its peak.

Wiring and Connectivity

Correct wiring and connectivity are key for smooth integration with your system. Make sure the load cell’s signals are connected to the right inputs on your controller. Use shielded cables to avoid interference and keep signals strong.

Proper grounding and strain relief are also important. They help prevent problems and keep your data reliable.

By following these best practices, you can enhance your automation system’s performance and lifespan. Choosing the right load cell and installing it correctly will greatly benefit your technology in the long run.

Testing and Validation

Ensuring the accuracy and reliability of automation load cells is key for any industrial process. At XJCSENSOR, we know how important thorough testing and validation are. These steps are vital to meet the load cell accuracy for automation and automation load cell requirements. Let’s look at the main steps in this process.

Pre-Installation Testing

Before adding a load cell to your automation system, it’s vital to do pre-installation testing. This step involves testing the load cell under various conditions like different loads, temperatures, and environments. By testing it in controlled conditions, we can check its accuracy and if it’s right for the job.

In-Situ Testing

After installing the load cell, in-situ testing is critical. This step checks how the load cell performs in real-world conditions. It ensures it meets the automation load cell requirements and load cell accuracy for automation standards. In-situ testing may include calibration, load simulations, and monitoring its performance in different situations.

Performance Validation

Regularly checking the load cell’s performance is essential. This includes inspections, calibration checks, and watching its output over time. By catching any performance issues early, you can keep your automation system accurate, reliable, and efficient.

At XJCSENSOR, we’re dedicated to helping our customers achieve the load cell accuracy for automation and meet their automation load cell requirements. Our detailed testing and validation ensure your load cells work well every day.

Common Load Cell Issues and Solutions

As industrial automation grows, knowing the common problems with load cells is key. We’ll look at three main issues: overloading, temperature changes, and mechanical stress. By solving these problems, professionals can keep their load cell systems working well and improve their automation.

Overloading

Overloading is a big problem with load cell types. If a load cell gets too much force, it can get damaged. This leads to wrong readings and system failures. To avoid this, pick a load cell that fits your needs well, with a bit of extra safety.

- Make sure the load cell can handle the maximum load you expect

- Use overload protection, like stops or electronic limits

- Check the load cell for damage or changes often

Temperature Fluctuations

Temperature changes can also hurt load cell performance. Big temperature swings can make the load cell’s readings off. Here’s how to deal with it:

- Choose load cells with temperature control or sensors

- Keep the load cell in a stable, controlled area

- Calibrate the load cell regularly to handle temperature changes

Mechanical Stress

Mechanical stress is another problem for load cells. Things like vibration, shock, and uneven loads can cause errors and damage. Here’s how to handle it:

- Mount and align the load cell right to reduce stress

- Use vibration dampeners or keep the load cell away from vibrations

- Check the load cell for wear or damage often and fix it fast

By tackling these common load cell problems, professionals can make their automation systems better. This improves productivity and cuts down on maintenance costs.

Maintenance Tips for Load Cells

Keeping your load cell systems in top shape is key. They are vital for accurate weighing and force measurement. Here are some tips to ensure your load cells work well.

Routine Inspections

Start by regularly checking your load cells. Look for damage like cracks or corrosion. Make sure they’re aligned and secure.

Also, check the wiring and connections for wear. Any damage can mess up data.

Cleaning Procedures

Dirt and dust can harm your load cells’ precision. Create a cleaning routine. Use a soft cloth to wipe them down.

For tough spots, a small brush or compressed air works well. This keeps them clean and working right.

Troubleshooting Techniques

Load cells might have issues now and then. If measurements are off, check the load cell amplifier and connections. Know common problems like overloading and temperature changes.

Follow the right steps to fix these issues. This keeps your load cells accurate and reliable.

By following these tips, your load cells will last longer. They’ll keep giving you accurate data. Regular care ensures they work their best.

“Proper load cell maintenance is the key to maximizing the accuracy and longevity of your automation systems.”

Conclusion: Making the Right Choice

Choosing the right load cell for your automation needs is a big decision. It involves looking at different types of load cells and their specifications. You also need to think about what your application requires.

By focusing on these key points, you can make a smart choice. This choice will improve the accuracy, efficiency, and reliability of your systems.

Summary of Key Points

When choosing the right load cell, consider a few important things. Look at the capacity and range, accuracy, and environmental ratings. Also, think about what your application needs and your budget.

Calibration and integration with your systems are also key. Following best practices for installation and maintenance is vital for long-term performance.

Final Thoughts on Load Cell Selection

By carefully evaluating these factors, you can find the best load cell for your needs. The right choice will help you measure forces accurately and cost-effectively.

With the right load cell, you can improve your automated processes. This will help you control quality better and make your operations more efficient.