The Compact 3-Axis Force Sensor is made for places where space is very limited. We know that big force sensors don’t always fit in tight spots. Our sensor is small but powerful, allowing for precise force measurements in small areas.

This innovation is perfect for industries that need to save space. It’s the top choice for accurate force sensing in tight spots.

Key Takeaways

- Compact 3-axis force sensors are ideal for environments with limited space applications.

- High precision force measurement is achievable without compromising on performance.

- Innovative design solutions cater to the growing demands of industrial professionals.

- Miniature sensors overcome challenges faced by larger force sensors in tight spaces.

- Effective for various industries that require space-efficient sensor solutions.

Understanding the Compact 3-Axis Force Sensor

The compact 3-axis force sensor is key in precise force measurements in tight spots. It accurately measures forces in three dimensions. This makes it perfect for complex engineering tasks. Its design fits well with many systems, giving important data from small places.

What is a Compact 3-Axis Force Sensor?

This sensor measures force in three axes at once. It’s great for detailed analysis in small spaces. Its small size lets it fit in places big sensors can’t, opening up new areas for testing.

Key Features of Compact Force Sensors

- High Precision: Offers exact readings under different loads, boosting reliability in important tasks.

- Lightweight Construction: Makes it easy to add to existing systems, keeping things running smoothly.

- Versatility: Works for both steady and moving forces, fitting many industries and settings.

Importance of Force Measurement in Limited Space Applications

Force measurement is key in many areas, but it’s even more important in tight spaces. These areas come with their own set of challenges. That’s why compact force sensors are so vital in solving these problems.

Challenges of Force Measurement in Tight Spaces

Getting accurate force measurements in tight spots is tough. It’s hard to get to the sensors and pick the right ones. The small size of these areas means sensors have to be tiny too. This makes it hard to keep them working well.

Advantages of Miniature Force Sensors for Space-Constrained Environments

Miniature force sensors bring big benefits to tight spaces. Their small size lets them fit in tight spots. This makes them easy to use in small machines, boosting their performance.

- They can be placed in many different ways, making setup easier.

- They fit well in small machines, making them more efficient.

These benefits make it easier to install and use these sensors. They help keep force measurements accurate in many situations.

| Aspect | Challenges | Advantages |

|---|---|---|

| Accessibility | Limited room for installation and operation. | Compact size allows for creative sensor placement. |

| Functionality | Potential loss of measurement accuracy. | High precision despite smaller dimensions. |

| Integration | Difficult to fit standard sensors into tight spaces. | Seamless integration into small or complex machinery. |

Applications of Compact 3-Axis Force Sensors

The applications of force sensors are wide-ranging, showing their value in many fields. Compact 3-axis force sensors are perfect for tight spaces. They give vital measurements without losing functionality.

Industries Utilizing Force Sensors

Many sectors use compact force sensors. These include:

- Automotive: For checking the strength and performance of car parts.

- Aerospace: Needed for precise weight and safety checks.

- Robotics: Key for robotic grippers and automated systems.

- Biomedical: Used in medical tools for accurate force tracking.

Real-World Examples of Limited Space Applications

Compact 3-axis force sensors are used in tight spots. Some examples are:

- Robotic grippers in automated lines needing exact force control.

- Sensors in surgical tools to track forces and better patient care.

- MEMS where sensors fit in small areas for enhanced performance.

At XJCSENSOR, quality and reliability are top priorities. They provide custom solutions for limited space applications.

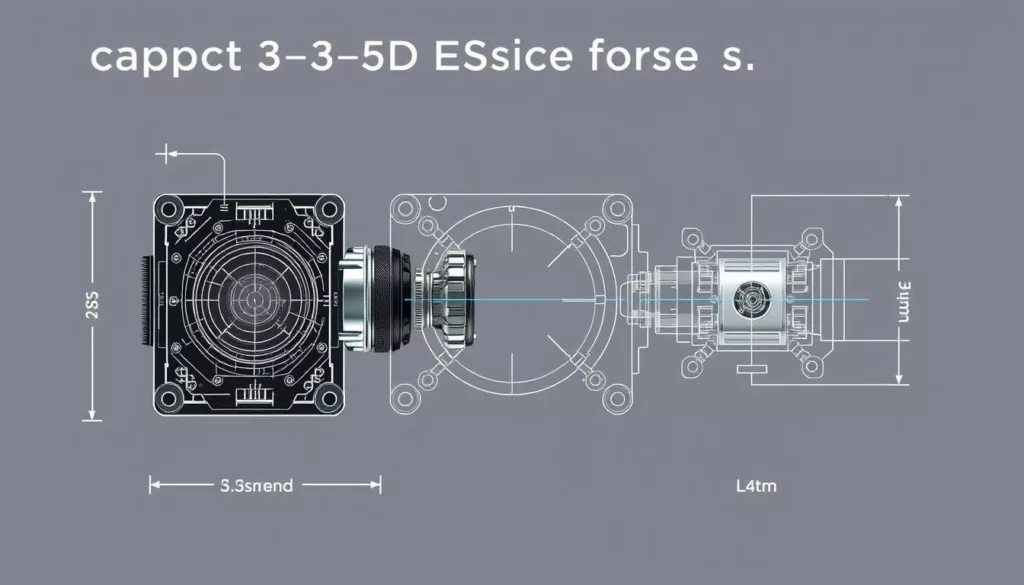

Technical Specifications of the Compact 3-Axis Force Sensor

The compact 3-axis force sensor has advanced specs for top-notch performance. These specs show its precision, sensitivity, and durability in tough settings.

Precision and Sensitivity

Our sensors offer precision and sensitivity at a high level. They give detailed force readings in all three axes. This is key for precise measurements, like in medical fields where small changes matter a lot.

Durability and Environmental Considerations

The durability of the force sensor is built to last in harsh conditions. It has:

- Water and dust resistance, meeting IP ratings.

- It can handle extreme temperatures, working well in many environments.

Our focus on technical specifications shows our dedication to top-notch force sensors. They are perfect for tight spaces, thanks to their precision, sensitivity, and toughness.

| Specification | Details |

|---|---|

| Accuracy | ±0.5% FS |

| Resolution | 0.01 N |

| IP Rating | IP67 |

| Operating Temperature Range | -40°C to 85°C |

| Weight | 50 grams |

Why Choose a Miniature Triaxial Force Sensor?

Choosing a miniature triaxial force sensor makes sense for many reasons. It’s small but packs a big punch in different settings. This tiny sensor is a big step forward in technology, fitting into tight spots without losing power.

Comparison with Standard Force Sensors

Miniature triaxial sensors have clear advantages of triaxial sensors over the old-school types. They’re smaller but just as strong. This means they can fit into tight spaces, making them perfect for new gadgets and machines.

Benefits of Compact Design

The small size of these sensors brings big benefits. Here are a few:

- They’re easy to add to existing systems

- They cost less to install because they’re smaller

- They work well in many different industries

Companies looking for efficient designs will find our sensors a great match. We focus on making them small without losing quality. Check out more on XJCSENSOR’s website.

Innovations in Space-Saving Force Sensing Technology

Force sensing technology is changing fast. We’re seeing new innovations in force sensors. These changes aim to make devices smaller and more efficient. They need to work well in tight spaces.

Designs are getting smaller and better. This is helping many industries. They can now use these sensors in new ways.

Recent Developments in Force Sensor Design

New designs in sensor technology are exciting. They use smart tech for easy communication. This lets sensors send data in real-time.

Some big changes include:

- Smaller designs that fit in tight spots.

- Sensors that work wirelessly for easy setup.

- Better accuracy thanks to new calibration methods.

The Future of Slimline Force Sensors

The future looks bright for force sensors. We’ll see more use of artificial intelligence and IoT. This will help analyze data quickly and make decisions fast.

These smart sensors will change how we monitor and control things. It’s a big step forward.

If you need special sensors, XJCSENSOR has custom solutions. They improve performance and reliability. These new sensors will help businesses stay ahead.

| Innovation Feature | Description | Impact on Applications |

|---|---|---|

| Miniaturization | Reduction in size while maintaining performance | Enables integration into compact systems |

| Smart Technology | Integration with cloud technology for data storage | Facilitates remote monitoring and analysis |

| Real-time Data Processing | Instantaneous analysis and feedback loops | Enhances reactive capabilities in critical applications |

Compact 3 Axis Force Sensor for Limited Space Applications

Our compact 3-axis force sensor is perfect for tight spaces. It works well in many places, giving accurate force readings. This doesn’t mean it loses power.

Engineers looking for a small force gauge will be amazed. It fits well in small areas, which is key in today’s projects.

This sensor is used in many fields like robotics, aerospace, and medical devices. It helps teams work better and keeps things accurate and reliable.

- High precision in force measurement

- Compact footprint for easy deployment

- Versatile applications across various sectors

Choosing the Right Force Measurement Solution

Choosing a force sensor needs careful thought. You must consider many factors to find the right one for your needs. Knowing the factors in sensor selection helps make your force measurement solutions better.

Factors to Consider for Selecting a Sensor

When looking at a force sensor, several important things matter:

- Measurement range: Make sure the sensor can measure the forces you need accurately.

- Acceptable error margin: Know how much error you can accept in your application.

- Installation flexibility: Check how well the sensor fits into your system.

- Environmental compliance: See if the sensor can handle the conditions it will be in.

How XJCSENSOR Stands Out in the Market

XJCSENSOR leads the market with our dedication to innovation and customization. We offer top-notch support and solutions tailored to each client. This ensures you get the right sensor for your needs. Our cutting-edge technologies make it simpler for experts to find reliable force measurement solutions.

| Factor | Description |

|---|---|

| Measurement Range | Defines the minimum and maximum forces the sensor can measure. |

| Error Margin | Indicates the degree of accuracy expected from the sensor. |

| Installation Flexibility | Describes how adaptable the sensor is for various setups and configurations. |

| Environmental Compliance | Assesses the sensor’s ability to function in specific conditions like temperature, humidity, etc. |

Conclusion

The compact 3-axis force sensor from XJCSENSOR is key in complex industrial settings. It’s made to be precise and strong, yet small. This makes it perfect for tight spaces.

Using these sensors boosts work efficiency and shows the value of force measurement in fields like robotics. We aim to give tools that help engineers and experts do their jobs well. They can work with confidence and precision.

Want to learn more about our products, like the customizable 3-axis force sensor? Check out XJCSENSOR. Our solutions are designed for the future, focusing on quality and function.