In today’s fast-paced world, the need for compact force sensors is growing. These sensors are made to fit in tight spaces. They’re used in many fields, like medicine and aerospace, where every inch matters.

These sensors are special because they’re accurate and small. Our team works hard to make them fit perfectly in tight spots. They help make products better without taking up too much space.

Let’s look at how these sensors work and where they’re used. They can make your work more efficient. See how they can help your business.

Key Takeaways

- Compact force sensors are essential for industries with stringent space constraints.

- They provide accurate measurements without sacrificing performance.

- Miniature load sensing equipment supports innovative designs in various sectors.

- Space-saving force sensors enhance reliability in compact applications.

- Integration is possible in high-performance contexts, such as aerospace and medical devices.

Understanding the Need for Compact Force Sensors

As industries grow, so does the need for compact force sensors. These sensors are key because they measure accurately without taking up much space. They meet the demand for precision and reliability in today’s world.

Importance in Modern Applications

Compact force sensors are vital in many technologies where space is limited. They fit into various devices, adding advanced features without losing performance. These sensors are essential in driving innovation in healthcare, automotive, and electronics.

Industries Benefiting from Compact Solutions

Many sectors benefit from the use of miniature force transducers. In healthcare, they’re used in medical tools like infusion pumps and prosthetics for accurate readings. Aerospace also gains from these sensors, allowing for more efficient designs. Key industries using these sensors include:

- Healthcare

- Aerospace

- Automotive

- Consumer Electronics

- Robotics

Features of Compact Force Sensors

Compact force sensors are key in many industries. They are small but powerful, thanks to new sensor technology. This section will look at what makes these sensors so valuable.

Miniaturization Technology

New sensor tech makes devices smaller and stronger. It lets engineers add complex tools to tight spaces. This is a big win for design innovation.

Durability and Reliability

These sensors are built to last, even in tough conditions. They handle stress and weather well, keeping them working long-term. This is critical in industries where sensors can’t fail.

High Precision Measurement

Compact force sensors are known for their exact measurements. Making accurate readings in small spaces is a big challenge. But, thanks to new materials and methods, they deliver precise data. This is vital for fields like medicine and space exploration.

| Feature | Description | Benefits |

|---|---|---|

| Miniaturization Technology | Enables smaller designs without sacrificing performance. | Increased design flexibility and space optimization. |

| Durability | Robust construction to resist wear and environmental damage. | Long lifespan and reduced maintenance costs. |

| High Precision Measurement | Accurate force measurements in compact devices. | Essential for critical applications needing reliable data. |

Compact Force Sensors for Limited Space Applications

There’s a growing need for compact force sensors, mainly in places where space is limited but performance is key. These sensors offer big benefits in many areas, where space is tight.

Advantages of Using Compact Sensors

Compact force sensors bring many benefits to industrial settings. Some of these include:

- High precision: They give accurate readings, helping make better decisions.

- Space-saving design: They fit well in small spaces, making the most of available room.

- Increased efficiency: Their smaller size means they can respond quicker in automated systems.

These benefits make compact force sensors perfect for today’s industrial needs. They ensure reliability and work well in tight spots.

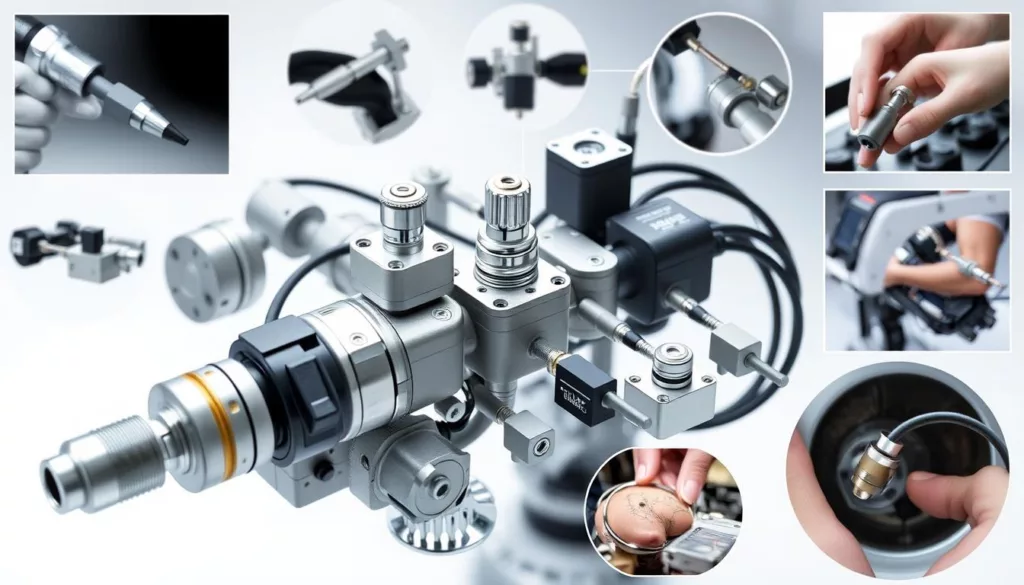

Integration in Small Devices

Putting space-saving force sensors in small devices shows their flexibility. They can fit where bigger sensors can’t, helping engineers solve space problems. This leads to:

- Robust performance: They work well even in small spaces.

- Enhanced safety: They help machines stay safe by measuring accurately.

- Broader application range: They open up new uses in robotics and automation.

For companies needing solutions for tight spaces, compact force sensors are a good choice. Leaders like XJCSENSOR are at the forefront, providing top-quality sensors.

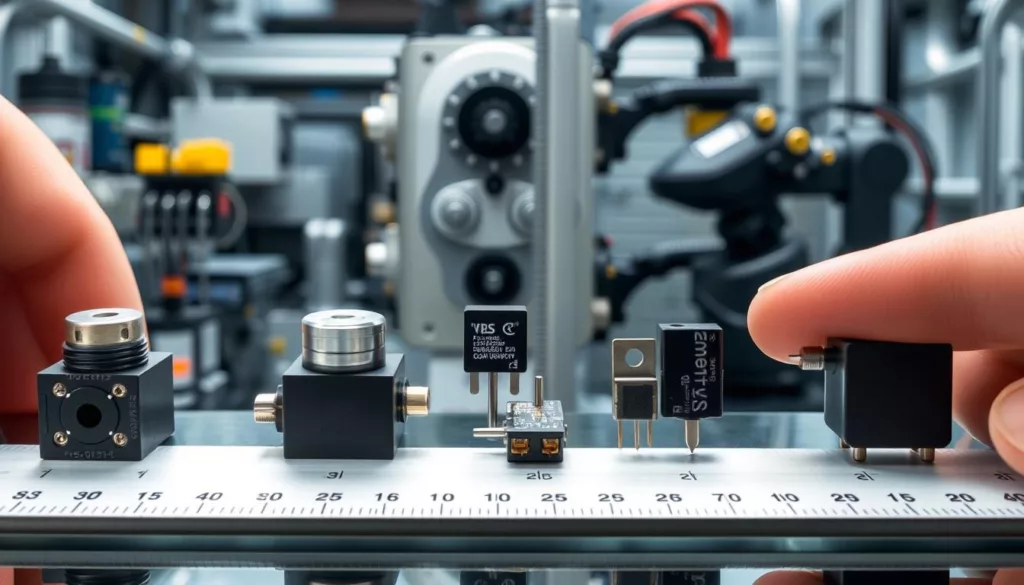

Types of Compact Force Sensors

It’s important to know the different types of compact force sensors. This knowledge helps choose the right one for your needs. These sensors come in many designs and work well in different places.

Miniature Force Transducers

Miniature force transducers turn mechanical force into electrical signals in a small package. They’re great when space is limited. They offer high precision and respond quickly.

These sensors are reliable in tight spaces. They’re a top pick for engineers and those in industry.

Small Load Cells

Small load cells are key in compact force sensors. They measure weight accurately, even in small areas. Their design makes them easy to fit into things like portable scales and medical tools.

They show how versatile they are in many small load cell uses.

Low Profile Force Gauges

Low profile force gauges are good at measuring forces in a short height. They’re perfect for places where you don’t want to block anything. They’re used in labs and factories to check materials and monitor forces.

For a full look at compact force sensors and their uses, check out this detailed resource.

Applications of Compact Force Sensors

Compact force sensors are key in many industries. They are made to fit in tight spaces where big sensors can’t. Knowing how they work helps us see their value in today’s tech world.

Medical Equipment

In medical applications, these sensors are vital. They help with patient care, robotic surgeries, and more. They give accurate readings, which is critical for health checks and treatments.

For example, they help make prosthetics that move like real limbs. This makes prosthetics more useful for users.

Aerospace Engineering

In aerospace, these sensors keep flights safe and smooth. They check the strength of aircraft parts. Their small size makes them easy to use in many ways.

They help check stress on wings and keep avionics systems working right.

Robotics and Automation

The need for sensors in robotics has grown fast. Compact force sensors improve robots’ ability to handle tasks. They give robots the feedback they need for precise work.

This is important for tasks like handling objects and checking quality. It’s also key for robots working with people safely and accurately.

Choosing the Right Compact Sensor

Choosing the right compact force sensor is key to getting the best performance and reliability. It might seem hard with so many options out there. But, focusing on the main considerations for sensor selection makes it easier.

Key Considerations

- Size and Fit: Make sure the sensor fits your space needs.

- Load Capacity: Check the sensor can handle the maximum load you need.

- Output Signal Type: Pick between analog and digital outputs based on your system’s needs.

- Environmental Conditions: Think about temperature, humidity, and chemical exposure that might impact the sensor.

- Installation Ease: Choose sensors that are easy to add to your system to save time and effort.

Performance Metrics to Evaluate

When choosing compact force sensors, it’s important to look at their performance. Key metrics include:

| Metric | Description |

|---|---|

| Sensitivity | The sensor’s ability to detect small force changes |

| Linearity | How well the sensor’s output matches the input force |

| Hysteresis | The difference in output when force is applied and removed |

| Temperature Coefficient | The impact of temperature changes on the sensor’s output |

Comparing Compact Force Sensors to Traditional Sensors

Looking at the differences between compact force sensors and traditional sensors shows their unique benefits. We can see how size and accuracy play a role in choosing the right sensor for different needs.

Size and Space Efficiency

Compact force sensors are perfect for tight spaces. They are great for places where size matters a lot. Traditional sensors, on the other hand, take up more room. This makes them less useful in small devices.

Here are some key points about size efficiency in force measurement:

- Compact sensors use miniaturized tech, fitting into small machines and devices.

- Traditional sensors need more space and infrastructure for setup.

- Compact sensors offer more design flexibility across many industries.

Accuracy and Measurement Range

Compact force sensors are very accurate. They often match or beat traditional sensors in accuracy, thanks to new tech. This leads to better efficiency and reliability in operations.

| Sensor Type | Size | Accuracy (%) | Typical Measurement Range (N) |

|---|---|---|---|

| Compact Force Sensor | Miniaturized | ±0.5 | 0 – 500 |

| Traditional Force Sensor | Larger | ±1.0 | 0 – 2000 |

The table shows compact sensors are as accurate but smaller. The trend of using compact solutions is growing. It shows a shift towards better measurement efficiency in many fields.

Maintenance and Care for Compact Sensors

Keeping compact sensors in good shape is key to their long-term performance. By following best practices, you can avoid failures and ensure accurate readings. Regular calibration of these sensors is also vital for consistent results.

Best Practices for Longevity

To keep your compact force sensors running smoothly, follow these tips:

- Regular Cleaning: Use the right cleaning methods to remove dust and contaminants.

- Environmental Control: Operate sensors within the recommended temperature and humidity levels.

- Protection from Shock: Choose mounting solutions that reduce vibrations and shocks.

- Routine Inspections: Check sensors regularly for wear or damage to catch issues early.

Calibration Procedures

Calibration of miniature sensors is critical for maintaining accuracy. Here’s how to do it right:

- Baseline Measurements: Take baseline measurements to compare against during calibration.

- Calibration Equipment: Use top-notch calibration tools that are regularly checked for accuracy.

- Document Results: Record all calibration results, including any adjustments made.

- Frequency of Calibration: Stick to the manufacturer’s recommended calibration schedule for best performance.

Conclusion

Compact force sensors are a big step forward in precision engineering. They are small but pack a lot of punch, making them key in many fields. From medical gear to space exploration, they play a big role.

As we all try to work faster and smarter, these sensors will become even more important. They show us the bright future of sensor technology.

In today’s world, we need sensors we can count on. We offer top-notch, custom sensors that meet exact needs. This lets engineers and leaders rely on us for their projects.

Our focus on quality and performance helps businesses stay ahead. It’s all about helping you reach your goals.

The future of sensors is exciting, blending with new industrial uses. We’re here to help you find the right solutions. Check out our options at XJCSENSOR.