In the world of industrial automation, sensor technology is key for precise control and optimization. The compact torque sensor is a vital part, made for tight spaces. XJCSENSOR leads in creating these small torque transducers, changing how we measure torque in small areas.

This guide will cover the basics of compact torque sensors, their main features, and benefits. We’ll explore how they work and their uses in tight spaces. You’ll learn how to use these advanced sensors to improve your operations.

Key Takeaways

- Compact torque sensors offer precise torque measurement in tight spaces

- Miniature torque transducers revolutionize industrial automation and robotic applications

- XJCSENSOR’s expertise in sensor technology ensures reliable and customizable solutions

- Low-profile torque measurement enables optimized equipment design and integration

- Innovative features like digital signal processing and wireless connectivity enhance functionality

Understanding Compact Torque Sensors: Basics and Fundamentals

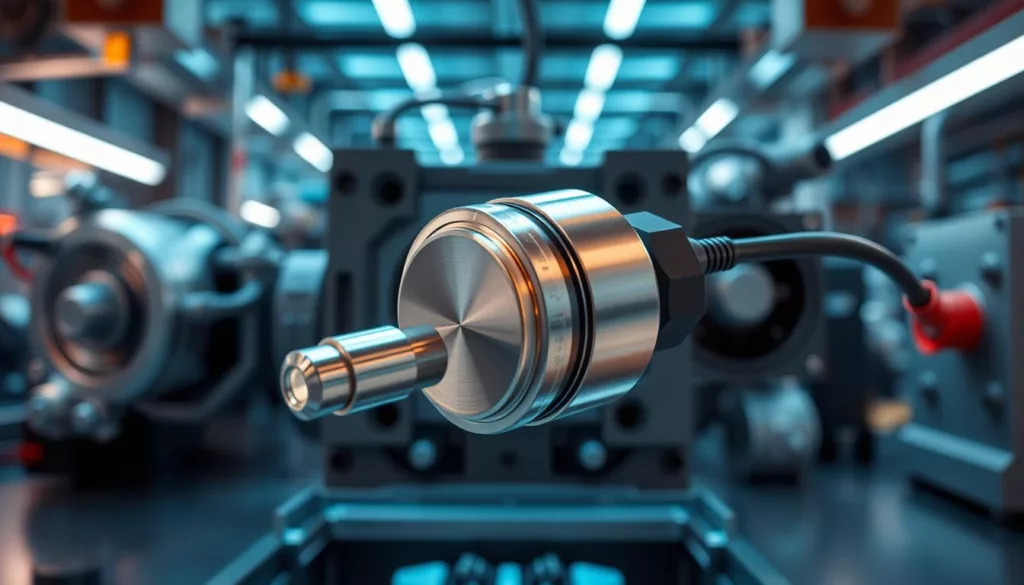

Precise torque measurement is key in many fields like automotive, industrial, aerospace, and defense. Compact torque sensors are vital in these areas, giving accurate data for monitoring and control. Knowing their parts, how they work, and what they can measure is essential.

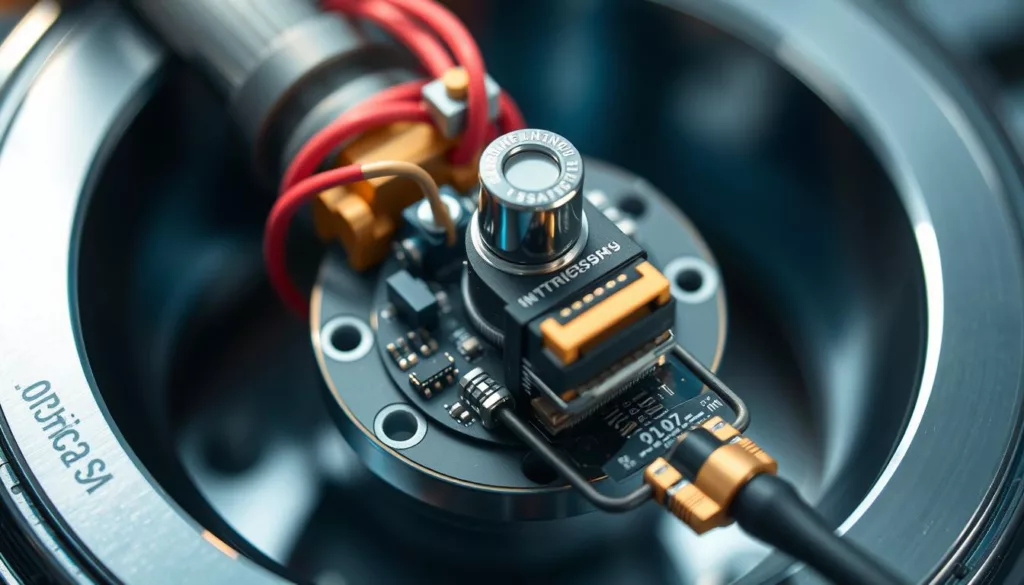

Key Components of Miniature Torque Sensors

Compact torque sensors have a few main parts. These include strain gauge sensing elements, circuitry for signal processing, and a small housing. These parts work together in a tight-space torque monitoring system to give accurate results.

Operating Principles in Confined Spaces

The way compact design torque sensors work is different from bigger ones. They use special algorithms, materials, and mounting methods for precise measurements in tight spots.

Measurement Range Capabilities

Miniaturized torque instrumentation can measure a wide range of torques. They can handle from very small to very large torques. This makes them useful in many industries and applications.

Knowing how compact torque sensors work helps engineers choose the right one for their needs. This ensures accurate torque monitoring and control in tight spaces.

Compact Torque Sensors for Space-Constrained Setups: Applications and Benefits

In today’s fast-changing industrial world, the need for small torque solutions is growing. Compact torque sensors are key in solving the challenges of tight spaces. They bring many benefits like better efficiency, accuracy, and safety to different industries.

These sensors are changing how we handle tight spaces in robotics and aerospace. They offer top-notch performance. This lets engineers and technicians improve their setups without losing important measurement abilities.

Unlocking the Potential of Tight Spaces

Compact torque sensors are great for places where big sensors won’t fit. Their small size lets them fit into tight spots. This is super useful in areas like:

- Robotic joint monitoring

- Aerospace actuator control

- Medical device joint monitoring

- Automotive powertrain diagnostics

Using these sensors saves space. This helps engineers make their systems better, more efficient, and reliable.

Enhancing Precision and Safety

These sensors are not just small. They also measure torque very accurately. Their advanced tech gives precise data, even in tough spots. This is key in places where small changes matter a lot, like:

- Aerospace flight control systems

- Robotic joint force feedback

- Medical device joint monitoring

- Automotive powertrain diagnostics

They provide reliable torque data. This keeps systems running well, makes things safer, and prevents failures in tight spots.

| Application | Torque Sensor Benefits |

|---|---|

| Robotic Systems | Precise joint monitoring, improved control, and enhanced safety |

| Aerospace Engineering | Accurate actuator control, reliable flight control, and weight optimization |

| Medical Devices | Precise joint monitoring, enhanced patient safety, and compact design |

| Automotive Diagnostics | Accurate powertrain analysis, improved maintenance, and space-saving integration |

As industries keep changing, compact torque sensors lead the way. They offer great solutions for tight spaces, high precision, and top performance.

“Compact torque sensors have revolutionized the way we approach space-constrained setups, providing unmatched precision and efficiency in critical applications.”

Miniature Torque Transducer Technology: Latest Innovations

In the world of compact torque sensors, new tech is changing how we handle tight spaces. XJCSENSOR leads in micro torque transducer technology and compact torque sensors for space-constrained setups. They keep pushing the limits of what’s possible.

Advanced Sensing Elements

The core of a torque sensor is its sensing elements. XJCSENSOR’s team has created top-notch sensing tech. It offers unmatched accuracy and reliability, even in tough spots.

Thanks to new materials and micro-fabrication, they’ve made sensors that fit tight spaces. These sensors give precise and consistent readings.

Digital Signal Processing Features

XJCSENSOR’s tech also includes advanced digital signal processing. This lets the sensors analyze data, filter it, and prepare it for use. The result is clean, reliable signals that meet specific needs.

Wireless Connectivity Options

Today, XJCSENSOR knows how key seamless data sharing is. Their sensors have top-notch wireless options. This makes it easy to send data to control systems and IoT platforms.

This wireless feature makes installation simple, even in small spaces. XJCSENSOR keeps innovating in sensing, digital processing, and wireless tech. They’re shaping the future of micro torque transducer technology and compact torque sensors for space-constrained setups.

These advancements mean professionals, engineers, and buyers get the best torque solutions. Even in the smallest spaces.

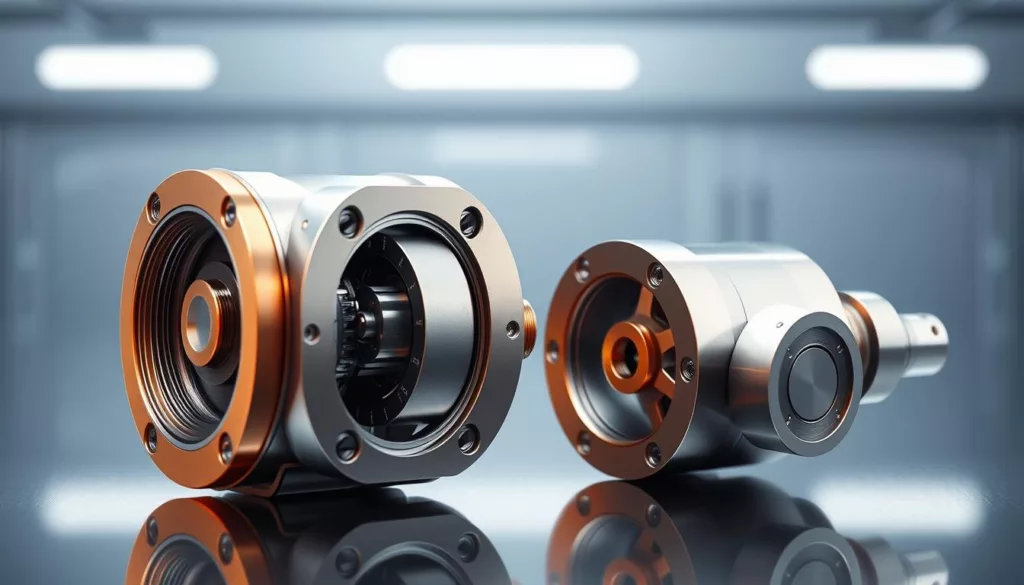

Design Considerations for Low-Profile Torque Measurement

As technology advances, the need for small, efficient sensors grows. Low-profile torque measurement is key in tight spaces. Designing these sensors requires careful thought to ensure they work well.

Making compact design torque sensors is tough. They must be small but accurate. Engineers use new ideas and deep knowledge to solve this problem.

It’s also important to fit space-saving torque solutions into systems easily. Designers must think about space, wiring, and how well it fits with other parts. This makes installation easier and more efficient.

- Miniaturization without compromising accuracy

- Seamless integration into tight spaces

- Optimized mounting and wiring solutions

- Scalable design for various application needs

| Design Consideration | Importance | Practical Approach |

|---|---|---|

| Sensor Size and Footprint | Crucial for space-constrained setups | Utilize advanced materials and manufacturing techniques to create ultra-thin, compact sensor designs |

| Measurement Range and Sensitivity | Ensure accurate torque data in limited spaces | Optimize sensor elements and signal processing algorithms for high-precision measurements |

| Mounting and Wiring Integration | Streamline installation and maintenance | Develop innovative mounting brackets and connection solutions tailored to tight spaces |

“Achieving the perfect balance between size, performance, and integration is the key to unlocking the true low-profile torque measurement solutions.”

By focusing on these design aspects, makers can create compact design torque sensors that work great. They fit well in tight spots. This approach helps technology and automation succeed, even in tough places.

Installation Guidelines in Tight-Space Environments

Installing compact torque sensors in tight spaces needs careful steps for the best results. Our team has put together detailed instructions. These cover mounting, wiring, and calibration in small areas.

Mounting Requirements

Mounting correctly is key for accurate torque monitoring in tight spaces. Here are some tips:

- Find stable points for mounting to reduce vibration.

- Use small mounting tools to save space.

- Make sure everything is tightly secured.

Wiring and Connection Optimization

Good wiring and connections are vital in tight spaces. Here’s how to do it right:

- Keep cables straight and smooth to avoid signal loss.

- Choose small connectors to save space.

- Use protection to keep wires safe from damage.

Calibration in Limited Spaces

Calibration is the last step and very important. Here’s what to do in tight spaces:

| Calibration Requirement | Recommendation |

|---|---|

| Calibration Equipment | Use small, portable tools for easy use in tight spots. |

| Calibration Procedures | Make calibration quick and simple to save time and space. |

| Documentation and Records | Keep detailed records for easy troubleshooting later. |

By following these steps, you can successfully install compact torque sensors in tight spaces. Our experts are ready to help with any questions or needs.

Performance Optimization in Constrained Spaces

Working with compact torque sensors in tight spaces requires top performance. At XJCSENSOR, we tackle the challenge of precise torque sensing in small areas. Our team has developed ways to reduce interference, boost accuracy, and ensure reliable readings, no matter the difficulty.

Minimizing electromagnetic interference (EMI) and other environmental factors is key. Our miniaturized torque instrumentation uses advanced shielding and filtering. This keeps the signal quality high, even in noisy environments.

Accuracy is essential with compact design torque sensors. We use the latest sensing technology and digital signal processing. This ensures precise and consistent measurements, even in tight spaces. Our calibration methods make sure your high-precision torque sensing solutions work their best, no matter the installation.

Reliable operation in tight spaces also means careful installation and integration. Our team helps with the best mounting, wiring, and calibration methods. This lets you get the most out of your space-saving torque monitoring systems.

“By combining our technical expertise with a deep understanding of the challenges faced in space-constrained environments, we’re able to help our customers unlock the true performance capabilities of their compact torque sensors.”

At XJCSENSOR, we aim to give our clients the tools and knowledge they need to succeed. Reach out to us today to learn more about optimizing performance in tight spaces. We can help you meet your torque measurement goals.

| Optimization Strategy | Key Benefits |

|---|---|

| EMI Mitigation | Maintains signal integrity in electrically noisy environments |

| Advanced Sensing Technology | Delivers precise, consistent torque measurements |

| Calibration Protocols | Ensures optimal performance in tight-fitting installations |

| Installation Guidance | Enables seamless integration and reliable operation |

Industry-Specific Applications and Case Studies

At XJCSENSOR, we’re proud of our miniature torque transducers and micro torque transducer technology. These small sensors work great in tight spaces across many industries. Here are some real examples of how our tech has made a big difference.

Aerospace Implementation Examples

In the aerospace world, every bit of space counts. Our miniature torque transducers are key. A top aircraft maker used our tech to solve a big problem in their flight systems. They made the system smaller without losing quality, improving safety and control.

Robotics Integration Solutions

- In robotics, our miniature torque transducers have changed the game for constrained-space torque applications. A famous robotic arm maker used our sensors for better precision and control. This made their robots work better in tight spaces.

- A new surgical robotics startup needed to add torque measurement to their small devices. They used our micro torque transducer technology for the needed precision. This helped make their medical robots safer and more effective.

Medical Device Applications

In medical devices, safety and performance are key. Our miniature torque transducers have been very helpful. A top prosthetic limb maker used our sensors to check joint torque in their new knee design. This made the prosthetic move smoothly and naturally, even in tight spaces.

“XJCSENSOR’s compact torque sensors have been a game-changer for our medical device development. Their innovative technology has allowed us to push the boundaries of what’s possible in constrained-space applications, delivering unparalleled performance and safety for our patients.”

– Chief Engineer, Leading Prosthetic Limb Manufacturer

Maintenance and Troubleshooting in Limited Access Areas

Keeping your compact torque sensors in top shape in tight spaces is key. XJCSENSOR’s team has come up with smart ways to keep your low-profile torque measurement systems running smoothly. This is true even in the most cramped areas.

Regular checks and upkeep are essential to avoid problems with your compact torque sensors. Our experts suggest a detailed maintenance plan. This includes checking for wear, managing cables, and ensuring everything is securely mounted. By being proactive, you can catch issues early and extend your sensors’ life.

If your sensors start acting up or don’t perform as expected, our team is ready to help. We’ll guide you through simple steps to find and fix the problem. Our goal is to help you maintain your sensors’ efficiency, even in the most challenging spaces.