At XJCSENSOR, we’re excited to provide advanced, customizable 6-axis force torque sensors. These solutions are changing the game in industrial automation. Our technology offers unmatched precision in measuring force and torque. This means better control and efficiency in many manufacturing processes.

Our 6-axis force torque sensors are made to meet the needs of today’s industries. They use the latest in multi-axis measurement tech. This gives you detailed data on forces and torques in six directions. It helps you achieve top precision, control, and process improvement.

Whether you’re in robotics, aerospace, or automotive testing, we’ve got you covered. Our sensors can be customized to fit your needs. With options like modular design and advanced signal processing, we aim to help you innovate and boost productivity.

Key Takeaways

- XJCSENSOR offers cutting-edge 6-axis force torque sensor solutions for industrial automation

- Sensors provide precise force and torque data in six degrees of freedom

- Customizable options available to suit specific application requirements

- Designed for enhanced control, efficiency, and process optimization in manufacturing

- Applications span robotics, aerospace, automotive, and other industrial sectors

Understanding Six-Axis Force Torque Sensor Technology

Modern industrial automation relies on multi-axis force torque sensors. These tools give us key insights into forces and torques in manufacturing. They help us control and improve our processes with precision. Let’s explore the basics, parts, and systems of six-axis force torque sensor technology.

Basic Principles of Multi-Axis Force Measurement

These sensors use strain gauges and smart algorithms to measure forces and torques. They track six axes: three for movement (X, Y, Z) and three for rotation (roll, pitch, yaw). This detailed data helps manufacturers understand mechanical stresses and loading conditions better.

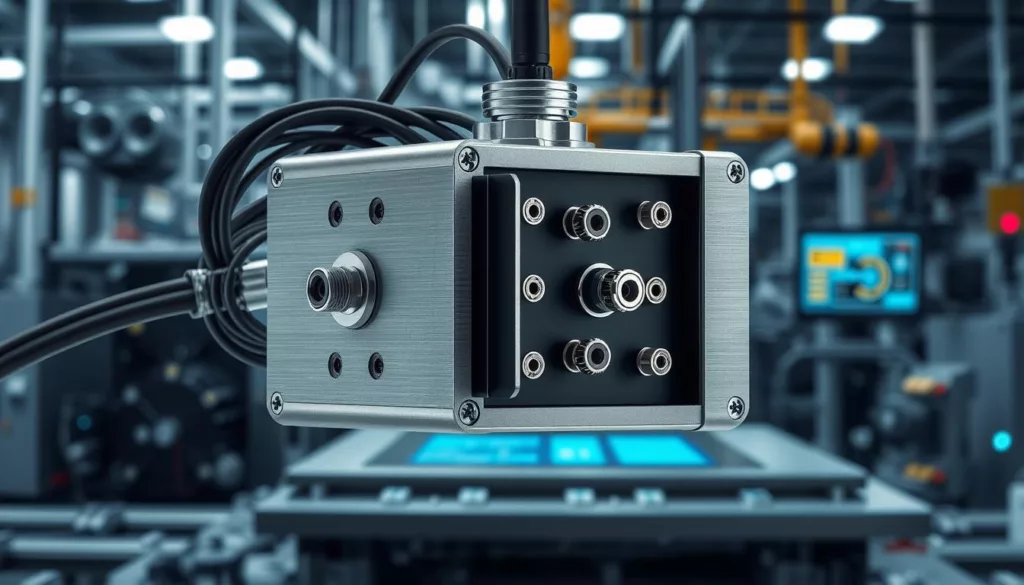

Components and Architecture of 6-Axis Sensors

A six-axis force torque sensor has a core element, often a metal alloy platform. This platform is equipped with strain gauges to measure forces and torques. The sensor also has circuits for processing and conditioning signals, turning raw data into useful measurements.

Signal Processing and Data Acquisition Systems

Advanced systems handle the complex task of turning sensor signals into useful data. They use algorithms to filter noise, adjust for environment, and provide detailed measurements. Connecting these systems with control and monitoring infrastructure is key to unlocking multi-axis load monitoring and custom sensor integration.

“The ability to precisely measure and monitor forces and torques in multiple dimensions is a game-changer for modern industrial automation.”

| Feature | Benefit |

|---|---|

| Comprehensive 6-axis measurement | Provides a complete picture of mechanical stresses and loading conditions |

| Advanced signal processing | Ensures high-accuracy, noise-free force and torque data |

| Seamless integration | Enables real-time monitoring and closed-loop control in industrial processes |

Key Applications in Modern Industrial Automation

The world of manufacturing is changing fast. Robotic force sensing and industrial automation force control are key to this change. At XJCSENSOR, we’ve made customizable 6-axis force torque sensors. These are changing how we do things in industrial automation.

Our sensors help make robotic assembly lines better. They also improve quality control systems. They give real-time data on force and torque. This helps systems adjust and work better, making production smoother and safer.

In the car industry, our sensors help robots weld and assemble parts. They make sure welds are good and parts fit right. In aerospace, they help robots put in fasteners accurately, which is key for safety.

Our sensors are also changing medical device making. They help with making delicate parts. They’re used in electronics too, for checking product quality.

As automation gets smarter and more data-driven, our sensors will be even more important. They help manufacturers improve, make things safer, and innovate. We’re helping shape the future of industrial automation.

“Our 6-axis force torque sensors are enabling manufacturers to unlock new levels of precision, efficiency, and safety in their production workflows.”

Customizable 6 axis force torque sensor solutions for industry

At [XJCSENSOR], we know every industry has its own needs for precise force measurement. That’s why we offer customizable 6 axis force torque sensors. They fit perfectly into many manufacturing and automation systems.

Modular Design Options

Our 6 axis force torque sensors have a modular design. This makes it easy to customize them. Customers can pick from different sensing elements, electronics, and interfaces. This way, we can make a sensor that fits their exact needs.

Customization Parameters and Specifications

Our engineers work with clients to adjust sensor details. We can change the measurement range, accuracy, resolution, and how well it works in different environments. This ensures the sensor works perfectly with the industrial process or automation system.

Integration Flexibility Features

Adding advanced sensors to complex manufacturing setups can be tough. That’s why our sensors have features like many communication protocols, programmable calibration, and distributed I/O. These features make it easier to use our sensors in various industrial settings.

With our modular design, customization, and integration flexibility, [XJCSENSOR] offers 6 axis force torque sensors. They optimize precision force measurement and custom sensor integration for many industrial uses.

Precision Force Measurement in Manufacturing Processes

In today’s fast-paced industrial world, precise force measurement is key. It ensures product quality, cuts down on waste, and boosts production efficiency. Our 6 axis force torque sensors lead the way, meeting the varied needs of manufacturers in different sectors.

Getting force measurement right is essential in making products. Even small changes can affect how well a product works. Our sensors use the latest tech for precision force measurement. This lets manufacturers keep a close eye on important factors during production.

- Optimize process control and quality assurance

- Detect and prevent possible defects or failures

- Boost production efficiency and cut down on material waste

Our industrial automation force control solutions bring a new level of insight and control. This technology helps manufacturers make better choices, improve their workflow, and consistently produce top-notch products.

“The ability to precisely measure and monitor forces in our manufacturing processes has been a game-changer for our company. We’ve seen a significant improvement in product quality and a reduction in production costs thanks to the customized 6 axis force torque sensors from XJCSENSOR.”

As the industry keeps moving forward, the need for better force measurement tools will grow. XJCSENSOR is leading this change, giving manufacturers the tools and knowledge they need to succeed in the smart manufacturing age.

Advanced Robotic Force Sensing Applications

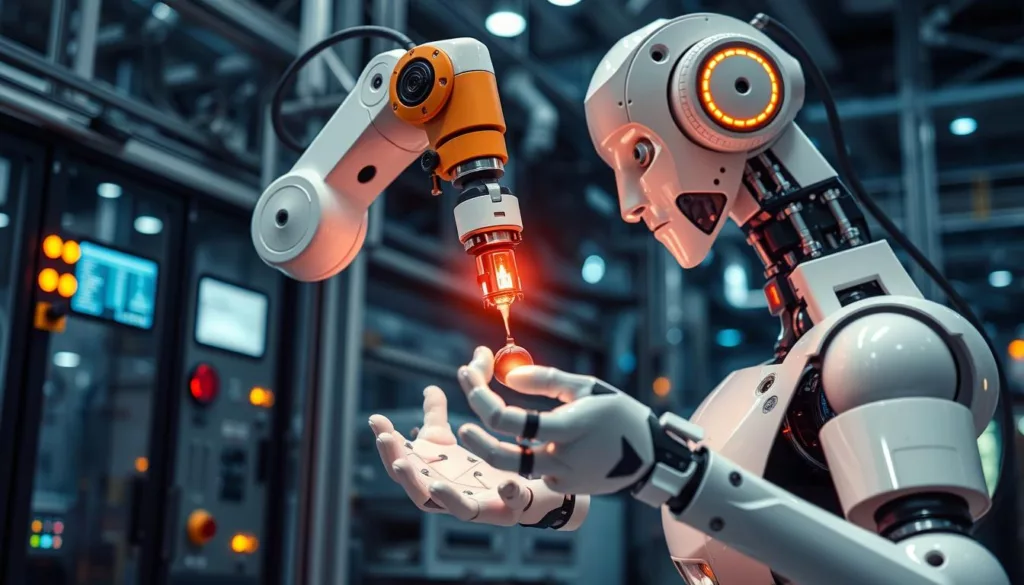

Robotic force sensing is changing the game in industrial automation. It’s making things more efficient and improving quality control. Our six-axis force torque sensors lead the way, making robots work better in many areas.

Collaborative Robot Integration

Our robotic force sensing helps collaborative robots work safely with humans. These sensors track forces and torques, making robots move smoothly. This reduces the chance of accidents or damage.

Assembly Line Automation

In assembly line automation, our robotic force sensing tech is key. It measures forces in assembly steps, giving insights for better production. This leads to fewer mistakes and better products.

Quality Control Systems

Our industrial automation force control sensors boost quality control. They capture force data in real-time, spotting small issues early. This ensures products are always up to standard.

| Application | Key Benefits |

|---|---|

| Collaborative Robot Integration | Enhanced safety, efficient human-robot collaboration, and dynamic response to forces |

| Assembly Line Automation | Optimized production processes, reduced errors, and improved product quality |

| Quality Control Systems | Precise detection of deviations, early identification of issues, and consistent quality |

“Our advanced force sensing solutions are redefining the boundaries of industrial automation, unlocking unprecedented levels of precision, efficiency, and quality control.”

Multi-Axis Load Monitoring and Analysis

In the world of industrial automation, it’s key to monitor and analyze multi-axis loads well. This helps improve process efficiency, product quality, and safety. XJCSENSOR’s force torque sensors give real-time data on multi-axis loads. This helps our customers make smart decisions to move their operations forward.

Our sensors can track loads in multiple axes, not just one. This gives a full view of forces and torques on important parts and systems. It lets our customers spot small changes, find issues early, and plan maintenance to cut downtime and extend equipment life.

Our multi-axis load monitoring solutions focus on precision force measurement. Our sensors give accurate and reliable data. This is vital for tasks like robotic assembly, quality control, and process monitoring.

“XJCSENSOR’s multi-axis load monitoring solutions have been a game-changer for our manufacturing operations. The detailed data and analysis have allowed us to identify and address issues before they become major problems, leading to significant improvements in efficiency and product quality.”

By using our force torque sensors, our customers get lots of useful information. This helps them make better decisions, improve their processes, and stay competitive. Join the many industries using XJCSENSOR’s solutions to reach new heights of excellence.

Integration Challenges and Solutions

Adding force torque sensors to industrial systems can be tricky. Issues range from hardware to software problems. At XJCSENSOR, we tackle these challenges with smart solutions. This ensures our sensors work well with your systems.

Hardware Compatibility Issues

It’s key to match sensors with your equipment. Our sensors fit easily and talk to many systems. We help you fit our sensors into your setup without trouble.

Software Integration Strategies

Getting sensor data into software can be hard. XJCSENSOR helps with programming and API work. Our team makes sure your data flows smoothly, helping you control your industrial processes better.

Calibration and Maintenance Protocols

Keeping sensors accurate and reliable is vital. XJCSENSOR offers clear guides for setup and upkeep. Our tools help you keep your sensors running well, saving you time and improving your data.

XJCSENSOR helps you get the most out of our sensors. This boosts your productivity and quality in industrial automation.

Future Trends in Force Torque Sensing Technology

The world of industrial automation is changing fast. The need for customizable 6 axis force torque sensors is growing quickly. Our team at XJCSENSOR is leading this change, finding new ways to improve our robotic force sensing solutions.

We see a big trend coming: using new materials and miniaturization. This will help us make smaller, stronger force torque sensors. These sensors will be ready for the tough demands of industrial settings.

We’re also working on smart data processing and machine learning. These technologies will make our sensors give real-time insights. This will help our customers improve their manufacturing and increase productivity.

“The future of force torque sensing lies in the seamless integration of hardware and software, delivering intelligent insights that drive innovation across a wide range of industries.”

We’re also looking into wireless communication and cloud data management. This will let our customers check their sensor data from anywhere. They can make quick decisions and adapt to production changes easily.

Collaborative Robotics and Advanced Automation

One exciting area is using our sensors in collaborative robots. These robots will work safely with humans, changing how industries automate. It’s a big step forward.

As we keep improving force torque sensing, our customers will see big changes. Their manufacturing will be more flexible and efficient. By working with XJCSENSOR, they’ll stay ahead in this fast-changing field.

Conclusion

Our customizable 6 axis force torque sensor solutions have changed the game in industrial automation. They help manufacturers reach new heights in precision, efficiency, and control. Our clients have seen big improvements in product quality, process optimization, and safety.

These sensors work well in many industrial settings. They’re used in robotics, assembly lines, quality control, and load monitoring. Their flexibility, along with our technical know-how and innovation, make us a reliable partner in force control.

We’re committed to advancing force and torque measurement technology. We aim to offer more advanced, customizable solutions to our partners. By leading in this field, we’re confident we can help our clients succeed and grow in the future.