It’s important to know the difference between force and torque sensors for those in sensor technology. Each sensor has its own role and knowing their uses can make your measurements more accurate and efficient. We’ll explore the main differences between these sensors, focusing on their basic principles and how they meet different measurement needs.

A force sensor, also known as a force measuring device, measures the force on an object. It turns forces like tension, compression, and pressure into electrical signals. In contrast, a torque sensor measures the twisting force on an object. Both sensors are crucial for precise measurements in engineering and industry. Choosing the right sensor can greatly improve how well things work.

Key Takeaways

- Force sensors measure mechanical forces like tension, compression, and pressure.

- Torque sensors measure twisting forces exerted on an object.

- Accurate sensor selection is crucial for specific applications and ensures operational efficiency.

- Understanding the principles of force and torque measurement is essential for precise data.

- Both sensors convert mechanical forces into measurable electrical signals.

- Consulting technical specifications and industry standards is beneficial for making informed decisions.

Introduction to Force Sensors and Torque Sensors

Understanding sensor technology is key in today’s industries. Force sensors and torque sensors are crucial for precision and efficiency.

What is a Force Sensor?

A force sensor measures the force on an object. It turns mechanical force into an electrical signal. This signal can be measured and analyzed.

Force sensors are used in many industrial settings. They help in manufacturing, testing, and automation.

What is a Torque Sensor?

A torque sensor measures twisting or rotational force. It’s different from a force sensor. It’s vital in engine testing, monitoring rotary equipment, and controlling machinery.

| Feature | Force Sensor | Torque Sensor |

|---|---|---|

| Primary Measurement | Linear Force | Rotational Force (Torque) |

| Common Applications | Manufacturing, Testing, Automation | Engine Testing, Machinery Control |

| Conversion Type | Mechanical to Electrical | Mechanical to Electrical |

As shown in the table, force and torque sensors have different roles. Yet, they work together in many industrial settings.

Key Differences Between Force Sensors and Torque Sensors

It’s important to know the differences between a precision force sensor and a high accuracy torque sensor. These sensors have unique features for measuring forces and torques. They are designed for various industrial and scientific uses.

Measurement Capabilities

A precision force sensor measures the force on an object, in Newtons (N). It can handle a wide range of forces, from very small to very large. This makes it useful for testing materials and studying biomechanics.

A high accuracy torque sensor, on the other hand, measures the rotational force, or torque, on an object. It records this in Newton-meters (Nm). This is vital for precise torque measurements in car testing and robotic systems.

Design and Structure

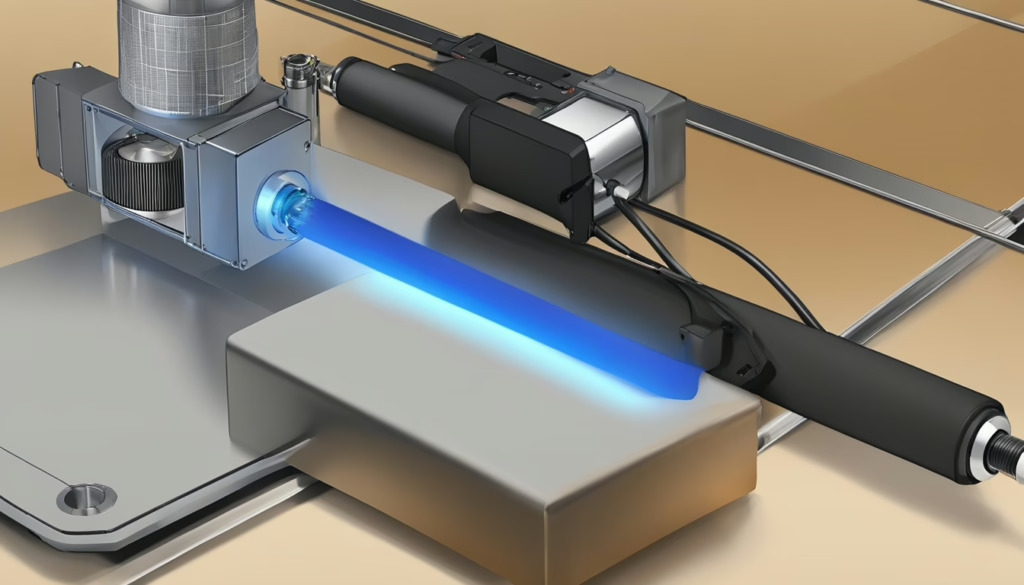

These sensors are built with specific designs for their tasks. Precision force sensors use strong materials like stainless steel or aluminum. They also have strain gauges to measure how much they bend under force.

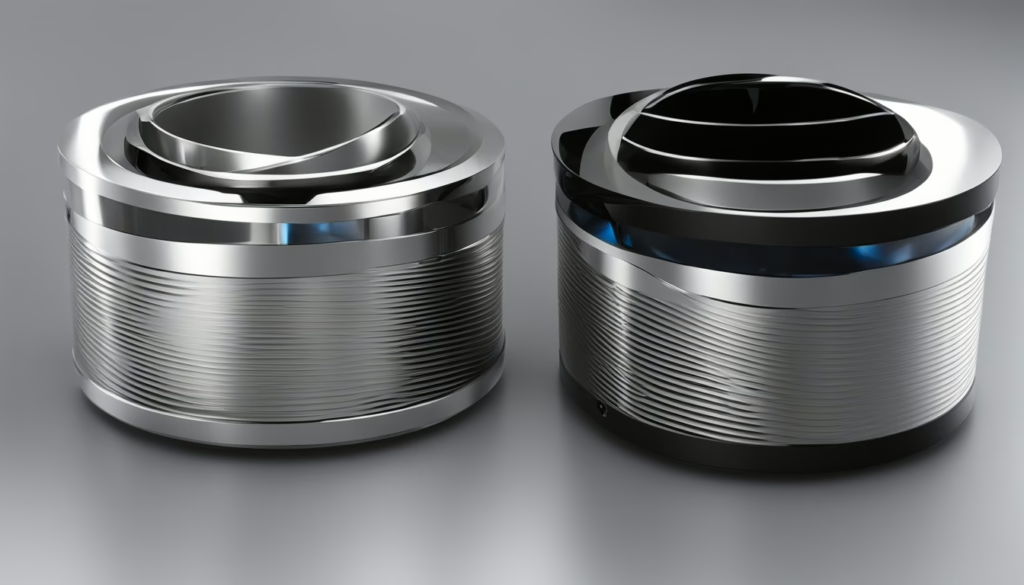

For torque sensors, the design includes a rotating part and precise strain gauge placement. This setup helps capture tiny twists and turns. The engineering ensures accurate readings, even in tough conditions.

One study from the National Institute of Standards and Technology (NIST) highlights the importance of structure and material for high accuracy in force and torque sensors.

| Aspect | Precision Force Sensor | High Accuracy Torque Sensor |

|---|---|---|

| Measurement Type | Force (Newtons) | Torque (Newton-meters) |

| Sensitivity Range | Very Low to High Forces | Extremely Precise Torque |

| Structural Materials | Stainless Steel, Aluminum | High-Precision Alloys |

| Application Focus | Material Testing, Biomechanics | Automotive Testing, Robotics |

Applications of Force Sensors

Force sensors are key in many industries for quality, safety, and performance. They help in making sure products are top-notch. Companies like FUTEK make sensors that are used in many ways, each one needing the exact force measurement these devices provide.

In robotics, force transducers are vital. They let robots move smoothly with their surroundings. This means robots can do tasks like putting together parts, picking up objects, and placing them down with much better accuracy.

The medical field uses force sensors too. They’re in surgical tools and systems that watch over patients. These sensors make sure medical devices work well and keep an eye on patients, helping keep them safe and improving their care.

In manufacturing, force transducers are a must. They’re used in checking quality, watching over machines, and in automated systems. These sensors make sure machines don’t push too hard or too soft, which helps avoid mistakes and makes things more efficient.

Force sensors are also in new and exciting areas. They’re in exoskeletons for helping people get better and in virtual reality for making experiences feel real. These sensors make things more realistic and help make therapy work better.

Here are some common places you’ll find force sensors:

- Robotics: They make robots move and interact safely and precisely.

- Medical Devices: They help with surgery and watching over patients.

- Manufacturing: They keep an eye on quality and machine performance.

- Automotive: They’re used in crash tests and checking car parts.

- Aerospace: They help control aircraft and test materials.

Seeing how force sensors are used shows how important they are in today’s tech world. They help make things work better and more efficiently, leading to new discoveries and improvements in many areas.

Applications of Torque Sensors

Torque sensors are key in many industries for their precise measurement and control. In the automotive world, they are vital for testing engines, gearboxes, and drive trains. Using a torque measuring instrument helps ensure parts meet high standards for performance and safety.

They’re not just for cars, though. In manufacturing, torque sensors are crucial for checking and controlling the assembly line. This ensures products are consistent and of high quality. They’re also essential in testing electric motors, where an accurate sensor keeps them running efficiently and reliably.

Torque transducers are vital in feedback systems and predictive maintenance. They keep track of torque output and warn operators of potential problems early. This reduces downtime and boosts efficiency.

New tech is finding new uses for torque sensors. In robotics, they help control movement precisely, crucial for both industrial and collaborative robots (cobots). As automation grows, so will the need for these sensors to improve accuracy and control.

To show how torque sensors are used across different sectors, look at this table:

| Industry | Application | Benefit |

|---|---|---|

| Automotive | Engine testing | Improved performance and safety |

| Industrial Manufacturing | Assembly line monitoring | Enhanced product consistency |

| Electric Motors | Performance testing | Increased reliability |

| Robotics | Movement control | Precise operation |

Torque sensors have many uses and are becoming even more important with new tech. For more info on their types and applications, check out the XJCSENSOR website.

Understanding Force Transducers and Load Cells

Force transducers and load cells are key in measuring force and weight across different fields. They offer high precision and reliability, making them crucial in many areas. These sensors use advanced tech to turn mechanical force into electrical signals we can read.

Force Transducers

Force transducers measure the strength of a force. They have a high-quality sensor that changes force into an electrical signal. Made from strong materials, they can handle tough industrial settings. Their goal is to stay accurate by reducing errors from temperature changes and other issues.

Calibration is key to making sure these sensors give correct readings all the time.

FUTEK’s force transducers show how precise they can be. They fit well into bigger measurement systems. Adding a precise force sensor to a transducer boosts the system’s performance and trustworthiness.

Load Cells

Load cells are a type of force transducer made for measuring weight. They’re used in many fields like manufacturing, healthcare, and transport. There are different types, like single-point, shear beam, and S-type, each for a particular use.

Load cells are made from strong materials like alloy steel, stainless steel, and aluminum. This lets them work well even in tough conditions. It’s important to calibrate them often to fix errors like zero offsets and linearity issues.

Having a top-notch sensor inside load cells means they give precise measurements. These are vital in important tasks. They help keep the measurement process reliable and accurate.

For more info on force measurement solutions, including choosing the right load cell, check out FUTEK’s technical guides.

Detailed Look at Torque Measuring Instruments

Getting accurate readings from torque measuring instruments is key in many fields. Thanks to sensor technology, we now have super precise torque transducers. These tools are vital for measuring torque accurately. They help make sure things work well in fields like cars and planes.

Torque Transducers

Torque transducers are crucial for exact measurements. They come in different types, each suited for certain needs and places. Here are the main types:

- Static Torque Transducers: These measure torque in still objects. They’re often used for setting standards and measuring torque that doesn’t change.

- Rotary Torque Transducers: These are for moving parts. They’re key in the car and machinery industries because they measure torque in action.

- Reaction Torque Transducers: These are for situations where the torque force stays the same and doesn’t spin. They’re simple to use.

Thanks to sensor technology, high accuracy torque sensors are now more important than ever. They help make products better and check their quality. Researchers keep working to make these sensors more sensitive and reliable.

In the car industry, high accuracy torque sensors make a big difference. They make sure the engine gets the right amount of torque, cutting down on mistakes and making the product better. In aerospace, getting torque right is key for safety and performance.

Companies like XJCSENSOR are always finding new ways to improve torque measuring tools. They use the latest sensor technology and strict testing to make sure their products meet the needs of various industries.

| Type | Application | Accuracy Level |

|---|---|---|

| Static Torque Transducer | Calibration tasks, static measurements | High |

| Rotary Torque Transducer | Dynamic measurements, rotating systems | Very High |

| Reaction Torque Transducer | Constant force applications | High |

Advantages of High Accuracy Torque Sensors

Using a high accuracy torque sensor brings many benefits, like better performance and safety. These sensors are key in fields like aerospace, defense, and automation. They make precise torque measurement crucial.

These sensors are very reliable. They make sure every reading is accurate and dependable. This means operations run smoother and more efficiently.

- Economic Benefits: High accuracy torque sensors mean less need for costly fixes and upkeep. They last longer, giving you more value for your money.

- Safety Implications: Accurate torque measurement is key for safety, especially in areas needing precise mechanical performance. It helps cut down risks and prevent accidents.

- Enhanced Productivity: Precision torque sensors help control processes better, cutting down on downtime. This makes workflows more efficient and boosts output.

Research, like technical briefs and white papers, shows how vital high accuracy torque sensors are. In manufacturing, their consistent, reliable performance ensures quality products. Safety reports also stress their importance in keeping up strict safety standards.

High accuracy torque sensors are more than just a tech upgrade. They’re essential for the efficient and safe operation of today’s industrial processes.

Precision in Force Sensors

In industries that need top-quality control, a precision force sensor is key. These sensors make sure measurements are right and dependable. This keeps production processes running smoothly. Thanks to new tech, these sensors can now handle tough environments better, giving accurate force measurement.

For top precision, makers use the latest materials and designs. This makes the sensors work better and last longer. Keeping them calibrated and maintained right is crucial. Following standards like those from the National Institute of Standards and Technology (NIST) keeps the sensors working well for a long time.

- Regular calibration boosts the sensor’s performance.

- Following global technical standards is key.

- Quality control managers stress the need for precise sensors for top products.

Top-notch sensors are built to meet strict standards, ensuring consistent and precise force readings. Companies like Honeywell, Futek, and TE Connectivity provide detailed manuals. These manuals cover how to calibrate and maintain the sensors. Following these guidelines helps keep the sensors working right, so industries can count on accurate force measurement.

Talking to quality control managers shows how much they value precision. They say the sensor’s precision affects product quality and how well things run. Investing in a high-quality sensor means better performance and steady quality in production.

Also, knowing how to properly care for and maintain precision force sensors helps them stay at their best. This keeps critical measurements accurate across different uses.

The Role of Sensor Technology in Industry

Today, sensor technology is key in making industries more efficient and precise. It’s not just a trend; it’s a must-have to stay ahead. Advanced sensor systems help improve automation and efficiency across many sectors.

Importance of Precision Sensors

Precision sensors are crucial for tasks that need high accuracy and reliability. They’re used in monitoring critical infrastructure and precision machining. These sensors help keep quality high and operations running smoothly.

Thanks to tech advances, like those from XJCSENSOR, industries can cut down on mistakes and work better.

Industrial Sensor Applications

Sensors are used in many areas, including manufacturing, healthcare, and transportation. In manufacturing, they help monitor and control machines in real-time. This ensures products are always top quality and reduces downtime.

In healthcare, they’re key for tracking patients’ vital signs. They give accurate data that’s vital for patient care. In transportation, sensors check how well vehicles are doing and make them safer.

Using these sensors makes things more efficient and gives important data for better decisions. Companies leading in this field offer customization and reliable supply chain management. This ensures clients are happy and projects succeed.

Choosing High-Quality Sensors

Picking a high-quality sensor is key for getting accurate and reliable results in many fields. It’s important to look at several key factors and the sensor manufacturer’s reputation.

- Accuracy and Precision: Make sure the sensor gives accurate and precise readings for your specific needs.

- Durability and Longevity: Good sensors should last long and handle tough conditions well.

- Calibration and Certification: Choose sensors that are properly calibrated and certified by trusted industry groups.

- Technical Support and Warranties: Good sensor suppliers offer great technical support and warranties, which are very helpful if there are problems.

Also, buying from well-known sensor manufacturers has many advantages:

- Enhanced Reputation: Using top sensors from respected suppliers can make your product look better in the market.

- Operational Efficiency: High-quality sensors usually work better and need less upkeep, making things run smoother.

- Comprehensive Support Ecosystem: Leading manufacturers offer strong support systems, including manuals, customer service, and help after you buy.

Looking at best practices and what customers say shows why it’s smart to invest in top-notch sensors. Customers often talk about the big wins of using premium sensors, like less downtime and better accuracy. Also, looking into the supply chain shows that top sensor suppliers can keep quality high and deliver on time, making things more reliable.

Force Sensor and Torque Sensor: Making the Right Choice

Choosing between a force sensor and a torque sensor depends on several factors. Each sensor has unique benefits for different needs. It’s important to know the difference between accurate force and precise torque measurement to make a good choice.

Here are some key points to consider:

- Application Requirements: Determine if you need to measure linear or rotational forces. Accurate force measurement is best for linear forces. Precise torque measurement is needed for rotational forces.

- Sensor Characteristics: Look at what each sensor can do. XJCSENSOR offers force sensors known for their accuracy and durability. Torque sensors are great for measuring rotational forces.

- Environmental Conditions: Think about where the sensor will be used. Some sensors can handle extreme temperatures, humidity, or mechanical stress.

- Integration and Customization: Choose sensors that are easy to add to your system and can be customized. XJCSENSOR provides expert advice and custom options for easy integration.

Here’s a table to help you pick the right sensor:

| Criteria | Force Sensor | Torque Sensor |

|---|---|---|

| Measurement Type | Linear Force | Rotational Force |

| Accuracy | High | High |

| Sensors Available | 2-6 Axes | 1-3 Axes |

| Customization | Yes | Yes |

| Environmental Suitability | Varies | Varies |

Engineering consultancies and industry guides can help with your decision. Looking at real-world examples and business success stories can also offer useful advice.

In conclusion, the right choice between force and torque sensors is crucial for your project’s success. By carefully considering your needs and the sensor’s features, you can make the best decision.

Conclusion

We’ve looked into the differences between force and torque sensors. We’ve seen how they are used and what to consider when choosing one. These sensors are key in many fields, like manufacturing and robotics, where being precise and reliable matters a lot.

Force sensors measure the force on an object, while torque sensors check rotational force. Knowing these differences helps pick the right sensor for the job. This choice boosts performance and efficiency. Plus, using accurate sensors can lead to better results now and in the future.

As sensor technology gets better, we’re looking forward to more precise and efficient sensors. Experts say we’re entering a new era in measuring things. This change will bring new ideas and make things work better in many areas. It promises a future that’s more connected and advanced.