Precision in Every Dimension – XJCSENSOR's 2 Axis Force Sensors

In today’s rapidly evolving industrial landscape, precision and reliability are paramount. XJCSENSOR stands at the forefront of sensor technology, offering state-of-the-art 2 Axis Force Sensors that empower industries to achieve unprecedented levels of accuracy and efficiency. Our sensors are meticulously engineered to support critical applications across automation, robotics, material testing, and more. This page delineates how our products meet the highest standards of innovation and quality.

- Precision Measurement

- Multi-Axis Sensitivity

- Durably Constructed

- Ease of Integration

- Stable and Reliable

Understanding 2 Axis Force Sensors

What Are 2 Axis Force Sensors?

Two-axis force sensors are sophisticated devices designed to measure force along two perpendicular axes. These sensors are essential in applications where forces are acting in multiple directions, providing precise data to facilitate complex analyses and control mechanisms.

Key Features:

- Dual-Directional Measurement: Offers the ability to capture forces in two independent directions.

- High Sensitivity: Ensures the detection of even minimal force changes.

- Robust Design: Suitable for harsh industrial environments.

The Role of Accurate Force Measurement

Force measurement plays a critical role in various industries. Whether it’s ensuring product quality in manufacturing or enhancing the capabilities of robotic systems, accurate force data is indispensable. XJCSENSOR’s 2 Axis Force Sensors provide the necessary precision and reliability to help businesses optimize operations and maintain competitive advantages.

Our Range of 2 Axis Force Sensors

Delve into our extensive list of 2 Axis Force Sensors, each one embodying XJCSENSOR’s commitment to quality and performance. Whether your requirement is for compact size, high capacity, or anything in between, our product lineup has a sensor to meet your needs.

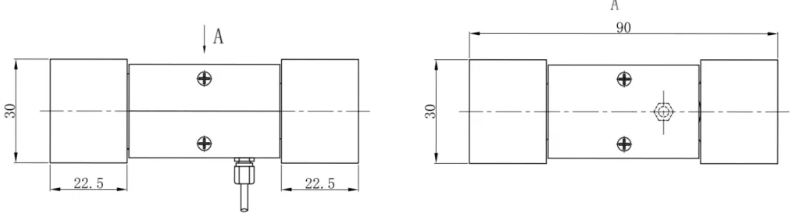

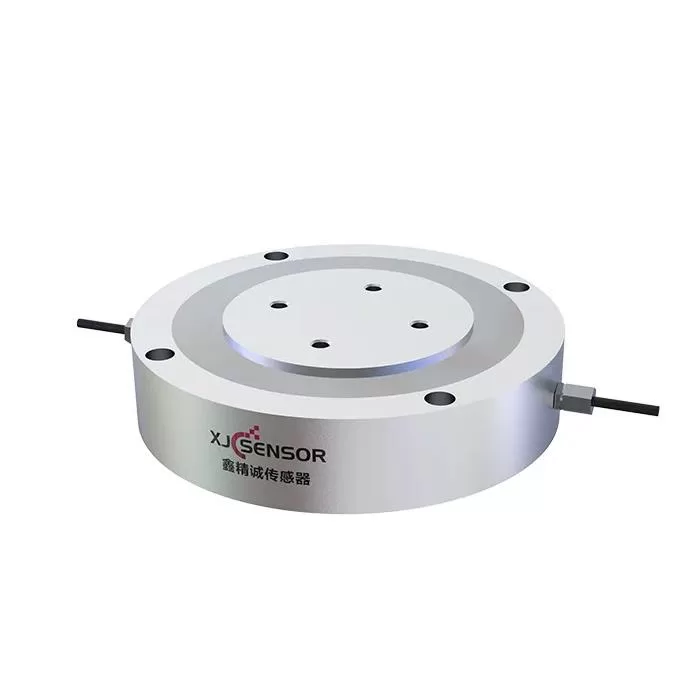

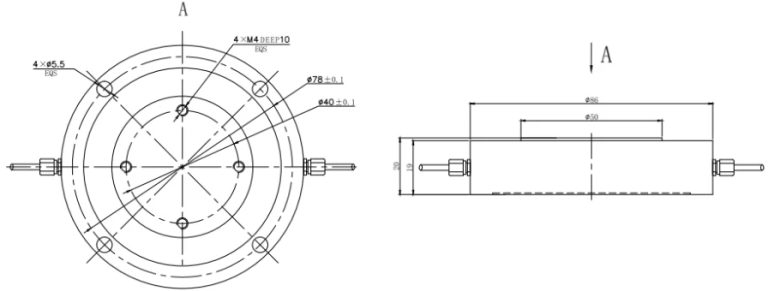

Model :X-2A-30-H90

Technical Parameter

- Non-linearity: ≤0.2%F.S.

- Repeatability: ≤0.05%F.S.

- Zero balance: ±5%F.S.

- Operating temp range: -20~80°C

- Compensated temp range: -10~40°C

- Insulation: ≥2000MΩ/50VDC

- Recommended excitation voltage: 12-30VDC

- Safe load limit: 300%F.S.

- Temp effect on output: ≤0.5%F.S./10°C

- Temp effect on zero: ≤0.5%F.S./10°C

- Long-term crosstalk error: ≤0.5%F.S.

- Protection class: IP65

- Cable size: φ2*3m

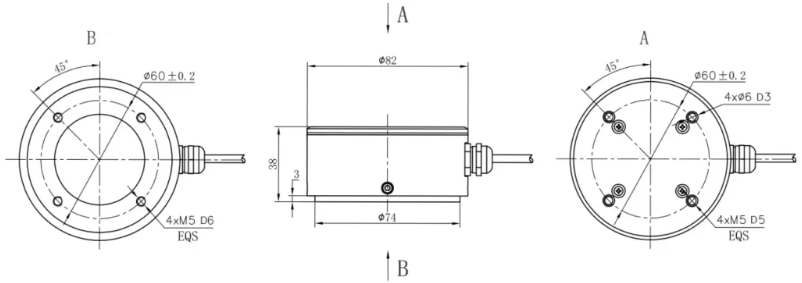

Model :X-2A-A-D82-H38

Technical Parameter

- Non-linearity: ≤0.2%F.S.

- Repeatability: ≤0.1%F.S.

- Zero balance: ±2%F.S.

- Operating temp range: -20~80°C

- Compensated temp range: -10~40°C

- Insulation: ≥2000MΩ/50VDC

- Recommended excitation voltage: 5-10VDC

- Safe load limit: 150%F.S.

- Temp effect on output: ≤0.2%F.S./10°C

- Temp effect on zero: ≤0.2%F.S./10°C

- Long-term crosstalk error: ≤0.5%F.S.

- Protection class: IP65

- Cable size: φ4*1m

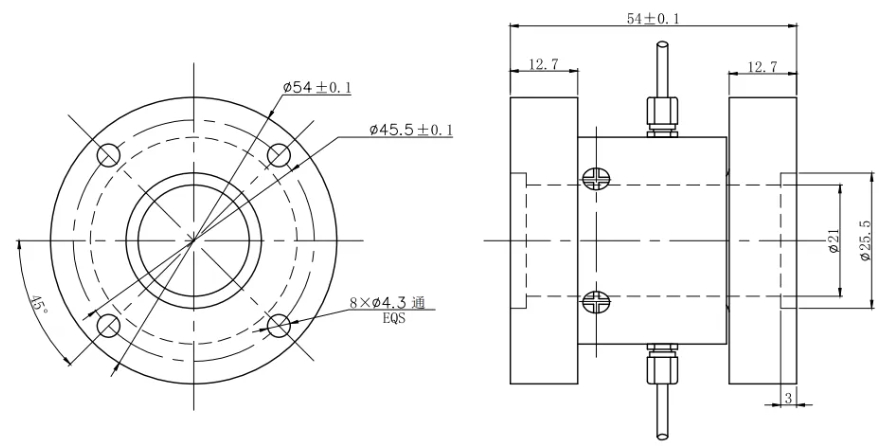

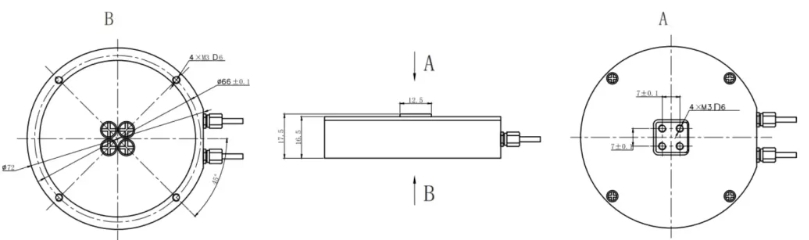

Model :X-2A-D54-H54

Technical Parameter

- Non-linearity: ≤0.2%F.S.

- Repeatability: ≤0.05%F.S.

- Zero balance: ±5%F.S.

- Operating temp range: -20~80°C

- Compensated temp range: -10~40°C

- Insulation: ≥2000MΩ/100VDC

- Recommended excitation voltage: 12-30VDC

- Safe load limit: 300%F.S.

- Temp effect on output: ≤0.5%F.S./10°C

- Temp effect on zero: ≤0.5%F.S./10°C

- Long-term crosstalk error: ≤0.5%F.S.

- Protection class: IP65

- Cable size: φ3*3m (two cable)

Model :X-2A-D60-H20

Technical Parameter

- Non-linearity: ≤0.3%F.S.

- Repeatability: ≤0.2%F.S.

- Zero balance: ±3%F.S.

- Operating temp range: -20~80°C

- Compensated temp range: -10~40°C

- Insulation: ≥2000MΩ/50VDC

- Recommended excitation voltage: 5-10VDC

- Safe load limit: 150%F.S.

- Temp effect on output: ≤0.05%F.S./10°C

- Temp effect on zero: ≤0.05%F.S./10°C

- Long-term crosstalk error: ≤0.5%F.S.

- Protection class: IP64

- Cable size: φ3*3m(two cable)

Model :X-2A-D72-H17.5

Technical Parameter

- Non-linearity: ≤0.1%F.S.

- Repeatability: ≤0.1%F.S.

- Zero balance: ±2%F.S.

- Operating temp range: -20~80°C

- Compensated temp range: -10~40°C

- Insulation: ≥2000MΩ/50VDC

- Recommended excitation voltage: 5-10VDC

- Safe load limit: 150%F.S.

- Temp effect on output: ≤0.5%F.S./10°C

- Temp effect on zero: ≤0.5%F.S./10°C

- Long-term crosstalk error: ≤1%F.S.

- Protection class: IP65

- Cable size: φ2*3m (two cable)

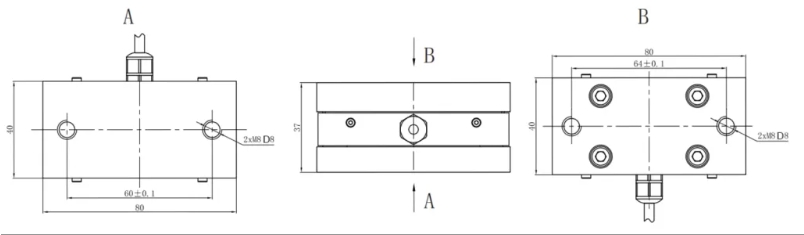

Model :X-2A-L80-W40-H37

Technical Parameter

- Non-linearity: ≤0.2%F.S.

- Repeatability: ≤0.1%F.S.

- Zero balance: ±2%F.S.

- Operating temp range: -20~80°C

- Compensated temp range: -10~40°C

- Insulation: ≥2000MΩ/50VDC

- Recommended excitation voltage: 5-10VDC

- Safe load limit: 150%F.S.

- Temp effect on output: ≤±0.2%F.S./10°C

- Temp effect on zero: ≤±0.2%F.S./10°C

- Long-term crosstalk error: ≤0.5%F.S.

- Protection class: IP66

- Cable size: φ4*1m

Product Features and Specifications

INNOVATIVE DESIGN: Compact and Efficient

Our 2 Axis Force Sensors feature an advanced design tailored to integrate seamlessly into diverse systems.

- Compact Form Factor: Allows for easy installation without requiring significant system redesigns.

- Precision Signal Processing: Minimizes noise, ensuring clean and reliable data output.

- Customizable Configurations: Flexibility in adapting to specific industry needs and applications.

PRECISION ENGINEERING: Unmatched Accuracy

XJCSENSOR sensors embody engineering excellence, characterized by their high accuracy and stability.

- Exceptional Resolution: Capable of detecting small force variations with great precision.

- Durability: Built to withstand extreme conditions, ensuring longevity and consistent performance.

- Versatile Applications: Suitable for environments ranging from controlled laboratories to rugged industrial sites.

Cutting-Edge Technology

Our sensors utilize advanced strain gauge technology to ensure precise measurements. With ongoing research and development, XJCSENSOR continuously enhances sensor capabilities, aligning with the latest technological advancements.

Applications Across Industries

AUTOMATION & ROBOTICS: Integrating Precision and Efficiency

In the realm of automation and robotics, precision is key. XJCSENSOR’s 2 Axis Force Sensors are integral to improving operational control and increasing the efficiency of robotic systems. By providing real-time feedback, these sensors enable robots to perform intricate tasks that require delicate handling and exact positioning.

Benefits in Robotics:

- Enhanced Manipulation: Facilitates gentle object handling in assembly lines.

- Dynamic Load Management: Optimizes the distribution of loads for balanced operation.

- Improved Safety: Helps in avoiding collisions through precise environmental feedback.

MATERIAL TESTING: Ensuring Quality and Compliance

Material testing relies heavily on accurate force measurement to assess properties such as strength, elasticity, and durability. Our force sensors deliver the precision required for thorough analysis and compliance with industry standards.

Key Applications:

- Tensile Testing: Measures material response to stress, aiding in quality assurance.

- Compression Analysis: Evaluates a material’s ability to withstand compressive forces.

- Research and Development: Supports innovation by providing reliable data for new material compositions.

Case Study: Successful Implementation in Smart Manufacturing

Background

A leading manufacturer sought to enhance its production line with precise force measurement tools to improve product consistency and reduce waste. By integrating XJCSENSOR’s 2 Axis Force Sensors, the company achieved significant improvements in product quality and operational efficiency.

Results

- Increased Precision: Improved process control resulted in a noticeable reduction in defects.

- Enhanced Productivity: Streamlined operations led to faster production cycles.

- Cost Savings: Reduced material wastage and improved resource allocation.

This case illustrates the transformative impact of our sensors in real-world applications, underscoring their value in smart manufacturing environments.

Why Choose XJCSENSOR?

EXPERTISE YOU CAN TRUST: Decades of Experience

With extensive experience in the development and supply of advanced sensing technologies, XJCSENSOR combines industry expertise with cutting-edge innovation to deliver superior products. Our commitment to quality and customer satisfaction sets us apart as a trusted partner in force measurement solutions.

COST-EFFECTIVE SOLUTIONS: Balancing Quality and Affordability

We understand the importance of cost-effectiveness. Our sensors provide exceptional value without compromising on performance, making them a viable option for businesses of all sizes. XJCSENSOR is dedicated to providing products that meet budgetary constraints while exceeding expectations in terms of functionality and durability.

CUSTOMIZED SOLUTIONS: Tailored to Meet Your Needs

Recognizing that each industry has unique challenges, we offer customizable sensor configurations to suit specific applications. Our team works closely with clients to develop bespoke solutions that align perfectly with operational goals and requirements.

Support and Services

COMPREHENSIVE MAINTENANCE AND CALIBRATION SERVICES

To ensure optimal performance and longevity, XJCSENSOR provides full maintenance and calibration services. Our expert technicians are equipped to handle routine maintenance as well as unexpected issues, minimizing downtime and maximizing productivity.

- Routine Maintenance: Regular check-ups to keep sensors operating efficiently.

- Calibration Services: Precise adjustments to ensure measurement accuracy.

- Technical Support: Dedicated assistance to address any operational challenges.

Future Trends: The Evolution of Multi-Directional Sensing

The field of force sensing is continually evolving, with new technologies promising further enhancements in accuracy and integration capabilities. At XJCSENSOR, we are committed to staying at the forefront of these developments. From artificial intelligence to IoT connectivity, we are actively exploring innovations that will shape the future of multi-directional sensing solutions.

FAQ

What distinguishes a 2 axis force sensor from other types?

2 axis force sensors provide dual-directional force measurement, capturing data along two perpendicular axes. This capability is essential for applications requiring a comprehensive analysis of force dynamics.

How do I integrate XJCSENSOR’s sensors into my existing systems?

Our sensors are designed for seamless integration. Detailed installation guides and technical support are available to assist with the process, ensuring compatibility and optimal functionality.

What maintenance is required for these sensors?

Regular maintenance, including periodic calibration, is recommended to maintain accuracy and extend lifespan. Our service team is available to provide these services as needed.