High-Accuracy 4 Axis Force Torque Sensor by XJCSENSOR

In industrial automation, robotics, and quality control, multi-axis sensors play an essential role. As a leader in sensor technology, XJCSENSOR offers high-precision 4 axis force torque sensors engineered to meet the demands of complex applications, providing reliable force and torque measurement across four axes.

- Exceptional Multi-Axis Accuracy

- Industrial Resilience

- Streamlined Integration

- Versatile and Customizable

- Innovative Structural Design

UNDERSTANDING 4 AXIS FORCE TORQUE SENSORS

4 axis force torque sensors are specialized devices that measure both force and torque across multiple axes (X, Y, Z, and rotational). This comprehensive multi-axis measurement is vital for applications that require detailed feedback to optimize performance and ensure safety. XJCSENSOR’s sensors deliver real-time data, supporting automation, robotics, and industrial systems with precision.

Our Selection of 4-Axis Force Torque Sensors

Delve into our extensive list of 4 Axis Force Sensors, each one embodying XJCSENSOR’s commitment to quality and performance. Whether your requirement is for compact size, high capacity, or anything in between, our product lineup has a sensor to meet your needs.

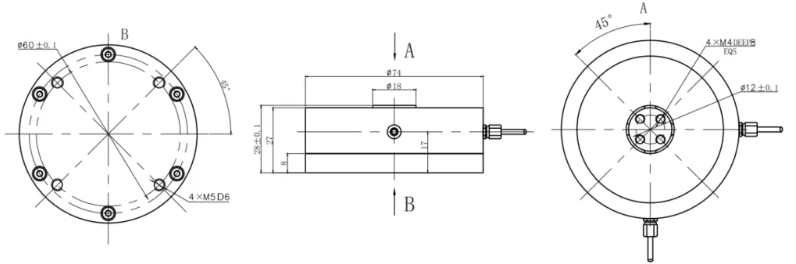

Model :X-4A-D74-H28

Technical Parameter:

- Non-linearity: ≤0.2%F.S.

- Repeatability: ≤0.1%F.S.

- Zero balance: ±0.05%F.S.

- Operating temp range: -20~80°C

- Compensated temp range: -10~40°C

- Insulation: ≥2000MΩ/50VDC

- Recommended excitation voltage: 5VDC

- Safe load limit: 200%F.S.

- Temp effect on output: ≤0.5%F.S./10°C

- Temp effect on zero: ≤0.5%F.S./10°C

- Long-term crosstalk error: ≤2%F.S.

- Protection class: IP65

- Cable size: φ2*3m (2 cables)

ADVANTAGES OF MULTI-AXIS FORCE TORQUE SENSORS

ADVANTAGES of multi-axis force torque sensors include the ability to capture forces and torques simultaneously, enabling advanced control in complex systems. XJCSENSOR’s 4 axis force torque sensors provide enhanced functionality and precision, ideal for industries that require robust and accurate data collection.

Key Benefits:

- Improved accuracy in multi-dimensional force and torque measurement

- Enhanced real-time feedback for system optimization

- Increased efficiency and safety in automated processes

THE ROLE OF 4 AXIS SENSORS IN ROBOTICS

ROBOTICS applications rely on accurate force and torque data to ensure smooth operation and safety. XJCSENSOR’s 4 axis force torque sensors allow robotic systems to handle complex tasks with greater control and precision, such as assembly, material handling, and manipulation. These sensors provide essential data for robotic arms, grippers, and collaborative robots in industrial settings.

Applications in Robotics:

- Precise control of robotic arm movement

- Safe and efficient manipulation of objects

- Enhanced interaction in collaborative robots (cobots)

4 AXIS FORCE TORQUE SENSORS IN AUTOMATION

AUTOMATION processes benefit significantly from 4 axis force torque sensors, which help monitor and adjust forces and torques in real time. XJCSENSOR’s sensors are built to handle high-stress industrial environments, providing the reliability and durability needed to enhance automation systems, from machining and quality control to packaging.

Benefits for Automation:

- Real-time adjustments for enhanced accuracy

- Reduced product defects and operational downtime

- Optimized production processes for efficiency

TYPES OF 4 AXIS FORCE TORQUE SENSORS FOR INDUSTRY NEEDS

TYPES of 4 axis force torque sensors vary depending on industry requirements. XJCSENSOR provides a range of models to suit different applications, each tailored for precision, durability, and compatibility.

- Compact 4 Axis Sensors – Designed for use in tight spaces or intricate systems.

- High-Capacity Sensors – Ideal for heavy-duty applications requiring robust measurements.

- Precision Sensors for Robotics – Calibrated for tasks that require high sensitivity and minimal margin for error.

CUSTOM SOLUTIONS FOR SPECIALIZED APPLICATIONS

CUSTOMIZATION is key to addressing the specific needs of various industries. XJCSENSOR offers customizable 4 axis force torque sensors, designed to meet unique requirements, from precise force ranges to environmental tolerances. We work closely with clients to ensure each sensor integrates seamlessly into their systems, providing reliable data and optimal performance.

THE IMPORTANCE OF HIGH-ACCURACY SENSORS IN TESTING

ACCURACY is essential in testing and measurement applications where precise data is required. XJCSENSOR’s 4 axis force torque sensors deliver highly accurate force and torque data, allowing users to conduct reliable tests and ensure product consistency. These sensors are ideal for applications in material testing, quality assurance, and product development.

Advantages in Testing:

- Reliable, repeatable data for quality control

- Consistent results in testing environments

- Support for advanced research and development processes

QUALITY CONTROL WITH MULTI-AXIS FORCE TORQUE SENSORS

QUALITY control applications rely on accurate data to maintain high standards across production lines. XJCSENSOR’s 4 axis force torque sensors support these efforts by providing comprehensive feedback on forces and torques during production, enabling early detection of errors and ensuring each product meets rigorous standards.

4 AXIS FORCE TORQUE SENSORS FOR INDUSTRIAL AUTOMATION

INDUSTRIAL automation processes depend on real-time force and torque data for optimization. XJCSENSOR’s 4 axis force torque sensors allow for continuous monitoring and adjustment of automated machinery, improving efficiency, reducing downtime, and ensuring quality control across production environments.

Industrial Benefits:

- Reduced operational costs through automation

- Enhanced product consistency

- Minimized risks of mechanical failure

WHY CHOOSE XJCSENSOR FOR YOUR 4 AXIS FORCE TORQUE SENSORS

TRUST in XJCSENSOR’s reputation for quality and expertise has made us a leading provider of 4 axis force torque sensors. Our products are manufactured to the highest industry standards, with a focus on precision, durability, and customer satisfaction. Whether for robotics, automation, or testing, XJCSENSOR’s sensors deliver reliable, accurate measurements that meet the demands of modern industry.

Conclusion

4 axis force torque sensors are indispensable tools in industrial automation, robotics, and quality control. XJCSENSOR’s sensors are engineered to provide reliable, multi-dimensional data, supporting industries in improving accuracy, safety, and efficiency. With customizable options and advanced technology, XJCSENSOR’s 4 axis force torque sensors offer the precision and robustness needed for demanding applications.

Whether in robotics, testing, or quality control, XJCSENSOR’s 4 axis force torque sensors empower businesses to achieve greater precision, ensuring optimized performance and consistent results.