Choosing the right sensor for medical robots is essential. Precision, safety, and efficiency in medical procedures depend on it. This guide provides the needed knowledge for selecting the best sensor solutions.

We’ll discuss different sensor types and how they fit with robotic systems. We’ll also look at regulatory compliance and costs. This will help you understand the complexities of choosing sensors. Our goal is to improve your operations with the best technology.

Key Takeaways

- Comprehensive understanding of sensor types used in medical robotics.

- Importance of compatibility with robotic systems.

- Consideration of regulatory standards for medical devices.

- Cost analysis of various sensor solutions.

- Strategies for effective testing and validation of sensors.

Understanding the Role of Sensors in Medical Robotics

Sensors are key in medical robotics. They improve how robots perform surgeries and keep patients safe. Sensors collect data in real time. This helps make important decisions during surgeries and rehab. Medical robotics sensor selection is critical. The right choice can boost a robot’s performance and effectiveness.

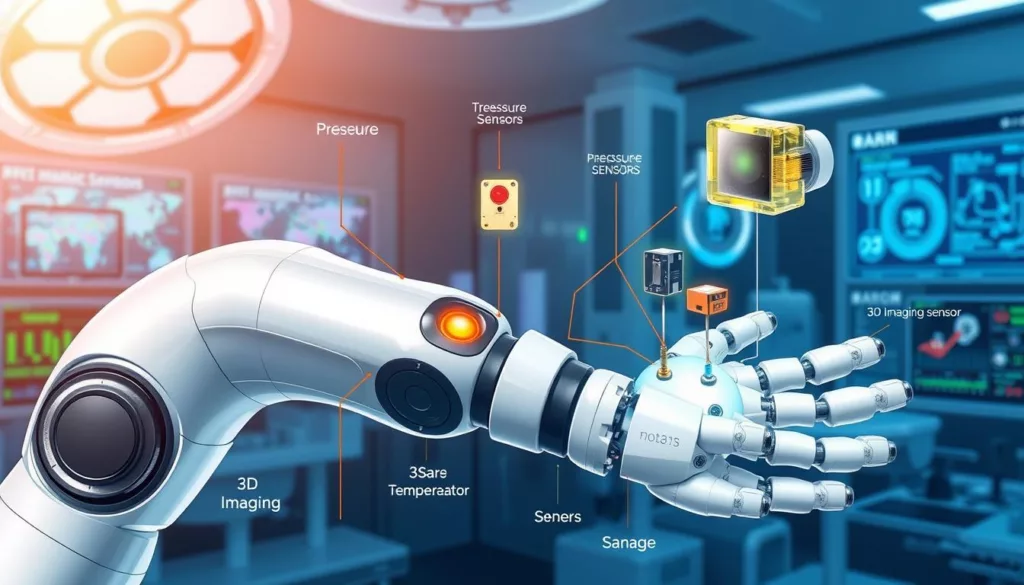

Types of Sensors Commonly Used

There are various sensor types for medical robotics. Each serves a unique purpose. Let’s look at the most common ones:

- Temperature Sensors: These sensors keep an eye on the patient’s temperature. It’s crucial for their safety during operations.

- Pressure Sensors: They help control pressure levels in surgical tools. This improves how doctors perform surgeries.

- Motion Sensors: These are used to monitor and interpret movement. They give vital feedback for robotic systems.

- Biosensors: This type analyzes biological data. It helps in diagnostics or adjusting procedures.

Importance of Sensor Selection

Picking the right sensors for robotic surgery matters a lot. It can make or break success. Here are the main points to consider:

- Functionality: It’s crucial to know what the sensor must do. This ensures it works well and is effective.

- Compatibility: The sensor needs to fit perfectly with other systems. This makes everything more reliable.

- Accuracy: Accurate sensors lead to better outcomes for patients.

- Specific Healthcare Needs: Choosing sensors based on the medical task improves results. It makes the tech more helpful.

For more tips, check out the guide to medical robotics sensors. This guide has valuable info to help you choose the right sensors.

Key Sensor Characteristics to Consider

When picking sensors for healthcare robots, it’s important to know their key features. You should look at their accuracy, response time, and how long they last. Each aspect is critical for the sensor to work well in health care. Let’s dive into these features to help you make better choices.

Accuracy and Precision

Accuracy in medical sensors matters a lot for patient safety and how well treatments work. Sensors with high accuracy give trustworthy data during surgeries with robotic help. Precision means sensors give the same results over and over. Both accuracy and precision make the best sensors for medical robots. They help improve how well surgeries go.

Response Time and Sensitivity

Response time is about how fast a sensor can notice changes. This is key for getting instant feedback during surgery. Sensitivity is the sensor’s ability to spot tiny differences, which is vital for watching over patients. Choosing sensors with great response time and sensitivity makes medical robotics sensor technology work better.

Durability and Reliability

In healthcare, sensors need to be tough. They must handle being cleaned a lot and being around different materials. They should still work well after all that. Reliability means they keep working well over time. Looking at sensor performance in medical applications helps find tough and dependable options. For more about sensor tech, go to this resource.

| Characteristic | Description | Importance in Medical Robotics |

|---|---|---|

| Accuracy | Proximity to true value | Ensures safe and effective surgeries |

| Precision | Consistency of readings | Facilitates repeated and reliable operation |

| Response Time | Time taken to react | Critical for real-time monitoring |

| Sensitivity | Detection of small changes | Improves monitoring capabilities |

| Durability | Ability to withstand conditions | Essential for long-term operation |

| Reliability | Consistency over time | Ensures ongoing performance |

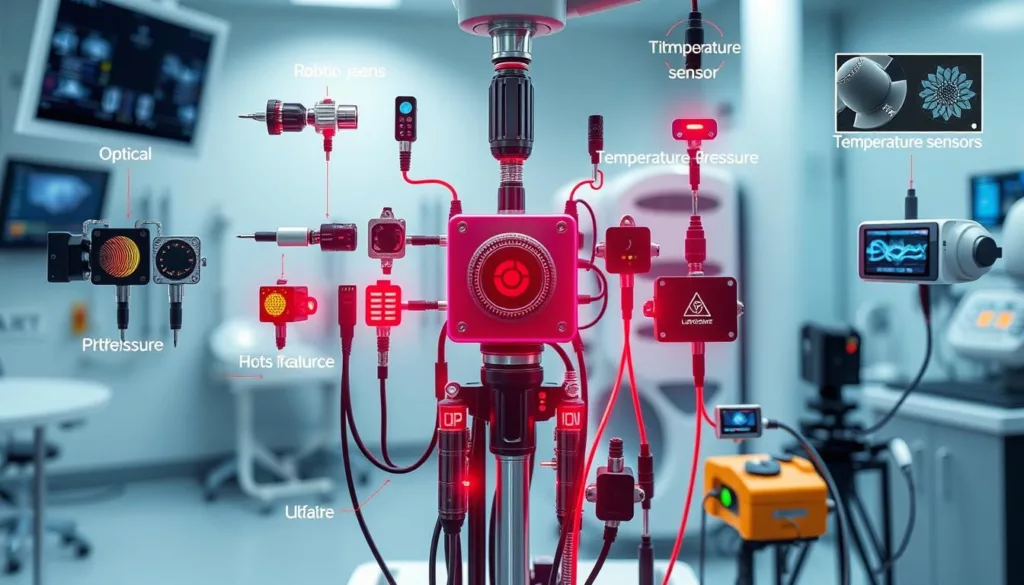

Different Types of Sensors for Medical Robotics

It’s crucial to know about sensor types for medical robotics. They help make surgeries and rehab processes better and safer. Each kind of sensor brings special features that help make patient care better.

Force Sensors

Force sensors are very important in medical robots. They give feedback on how much pressure to use during surgery. This helps the surgical team work with more precision, lowering the risk of hurting the patient. Robotic surgery sensors make operations more exact, letting doctors do complex tasks safely.

Proximity Sensors

Proximity sensors are key for keeping patients safe. They can tell if there are obstacles or people near, helping robots move safely. This tech makes surgical robots more accurate. It also makes sure robots work well in their settings.

Imaging Sensors

Imaging sensors are vital for medical robots. They take and send clear pictures, important for diagnosing and surgery in real-time. These sensors help doctors look closely at the surgery area, making better choices and outcomes.

Inertial Sensors

Inertial sensors are great for studying movement, like in rehab devices. They check speed and rotation, giving info that helps track and improve patient care. Inertial sensors in rehab robots help adjust and respond in therapy.

| Sensor Type | Primary Function | Application in Medical Robotics |

|---|---|---|

| Force Sensors | Measure pressure to enhance precision | Robotic surgery sensors for delicate operations |

| Proximity Sensors | Detect nearby obstacles and patient presence | Ensure safe navigation in healthcare environments |

| Imaging Sensors | Capture and transmit visual data | Aid in diagnostics and provide real-time imaging |

| Inertial Sensors | Measure acceleration and angular velocity | Enhance motion analysis in rehabilitation devices |

Evaluating Sensor Compatibility with Systems

For medical applications to work well, sensors and robotic systems must match perfectly. Knowing how these parts connect makes operations smooth. This depends on how they talk to each other and their electrical needs. Making sure they match up means the system works well together. This is crucial for keeping patients safe.

Interfacing with Robotic Systems

There are important things to think about when connecting sensors to robots:

- Communication Protocols: It’s important that the sensor and robot speak the same language to avoid losing data.

- Electrical Specifications: They must meet the power needs to ensure they work well together.

- Physical Connections: The physical parts must fit well for easy setup and care.

Power Requirements and Consumption

Sensors have specific power needs to perform well in robots. They have different power features that need checking before use:

- Power Ratings: Knowing the power needs of a sensor helps make sure it fits with the robot.

- Operational Efficiency: Look for sensors that do a lot without using too much power.

- Sensor Power Consumption Analysis: Studying how much energy a sensor uses helps make the system more efficient.

Getting these aspects right helps sensors and robots work better together in medical care.

| Sensor Type | Power Rating (V) | Current Requirement (mA) | Efficiency Rating |

|---|---|---|---|

| Force Sensor | 5 | 20 | 85% |

| Proximity Sensor | 12 | 30 | 90% |

| Imaging Sensor | 3.3 | 100 | 80% |

| Inertial Sensor | 3.0 | 15 | 95% |

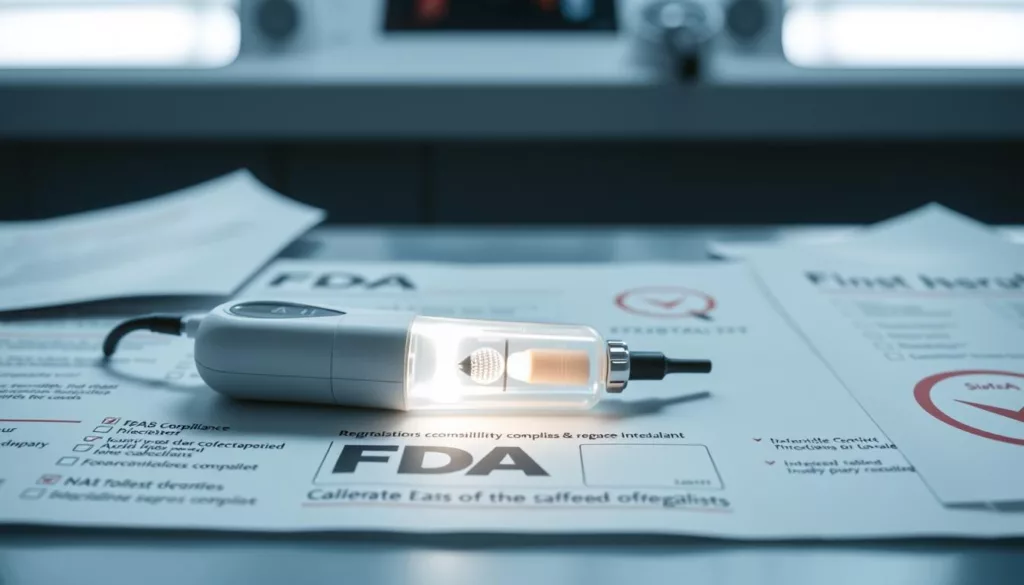

Regulatory Standards and Compliance

In medical robotics, following regulations strictly is key. Making sure medical sensors meet FDA rules affects their development and use in clinics. Medical device regulation standards are met to ensure safety in healthcare.

FDA Regulations for Medical Devices

The FDA is vital in approving medical devices. Makers must show their devices are safe and work well. They need to submit:

- Product descriptions

- Intended use and indications

- Design and manufacturing processes

- Clinical performance data

Knowing and meeting FDA needs is crucial for medical sensors to get market access and ensure patient safety.

IEC Standards for Safety and Performance

The International Electrotechnical Commission (IEC) sets important safety standards for sensors. IEC standards for medical devices look at performance, reliability, and safety. They help devices work well in medical settings. Key areas these standards cover include:

| Standard | Description |

|---|---|

| IEC 60601 | General requirements for the safety and essential performance of medical electrical equipment. |

| IEC 61508 | Functional safety of electrical/electronic/programmable electronic safety-related systems. |

| IEC 62304 | Software life cycle processes for medical device software. |

Following these standards boosts product trust. It also assures users of the sensors’ reliability. For robotics and sensor information, see our website.

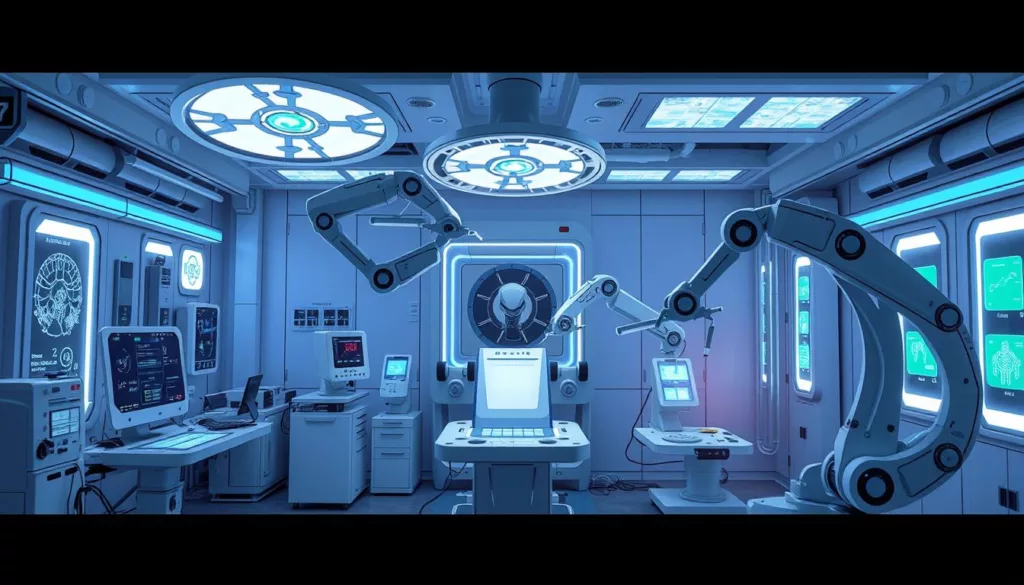

Real-World Applications of Sensors in Medical Robotics

In the field of medical robotics, sensors are key. They boost various technologies in surgery, rehab, and diagnosis. This section highlights three main uses of sensors in robotic surgery.

Surgical Robots

Applications of robotics in surgery are empowered by sensors. They give critical data for precise movements. This leads to less invasive surgeries with faster recovery and fewer complications.

Rehabilitation Devices

Rehabilitation robotics sensors advance monitoring in health care. They track movements accurately, offering instant feedback. This helps create personal rehab programs for better recovery results.

Diagnostic Equipment

Medical diagnostic sensors are crucial for accurate tests and finding conditions early. Applications of sensor technology in diagnostics boost the accuracy of diagnoses. This enables doctors to make decisions based on solid data.

Emerging Technologies in Sensor Development

The world of sensor tech is quickly changing, thanks to new materials and tech breakthroughs. These changes are super important for making sensors better in medical robots. By learning about new materials and how they are made, we understand how to improve these devices.

Advanced Materials and Manufacturing

New materials make sensors lighter and more sensitive. This step up in quality is great for medical uses, making sensors not just better but also right on target for specific needs. Better manufacturing methods are also key. They make sure we can make smart sensors reliably and get them out there fast.

AI Integration for Enhanced Performance

Adding AI to sensor tech makes a huge difference. It leads to smarter decisions in medical robots. These sensors get smarter over time with machine learning, making patient care better. AI lets sensors quickly work through complex data. This means more accurate and efficient medical checks and treatments.

| Feature | Advanced Materials | AI Integration |

|---|---|---|

| Weight | Lighter materials enhance portability | Algorithms reduce processing load |

| Sensitivity | Higher sensitivity improves detection | Adaptive learning enhances performance |

| Manufacturing | Streamlined processes reduce time | Predictive maintenance minimizes downtime |

| Data Processing | N/A | Real-time analysis for better diagnostics |

Cost Considerations in Sensor Selection

In medical robotics, cost-effective sensor solutions play a big role in making choices. It’s key to know the budget to keep quality up and costs down. Knowing how much you can spend on medical robotics sensors helps match buying plans with performance needs.

Budget Constraints and Options

There are many things to think about when setting a budget. You have choices like:

- Initial purchase costs

- Long-term maintenance expenses

- Replacement costs over time

Choosing cost-effective sensor solutions is important to get good performance without spending too much. Knowing about different prices helps spend your budget wisely.

Total Cost of Ownership

The total cost of sensor ownership includes more than just buying it. It involves:

| Cost Type | Description | Example |

|---|---|---|

| Initial Purchase | Cost to acquire the sensor | Basic sensor unit price |

| Maintenance | Routine upkeep to ensure sensor functionality | Service contracts or part replacement |

| Replacement | Costs incurred when sensors reach end-of-life | New sensor purchases after failure |

Buying quality sensors might be more expensive at first, but they’re a good long-term choice. They lower the need for frequent maintenance and replacements. So, it’s vital to understand total ownership cost to get the most value. For detailed info on sensor tech, check this resource.

Testing and Validation of Sensor Performance

To make sure sensors work perfectly, especially in robots for medicine, we need to test them a lot. Making sensors for healthcare means trying out different styles and materials. This way, we make sure they do what we need. Testing over and over again helps make our products better. It also helps us avoid problems that could happen if something was wrong in the design.

Prototyping and Iteration

Making a prototype is a key step when we create sensors. It gives us a real model to check if the sensor does its job. With each test, we learn and make the sensor better based on what we find out. This helps us fix problems, improve how the sensor works, and make sure it meets high medical standards.

Performance Metrics and Benchmarks

It’s very important to set goals for how well sensors should work. We’ll talk about what makes a sensor good, like how accurate it is, how quickly it responds, and how long it lasts. By looking at these goals, we can decide how well our sensors are doing. This helps us do great in creating robots for healthcare.