In the world of industrial manufacturing, precision and reliability are key. Heavy-duty industrial load cells play a big role in this. They help ensure accurate measurements and efficient operations.

These advanced weighing sensors are vital for many applications. They are used in construction, logistics, process control, and quality assurance. This guide will explore the importance of these load cells, their types, features, and how to choose them.

We will look at their practical uses across different industries. We will also cover the latest technology and standards for their use. Whether you’re an engineer, plant manager, or procurement specialist, this guide will help you make informed decisions about load cell solutions.

Key Takeaways

- Heavy-duty industrial load cells are vital for precise force and weight measurement in a variety of industries.

- Understanding the different types of load cells, such as compression, tension, and shear beam, is critical for selecting the right solution.

- Key features like high capacity, environmental resistance, and durability are essential for heavy-duty applications.

- Proper installation, calibration, and maintenance practices are critical to ensure accurate and reliable load cell performance.

- Advancements in load cell technology, including smart sensors and wireless monitoring, are driving innovation in the industry.

Understanding Load Cells and Their Importance in Industry

Load cells are key in force measurement and industrial scales. They accurately measure weights and forces in many industries. Knowing how load cells work is vital for better industrial operations and reliable measurements.

What Are Load Cells?

Load cells are devices that turn applied forces into electrical signals. They use strain gauge technology to measure the changes in electrical resistance due to material deformation. This electrical signal is then processed to give precise weight or force measurements.

How Load Cells Work

When a load is applied to a load cell, the strain gauge elements deform slightly. This deformation changes the electrical resistance. The resistance change is amplified and turned into an electrical signal, like voltage or current. This signal is then read and interpreted by a connected system.

By calibrating the load cell, manufacturers can accurately match the electrical signal to the applied force or weight. This makes force measurement and industrial scale readings precise and reliable.

Benefits of Using Load Cells

- Accurate and Reliable Measurements: Load cells give precise, repeatable, and stable weight and force measurements, ensuring the integrity of industrial processes.

- Enhanced Efficiency: Using load cells in industrial scales and process weighing systems can optimize workflows, reduce errors, and improve overall operational efficiency.

- Improved Safety and Compliance: Accurate load cell-based measurements contribute to enhanced safety standards and compliance with relevant industry regulations.

- Cost Savings: The use of load cells can lead to reduced maintenance costs, lower material waste, and improved productivity, resulting in overall cost savings for industrial operations.

Understanding load cells and their benefits is key for industrial professionals. It helps improve force measurement capabilities, optimize industrial scale performance, and drive more efficient process weighing operations.

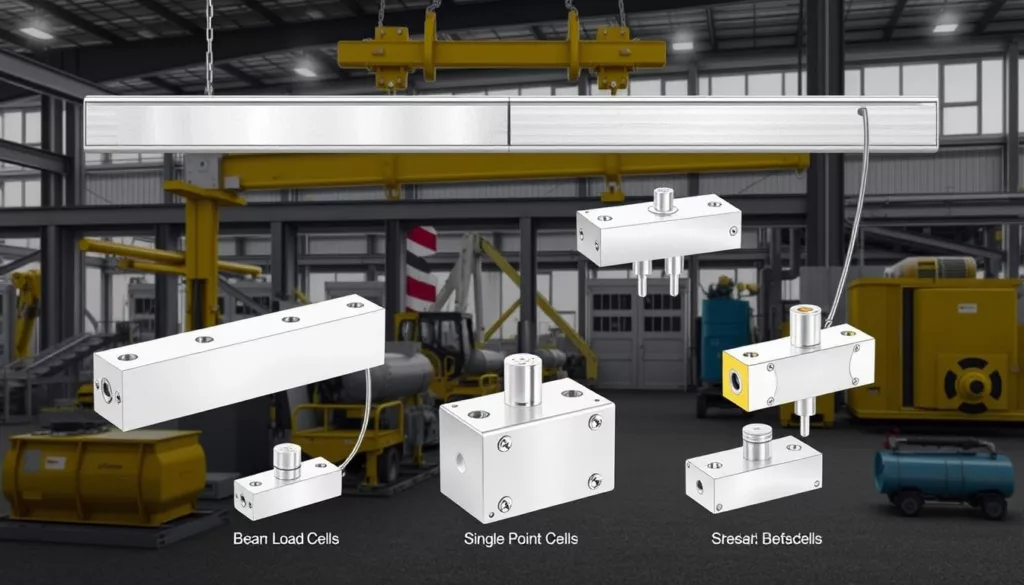

Types of Load Cells for Heavy-Duty Applications

In heavy-duty industrial settings, picking the right load cell technology is key. XJCSENSOR has a variety of load cells for high-capacity weighing. Each type has its own benefits and features. Let’s look at the main types of load cells for these tough environments.

Compression Load Cells

Compression load cells handle big downward forces well. They’re used in places like platform scales and silo weighing systems. These load cells are durable and accurate, making them great for heavy tasks.

Tension Load Cells

Tension load cells measure upward forces. They’re used in crane scales and overhead systems. These load cells are reliable and precise for suspended or lifted items, ensuring safe operations.

Shear Beam Load Cells

Shear beam load cells work for both compression and tension. They’re good for angled loads, like in truck scales. These load cells are strong and reliable for many industrial needs.

| Load Cell Type | Typical Applications | Key Features |

|---|---|---|

| Compression Load Cells | Platform scales, hopper scales, silo weighing | Durable, accurate, high-capacity |

| Tension Load Cells | Crane scales, suspended hoppers, overhead weighing | Reliable for measuring upward forces, precise |

| Shear Beam Load Cells | Truck scales, floor scales, weighbridges | Versatile for compression and tension, robust |

Knowing the special features of each load cell type helps professionals choose the best for their needs. Whether it’s compression load cells, tension load cells, or shear beam load cells, the right choice is important.

Key Features of Heavy-Duty Load Cells

At the heart of reliable industrial scales and weighing systems are heavy-duty load cells. They have impressive features. These components are made to perform well, even in tough industrial settings.

High Capacity and Precision

Heavy-duty load cells are built for big jobs. They can handle a few kilograms to hundreds of tons. They also keep precise measurements, ensuring accurate overload protection and reliable force readings.

This precision boosts productivity and safety in many fields like manufacturing, construction, and logistics.

Environmental Resistance

Industrial settings can be tough, with extreme temperatures and moisture. Heavy-duty load cells are made to handle these conditions. Their strong build and special coatings keep readings accurate, no matter the environment.

Durability and Longevity

Choosing high-quality heavy-duty load cells saves money in the long run. They are built to last, with lifespans of decades. Their durability means less maintenance and lower costs over time.

| Feature | Benefit |

|---|---|

| High Capacity and Precision | Accurate overload protection and reliable force measurements for enhanced productivity and safety |

| Environmental Resistance | Reliable performance in harsh industrial environments with exposure to extreme temperatures, moisture, and other challenges |

| Durability and Longevity | Exceptional build quality and long service life, leading to reduced maintenance costs and long-term cost savings |

“Investing in high-quality heavy-duty load cells is a strategic decision that can pay dividends for years to come, ensuring reliable performance and optimal operational efficiency in demanding industrial settings.”

Selection Criteria for Heavy-Duty Load Cells

Choosing the right heavy-duty load cells for industrial use is key. They must be accurate and reliable in tough environments. Look for load cells designed for heavy-duty applications in industry and force measurement.

Capacity and Range

The load cell’s capacity and range are vital. It must handle the expected loads with a safety margin. If it’s too small, it might get damaged. If it’s too big, it won’t be as precise.

Accuracy and Calibration

Accuracy is a must when picking load cells. The precision needed varies by application. Regular calibration keeps the load cell accurate over time.

Environmental Conditions

The environment matters a lot. Industrial settings can be harsh, with extreme temperatures and vibrations. A load cell that can handle these conditions is essential for lasting performance.

| Criteria | Importance | Key Considerations |

|---|---|---|

| Capacity and Range | High | Ensure the load cell can handle the expected load requirements with a sufficient safety margin. |

| Accuracy and Calibration | High | Determine the required level of precision and maintain accuracy through regular calibration. |

| Environmental Conditions | High | Choose a load cell that can withstand the specific environmental factors in the industrial setting. |

By focusing on these key criteria, you can pick the best heavy-duty load cells. They will meet your needs for accuracy, reliability, and longevity in industrial settings.

Applications of Heavy-Duty Load Cells in Industry

Heavy-duty load cells are key in many industries, like manufacturing and transportation. They help improve efficiency, safety, and quality. These devices are used in many ways, helping to make things better and more efficient.

Manufacturing and Production

In manufacturing, truck weighbridges with load cells measure materials and products accurately. This helps manage inventory and improve production. It also makes sure products meet quality standards.

Load cells in industrial scales also help. They monitor product weight in real-time. This means better quality control and consistent products.

Construction and Civil Engineering

Construction and civil engineering use load cells to check project safety and strength. They track the weight of heavy equipment and the stress on materials. This helps manage projects better and follow rules.

Transportation and Logistics

In transportation and logistics, industrial scales with load cells are very important. They help weigh vehicles and track cargo. This information helps plan routes, use resources better, and follow weight rules.

Heavy-duty load cells are vital in many industries. They help improve how things are made, moved, and checked. By using them, companies can make better choices, work more efficiently, and stay competitive.

Advantages of Using Heavy-Duty Load Cells

Heavy-duty load cells are key for accurate force measurement and weighing systems in industries. They bring many benefits that boost efficiency and productivity. These sensors are vital for precise and reliable results in high-capacity weighing.

Enhanced Measurement Precision

Heavy-duty load cells offer unmatched measurement precision. This is essential for industries where small errors can greatly affect product quality and process control. Their accuracy is critical for maintaining high standards in operations.

Increased Safety Standards

- These load cells are built to handle tough industrial settings, improving safety standards in your facility.

- Their strong build and long life reduce the chance of sensor failures. This lowers the risk of accidents, injuries, and downtime costs.

- With these load cells, you get consistent and reliable force measurement data. This allows for better safety measures and informed decisions.

Cost Efficiency in Operations

Heavy-duty load cells can save you money in the long term. Their high-quality build and long life mean less maintenance and replacement costs. They also help use resources better and reduce waste.

Using heavy-duty load cells can make your operations better, safer, and more cost-effective. This leads to a more competitive and sustainable business model.

Installation Best Practices for Load Cells

Installing load cells correctly is key for their accurate and reliable use in heavy-duty settings. It’s important to mount them properly and calibrate them regularly. This ensures they work well for a long time.

Proper Mounting Techniques

Mounting load cells needs careful attention. They must be securely attached to the platform or structure. Make sure the surface is level and free of any obstacles.

Using the right mounting hardware and following the manufacturer’s instructions is vital. This helps avoid problems that could affect the accuracy of the measurements.

Calibration Procedures

Calibrating load cells regularly is essential. This involves checking their output against known weights and making adjustments as needed. This keeps the device accurate within a certain range.

Having a detailed calibration schedule, as suggested by the manufacturer, is important. It helps catch any changes in the cell’s sensitivity over time.

Regular Maintenance Tips

- Check the mounting points and connections for wear or damage and fix them quickly.

- Keep the load cell and its area clean to avoid accuracy issues.

- Shield load cells from extreme temperatures, moisture, and vibrations to protect their performance.

- Do regular tests to ensure the load cell is working correctly.

By following these steps for load cells for heavy-duty applications in industry and industrial scales, you can get the most out of these important tools. They will provide accurate and reliable results for your industrial needs.

Troubleshooting Common Issues with Load Cells

In the world of industrial force measurement and weighing systems, keeping your load cells accurate and reliable is key. Even the best load cells can face problems. Here, we’ll look at common issues and how to fix them, helping your force measurement and weighing systems work their best.

Identifying Calibration Errors

Calibration is vital for load cell performance. If it’s off, your weight measurements will be wrong. This can mess up your overload protection and slow down your process. Check your calibration steps, like sensor placement and reference weights, and make sure your software or tools are correct.

Diagnosing Load Cell Failures

Load cell failures can happen for many reasons, like damage, stress, or electrical problems. To find out why, do a detailed check. Look for damage, test the electrical parts, and see how the load cell works under different conditions. This way, you can quickly find and fix the problem.

Resolving Signal Interference

Signals from your load cells can get messed up by EMI and RFI. This can cause wrong readings and system failures. To fix this, make sure your wiring is shielded and grounded well. Also, find and reduce any outside interference.

By using these tips for fixing common load cell problems, you can keep your force measurement and weighing systems accurate and reliable. This ensures they work well and meet industry standards.

Leading Brands and Manufacturers of Heavy-Duty Load Cells

In the world of industrial load cells, a few top manufacturers stand out. They offer high-quality products and great customer support. These brands are the first choice for heavy-duty needs in industry, including industrial scales. Let’s explore some of the top players in this field.

Overview of Industry Leaders

Top names in heavy-duty load cells include Mettler-Toledo, Flintec, HBM, and Vishay Precision Group. These companies are known for making durable, precise, and reliable load cells. They meet the needs of many industrial sectors.

Comparing Features and Offerings

| Manufacturer | Load Cell Types | Capacity Range | Accuracy |

|---|---|---|---|

| Mettler-Toledo | Compression, Tension, Shear Beam | Up to 1000 tons | ±0.02% to ±0.1% of full scale |

| Flintec | Compression, Tension, Bending Beam | Up to 500 tons | ±0.03% to ±0.1% of full scale |

| HBM | Compression, Tension, Shear Beam | Up to 1000 tons | ±0.02% to ±0.1% of full scale |

| Vishay Precision Group | Compression, Tension, Bending Beam | Up to 500 tons | ±0.03% to ±0.1% of full scale |

Customer Support and Warranty Information

These leading manufacturers also offer great customer support and warranties. They help with technical issues, installation, and maintenance. This ensures their load cells for heavy-duty applications in industry and industrial scales work well. Warranties last from 1 to 5 years, giving customers confidence in their purchases.

“These industry-leading brands have set the standard for quality and reliability in the heavy-duty load cell market. Their commitment to customer service and innovative product development make them the trusted partners for industrial applications.”

Innovations in Load Cell Technology

Load cell technology has seen big changes in the world of industrial weighing and force measurement. XJCSENSOR is excited to share the latest advancements in this field. These innovations are changing how we do things in modern manufacturing and process control.

Smart Load Cells

Smart load cells have changed how we measure force. They use advanced tech like microprocessors and data analysis. This lets us monitor and maintain our systems in real-time.

These smart sensors give us accurate and reliable data. They also help us understand how well our weighing systems are working.

Wireless Load Monitoring Systems

XJCSENSOR has brought wireless load monitoring systems to the table. These systems get rid of the need for messy wiring. They use RF and Bluetooth to send force data securely and easily.

This makes it possible to check on our weighing systems from anywhere. It’s a big step forward for industrial facilities.

Integration with IoT Solutions

Load cell tech and IoT are coming together in a big way. XJCSENSOR’s load cells work with IoT platforms. This means we can collect and analyze data in real-time.

This helps us make better decisions and improve how we use our assets. It’s all about making our operations more efficient.

“The future of industrial weighing lies in the convergence of smart sensors, wireless connectivity, and the power of data-driven insights. XJCSENSOR is at the forefront of these transformative innovations, redefining the boundaries of what’s possible in the world of weighing systems.”

Regulatory Standards for Load Cells in Industrial Use

In industrial settings, load cells for heavy-duty applications and industrial scales face strict rules. These rules are in place to ensure safety, accuracy, and legal compliance. Both makers and users must follow these standards closely.

Overview of Relevant Standards

The OIML R60 is a key standard for load cells worldwide. It’s made by the International Organization of Legal Metrology. It sets rules for how well load cells work, including their accuracy and how they handle temperature changes.

In the U.S., the NTEP (National Type Evaluation Program) also checks these standards. They make sure load cells are legal for trade use.

Compliance Requirements

- Load cells must go through tough tests to meet OIML R60 and NTEP rules.

- It’s up to the makers to make sure their load cells follow these standards.

- Users need to install, calibrate, and keep load cells in good shape to stay compliant.

Importance of Certification

Getting certified to these standards is key for load cell use in many industries. Without the right certifications, load cell data might not be accepted for official use. This could lead to fines, legal issues, and problems for businesses.

Keeping up with compliance through regular checks and recertification is vital. It makes sure load cells are reliable and trustworthy for heavy-duty and industrial uses.

Future Trends in Heavy-Duty Load Cells

The future of heavy-duty load cells is exciting. We can expect new technologies, sustainable practices, and market growth. XJCSENSOR is leading the way with innovations that improve performance, efficiency, and care for the environment.

Technological Advancements

Heavy-duty load cells are changing fast with new technologies. Smart load cells with advanced sensors and microprocessors are coming. They will make weighing more precise and accurate.

These smart solutions offer real-time monitoring and data analysis. They also connect with the Industrial Internet of Things (IIoT). This allows for predictive maintenance and better production processes.

Sustainable Practices

Sustainability is key in manufacturing, and XJCSENSOR is leading the way. They use eco-friendly materials and energy-efficient processes. This reduces their carbon footprint and helps the environment.

They also make load cells that last longer and need less maintenance. This makes these important industrial components even more environmentally friendly.

Market Growth Insights

The global market for heavy-duty load cells is growing. This is because more industries need high-capacity weighing systems. XJCSENSOR is ready to grow with this market.

They focus on new technologies and sustainable practices. This makes them a trusted provider of innovative and eco-friendly solutions for industries.