Dual-axis load cells are a big step forward in precise force measurement. They are like doing many tasks at once in industry. These cells can measure forces in two directions. They help us understand how much stress and strain machines and materials face. Their top-notch accuracy is important for keeping products safe and high-quality. Our solutions use this innovative load sensing tech to meet high standards.

Dual-axis load cell technology is super useful in many industries. It works well even in tough conditions and responds quickly. This makes our systems perfect for important jobs that need careful watching. It shows how force measurement tech has improved.

Key Takeaways

- Dual-axis load cells provide precise force measurement along two axes.

- They offer a comprehensive analysis of stress and strain.

- Our load cells prioritize innovative load sensing technology.

- Unparalleled accuracy is crucial for safety and product quality.

- Fast response times make them ideal for critical monitoring processes.

Introduction to Dual-axis Load Cell Solutions

Dual-axis load cell solutions changed how we measure force. They provide top-notch accuracy and reliability for many industries. By measuring force along two axes at the same time, they offer benefits traditional single-axis cells cannot.

What Are Dual-axis Load Cells?

Dual-axis load cells are high-tech tools for precise force measurement in two directions. They capture data from two axes, unlike old-school cells that only measure one. This way, they give deeper and more accurate insights on force.

Importance in Industrial Applications

Dual-axis load cells are vital in industries. They are especially important in aerospace testing, car trials, and checking structures. These cells help achieve better work efficiency, lower risks, and keep quality high.

They provide exact load information which is key for improving designs and making sure structures are safe.

| Application | Benefits | Examples |

|---|---|---|

| Aerospace Testing | Enhanced precision force measurement | Wing stress analysis, fuselage integrity |

| Automotive Trials | Multi-axis load cell applications | Crash testing, component fatigue tests |

| Structural Monitoring | Real-time force measurement | Bridge load analysis, building stability |

Advantages of High-accuracy Load Cells

High-accuracy load cells bring big benefits to industrial tasks. They boost precision, reliability, and save money. These perks let businesses excel in making sure their products are top notch.

Enhanced Precision

High-accuracy load cells make errors almost nonexistent. This is vital in fields that need precise measurements. Thanks to them, even tiny mistakes are caught, keeping product quality high.

Improved Reliability

These load cells are built for dependable force measurement, no matter the setting. They work great under tough conditions and for a long time. Their strong design means they keep providing accurate data for longer.

Cost-effectiveness

Choosing high-accuracy load cells is smart for your budget. They’re cost-effective because they don’t need much upkeep or recalibration. This means less downtime and better operations, saving companies money in the long run.

Force Measurement Technology in Dual-axis Load Cells

The growth of force measurement technology has greatly changed dual-axis load cells. Now, they are key in many fields. This progress provides accurate force data, ensuring things work best and stay reliable.

Innovations in Load Cell Design

Cutting-edge load cell design has evolved a lot, leading to more accurate and tough products. These advancements use new materials and methods. So, the load cells work well even when conditions change. Now, we have an innovative load sensing solution for modern industry needs.

Technological Advances

New tech has made dual-axis load cells much better. These updates make them more sensitive and reduce mistakes. They now have better signal processing and can easily integrate with other systems. This gives a full and trusted solution for measuring force.

| Innovation | Impact |

|---|---|

| Advanced Materials | Increased Durability |

| Enhanced Signal Processing | Higher Sensitivity |

| Optimized Manufacturing | Consistency in Performance |

| Integration Capabilities | Streamlined Data Acquisition |

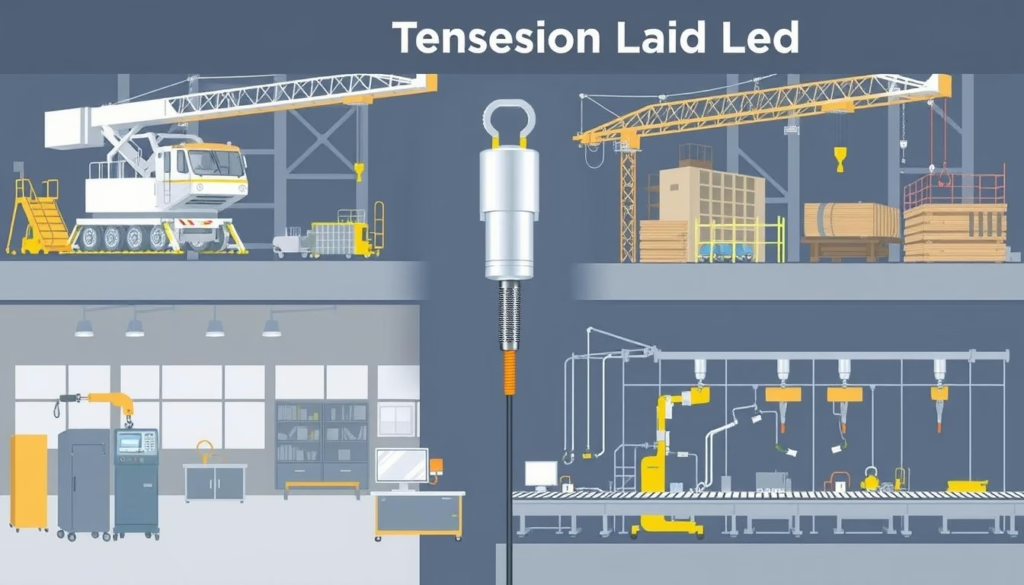

Applications of Tension and Compression Load Cells

Tension and compression load cells are crucial in various industries. They accurately measure tensile and compressive forces. These devices are key for maintaining integrity and controlling processes in different fields.

In construction engineering, they monitor stresses on structures like beams, bridges, and towers. This data ensures safety and meets engineering standards.

In electronics manufacturing, compression load cells check the strength of electronic parts. They ensure products are durable and reliable. The accuracy of these load cells meets the industry’s high standards.

Tension and compression load cells are also used in aerospace, automotive, and medical equipment manufacturing. In aerospace, they test aircraft component strength under various forces. These load cells improve safety and performance across industries.

| Industry | Key Applications |

|---|---|

| Construction Engineering | Structural stress monitoring of beams, bridges, and towers |

| Electronics Manufacturing | Tensile and compressive strength tests of components |

| Aerospace | Structural integrity evaluation of aircraft components |

| Automotive | Load transfers and impact force tests |

| Medical Equipment | Durability tests of medical devices |

These load cells have wide-ranging industrial uses. They are essential for quality, safety, and innovation. Understanding their applications shows their universal importance.

Integration with Industrial Weighing Systems

Integrating load cell technology in industrial scales is a big step towards better accuracy and efficiency. These dual-axis load cells give precise measurements, even in difficult conditions. This is very important for industries like pharmaceuticals, food production, and logistics.

Advanced load cells have changed the game for automated weighing processes. They are highly reliable and repeatable. This is crucial for meeting the high standards of different industries. As a result, the role of load cell integration is becoming more important.

| Industry | Application | Outcome |

|---|---|---|

| Pharmaceuticals | Precision Drug Weighing | Increased Dosage Accuracy |

| Food Production | Ingredient Weighing | Consistent Product Quality |

| Logistics | Package Weight Verification | Reduced Shipping Errors |

Load cell integration is key for modern manufacturing and processing. It ensures automated weighing systems are up to today’s high standards. This fusion of tech and industrial scales boosts efficiency and shapes the future in demanding fields.

The Role of High Precision Force Sensors

High precision force sensors are crucial in many fields. They give accurate measurements that help people make smart decisions. Even tiny differences in force can lead to big changes. We will look at how these sensors work and see examples of their impact.

Critical Performance Metrics

To make sure high precision force sensors do their job, we look at key things. These include:

- Accuracy: How close the sensor’s measurements are to the real force.

- Sensitivity: The ability to notice small changes in force.

- Linearity: How consistent the sensor responds across its measuring range.

- Temperature Stability: How well the sensor works in different conditions.

High accuracy, sensitivity, and stability mean industries can trust their data. This helps them make better choices.

Real-world Case Studies

Looking at real examples shows the value of high precision force sensors. We’ll explore their role in different areas:

- Automotive Industry: In crash tests, these sensors measure the forces on cars. This helps make cars safer.

- Aerospace Engineering: They check the stresses on aircraft parts in tough conditions. This ensures planes are safe to fly.

- Medical Devices: They are used in creating surgical tools, making surgeries more precise and safe.

These examples show how high precision force sensors are vital in many sectors. They prove the sensors’ effectiveness and wide use.

Dynamic Force Sensing Technology by XJCSENSOR

XJCSENSOR leads in dynamic force sensing technology. We offer futuristic solutions with top-notch dual-axis load cells. Our dedication to innovation is evident in our extensive research and development. This effort has given rise to advanced load cell systems. These systems surpass usual industry standards in both accuracy and reliability.

Integrating XJCSENSOR’s force technology boosts precision and efficiency in operations. Using our dynamic force sensing systems enhances your business’s effectiveness. It also cuts downtime, helping save on costs.

Our load cell systems are tailored for today’s industry needs. They work well under changing conditions, perfect for jobs needing high precision and flexibility. Here’s a look at how our XJCSENSOR force technology stands out:

| Feature | XJCSENSOR Dynamic Force Sensing Systems | Traditional Load Cells |

|---|---|---|

| Accuracy | High-precision dual-axis | Single-axis limited precision |

| Reliability | Superior under dynamic conditions | Moderate under static conditions |

| Adaptability | Real-time flexural adaptability | Standard mechanical adaptability |

Choosing us brings unmatched expertise in dynamic force sensing technology. With our cutting-edge load cell systems, your company can lead in the competitive market. Benefit from short-term and long-term growth with our innovative solutions.

Custom Load Cell Design for Unique Requirements

At XJCSENSOR, we understand that custom load cell design is crucial for various industries. We specialize in creating unique force measurement solutions. These are designed to mix well with systems already in place or solve unique challenges. We aim to provide load sensing systems that are precise and efficient.

Customization Capabilities

We can modify designs or create new load cells based on specific client needs. Our goal is to craft solutions that deliver top accuracy and reliability for unusual applications or specialized equipment. Each project shows our commitment to delivering quality and unique tailored systems.

Client-specific Solutions

Working closely with clients lets us create load cells that match each project’s requirements perfectly. We focus on detailed planning and design to surpass expectations. Our systems fit well in different industrial settings, meeting every need with precision.

- R&D Collaboration

- Customization Consultation

- Prototyping & Testing

- Final Implementation

| Feature | Standard Load Cell | Custom Load Cell |

|---|---|---|

| Design Flexibility | Limited | High |

| Integration Ease | Standard Systems | Tailored Systems |

| Precision Levels | Fixed | Variable as Needed |

| Client-specific Adjustments | No | Yes |

Custom load cell designs have clear advantages over standard ones, as highlighted. They are designed to fit the unique needs of each project. Our systems are adaptable and engineered for specific industry standards.

Conclusion

We’re wrapping up our look at high-accuracy dual-axis load cells. It’s clear that XJCSENSOR leads in load cell technology. They offer unparalleled precision and reliability. This matters a lot for various industries.

XJCSENSOR uses clever design and technology to stay top. Their load cells are precise, reliable, and affordable. This helps our clients meet their needs well.

Our faith in XJCSENSOR comes from their dedication to getting better and focusing on the customer. They make sure their load cells meet every unique need with precision. As the world changes, industries can count on XJCSENSOR. They provide the accurate and reliable technology needed today.