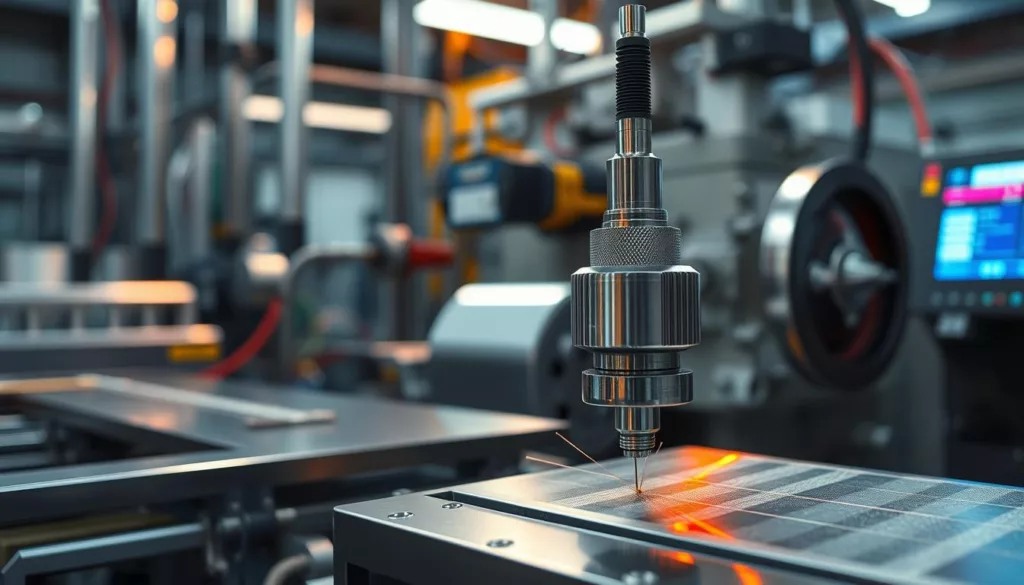

In today’s world, handling delicate materials is key. This includes making fine textiles and engineering advanced composites. XJCSENSOR offers a top-notch tension sensor for these tasks.

XJCSENSOR’s tension sensor is a big leap forward. It uses the latest in engineering and sensor tech. This lets it measure tension on delicate materials with unmatched precision. It helps makers improve their work, cut down on waste, and make better products.

Key Takeaways

- XJCSENSOR’s high-precision tension sensors are designed for sensitive material processing applications

- These specialized sensors provide unparalleled accuracy and reliability in tension measurement

- Optimized for handling and processing of delicate materials like textiles and advanced composites

- Enable manufacturers to enhance product quality, reduce waste, and improve overall production efficiency

- Represent a significant advancement in the field of customized force sensing solutions

Understanding High-precision tension sensor for delicate materials

When working with delicate materials like fine fabrics or fragile composites, precision is key. High-precision tension sensors offer the control and monitoring needed for optimal performance. They are designed to provide ultra-precise force sensing, making fiber tension monitoring and delicate fabric tensioning possible with great accuracy.

Core Components and Operating Principles

High-precision tension sensors have carefully engineered components that work together to give accurate measurements. They often use strain gauges, load cells, or other transducers to convert mechanical force into electrical signals. These sensors measure the tiny changes in these signals to show the tension on the material.

Key Features of Modern Tension Sensors

- Exceptional sensitivity to detect even the slightest variations in tension

- Robust construction to withstand challenging industrial environments

- Real-time data processing for immediate feedback and responsiveness

- Seamless integration with automated production systems

- Advanced calibration and maintenance capabilities

Sensitivity Ranges and Measurement Accuracy

Modern high-precision tension sensors offer unmatched sensitivity and accuracy. They can measure tension with resolutions as fine as 0.1 grams-force or even lower. Their accuracy is usually within 0.1% to 0.5% of the full-scale reading, ensuring top-notch control and monitoring of delicate materials.

“The ability to precisely monitor and control tension is critical for maintaining the integrity and quality of delicate materials throughout the manufacturing process.”

Applications in Textile Manufacturing and Processing

High-precision tension sensors are key in keeping fragile textile materials in top shape during production. They are used at every step, from fiber spinning to fabric finishing.

In the fiber spinning stage, these sensors help control the tension of the fibers. This is vital for sensitive material processing, like making high-quality synthetic or natural fibers.

- Monitoring and adjusting tension during fiber extrusion and drawing

- Maintaining uniform fiber thickness and strength

- Minimizing material waste and boosting productivity

As materials move through production, precision material handling is essential. Tension sensors in weaving, knitting, and fabric machines keep an eye on fabric tension. This prevents damage and keeps the quality high.

| Textile Production Stage | Role of Tension Sensors |

|---|---|

| Fiber Spinning | Precise control over fragile textile filaments, preventing breakages and maintaining consistent tension |

| Fabric Formation | Monitoring and regulating the tension of delicate fabrics to avoid distortion, tearing, or other defects |

| Fabric Finishing | Ensuring fragile textile tension control during processes like dyeing, printing, and finishing to preserve the desired characteristics |

In the fabric finishing stage, tension sensors are vital for fragile textile tension control. They help keep the fabric’s quality and characteristics consistent.

“The integration of high-precision tension sensors in textile manufacturing has transformed the industry, enabling us to achieve unprecedented levels of quality and consistency in our products.”

Advanced Fiber Tension Monitoring Technologies

The need for precision in making textiles is higher than ever. Advanced fiber tension monitoring technologies are key. They offer ultra-precise force sensing and non-destructive tension measurement. This changes how manufacturers check quality and improve their processes.

Digital Sensing Mechanisms

These technologies use digital sensing mechanisms for top accuracy and stability. These sensors turn mechanical forces into digital signals for monitoring. This lets manufacturers control fiber tension with great care, even for the most delicate materials.

Real-time Data Processing Systems

These systems also have real-time data processing for quick feedback. They analyze sensor data fast, helping manufacturers make smart choices. This lets them keep quality high and production smooth.

Calibration and Maintenance Requirements

Keeping these systems precise needs regular calibration and upkeep. Manufacturers must follow strict calibration steps. They also need to clean and check sensors often. This keeps the technology working well in today’s tough industrial settings.

“The ability to monitor and control fiber tension with unprecedented precision is a game-changer in the textile industry, driving significant improvements in product quality and process efficiency.”

Integration with Industrial Production Systems

Modern industrial production relies on advanced sensor technologies. XJCSENSOR makes precision tension sensors. These sensors work well with many industrial systems, making processes more efficient and improving quality control.

These sensors are key in handling delicate fabrics and fragile electronic parts. They help keep the right tension in the production line. This way, manufacturers can make sure products are consistent and reduce waste.

Seamless Integration with Manufacturing Automation

XJCSENSOR tension sensors work great with automated systems. They can be placed anywhere in the production line. This lets them monitor tension and send data to control systems.

- They help adjust process settings for the best tension levels.

- They spot problems early, making it easier to fix them.

- They work with Industry 4.0 and IoT for better monitoring and optimization.

Enhancing Overall Process Efficiency

Using XJCSENSOR tension sensors in production brings many benefits. These benefits help companies save money and improve quality.

| Benefit | Description |

|---|---|

| Improved Product Quality | Controlled tension means better material quality, fewer defects, and happier customers. |

| Enhanced Process Efficiency | Monitoring tension in real-time helps avoid downtime and waste. |

| Increased Productivity | Automated control means faster production and lower labor costs. |

By adding XJCSENSOR sensors to their systems, manufacturers can improve a lot. They get better at handling materials, processing them carefully, and keeping fabric tension right. This leads to better quality, efficiency, and profits.

Non-destructive Measurement Techniques for Fragile Materials

In the world of high-precision sensors, keeping delicate materials safe is key. Engineers have come up with new ways to measure tension without harming fragile items. These methods are for non-destructive tension measurement, low-stress material sensing, and fragile textile tension control.

Contact-based Sensing Methods

Contact-based sensing is one way to measure tension without harm. It uses special sensors that touch the material lightly. This way, the material stays safe. Here are some examples:

- Strain gauges on flexible supports

- Capacitive sensors for material displacement

- Optical interferometry for surface changes

Non-contact Measurement Solutions

Non-contact methods are another safe way to check tension. They use technology that doesn’t touch the material. This keeps it safe. Some examples are:

- Laser displacement sensors

- Eddy current detectors

- Computer vision with image processing

Precision Control Algorithms

Using smart algorithms is vital for precise tension measurement. These algorithms work with real-time data. They adjust settings to keep tension right without harming the material.

These methods help manufacturers keep an eye on tension in sensitive materials. This leads to better quality and efficiency in many fields. It’s all about making things better and safer.

Benefits for Quality Control and Process Optimization

High-precision tension sensors are key for better quality control and process improvement, mainly with delicate materials. They offer accurate, real-time tension monitoring. This helps keep tight control over sensitive materials, ensuring quality and cutting down on waste.

Using precision material handling sensors helps spot and fix small tension changes. This prevents damage to fragile materials during sensitive material processing. The data from these high-precision tension sensors for delicate materials also helps adjust production settings. This makes material flow better and cuts down on breakages or errors.

| Key Benefits | Impact on Manufacturing |

|---|---|

| Consistent product quality | Reduced material waste and rework |

| Improved process efficiency | Enhanced production throughput |

| Real-time tension monitoring | Proactive issue identification and resolution |

Adding high-precision tension sensors to manufacturing processes brings big wins for quality, efficiency, and overall performance. These sensors give the needed data for better control over delicate materials. This leads to ongoing improvement and better use of production resources.

“The use of high-precision tension sensors has been a game-changer for our textile manufacturing operations. We’ve seen a marked improvement in product consistency and a dramatic reduction in material waste, all while boosting our overall production efficiency.”

Implementing Tension Sensors in Automated Manufacturing

Adding high-precision tension sensors to automated manufacturing needs careful setup and constant checks. This part talks about how to use these advanced tools for smooth delicate fabric tensioning, precision material handling, and sensitive material processing on your production lines.

System Setup and Configuration

Setting up your system right is key to using tension sensors fully. You need to calibrate the sensors, connect them with your machines, and set up data sharing. Our experts will help you set everything up right and keep it running well.

Performance Monitoring and Adjustment

Keeping an eye on how your sensors perform is vital for good tension control. Our advanced analytics let you watch sensor data live, spot any problems, and adjust as needed. This way, you can cut down on waste and improve your product quality.

Troubleshooting Common Issues

Even with our top-notch sensors, sometimes problems can pop up. Our detailed guide helps you find and fix common issues, like calibration mistakes or data connection problems. With our support team, you can fix issues fast and keep your production running smoothly.

| Tension Sensor Feature | Benefit |

|---|---|

| Precision Measurement | Ensures consistent delicate fabric tensioning and sensitive material processing |

| Real-time Data Monitoring | Enables proactive precision material handling and process optimization |

| Easy Integration | Seamless deployment into automated manufacturing systems |

With our advanced tension sensor tech and full support, you can boost your automated manufacturing. This means better efficiency and quality for your customers.

Future Trends in Tension Sensing Technology

The need for ultra-precise force sensing, non-destructive tension measurement, and precise sensors for delicate materials is growing. Experts predict exciting changes in tension sensing technology soon.

One big trend is the creation of smart tension sensors. These will work well with automated systems. They will give real-time tension data and use advanced analytics to improve production and quality.

- New sensor designs, like using special materials and making them smaller, will lead to more accurate and reliable measurements.

- Improved data processing and communication will let sensors send data straight to control systems. This will help with predictive maintenance and making process changes before they’re needed.

- Features for calibration and self-diagnostics will make sure sensors work well all the time. This will cut down on the need for manual checks, making tension monitoring systems more efficient.

Also, combining tension sensing with new Industry 4.0 tech like IoT and cloud analytics will change how we monitor and improve production. This will help companies get better at sensing forces, measuring tension, and controlling delicate materials with high precision.

“The future of tension sensing lies in the seamless integration of advanced technologies, enabling manufacturers to optimize their processes and deliver superior quality products.”

XJCSENSOR is leading the way in tension sensing innovation. We’re working on new solutions that meet our customers’ changing needs.

Conclusion

High-precision tension sensors are key in improving sensitive material processing and handling. They help keep product quality high, reduce waste, and make production more efficient. These sensors accurately measure and control tension forces on delicate materials.

Modern tension sensors have changed how industries work with fragile materials. They are used in textile and fiber processing, improving quality control and process optimization. This has made production better and more precise.

The need for high-quality products is growing. Precision tension monitoring technologies are becoming more important. By using these advanced solutions, manufacturers can improve control, increase yield, and cut costs. The future of material processing depends on these advanced sensors.