In today’s fast-paced world, knowing the benefits of sensors in industrial automation is key. These sensors are at the core of making operations better, more accurate, and safer. As sensor technology grows, it helps industries take proactive steps and use integrated systems.

This guide will show you the main advantages and new uses of sensor technology. It will help you stay on top in the ever-changing industrial world.

Key Takeaways

- Sensors greatly improve how well things work in factories.

- They make sure things are done right and with precision.

- They give real-time data, helping make better decisions.

- Sensors make work places safer in factories.

- Using sensors helps systems talk better to each other.

Understanding Industrial Automation Sensors

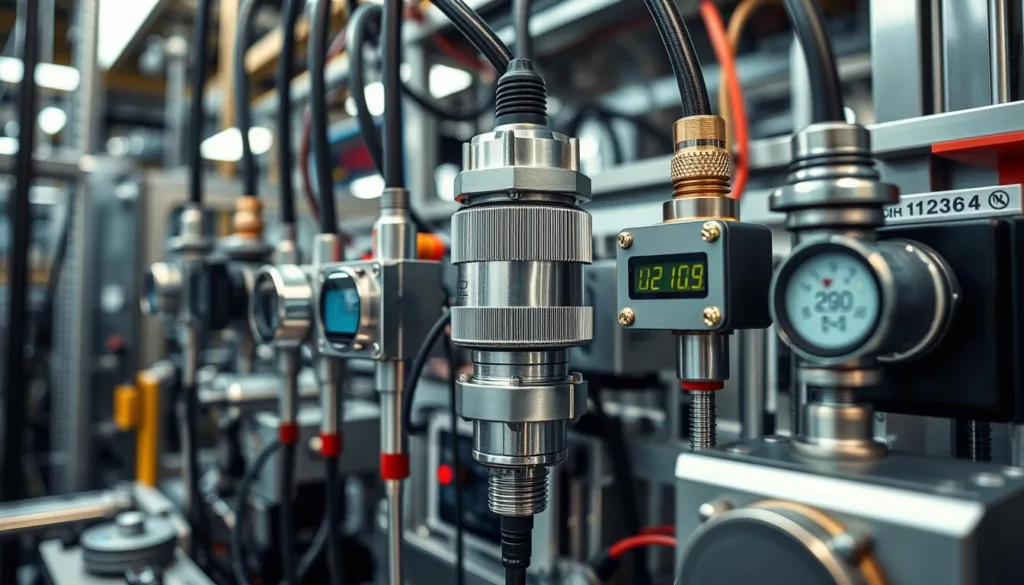

Industrial automation sensors are key to making systems work better and faster. They can sense and measure different physical things. Then, they turn these into electrical signals to automate tasks and keep things running smoothly.

Some common sensors include:

- Temperature Sensors: Keep things at the right temperature.

- Pressure Sensors: Watch over pressure levels, important in systems like hydraulics and pneumatics.

- Proximity Sensors: Find objects without touching them.

- Flow Sensors: Track how fast liquids and gases move, helping use resources better.

Each sensor type is vital in industrial automation. They help figure out how things are working, making things better and safer. Knowing about these devices helps us see how sensor technology in industrial automation keeps getting better, leading to new ideas in many fields.

As systems get more complex, it’s important to know about the different sensors and how they work. With better sensors, companies get more accurate data, consistent operations, and reliable systems.

| Sensor Type | Application | Key Benefit |

|---|---|---|

| Temperature Sensors | Climate Control | Maintains optimal operating temperatures |

| Pressure Sensors | Fluid Mechanics | Ensures pressure safety and efficiency |

| Proximity Sensors | Part Detection | Enhances automation without contact |

| Flow Sensors | Resource Management | Improves efficiency in fluid movement |

Key benefits of using sensors in industrial automation

Sensors bring big advantages to industrial automation. They make operations more efficient. The main benefits are better accuracy and real-time data. These help in making smart decisions and boost productivity.

Enhanced Accuracy and Precision

Sensors are key for enhanced accuracy in making things. They watch over things like temperature, pressure, and humidity. This helps keep everything running just right, cutting down on mistakes.

Real-time Data Monitoring

Real-time data monitoring lets teams act fast. Sensors give quick updates on how things are working. This helps catch problems early, keeping things running smoothly.

| Benefit | Description |

|---|---|

| Enhanced Accuracy | Ensures high precision in monitoring production conditions |

| Real-time Data Monitoring | Allows immediate response to system anomalies |

| Reduced Errors | Minimizes the chance of production mistakes |

| Informed Decision-Making | Facilitates prompt corrective actions |

The Role of Sensors in Industrial Automation

Sensors play a key role in industrial automation. They are the backbone of modern manufacturing systems. These sensors give real-time feedback to keep machinery running well.

They capture data like temperature, pressure, and humidity. This helps automated systems work smoothly and efficiently.

Adding sensors to automated systems makes operations run smoothly. This is key for staying competitive. With sensors, manufacturers can quickly adapt to changes.

This quick response boosts productivity and cuts down on waste. It’s a win-win for companies.

- Continuous monitoring of machinery performance

- Precision in the automation process

- Data-driven decision-making capabilities

- Improved safety protocols through real-time alerts

As sensors’ role grows, companies are adopting new technologies. These advancements improve current processes and open doors to new strategies. This leads to better performance and growth.

Advantages of Sensors in Automation

Adding sensors to industrial systems brings many benefits. These devices help improve how things work and cut costs in many areas. They do more than just watch things; they are key to making things better and cheaper.

Cost Reduction through Efficiency

Using sensors helps lower costs by making things work better. They give real-time info on how equipment is doing. This lets companies manage better and use resources wisely.

- Less energy used

- Lower labor costs with automation

- Less waste of materials

This makes operations smoother, boosting profits.

Minimized Downtime and Maintenance

Sensors are important for keeping things running smoothly. They watch over machines and processes, spotting problems early. This means:

- Quick fixes before things break down

- Planned maintenance based on real needs

- Better use of equipment (OEE)

| Benefits | Cost Reduction | Minimized Downtime |

|---|---|---|

| Energy Efficiency | Yes | No Impact |

| Labor Savings | Yes | No Impact |

| Material Waste | Yes | No Impact |

| Proactive Maintenance | No Impact | Yes |

| Overall Equipment Effectiveness | No Impact | Yes |

Importance of Sensors in Manufacturing Processes

In today’s world, sensors are key in making manufacturing better. They help keep production running smoothly and products up to standard. With advanced sensors, companies can watch over their work better. This leads to better products and a smoother workflow.

Improved Product Quality

Sensors are vital for keeping product quality high. They check things like temperature, pressure, and humidity all the time. This lets companies fix problems right away.

So, they can make fewer mistakes and keep their products top-notch.

Streamlined Production Flow

Sensors also make production flow better. They help collect and analyze data automatically. This makes operations more efficient and cuts down on delays.

With sensors, companies can make things faster and more consistently. This makes their production lines more effective.

Sensor Technology in Industrial Automation

Advances in sensor tech have changed how industries work. The Internet of Things (IoT) lets smart sensors talk to each other in factories. This sharing of data helps make decisions faster and safer.

Wireless sensors are getting more common. They don’t need cables, making it easier to place them anywhere. This helps keep an eye on things and makes fixing problems quicker. Predictive maintenance uses this data to predict when machines might break down, avoiding big losses.

Data analysis is key in using these sensors. It helps companies make smart choices. This analysis boosts efficiency and safety by spotting dangers early.

| Technology | Description | Benefit |

|---|---|---|

| IoT Integration | Seamless connection of sensors to the internet for real-time data access. | Enhanced decision-making and operational efficiency. |

| Wireless Capabilities | Reduction of wiring systems by utilizing wireless sensors. | Increased flexibility and reduced installation costs. |

| Smart Sensors | Sensors with integrated data processing capabilities. | Real-time analytics and improved automation. |

| Predictive Maintenance | Monitoring of equipment performance to anticipate failures. | Cuts down on unexpected downtime and repair costs. |

| Data Analytics | Analysis of data trends for better insight into operations. | Improves safety and compliance with regulations. |

These changes show how important sensor tech is for better factory work. For instance, force and torque sensors improve how we measure things in making stuff.

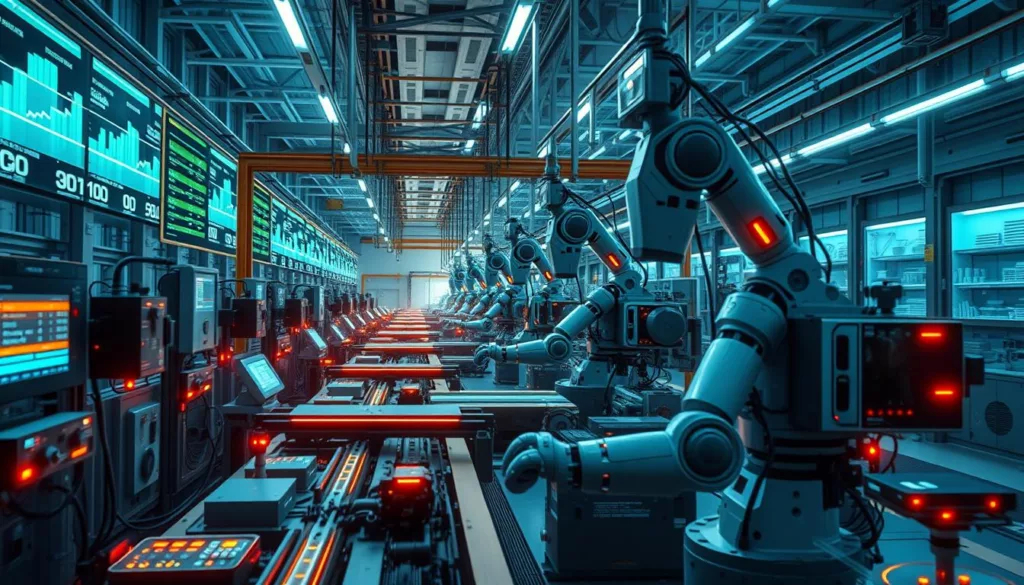

Benefits of Sensor Integration in Factories

Effective sensor integration is key for advanced manufacturing systems. It makes sure machines talk to each other smoothly. This helps factories adapt quickly to changing production needs.

Seamless Communication between Machines

Sensors let machines share important data right away. This makes it easier to make quick decisions. The main benefits are:

- Increased operational awareness

- Improved troubleshooting efficiency

- Enhanced preventative maintenance strategies

Increased Operational Flexibility

Connected sensors bring big flexibility to factories. They can quickly change to meet new production demands. This keeps factories competitive in a fast-changing world. Some key benefits are:

- Dynamic reconfiguration of production lines

- Customized manufacturing processes

- Real-time adjustments to operational parameters

Sensor Applications in Industrial Settings

In today’s fast-changing industrial world, sensors are key in many areas. They help improve how things work, keep people safe, and follow rules. This is true in oil and gas, food, pharmaceuticals, and car making.

In oil and gas, sensors watch over pipelines. They spot leaks and changes in pressure. This cuts down on harm to the environment and stops big problems.

In food making, sensors check the quality and safety of products. They watch the temperature and humidity. This stops food from getting spoiled.

Pharmaceuticals use sensors to keep drugs at the right temperature. This keeps the drugs safe and follows the rules. In car making, sensors help make sure everything is just right. This makes cars better and saves resources.

| Industry | Application | Benefits |

|---|---|---|

| Oil and Gas | Pipeline monitoring | Leak detection and safety compliance |

| Food Processing | Temperature and humidity sensors | Ensures food safety and quality |

| Pharmaceutical | Environmental monitoring | Regulatory compliance and product integrity |

| Automotive Manufacturing | Quality control sensors | Enhances production accuracy and efficiency |

In short, sensors are vital in making industries better. They help with safety, quality, and following rules. Sensors are flexible and will keep changing how we work in the future.

Innovative Sensor Solutions for Automation

The world of industrial automation is changing fast thanks to new sensor solutions. These changes are key to making modern manufacturing better. They help businesses work more efficiently and accurately.

- Multisensory Networks: They collect data in real-time, giving a full picture of the environment.

- Advanced Analytics: They help make decisions based on data, improving how things work.

- Adaptive Technology: It adjusts to different situations, keeping equipment and products up to standard.

These sensor solutions do more than just improve old ways of doing things. They set new standards for how automation works. As more industries use these technologies, we can expect even more innovation in making things.

| Innovation Type | Impact on Automation | Example Applications |

|---|---|---|

| Multisensory Networks | Improved data accuracy and operational visibility | Smart factories, IoT devices |

| Advanced Analytics | Enhanced predictive maintenance capabilities | Facility management, supply chain optimization |

| Adaptive Technology | Increased system flexibility and reliability | Automated assembly lines, quality control |

Using these new sensor solutions will lead industries to a smarter future. They will create systems that work better than ever before.

Sensor Innovations in Industrial Automation

Recent sensor innovations in industrial automation show big steps forward. These changes are making industrial processes more efficient and adaptable. They focus on several key areas.

- Miniaturization has led to the creation of compact sensors. These can be easily added to existing equipment, improving its function without big changes.

- Enhanced sensitivity in sensors allows for precise measurements. This makes real-time monitoring and better decision-making possible.

- Connectivity improvements let sensors talk easily with bigger systems. This opens the door to smarter factories that use data to improve production.

- Sustainability efforts push for eco-friendly sensor tech. This tech cuts down on energy use and waste in production lines.

These advancements are key for making modern manufacturing smarter and more efficient. XJCSENSOR shows their dedication to innovation with their customizable sensor solutions. These are made for precision and reliability.

The future of sensor innovations in industrial automation looks bright. It will help industries tackle big challenges. This will give them the tools they need to succeed in a competitive world.

Conclusion

Sensors play a key role in today’s industrial automation. They make processes more accurate and efficient. They also provide real-time data for better decision-making.

As markets change, using sensors becomes more important. It helps companies stay ahead in the game.

At XJCSENSOR, we focus on innovation and teamwork. We offer top-notch, customizable sensor solutions. Our goal is to help businesses succeed by improving their operations.

Using sensors makes operations smoother and supports growth. It helps industries work better and grow for the long term. This is key in an automated world.