What is a Load Cell Amplifier?

A load cell amplifier is an electronic device that increases the signal strength from a load cell to a usable level. Load cells typically output a very low signal in millivolts per volt (mV/V), which is insufficient for most control systems to read. The amplifier boosts this signal and often converts it to a standardized output like 0–10V, 4–20mA, or a digital protocol such as RS232 or USB.

The amplifier is an integral part of any system using load cells, especially in industrial, agricultural, and medical settings. Without amplification, the sensor’s signal would be too faint and noisy for accurate interpretation.

Why Use a Load Cell Amplifier?

Amplification is necessary for several reasons:

- Signal Strength: Converts microvolt signals into readable output.

- Noise Reduction: Filters out EMI and signal interference.

- Integration: Matches signal format with PLCs, SCADA, and HMIs.

- Accuracy: Enhances sensitivity and resolution.

Amplifiers also support zeroing, gain adjustment, and temperature compensation, which ensures more stable and repeatable measurements.

How Does a Load Cell Amplifier Work?

From Sensing to Signal

Load cells use strain gauges that deform under load, changing their resistance. This change generates a very small electrical signal. The load cell amplifier:

1. Supplies Excitation Voltage

Provides stable power (usually 5V or 10V DC) to the load cell.

2. Amplifies the Signal

Boosts the millivolt signal into a larger voltage or current.

3. Filters Noise

Eliminates unwanted frequency components.

4. Converts Output

Changes signal format to match your data acquisition system (analog/digital).

Load Cell Amplifier in Industrial Automation

In automated environments, amplifiers are embedded in machines that rely on weight or force data for precise operations. Examples include:

- Press Force Monitoring

- Robotic Assembly Feedback

- Conveyor Belt Load Control

- Tension Control in Textile Machines

These applications depend on clean, accurate, real-time data — something a good amplifier delivers with consistency.

Load Cell Amplifier vs Load Cell

A load cell is the sensor that measures force or weight. A load cell amplifier boosts and conditions the signal from that sensor.

They’re separate but complementary. Think of the load cell as the sensor and the amplifier as its translator.

Analog vs Digital Load Cell Amplifiers

Analog Amplifiers

- Simpler integration

- Outputs: 0–10V, 4–20mA

- Great for legacy systems and basic automation

Digital Amplifiers

- Support USB, RS485, Modbus

- Allow digital calibration

- Include advanced features like data logging and diagnostics

Types of Load Cell Amplifier Outputs

- Voltage: 0–5V, 0–10V

- Current: 4–20mA (ideal for long distances)

- Digital: RS232, RS485, USB, Modbus RTU, CAN

Choose based on compatibility with your control system.

Features to Look for in a Load Cell Amplifier

- Signal range and resolution

- Adjustable gain and zero

- Excitation voltage stability

- Filtering and noise suppression

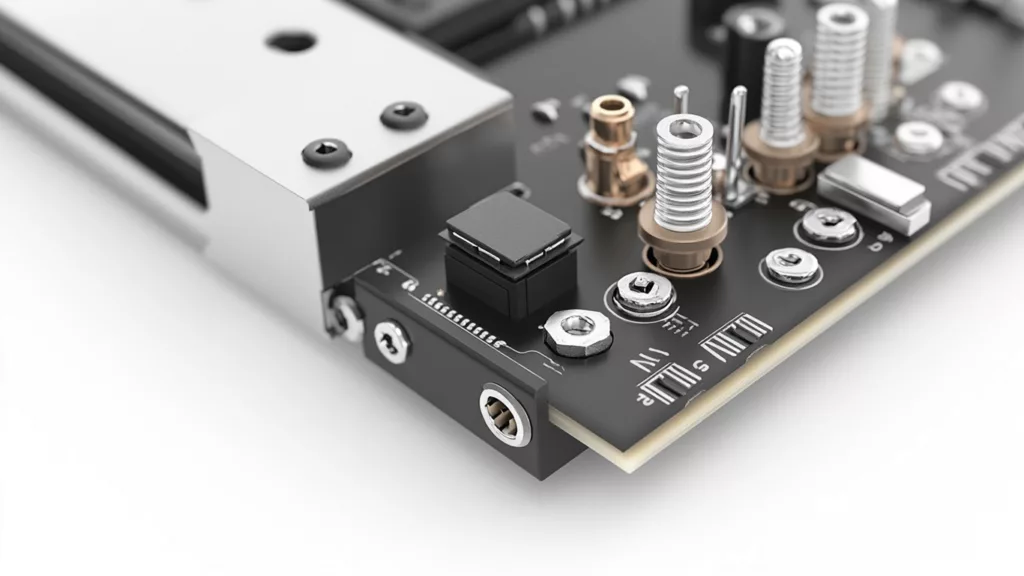

- Mounting style (DIN rail, PCB, enclosure)

- Operating temperature and IP rating

Basic Wiring of a Load Cell Amplifier

Typical configurations:

- 4-wire: Excitation + Signal

- 6-wire: Adds sense wires for better compensation

Use shielded twisted-pair cables and proper grounding to reduce interference.

Power Supply Requirements for Amplifiers

Amplifiers may require:

- 5V, 12V, or 24V DC

- Stable power to avoid drift

- Overvoltage protection in harsh environments

Load Cell Amplifier in PLC Integration

- Connect output to analog/digital input module

- Use scaling instructions to convert raw signal to engineering units

- Implement alarms and triggers based on weight

Wireless Load Cell Amplifiers

- Use RF, Bluetooth, or Wi-Fi

- Ideal for rotating or hard-to-reach setups

- Battery or solar-powered options available

- Suitable for logistics, vehicle monitoring, and smart farming

DIN-Rail Load Cell Amplifier

- Mounts easily in control panels

- Clean cable routing

- Often supports multiple input/output formats

Applications in Weighing Systems

Used in:

- Tank/Hopper/Silo Weighing

- Batching/Filling Lines

- Floor Scales and Conveyor Systems

Medical Equipment and Load Cell Amplifiers

- Infusion pumps and dosing systems

- Bed monitoring for patient movement

- Force sensors in prosthetics

Aerospace Testing with Load Cell Amplifiers

- Structural stress testing

- Load frame data capture

- Aircraft component quality checks

Load Cell Amplifier in Robotics

- Gripping force control

- Haptic feedback systems

- Tool-load measurement

Challenges in Load Cell Signal Amplification

- Signal drift due to temperature changes

- EMI from nearby motors

- Cable length causing attenuation

Solutions include shielded cables, proper grounding, and regular calibration.

Calibration of Load Cell Amplifiers

- Apply zero load, set output to 0.

- Add known weight, adjust gain.

- Repeat for multiple points.

- Confirm linearity and stability.

Signal Noise Reduction Techniques

- Differential inputs

- Hardware and software filters

- Twisted pair and shielded wiring

- Physical separation from noise sources

Environmental Protection of Amplifiers

Look for:

- IP67 or IP68 for outdoor use

- Conformal coating against humidity

- Surge protection and sealed housings

Miniature Load Cell Amplifiers

- Used in medical, wearable, or handheld devices

- Compact PCB modules

- Ideal for embedded systems

Smart Load Cell Amplifiers and IoT

- Wireless communication

- Onboard memory and data logging

- Remote calibration via app or software

Maintenance Tips for Longevity

- Check wiring periodically

- Recalibrate annually

- Protect from moisture and vibration

Common Troubleshooting Tips

- Check power supply and signal wiring

- Inspect connectors for corrosion

- Use multimeter to verify output levels

Myths About Load Cell Amplifiers

- “Any amplifier works with any load cell” – False

- “Once calibrated, it never needs adjustment” – False

- “Digital is always better than analog” – Not always

Future of Load Cell Amplification

- AI-powered signal processing

- Predictive diagnostics

- Edge computing integration

- Cloud-native force monitoring

Clear Call-to-Action (CTA)

XJCSENSOR is a global leader in high-performance load cell amplifiers and force measurement technology. We specialize in custom amplifier solutions for industrial automation, robotics, medical devices, agriculture, and aerospace.

👉 Contact us now for expert support on amplifier integration

🔍 Explore our full range of load cell amplifiers on our website

📬 Subscribe to our newsletter for the latest in sensor technology

📱 Follow XJCSENSOR on LinkedIn to see real-world applications and innovations

Precision starts with the right amplifier — trust XJCSENSOR.