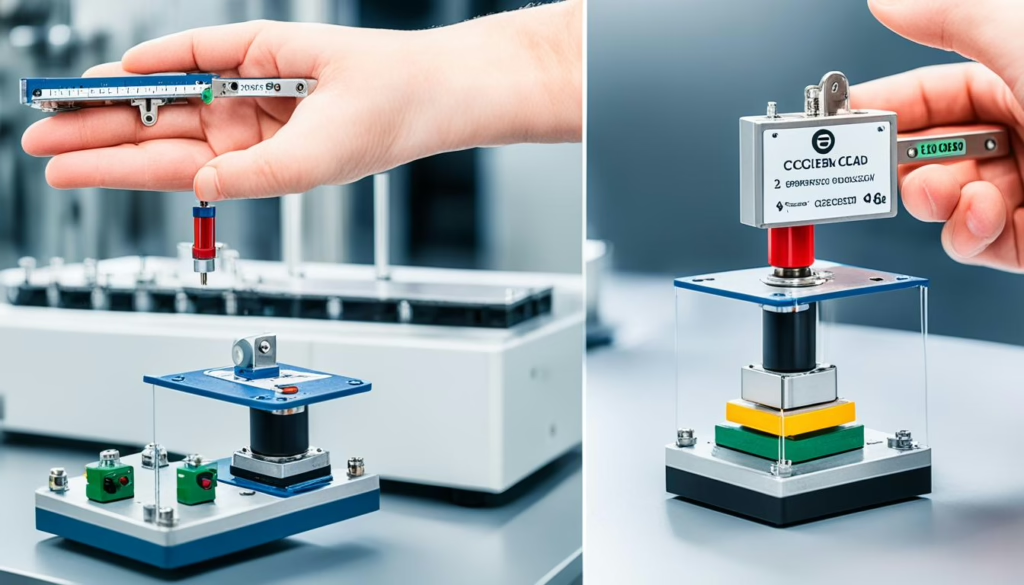

As devices get smaller, we need precise tools for small spaces more than ever. Miniature load cell sensors are key in measuring forces where space is tight. XJCSENSOR offers these small but essential sensors. They are perfect for high-precision tasks in many fields, including medical and electronics.

There’s a high demand for these sensors in tiny places. Low profile load cells were created to answer this need. They are made to work well in different industries. This shows their importance in advancing today’s tech.

Key Takeaways

- A miniature load cell sensor is essential for accurate force measurement in confined spaces.

- XJCSENSOR provides high-quality, compact load sensors for various industries.

- Accurate force measurement is vital for the miniaturization of technology.

- Low profile load cells are designed to meet the unique needs of modern engineering.

- These sensors are crucial in applications like medical devices and consumer electronics.

Understanding Miniature Load Cell Sensors

Miniature load cell sensors convert force into an electrical signal. They are small yet very accurate. This makes them perfect for tight spaces. They change mechanical force into electrical output. This is key in many high-tech systems today.

What is a Miniature Load Cell Sensor?

These sensors measure weight or force in small areas, but still give correct data. They use strain gauges to notice tiny bends in the material when force is applied. This bend changes the electrical resistance. Then, it’s turned into an electrical signal that matches the force. The precision of a miniature weight sensor is crucial for many uses.

Principle of Operation

To grasp how load cells work, we need to look at their operation principle. When force hits the sensor, it strains the sensor’s material. Strain gauges on the sensor spot this strain as a resistance change. This change then becomes an electrical signal through a Wheatstone bridge circuit. The signal is boosted, filtered, and analyzed to give accurate force or weight readings. The durability and accuracy of these sensors show why it’s important to understand them for various fields.

Benefits of Using Compact Load Sensors

Compact load sensors are crucial for many fields. They’re especially helpful in places where space is tight but accuracy is vital. This makes them perfect for areas like aerospace or robotics.

Precision Measurement in Limited Spaces

Load sensors are great for precise measurements in small spaces. They fit well in places like cars and robots where every inch counts. Despite their small size, they ensure accurate force readings.

Versatility and Application Compatibility

These sensors are not only adaptable but also compatible with many applications. They work well in things like medical devices and consumer electronics. Their adaptability makes them useful in numerous fields, improving functionality and integration.

| Key Benefit | Details |

|---|---|

| Precision in Limited Spaces | Accurate force measurement in tight environments |

| Versatility | Suitable for multiple applications and conditions |

| Application Compatibility | Flexible integration with various instruments and systems |

Applications of Small Load Cells

Small load cells are crucial in many industries. They offer precise measurements in various devices. You’ll find these tiny sensors in medical equipment, industrial machines, and consumer electronics.

Medical Equipment

In healthcare, small load cells are very important. They’re in devices that diagnose, monitor patients, and even in surgical tools. Take infusion pumps as an example. They use these sensors to control how much medicine a patient gets.

This makes sure patients are safe and helps treatments work better. Also, in prosthetics, these sensors measure force. This helps make the prosthetics work better and feel more comfortable for the user.

Industrial Automation

Industrial automation relies on small load cells too. They are part of machines that need to measure force accurately. This ensures the machines work safely and well. For example, in robotics, they help control movements precisely.

And, in packaging, they make sure each product weighs the right amount. This helps factories run better and avoids wasting time fixing machines.

Consumer Electronics

In gadgets we use every day, small load cells play a key role. They’re in gaming controllers, making games feel more real. Also, they’re in smartwatches and fitness trackers, tracking our activity levels.

Even touchscreens and devices that give you a sense of touch use them. This all comes down to the accuracy and sensitivity of these sensors.

| Industry | Application | Benefits |

|---|---|---|

| Medical | Infusion Pumps, Prosthetics | Enhanced Safety, Improved Comfort |

| Industrial | Robotics, Packaging | Operational Accuracy, Efficiency |

| Consumer Electronics | Gaming Controllers, Smartwatches | Better Experience, Accurate Tracking |

Types of Tiny Load Sensors

The world of tiny load sensors is big and filled with options. They offer many capabilities and serve different purposes. Knowing about the most common types helps you pick the best one for your needs.

Button Load Cells

The button load cell stands out for its small, slim look. It’s perfect for tight spots. These sensors measure pushing force well. They’re used in medical gadgets and materials testing gear. Despite their size, they can handle big forces. This makes them key in precise measurement systems.

Pancake Load Cells

The pancake load sensor looks like a disc. It’s good for pulling and pushing force measurements. These sensors are key in high-accuracy tasks like car testing and aerospace work. Their design makes it easy to add them to existing setups, which appeals to precision-focused fields.

S-Beam Load Cells

S-beam load cells are flexible and often chosen for their dual-measurement ability. Their unique S-shape makes mounting and integration simple. They are found in scales, materials testing, and factory automation. These load cells deliver consistent results in a variety of settings. Their versatility and ease of use make them a favored choice for different measurement tasks.

Looking into these types of load sensors helps you find the right match for your project. Whether you need a button load cell for small areas, a pancake load sensor for flexible force measurement, or an S-beam load cell for ease in tension and compression tasks.

Design and Features of Micro Load Cells

Leading brands like XJCSENSOR focus on making micro load cells durable and reliable. They use innovative sensor techniques. This makes the cells both effective and precise.

Micro load cells are designed to meet the demands of different industries. They include advanced side load compensation and protection against harsh conditions. This makes them perfect for tough situations.

These cells can handle weights from 10 grams to 20,000 pounds. They come with special mounting options like load buttons and through-hole designs. This smart design improves their use in areas like automation and robotic sensing.

Companies like FUTEK make sensors that can measure both tension and compression. This makes them more versatile than other load cells. It shows the innovation in their design.

To better understand modern micro load cells, it helps to compare their accuracy, materials, and design.:

| Feature | Benefits |

|---|---|

| Side Load Compensation | Improves precision by compensating for off-axis loads. |

| Environmental Protection | Ensures durability and reliability in harsh conditions. |

| Mounting Provisions | Allows for flexible installation options, catering to various applications. |

| Dual Measurement (Tension & Compression) | Increases versatility in application, providing more comprehensive data. |

The design of these tiny sensors is constantly evolving. This shows a strong commitment to improving accuracy and reliability. Tiny load sensor technology helps industries get precise results, even in the toughest environments.

Choosing the Right Miniature Weight Measurement Tool

When choosing miniature sensors, it’s vital to think about key factors. This makes sure you pick the best weight measurement tool for your needs. Working with XJCSENSOR’s expert team helps. They offer advice based on your specific requirements.

- Load Capacity: Identifying the sensor’s maximum load capacity is essential. Different needs require different load capacities.

- Size Constraints: Miniature sensors must often fit in small spaces. Their size is therefore very important.

- Environmental Conditions: The sensor’s surroundings can impact its performance. It’s important to consider temperature, humidity, and exposure to chemicals or vibrations.

Now, let’s discuss why some industries prefer certain sensor types:

| Industry | Preferred Sensor Type | Reasons |

|---|---|---|

| Medical Equipment | Micro Load Cells | Precision and size are crucial for medical device integration. |

| Industrial Automation | S-Beam Load Cells | They need high reliability and durability in tough conditions. |

| Consumer Electronics | Button Load Cells | They value compact design and affordability. |

Evaluating these factors ensures our clients get the best solutions for their needs. Whether it’s for medical, industrial, or consumer electronics, our knowledge in micro load cell selection guarantees the most reliable and accurate weight measurement tool.

Installation and Maintenance Tips

Proper installation and routine upkeep are key for miniature load cell sensors to work well and last long. Here are important tips for setting up and maintaining these sensors to keep measurements precise and dependable.

Proper Installation Procedures

Putting in miniature load cell sensors the right way is crucial. Keep these tips in mind for setup:

- Mounting Surface Preparation: Make sure the surface where you’re mounting the sensor is clean, smooth, and free of dirt. This step is critical for accurate force readings.

- Alignment: It’s important to align the load cell correctly to avoid errors caused by loading it the wrong way.

- Torque Specifications: Follow the torque guidelines from the manufacturer. This will prevent damage and keep readings accurate.

- Environmental Considerations: Shield the load cell from harsh environmental elements like extreme heat, moisture, or corrosive materials.

Regular Maintenance Practices

Maintaining your miniature sensors regularly is crucial for their performance. Here are key maintenance activities to ensure they stay accurate:

- Visual Inspections: Frequently check for any damage or wear, including the condition of cables and connections.

- Calibration: Recalibrate the load cell periodically to maintain its accuracy over time.

- Cleaning: Keep the load cell clean with suitable cleaning agents to prevent the accumulation of harmful substances.

- Environmental Adaptation: Make sure the load cell operates within its environmental guidelines to avoid long-term damage.

Following these guidelines for installation and care keeps your miniature load cells performing reliably. By doing so, you can trust them for accurate results, even in tough conditions.

Advancements in Miniature Sensor Technology

The ongoing evolution in sensor technology advancements is pivotal. It’s enhancing the abilities of tiny sensors. This is thanks to better materials and the use of IoT, setting new standards.

Innovations in Sensor Materials

The latest breakthroughs in sensor materials are key. They are moving tiny sensors forward. New materials lead to more accurate and tough sensors. This is great for measuring forces and means sensors can be trusted in different places. This includes both work settings and gadgets we use every day.

Integration with IoT

Linking sensors with the Internet of Things (IoT) is changing how we collect and analyze data. This connection boosts real-time monitoring and sharing data. It lets sensors talk to each other easily. This not only makes things more efficient. It also makes it easier to automate things and predict when things need fixing in many fields.

Enhanced Data Transmission and Processing

There have been big steps in improving how sensors process and send data. Now, sensors can manage more data more accurately. This means we can diagnose problems faster and get updates in real time. These improvements help us make quick decisions based on data. This is super important in critical areas like health care, flying planes, and making things.

- Innovations in Sensor Materials:

- Higher accuracy

- Increased resilience

- Integration with IoT:

- Real-time monitoring

- Seamless communication

- Enhanced Data Transmission and Processing:

- Speed and efficiency

- Real-time feedback

As we keep exploring sensor technology advancements, IoT sensors and better data handling are key. They are pushing the limits. They aim for unmatched precision and efficiency.

XJCSENSOR: Leading the Way in Miniature Load Cell Innovation

At XJCSENSOR, we are proud of our commitment to miniature load cell technology. Our work shows in our wide range of products, customizable options, and customer successes.

Our Product Range

Our miniature load cells are made for accuracy and dependability in many fields. Whether it’s for medical devices, industrial automation, or consumer gadgets, we have you covered. Our main offerings include:

- Button Load Cells

- Pancake Load Cells

- S-Beam Load Cells

Customization Options

We understand each project is different and offer custom load cells for your needs. Our engineers work with clients to build sensors for top performance and easy system fit. Thanks to XJCSENSOR innovation, our custom solutions provide accurate force measurement and improve efficiency.

Client Success Stories

Our clients’ achievements speak to our dedication to success in force measurement. Various industries have seen great results using our miniature load cell technology. These stories prove our products’ reliability and effectiveness in real situations, marking us as industry leaders.

| Industry | Application | Result |

|---|---|---|

| Medical | Portable devices | Enhanced accuracy and reliability |

| Industrial Automation | Robotic arms | Increased operational efficiency |

| Consumer Electronics | Wearable tech | Precision in miniaturized designs |

Conclusion

Miniature load cell sensors mark a breakthrough in force measurement. They are key in providing exact measurements, even in tiny spaces. Used in many fields, like health care, automation, and electronics, their importance is clear. These sensors adapt well to various uses, showing the need for the right match for each task.

Thanks to newer materials and the Internet of Things (IoT), these sensors are better than ever. This progress means you should choose top-grade sensors from leaders like XJCSENSOR. Their expertise means every measurement challenge is met perfectly. Features like filtering and temperature control make these devices even more precise, essential for both industry and health care.

Recognizing the real value and uses of these sensors shows how vital a reliable provider is. XJCSENSOR stands out with their wide range and custom solutions. We invite you to see what we offer. To support your specific goals with accurate and reliable measures, check our load cell amplifier page. Find out how our advanced sensor solutions can help you.