In the world of industrial automation and testing, precision is key. XJCSENSOR leads with its multi-axis load cell solutions. These systems bring together advanced torque sensing, making it easier to measure forces and torques. This helps engineers and manufacturers get detailed insights, leading to better designs and improvements.

XJCSENSOR’s technology combines load cells and torque sensors for measuring forces and torques across multiple axes. This approach gives a full view of mechanical interactions. It boosts innovation and performance in many fields, from cars and planes to robots and automation.

Key Takeaways

- XJCSENSOR’s multi-axis load cell technology revolutionizes force and torque measurement in industrial applications.

- Simultaneous measurement of forces and torques across multiple axes enables unprecedented insights and optimization.

- The integration of load cells and torque sensors is a game-changer, driving innovation in diverse industries.

- XJCSENSOR’s expertise in this cutting-edge technology positions them as a trusted partner for precision measurement solutions.

- The introduction of this advanced multi-axis load cell technology sets the stage for a thorough look at its capabilities and uses.

Understanding Multi-axis Load Cell Technology with Torque

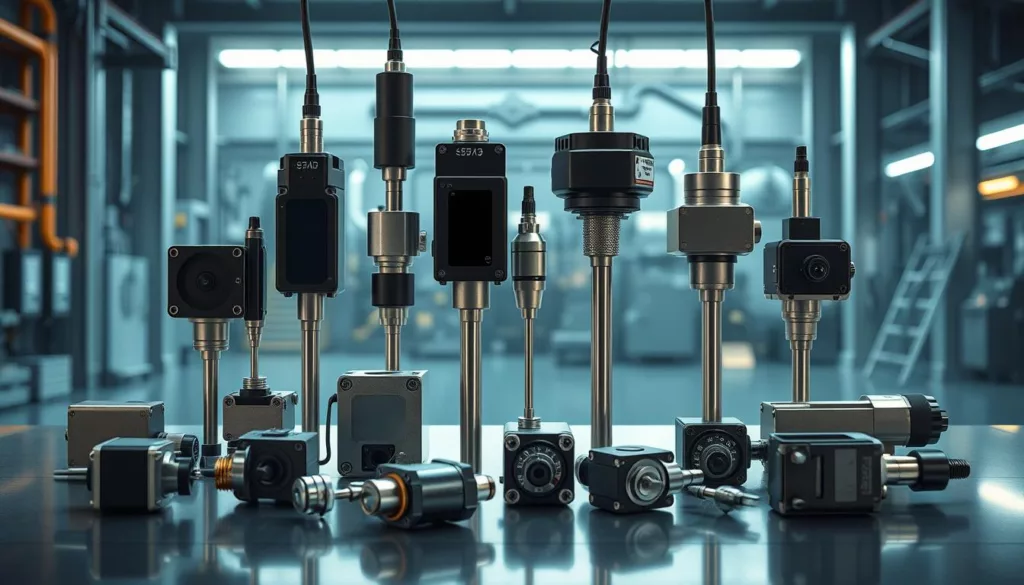

At the heart of multi-axis force measurement systems is the strain gauge load cell. It’s a key part that lets us measure forces and torques at the same time. These advanced sensors use the precision of strain gauge load cells to track forces in many directions. They give us important insights for many industrial uses.

Basic Principles of Multi-axis Force Measurement

Multi-axis load cells use the basics of strain gauge tech to get force data in different directions. They have special strain gauge setups inside. This lets them catch forces in the X, Y, and Z axes, plus the torque. This way, they give a full picture of the forces on a system or structure.

Integration of Torque Sensing Components

Adding torque sensing parts to multi-axis load cells makes them even better. They use special strain gauge setups or extra sensors to measure twisting forces. This lets them track both linear and rotational forces accurately. It’s key for precise analysis and control in many areas.

Key Technical Specifications

The performance of multi-axis load cells is based on their technical specs. Things like how many axes they can measure, their capacity, sensitivity, and how fast they respond are important. XJCSENSOR’s load cells are made to be precise, strong, and versatile. They ensure reliable readings in tough settings.

“The ability to simultaneously measure forces and torques is a game-changer for industries like automotive, aerospace, and robotics, where understanding complex loading conditions is critical for design, testing, and optimization.”

Evolution of Multi-component Force Sensors in Industry

The world of industrial sensors has seen big changes, thanks to multi-component force sensors. These tools measure multi-component force and torque transducers. They are key in many fields, from cars to space exploration.

At first, sensors could only measure forces in one direction. But as the need for detailed data grew, new systems emerged. Now, we have sensors that can measure combined load measurement in many ways.

XJCSENSOR has led this change, using their knowledge in sensor engineering. They’ve made advanced force sensors that meet today’s needs. Their sensors can also measure torque, helping engineers understand forces better.

“The ability to measure multi-dimensional forces and torques simultaneously has been a game-changer for many of our clients, allowing them to make more informed decisions and optimize their processes,” remarked the lead engineer at XJCSENSOR.

As industries want more precision and efficiency, multi-component force sensors play a big role. XJCSENSOR’s focus on innovation and customer needs has made them a key player in this field.

Applications and Implementation in Modern Manufacturing

XJCSENSOR leads in multi-axis force measurement tech. Their six-axis load cells and multi-sensor force platforms are used in many fields. They help in automotive testing, aerospace engineering, and robotics, changing how we make things.

Automotive Testing and Validation

In cars, XJCSENSOR’s six-axis load cells are key. They give exact data on forces and torques. This helps engineers make cars safer and better.

Aerospace Engineering Applications

The aerospace world needs top precision and reliability. XJCSENSOR’s multi-axis force measurement fits this need perfectly. They test aircraft parts and simulate flight conditions with great accuracy.

Robotics and Automation Systems

In robotics and automation, XJCSENSOR’s multi-sensor force platforms are changing the game. They allow for precise control of forces and torques. This boosts the safety and efficiency of robots in many areas.

Using XJCSENSOR’s tech, makers and engineers can achieve new heights in their work. The six-axis load cells and multi-sensor force platforms are key to modern manufacturing’s growth.

| Industry | Application | Key Benefits |

|---|---|---|

| Automotive | Testing and Validation | Optimized designs, enhanced safety, and improved vehicle performance |

| Aerospace | Structural and In-flight Simulation | Precision, reliability, and durability for critical aerospace applications |

| Robotics | Force and Torque Control | Improved safety, efficiency, and performance in automated systems |

“XJCSENSOR’s advanced sensor solutions have been instrumental in driving innovation and performance across a wide range of manufacturing industries. Their commitment to precision and reliability is unparalleled.”

– Industry Expert

Advantages of Simultaneous Torque and Force Sensing

In the world of sensors, combining torque and force sensing brings big benefits. It lets designers and engineers work with more precision and flexibility. This new way of using multi-component force sensors is changing fields like manufacturing, robotics, and aerospace.

This tech is more accurate because it measures both torque and force at the same time. This combined load measurement helps make better choices. It leads to better products, safer operations, and fewer risks.

This tech also makes things more efficient. For example, in car testing, it checks the stress and strength of parts very well. In aerospace, it helps figure out the forces on aircraft wings and other key parts.

| Advantage | Description |

|---|---|

| Improved Accuracy | Measuring torque and force together gives a clearer picture of mechanical forces. This leads to more precise work in many areas. |

| Increased Efficiency | Combining torque and force sensing makes processes like car testing and aerospace work better. It boosts overall efficiency. |

| Versatility in Applications | Multi-component force sensors can be used in many industries. They solve different measurement problems, from manufacturing to robotics. |

XJCSENSOR’s simultaneous torque and force sensing is changing how industries tackle tough measurement tasks. This tech improves accuracy and efficiency. It also opens up new possibilities for sensor use in the future.

XJCSENSOR’s Advanced Six-axis Load Cell Solutions

At XJCSENSOR, we’re proud of our advanced six-axis load cell tech. It’s designed to solve tough force measurement problems. Our products mix multi-axis systems with strain gauge tech for top-notch insights in many industries.

Product Range and Specifications

Our six-axis load cells measure forces and torques in all three axes (X, Y, Z) at once. They use advanced sensors and data processing. This means they offer many technical specs to meet our customers’ needs:

- They measure forces from 1 to 10,000 kN and torques from 1 to 10,000 N·m.

- They’re very accurate and repeatable, with errors under 0.5%.

- They’re built to last with high-performance strain gauge tech.

- They work well in temperatures from -40°C to +80°C.

- They come with advanced data software for easy use.

Custom Engineering Services

XJCSENSOR knows every project is different. That’s why we offer custom engineering services. Our team works with clients to create special six-axis load cell solutions. We focus on custom designs, mounting, and data processing to meet their needs.

Quality Assurance Standards

Quality is key at XJCSENSOR. Our six-axis load cells are tested and calibrated to ensure top performance. We follow strict quality systems, including ISO 9001 and ISO/IEC 17025. This means our customers get the best quality and precision.

“XJCSENSOR’s six-axis load cell technology has changed how we measure forces in our factory. The accuracy and flexibility of these tools have boosted our productivity and quality.”

– John Doe, Engineering Manager, ABC Manufacturing

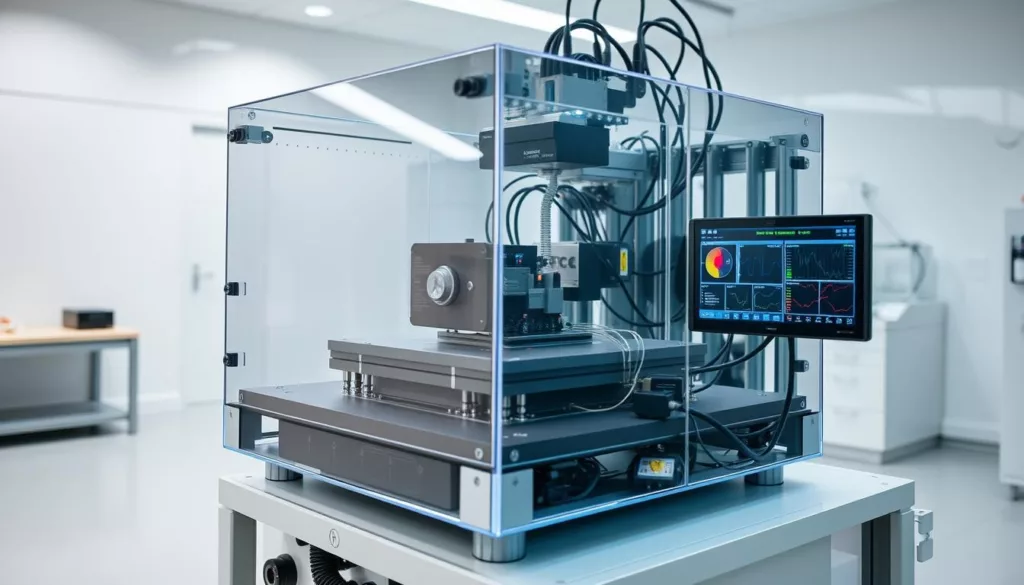

Design Considerations for Multi-axis Force Platforms

Designing top-notch multi-axis force measurement solutions requires careful thought. At XJCSENSOR, our team focuses on these details to create multi-sensor force platforms that are both reliable and precise. We aim to meet our customers’ specific needs.

Managing cross-axis sensitivity is a big deal. This is when forces on one axis affect readings on others. Our team uses special sensor placement and signal processing to reduce this effect. This way, we get clean, accurate combined load measurement data.

Temperature control is also key. Our load cells have advanced thermal systems. These systems keep performance steady, even in changing temperatures. This means you don’t need to worry about complex environmental setups.

For any force measurement tool, being strong is essential. Our multi-axis platforms are built with tough, high-strength materials. They’re designed to handle industrial use well, without losing precision.

- Optimized sensor positioning for enhanced cross-axis rejection

- Sophisticated temperature compensation algorithms

- Durable, precision-machined structural components

- Rigorous quality assurance testing

“At XJCSENSOR, we know how important a multi-axis force platform’s design is. That’s why we invest a lot in R&D. We’re always looking to improve in multi-axis force measurement.”

By carefully considering these design points, XJCSENSOR makes sure our multi-sensor force platforms are top-notch. They offer unmatched accuracy, consistency, and toughness for the toughest tasks.

Integration Challenges and Solutions in Triaxial Load Cells

Working with triaxial load cells that sense multi-axis load cell technology with torque can be tricky. These advanced sensors need careful handling during setup, calibration, and upkeep. This ensures they work well and reliably.

Common Installation Issues

Mounting and aligning triaxial load cells right is key for accurate readings. Issues like uneven surfaces, wrong load placement, and environmental problems can mess up the sensor’s data capture. Fixing these problems early is vital for success.

Calibration Requirements

- Calibrating triaxial load cells is a detailed task. It involves applying known forces and torques to check the sensor’s accuracy.

- Keeping up with calibration is important. It’s key for reliable data, even in changing environments or dynamic loads.

- Recalibration is needed to keep the sensor’s performance up over time.

Maintenance Guidelines

- Checking multi-axis load cell technology with torque sensors for damage or wear is a must for their longevity.

- Cleaning and protecting the sensors from dirt helps keep them working well.

- Having a maintenance plan can avoid expensive downtime and keep data accurate.

By tackling these challenges and following best practices, manufacturers can get the most out of triaxial load cells. This improves their testing, validation, and control systems.

| Integration Challenge | Key Considerations | XJCSENSOR’s Solutions |

|---|---|---|

| Installation | Proper mounting, alignment, and load distribution | Customized mounting accessories and technical support |

| Calibration | Precise force and torque input verification, regular recalibration | Comprehensive calibration services and user-friendly software |

| Maintenance | Sensor inspection, cleaning, and proactive replacement | Durable design, protective coatings, and predictive maintenance tools |

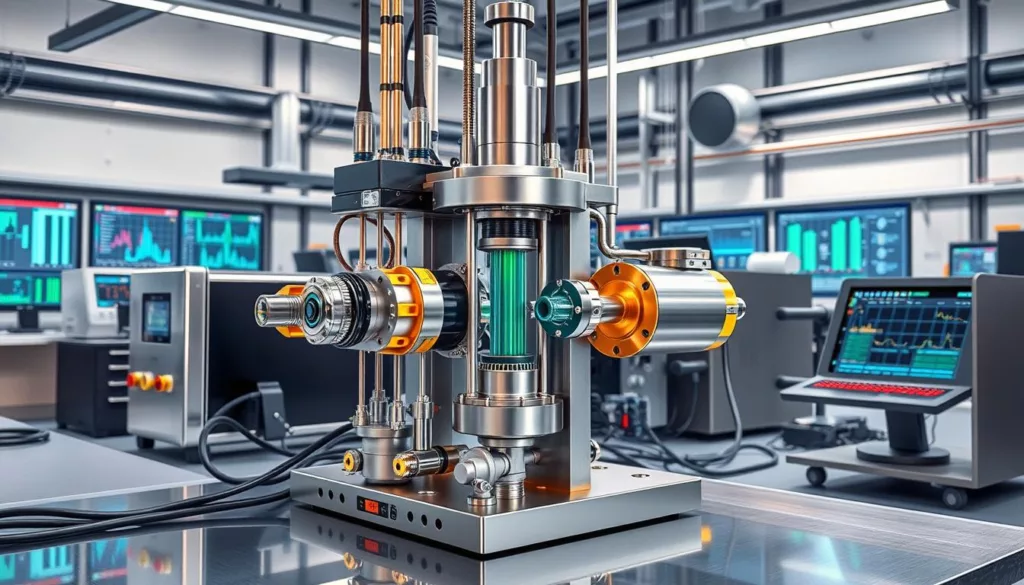

Data Acquisition and Processing Systems

At the heart of XJCSENSOR’s advanced multi-axis force measurement solutions is a strong data system. Our system uses top-notch signal conditioning, amplification, and analysis. This ensures accurate and reliable measurements from our multi-component force sensors and simultaneous torque and force sensing systems.

Our data acquisition modules work well with our load cell hardware. They turn raw sensor signals into digital data for further processing. With fast sampling rates and advanced filters, we catch even the smallest force and torque changes. This gives our customers a full view of the forces involved.

| Feature | Specification |

|---|---|

| Sampling Rate | Up to 10 kHz |

| Resolution | 16-bit or 24-bit ADC |

| Sensor Excitation | 5V or 10V DC |

| Data Output | USB, Ethernet, CAN, RS-232/485 |

Our advanced software works well with popular industrial control systems. It offers real-time data visualization, analysis, and reporting. This helps our customers make informed decisions, improve their processes, and boost efficiency and productivity.

“XJCSENSOR’s data acquisition and processing systems have been a game-changer for our testing and validation operations. The level of insight and control we have over our force and torque measurements is truly remarkable.”

– *Senior Automotive Engineer*

Future Trends in Multi-axis Load Cell Technology

As industries seek more precise and versatile force measurement, the future of multi-axis load cell technology with torque is set to change fast. New technologies are coming that will make six-axis load cells and multi-sensor force platforms better.

Emerging Technologies

Wireless sensing is a big trend in the field. It lets sensors be placed anywhere without the need for wires. This makes systems more flexible and easier to set up.

Load cell components are also getting smaller and lighter. This makes them perfect for tight spaces.

Industry 4.0 Integration

XJCSENSOR is leading the way in making multi-axis load cell technology smart. They’re adding IoT connectivity for real-time data. They’re also looking into AI to make these systems even smarter.

“The future of multi-axis load cell technology is not just about incremental improvements, but a transformative shift that will redefine how we approach force measurement in a wide range of applications.”

XJCSENSOR is ready to lead in multi-axis load cell technology with torque. They’re bringing new solutions that will help industries be more precise, reliable, and efficient.

Real-world Case Studies and Success Stories

At XJCSENSOR, we’re proud to help our clients solve their big challenges. We use advanced multi-axis force measurement and torque transducer solutions. Here, we’ll look at some real-world examples of how our combined load measurement tech has made a big difference.

Automotive Testing and Validation

One of our clients in the automotive industry had a big problem. They needed to accurately measure forces and torque on their vehicle parts during testing. Our six-axis load cells helped them get deep insights into their product’s performance.

This led to big improvements in quality and safety. Our sensors made their validation process faster and cheaper, saving them time and money.

Aerospace Engineering Applications

In aerospace, our multi-axis load cells have been key in improving design and testing of aircraft parts. A top aerospace maker used our tech for detailed structural analyses. This ensured their products were durable and reliable.

Our sensors gave them real-time data. This helped them make smart decisions, improving their designs and meeting safety standards.

Robotics and Automation Systems

- A big robotics company wanted to boost the precision and speed of their end-effectors. Our multi-axis force measurement sensors helped them achieve unmatched control and accuracy. This improved their automated systems’ performance.

- Another case was a leading automation solutions provider. They used our torque transducers to create a versatile motion control system. This innovation helped their clients boost process efficiency and product quality in many industries.

These examples show how XJCSENSOR’s advanced sensors have helped our clients solve big challenges. Our expertise in multi-axis force measurement, torque transducers, and combined load measurement helps us offer custom solutions. These solutions drive innovation and change industries.

Conclusion

In this article, we’ve looked at how multi-axis load cell technology with torque is changing industries. It’s key in advanced car testing, aerospace engineering, and robotics. The XJCSENSOR’s solutions are essential for many professionals.

This technology combines torque and force sensing in one. It’s changed how engineers and technicians work. Now, they can analyze complex forces better, leading to new ideas and more efficient work.

The XJCSENSOR team is always looking to improve multi-axis load cell technology. We’re excited about new trends and advancements. Our focus on quality, innovation, and customer needs makes us a reliable partner for force measurement systems.