High-Precision Sealing Machines Sensor for Industrial Use

SEALING MACHINES SENSOR: INNOVATION FOR INDUSTRIAL PACKAGING

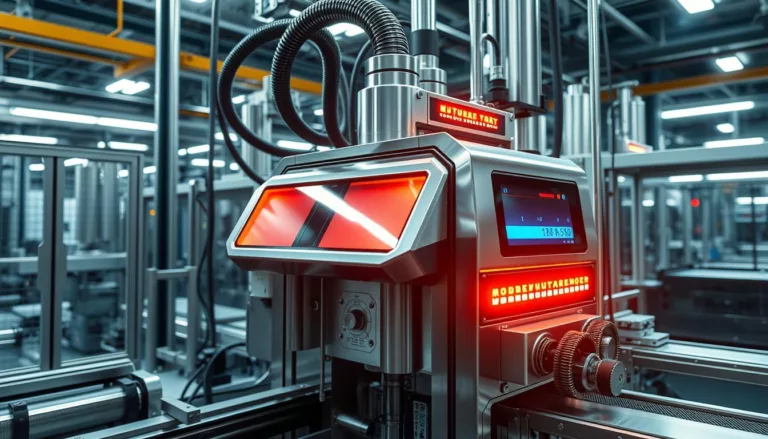

The Sealing Machines Sensor is an essential technology used in various industries for the precise measurement and control of sealing processes. By enhancing the accuracy and efficiency of sealing machines, these sensors ensure high-quality, reliable packaging, making them a crucial component for modern packaging lines. XJCSENSOR specializes in high-precision sealing machine sensors, offering customizable solutions for a wide range of industrial applications.

WHAT ARE SEALING MACHINES SENSORS?

Sealing machines sensors are sophisticated devices designed to monitor and control the sealing process in packaging machines. These sensors play a pivotal role in ensuring that packaging materials are securely sealed, preserving the integrity of the products inside. Typically, these sensors detect various factors, including temperature, pressure, and sealing time, to ensure that the seals are strong and airtight. The use of sensors in sealing machines helps to automate the packaging process, reduce errors, and increase efficiency.

HOW SEALING MACHINES SENSORS IMPROVE PACKAGING EFFICIENCY

By integrating sealing machines sensors, manufacturers can significantly improve the efficiency of packaging lines. These sensors enable real-time monitoring of key sealing parameters such as temperature and pressure, ensuring that each package is sealed correctly. With enhanced precision, sensors minimize the risk of defective seals, reducing waste and ensuring product safety. This leads to faster production times, improved operational efficiency, and cost savings for manufacturers.

TYPES OF SEALING MACHINES SENSORS AVAILABLE

XJCSENSOR offers a variety of sealing machine sensors tailored to meet specific requirements in industrial packaging applications. Some of the most commonly used types include:

- Temperature Sensors: Used to monitor the heat during the sealing process, ensuring that the materials are sealed at the optimal temperature.

- Pressure Sensors: These sensors ensure that the correct pressure is applied during the sealing process, maintaining consistency in the seal strength.

- Force Sensors: Force sensors monitor the amount of force applied by the sealing jaws, which is critical for ensuring the integrity of the seal.

- Multi-sensor Systems: These combine several types of sensors for a more comprehensive measurement, providing greater control over the entire sealing process.

WHY XJCSENSOR'S SEALING MACHINES SENSORS STAND OUT

XJCSENSOR’s sealing machine sensors are designed with cutting-edge technology, ensuring high reliability and performance in demanding environments. Our sensors are built for durability and precision, ensuring consistent results in packaging operations. Additionally, we offer customizable sensor solutions to fit unique production requirements, making us a trusted partner for industries that demand excellence.

KEY BENEFITS OF USING SEALING MACHINE SENSORS IN AUTOMATED PACKAGING LINES

- Increased Precision: Sensors ensure that sealing temperatures, pressure, and force are precisely controlled, leading to optimal packaging quality.

- Enhanced Efficiency: Automation via sensors reduces manual intervention, speeding up the production process.

- Reduced Defects: With real-time monitoring, sensors identify potential issues early, preventing defective seals.

- Cost Savings: By reducing waste, minimizing defects, and improving throughput, sealing machine sensors help lower production costs.

- Improved Quality Control: Sensors enable constant monitoring, ensuring that every sealed package meets the required standards.

HOW SEALING MACHINE SENSORS WORK IN PACKAGING APPLICATIONS

Sealing machine sensors are typically integrated into the packaging line to monitor and adjust critical parameters such as temperature, pressure, and sealing time. In an automated system, these sensors provide real-time feedback to the control system, which adjusts the sealing process parameters accordingly. For example, if a temperature sensor detects that the sealing jaws are too hot or too cold, the control system will adjust the heating elements to ensure optimal sealing conditions. This constant feedback loop ensures that each package is sealed correctly, even during high-speed production runs.

CUSTOMIZING SEALING MACHINES SENSORS FOR SPECIFIC NEEDS

One of the key advantages of choosing XJCSENSOR for sealing machine sensors is our ability to customize solutions based on your specific application. We understand that every industry and packaging process may have unique requirements, which is why we offer tailor-made sensors that integrate seamlessly with your existing machinery. Whether you need sensors for high-temperature sealing machines or pressure-sensitive packaging lines, XJCSENSOR can provide solutions that enhance the performance and reliability of your production line.

APPLICATIONS OF SEALING MACHINES SENSORS IN INDUSTRIES

Sealing machines sensors are widely used in industries such as food packaging, pharmaceuticals, electronics, and consumer goods. These sensors are integral to ensuring the safety, quality, and integrity of the products inside the packaging. For example, in the food industry, maintaining airtight seals is crucial for product preservation and preventing contamination. In the pharmaceutical sector, packaging seals must be strong enough to protect medicines from environmental factors, ensuring their potency and safety. With a robust and reliable sensor system, these industries can meet their stringent quality control standards.

SEALING MACHINES SENSOR MAINTENANCE AND LONGEVITY

To ensure that sealing machine sensors continue to perform at their best, regular maintenance is essential. XJCSENSOR recommends that businesses follow a routine maintenance schedule, which may include cleaning the sensors, calibrating them, and checking for any signs of wear or malfunction. Proper maintenance ensures that the sensors continue to provide accurate measurements, reducing the risk of production downtime and ensuring the longevity of your machinery. Additionally, XJCSENSOR offers sensor calibration and repair services to extend the life of your equipment.

THE FUTURE OF SEALING MACHINES SENSORS: TRENDS AND INNOVATIONS

As industries continue to evolve, so does the technology behind sealing machines sensors. The future of these sensors lies in further automation, enhanced precision, and increased integration with Industry 4.0 technologies. With advancements in AI and machine learning, sealing machine sensors will become even more intuitive, offering predictive maintenance capabilities and adaptive control. As manufacturing moves toward smarter and more efficient systems, sensors will play a crucial role in optimizing packaging processes.

CONCLUSION: WHY CHOOSE XJCSENSOR FOR SEALING MACHINES SENSORS

XJCSENSOR provides high-quality, customizable sealing machine sensors that enhance efficiency, reliability, and quality control across packaging operations. Our sensors are designed to meet the diverse needs of industries worldwide, ensuring that every product is packaged with the utmost precision. With advanced technology, reliable performance, and tailored solutions, XJCSENSOR is the trusted partner for your sealing machine sensor needs. Contact us today to learn more about how our sensors can transform your packaging operations.