Introduction

In industries where precision and safety are paramount, tools like vice grips are essential for tasks requiring a firm hold. Vice grips are commonly used in various applications, ranging from industrial machinery to automotive repair. Their primary purpose is to hold objects securely in place, ensuring that they don’t slip during a task. However, achieving consistent, reliable performance from a vice grip isn’t as simple as applying manual force. This is where the role of sensors comes into play, offering enhanced accuracy, reliability, and safety.

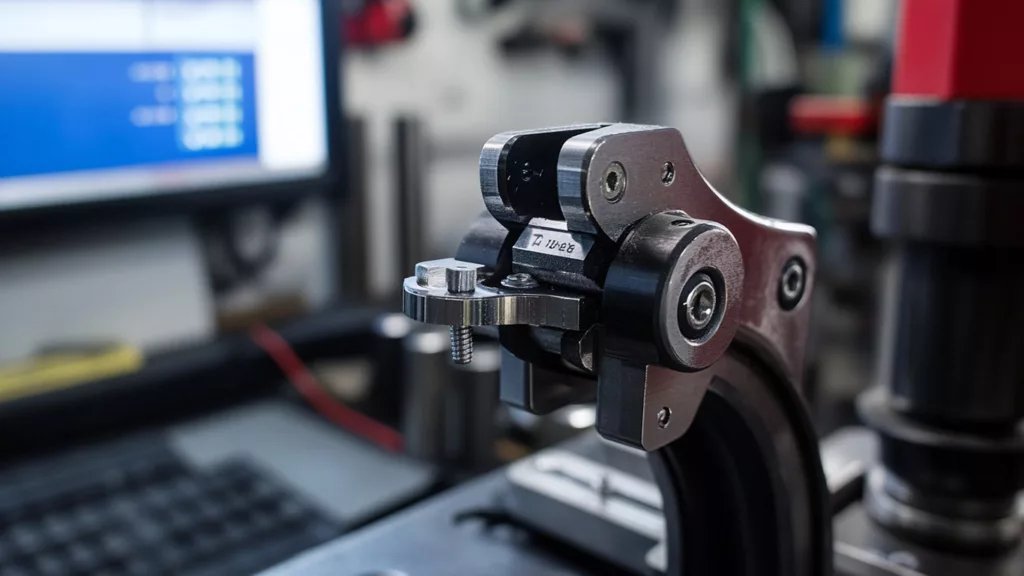

Sensors enable vice grips to operate more effectively by detecting variables such as force, pressure, and position. This technological integration transforms an otherwise simple tool into an intelligent device capable of delivering optimal performance. In this blog, we will explore the basic principles of vice grips, the role of sensors in optimizing their operation, and the future of smart vice grips, where automation and safety work hand in hand.

Understanding Vice Grips: Basic Working Principles and Applications

At its core, a vice grip is a clamping tool designed to lock onto objects securely. It operates through a locking mechanism that uses a trigger to adjust the grip’s tension, providing a firm and reliable hold. The adjustable jaw allows for various sizes of workpieces to be gripped tightly. Unlike standard pliers, vice grips remain locked onto an object without constant pressure from the user, which makes them ideal for tasks requiring precision.

Vice grips are used across numerous industries, including automotive, construction, manufacturing, and even home repairs. Their versatility makes them indispensable for tasks such as holding objects during welding, clamping workpieces for cutting or grinding, and even fixing machinery in place.

While vice grips have been in use for decades, their application today is being enhanced by the integration of sensors. These sensors ensure that the vice grip operates with an increased level of control and accuracy, improving both its performance and safety.

The Role of Sensors in Enhancing Vice Grip Operations

In the world of precision tools, sensors play a crucial role in optimizing the functionality and performance of vice grips. By providing real-time data and feedback on various parameters, sensors ensure that the tool operates with the highest level of accuracy and safety. Here’s how sensors contribute to vice grip performance:

- Force Monitoring: Force sensors help to monitor the amount of pressure applied by the vice grip. By tracking the force, they ensure that the grip isn’t too tight, which could damage the workpiece or cause unnecessary strain on the tool. Conversely, it prevents the grip from being too loose, ensuring the object is held firmly.

- Pressure Detection: Pressure sensors can detect changes in pressure within the vice grip mechanism. This is particularly useful in applications where the object being clamped requires specific pressure to remain secure without causing deformation or damage. The sensor feedback allows operators to adjust the grip to maintain the perfect pressure for various materials.

- Position Sensing: Position sensors allow for real-time monitoring of the vice grip’s jaw alignment. These sensors ensure that the tool is properly positioned to grip the object securely and efficiently. By detecting the position of the jaws, the sensor can alert the operator if the grip isn’t aligned correctly or if any adjustments are needed to enhance precision.

Different Types of Sensors Used in Vice Grips

To enhance the precision and safety of vice grip operations, several different types of sensors are employed. These sensors each address specific aspects of the grip’s functionality, allowing for optimal control and safety in various applications. Let’s explore some of the key sensor types:

- Force Sensors

Force sensors are vital in applications where the amount of clamping force is critical. These sensors detect the pressure applied by the vice grip’s jaws on the object. Through real-time data, they can ensure that the applied force does not exceed a certain threshold, preventing damage to the workpiece. This feature is particularly important when dealing with delicate or sensitive materials such as thin metals, glass, or plastic. - Pressure Sensors

Pressure sensors help monitor and control the pressure exerted by the vice grip. This type of sensor is essential for applications where the exact pressure needed to hold a material securely is essential. Pressure sensors enable operators to monitor any fluctuations in pressure that may affect the vice grip’s ability to maintain a consistent hold. This feature helps improve the reliability of the grip in automated systems, reducing human error. - Position Sensors

Position sensors track the movement of the vice grip’s jaw and provide data about its alignment with the workpiece. These sensors ensure that the tool is properly engaged with the material, allowing for more precise handling. Position sensors can be used to adjust the grip in real-time, ensuring that the vice grip operates at the optimal angle and pressure for maximum efficiency. - Temperature Sensors

In some applications, temperature sensors are used to monitor the heat levels around the vice grip. These sensors help detect excessive heat generated by prolonged use or contact with heated materials. By monitoring temperature levels, these sensors can protect both the vice grip and the workpiece from heat damage. - Load Sensors

Load sensors are employed to measure the overall load applied by the vice grip. These sensors help prevent overloading, ensuring that the vice grip operates within its specified capacity. In automated environments, load sensors contribute to enhancing both safety and the efficiency of operations, reducing the risk of tool failure.

Smart Vice Grips: The Future of Automation and Safety

The future of vice grips is inextricably tied to smart technology and sensor integration. As industries move towards more automated systems, tools like vice grips are evolving into intelligent devices capable of not only performing tasks but also making adjustments on their own.

Smart vice grips equipped with sensors are already being explored in various industries, particularly in manufacturing and robotics. These advanced tools can automatically adjust their clamping force, pressure, and alignment based on real-time feedback, significantly reducing human error and improving operational efficiency. This is especially valuable in automated manufacturing settings where precision and speed are critical.

The combination of sensors and machine learning could allow vice grips to adapt to different materials automatically. By analyzing the properties of the material being clamped (such as hardness, thickness, and temperature), the vice grip could adjust its clamping force and pressure accordingly, ensuring a perfect hold every time.

Furthermore, with the rise of IoT (Internet of Things) technology, vice grips could be part of a larger network of smart tools that communicate with each other to streamline workflows. For example, a smart vice grip could alert other connected tools or systems when it’s time to release the grip, adjust its pressure, or when it has completed its task.

Conclusion

In conclusion, the integration of sensors into vice grip technology is revolutionizing the way these tools are used in various industries. Sensors such as force, pressure, position, and temperature sensors improve the performance, accuracy, and safety of vice grips, allowing for more reliable and efficient operations. As technology continues to advance, the potential for smart vice grips equipped with IoT capabilities and machine learning algorithms will further optimize their usage, making them a crucial tool in the automation of many industries.

With these innovations, vice grips are no longer just manual tools—they are becoming part of a smarter, more connected world, enabling enhanced precision control and greater safety across numerous applications.

FAQs

What is the primary function of a vice grip?

How do sensors improve the performance of vice grips?

What types of sensors are used in vice grips?

How do force sensors benefit vice grip operations?

Can smart vice grips help automate industrial operations?

What industries benefit the most from sensor-equipped vice grips?

Clear Call-to-Action (CTA):

For businesses looking to enhance their precision control systems with cutting-edge sensor technology, XJCSENSOR offers customized sensors that can optimize the performance and safety of vice grips and other automation tools. Contact us today to explore how our sensor solutions can elevate your operations and improve overall efficiency!