Pressure sensors play a vital role in countless industries, from automotive systems to aerospace technology and healthcare. These devices are the unsung heroes of precision and safety, delivering accurate measurements that help systems run efficiently. This article explores the intricate world of pressure sensors, offering everything you need to know about their types, functions, and significance in modern applications.

Understanding the Pressure Sensor

What is a Pressure Sensor?

A pressure sensor is a device that measures and converts pressure into an electrical signal. This signal is then processed to provide meaningful data, such as pressure level, which can be displayed on gauges or sent to control systems. These sensors are commonly used in industries ranging from manufacturing to medicine. With advanced designs, they are reliable, versatile, and integral to modern engineering solutions.

Why are Pressure Sensors Essential?

Without pressure sensors, critical systems like fuel injection in cars, oxygen supply in medical devices, and hydraulic systems in airplanes would lack the precision required for safe operation. These sensors ensure efficiency and safety by monitoring and maintaining optimal pressure levels, preventing catastrophic failures, and enabling predictive maintenance.

Applications of Pressure Sensors

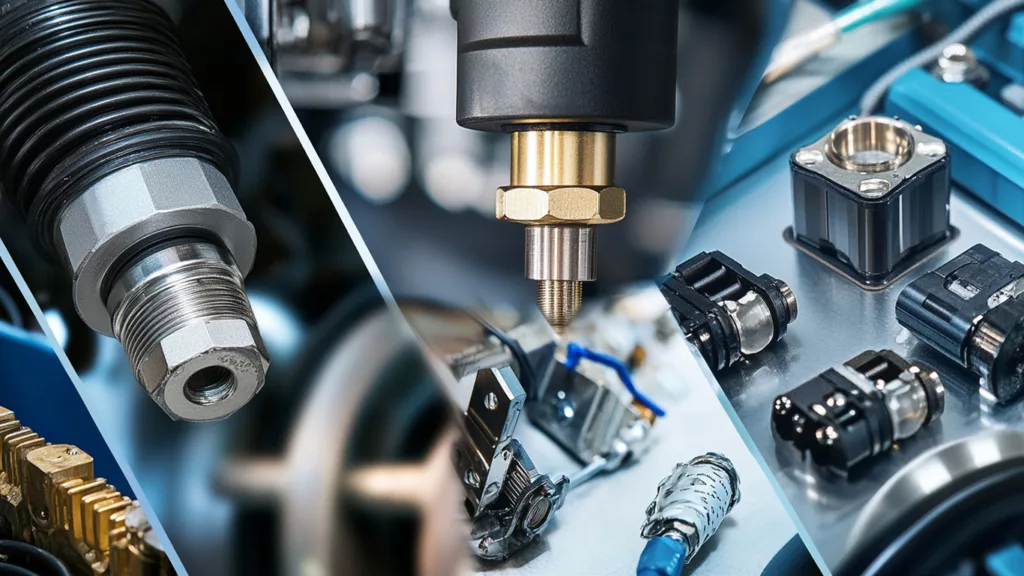

Industrial Uses of Pressure Sensors

Pressure sensors are indispensable in industrial automation and process control. They help regulate systems by measuring variables like liquid and gas pressures, ensuring smooth and safe operations in manufacturing plants, power generation, and oil refineries.

Automotive and Aerospace Applications

From monitoring tire pressure to regulating aircraft cabin environments, pressure sensors are foundational in these industries. In automotive systems, they ensure proper engine function, brake system reliability, and fuel efficiency. Aerospace applications rely on them for altitude measurements and structural integrity monitoring.

Pressure Sensors in Healthcare

Medical devices such as ventilators, blood pressure monitors, and infusion pumps utilize pressure sensors to maintain precise control. They are also used in wearable devices for real-time health monitoring, showcasing their life-saving potential.

Types of Pressure Sensors

Absolute Pressure Sensors

Absolute pressure sensors measure pressure relative to a perfect vacuum. They are widely used in meteorology, space applications, and vacuum systems.

Gauge Pressure Sensors

Gauge sensors measure pressure relative to the ambient atmospheric pressure. Commonly found in automotive and industrial applications, these sensors are ideal for everyday pressure measurements.

Differential Pressure Sensors

Differential pressure sensors measure the difference between two pressure points. These are crucial in HVAC systems, filter monitoring, and process control applications.

How Pressure Sensors Work

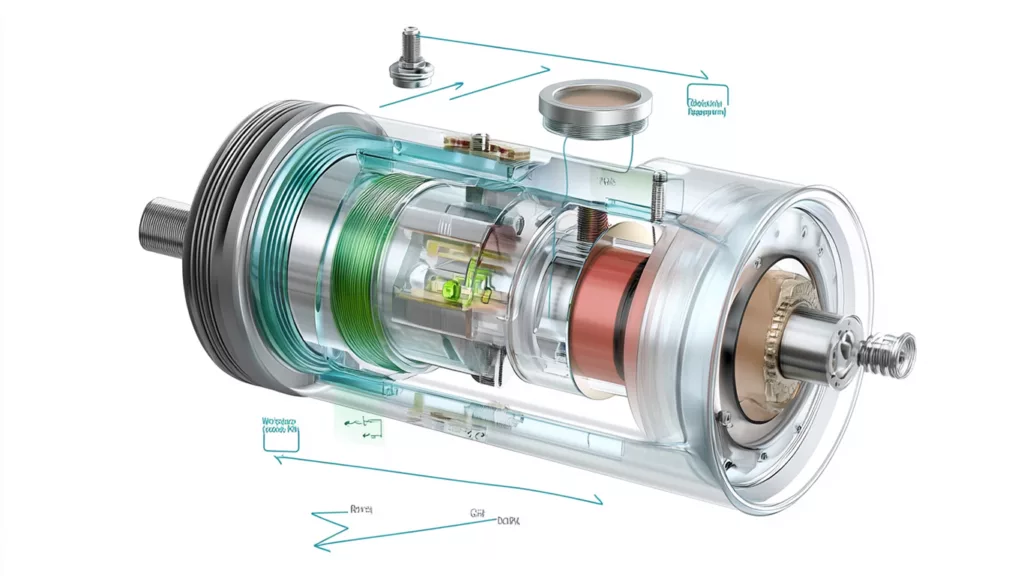

Core Components of a Pressure Sensor

Pressure sensors consist of a sensing element (such as a diaphragm or strain gauge), a transducer, and signal processing components. Together, they capture pressure changes and convert them into electrical signals.

Converting Pressure into Electrical Signals

The sensing element deforms under pressure, which alters its electrical properties. These changes are measured and converted into signals proportional to the pressure applied. This data can be displayed, stored, or analyzed for further use.

XJCSENSOR’s Innovations in Pressure Sensors

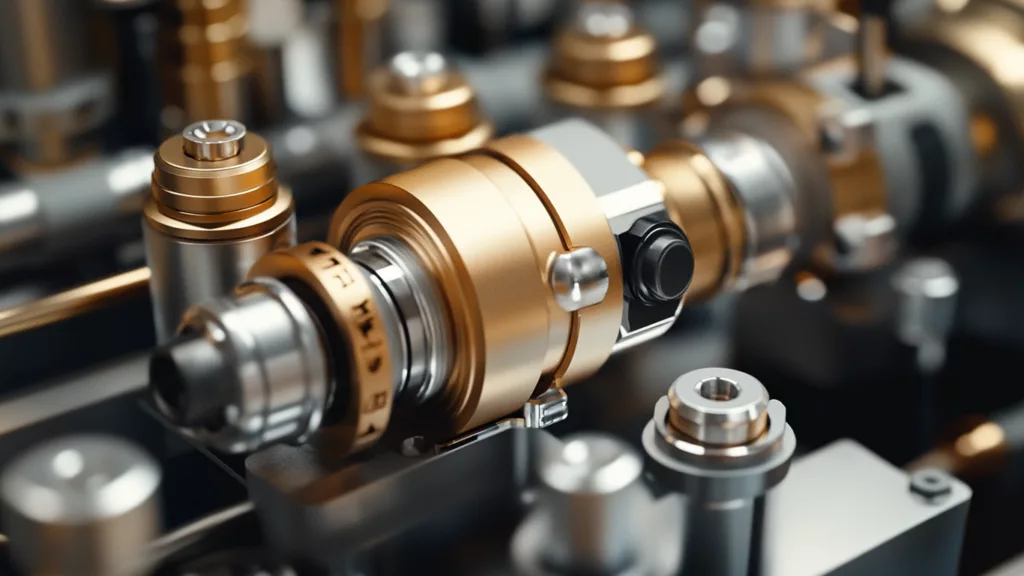

Overview of XJCSENSOR’s Expertise

XJCSENSOR, a leader in the sensor industry, specializes in cutting-edge pressure sensors. Their products are known for precision, durability, and adaptability, catering to diverse applications globally.

Advanced Technology Behind XJCSENSOR Pressure Sensors

XJCSENSOR employs advanced materials and designs to ensure high accuracy and reliability. Their pressure sensors integrate seamlessly with modern systems, providing unparalleled performance even in extreme conditions.

Benefits of Using Pressure Sensors

Improving Efficiency in Systems

Pressure sensors optimize system performance by maintaining ideal operating conditions. They reduce energy consumption and minimize downtime by detecting issues early.

Enhancing Safety Through Precision

Accurate pressure monitoring prevents accidents caused by overpressure or underpressure. This is especially critical in high-stakes environments like aerospace and healthcare.

Troubleshooting Pressure Sensor Issues

Common Problems with Pressure Sensors

Faulty readings, slow response times, or complete sensor failure are common issues. These problems can arise due to wear and tear, contamination, or improper installation.

Steps to Diagnose and Resolve Issues

Inspect connections, clean sensor components, and recalibrate the device. If problems persist, replacing the sensor might be necessary to restore functionality.

Maintenance Tips for Longevity

Extending the Lifespan of Pressure Sensors

Regular inspections, avoiding exposure to extreme conditions, and following manufacturer guidelines can significantly extend a sensor’s life.

Regular Calibration Practices

Calibration ensures accuracy and reliability. Establishing a routine schedule for recalibration minimizes errors and maintains sensor performance.

Selecting the Right Pressure Sensor

Key Factors to Consider

Choose a sensor based on factors like pressure range, environment, and compatibility with existing systems. Consult experts or manufacturers like XJCSENSOR for guidance.

Top Pressure Sensor Models from XJCSENSOR

XJCSENSOR offers a wide range of sensors tailored to specific needs, from high-precision models for medical applications to rugged designs for industrial use.

FAQs

What is the role of a pressure sensor in industrial automation?

Can a faulty pressure sensor be repaired?

How do I choose the right pressure sensor for my needs?

How often should pressure sensors be calibrated?

What are the advantages of using XJCSENSOR pressure sensors?

What’s the difference between absolute and gauge pressure sensors?

Conclusion

Pressure sensors are indispensable in today’s technological landscape, ensuring safety, efficiency, and innovation across various fields. XJCSENSOR’s expertise in manufacturing top-tier pressure sensors further highlights their importance. By understanding how these sensors work, their applications, and maintenance requirements, you can unlock their full potential, keeping systems running smoothly and reliably.