Reliable 3 Axis Force Sensor for Industrial Use

Precision Measurement with 3 Axis Force Sensors by XJCSENSOR

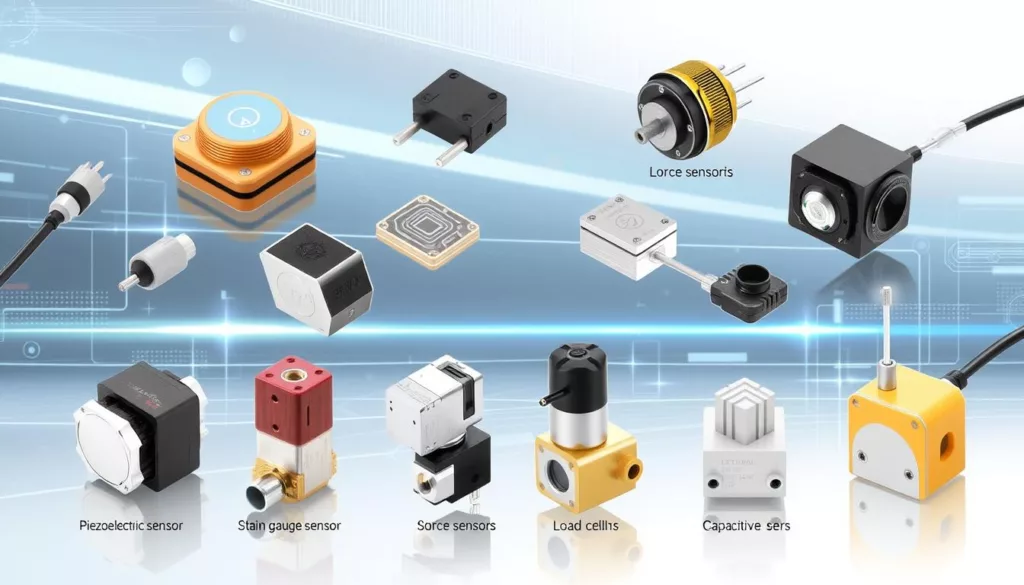

In modern industries, where accuracy and multi-dimensional data are critical, 3 axis force sensors play an essential role. XJCSENSOR, a trusted manufacturer and supplier, offers high-performance 3 axis force sensors designed to meet the needs of industries ranging from robotics and manufacturing to testing and research.

- Three-Dimensional Precision

- Rapid Response Times

- Temperature Compensated Accuracy

- Stable and Crosstalk-Free Performance

- Compact and Robust Design

Our Range of 3-Axis Force Sensor

Delve into our extensive list of 3 Axis Force Sensors, each one embodying XJCSENSOR’s commitment to quality and performance. Whether your requirement is for compact size, high capacity, or anything in between, our product lineup has a sensor to meet your needs.

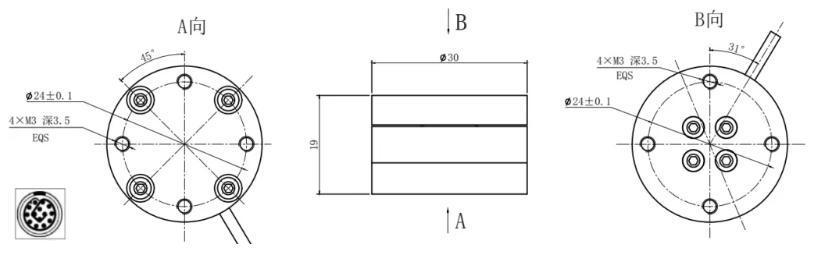

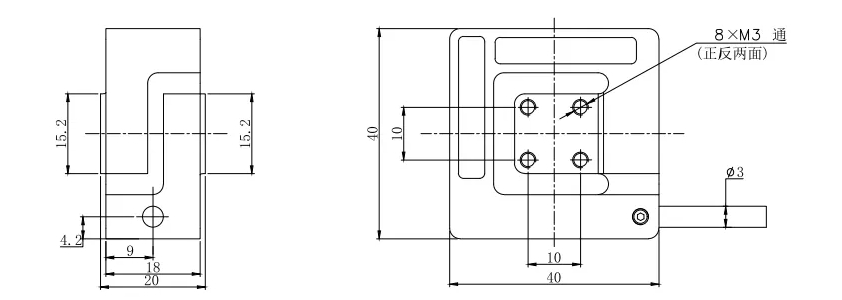

Model :X-3A-D30-C

Technical Parameter:

- Non-linearity: ≤±0.5%F.S.

- Repeatability: ≤±0.05%F.S.

- Zero balance: ±5%F.S.

- Operating temp range: -20~80°C

- Compensated temp range: -10~40°C

- Insulation: ≥2000MΩ/50VDC

- Recommended excitation voltage: 5-10VDC

- Safe load limit: 300%F.S.

- Temp effect on output: ≤0.2%F.S./10°C

- Temp effect on zero: ≤0.2%F.S./10°C

- Long-term crosstalk error: ≤3%F.S.

- Protection class: IP64

- Cable size: φ2.4*3m

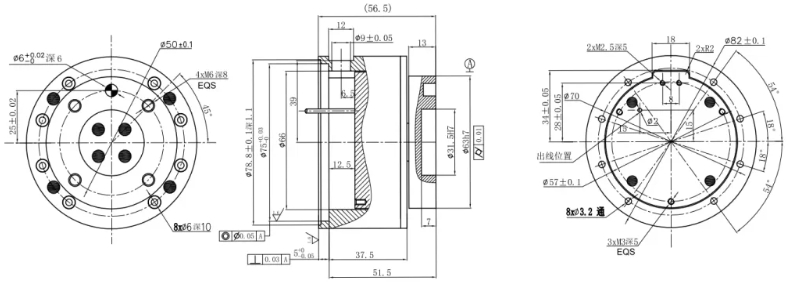

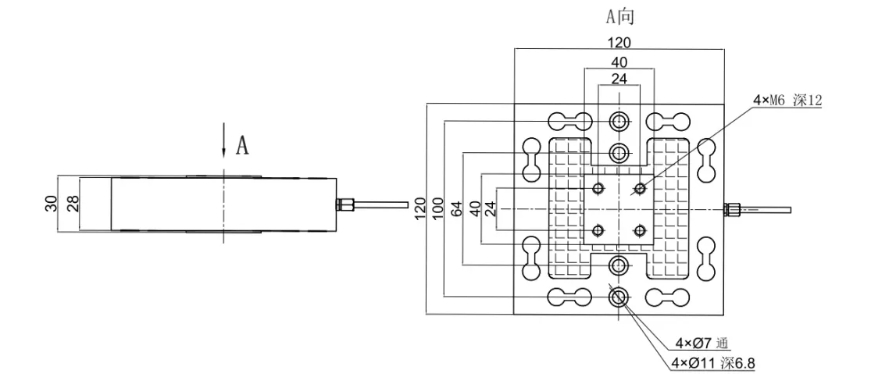

Model :X-3A-D90-H27

Technical Parameter:

- Non-linearity: ≤0.5%F.S.

- Repeatability: ≤0.05%F.S.

- Zero balance: ±5%F.S.

- Operating temp range: -20~80°C

- Compensated temp range: -10~40°C

- Insulation: ≥2000MΩ/100VDC

- Recommended excitation voltage: 12-30VDC

- Safe load limit: 300%F.S.

- Temp effect on output: ≤±0.05%F.S./10°C

- Temp effect on zero: ≤±0.05%F.S./10°C

- Long-term crosstalk error: ≤1%F.S.

- Protection class: IP65

- Cable size: φ2*1m

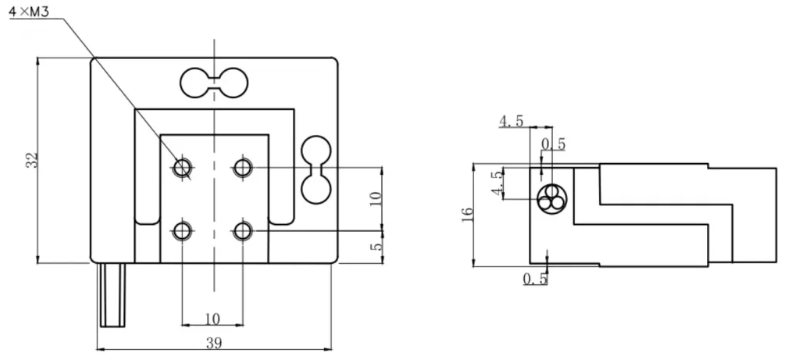

Model :X-3A-F39-B

Technical Parameter:

- Non-linearity: ≤0.5%F.S.

- Repeatability: ≤0.5%F.S.

- Zero balance: ±3%F.S.

- Operating temp range: -20~60°C

- Compensated temp range: -10~40°C

- Insulation: ≥5000MΩ/100VDC

- Recommended excitation voltage: 5-12VDC

- Safe load limit: 150%F.S.

- Temp effect on output: ≤0.2%F.S./10°C

- Temp effect on zero: ≤0.2%F.S./10°C

- Long-term crosstalk error: ≤1%F.S.

- Protection class: IP64

- Cable size: φ3*0.5m (3 cables)

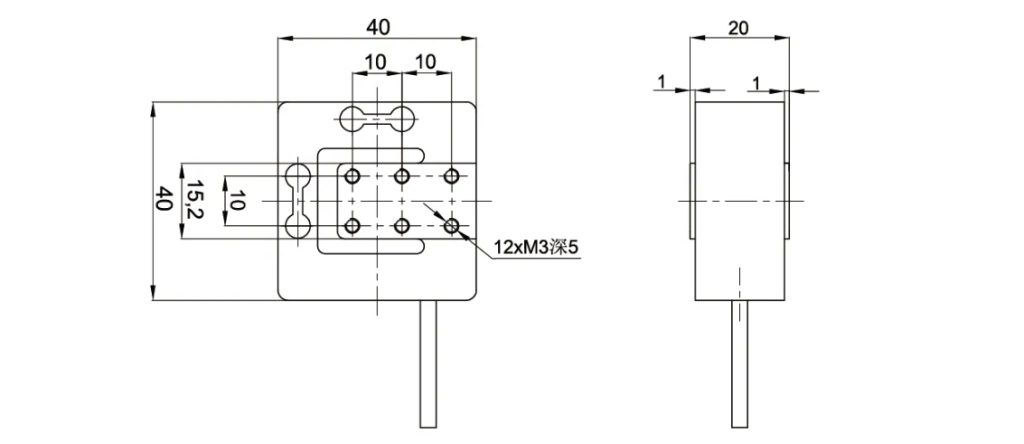

Model :X-3A-F40

Technical Parameter:

- Non-linearity: ≤1%F.S.

- Repeatability: ≤0.2%F.S.

- Zero balance: ±2%F.S.

- Operating temp range: -20~80°C

- Compensated temp range: -10~40°C

- Insulation: ≥2000MΩ/50VDC

- Recommended excitation voltage: 5-10VDC

- Safe load limit: 150%F.S.

- Temp effect on output: ≤0.2%F.S./10°C

- Temp effect on zero: ≤0.1%F.S./10°C

- Long-term crosstalk error: ≤1%F.S.

- Protection class: IP64

- Cable size: φ3*4m

Model :X-3A-F40-C

Technical Parameter:

- Non-linearity: ≤0.1%F.S.

- Repeatability: ≤0.1%F.S.

- Zero balance: ±3%F.S.

- Operating temp range: -20~60°C

- Compensated temp range: -10~40°C

- Insulation: ≥5000MΩ/100VDC

- Recommended excitation voltage: 5-10VDC

- Safe load limit: 120%F.S.

- Temp effect on output: ≤0.2%F.S./10°C

- Temp effect on zero: ≤0.1%F.S./10°C

- Long-term crosstalk error: ≤3%F.S.

- Protection class: IP65

- Cable size: φ3*4m

Model :X-3A-F120

Technical Parameter:

- Non-linearity: ≤0.5%F.S.

- Repeatability: ≤0.2%F.S.

- Zero balance: ±2%F.S.

- Operating temp range: -20~80°C

- Compensated temp range: -10~40°C

- Insulation: ≥2000MΩ/50VDC

- Recommended excitation voltage: 5-10VDC

- Safe load limit: 150%F.S.

- Temp effect on output: ≤0.1%F.S./10°C

- Temp effect on zero: ≤0.1%F.S./10°C

- Long-term crosstalk error: ≤1%F.S.

- Protection class: IP65

- Cable size: φ4.5*4m

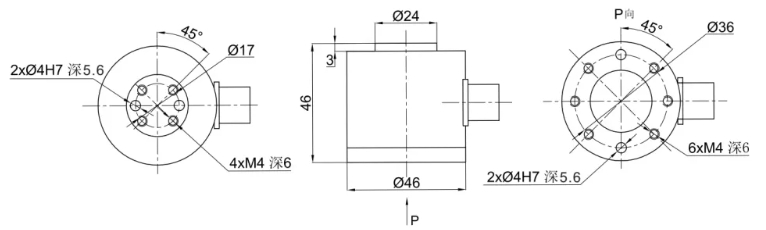

Model :X-3A-Y46

Technical Parameter:

- Non-linearity: ≤1%F.S.

- Repeatability: ≤0.2%F.S.

- Zero balance: ±2%F.S.

- Operating temp range: -20~75°C

- Compensated temp range: -20~80°C

- Insulation: ≥2000MΩ/50VDC

- Recommended excitation voltage: 5-10VDC

- Safe load limit: 150%F.S.

- Temp effect on output: ≤0.1%F.S./10°C

- Temp effect on zero: ≤0.1%F.S./10°C

- Long-term crosstalk error: ≤1%F.S.

- Protection class: IP64

- Cable size: φ6*5m

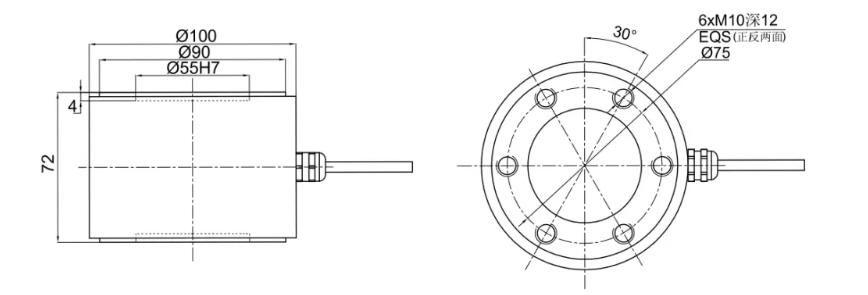

Model :X-3A-Y100

Technical Parameter:

- Non-linearity: ≤1%F.S.

- Repeatability: ≤0.2%F.S.

- Zero balance: ±2%F.S.

- Operating temp range: -20~75°C

- Compensated temp range: -10~40°C

- Insulation: ≥2000MΩ/50VDC

- Recommended excitation voltage: 5-10VDC

- Safe load limit: 150%F.S.

- Temp effect on output: ≤0.1%F.S./10°C

- Temp effect on zero: ≤0.1%F.S./10°C

- Long-term crosstalk error: ≤1%F.S.

- Protection class: IP65

- Cable size: φ6*4m

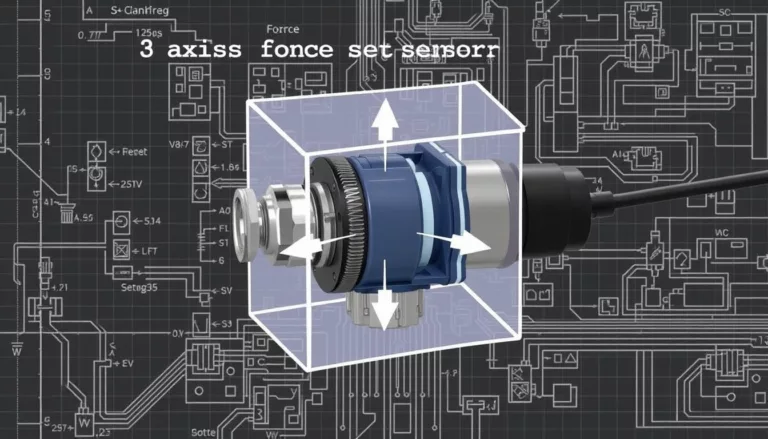

INTRODUCTION TO 3 AXIS FORCE SENSORS

3 axis force sensors are specialized devices that measure forces along three perpendicular axes (X, Y, and Z). This capability makes them essential in applications that require multi-dimensional data for precision measurement and control. XJCSENSOR’s 3 axis force sensors are engineered to deliver reliable, high-accuracy measurements, ideal for applications in automation, testing, and robotics.

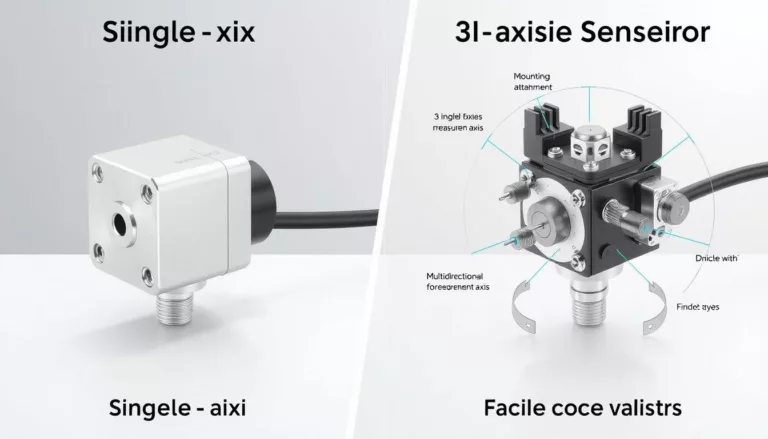

WHY CHOOSE MULTI-AXIS FORCE SENSORS?

MULTI-AXIS force sensors provide advantages over single-axis sensors, as they can capture complex force data across multiple dimensions in a single measurement. This feature is valuable in applications where forces along different axes must be monitored simultaneously. XJCSENSOR’s sensors are designed to maintain stability and accuracy, enabling seamless integration into sophisticated systems for improved efficiency.

PRECISION ENGINEERING FOR ROBOTIC APPLICATIONS

PRECISION is critical in robotic applications, where even slight deviations can impact functionality. XJCSENSOR’s 3 axis force sensors are specifically calibrated to provide accurate force feedback, which is essential for tasks such as gripping, assembly, and load handling. These sensors allow robots to interact with their environment more effectively, enhancing their functionality and ensuring the safe handling of objects.

HOW 3 AXIS FORCE SENSORS IMPROVE AUTOMATION

AUTOMATION benefits greatly from 3 axis force sensors, which provide real-time force data that can be used to optimize automated processes. In complex systems, such as robotic arms or automated testing equipment, these sensors allow for adjustments to be made instantly based on feedback from the environment. XJCSENSOR’s sensors improve automation by ensuring consistency, reducing errors, and enhancing operational efficiency.

TYPES OF 3 AXIS FORCE SENSORS FOR INDUSTRY NEEDS

There are several TYPES of 3 axis force sensors, each tailored to specific industrial needs:

- Compact 3 Axis Force Sensors – Ideal for applications with limited space.

- High-Capacity 3 Axis Sensors – Suitable for heavy load measurements.

- Precision Sensors for Robotics – Designed for fine-tuned applications requiring high sensitivity.

XJCSENSOR provides a variety of 3 axis force sensors, enabling clients to choose the right fit for their specific applications, whether in manufacturing, aerospace, or research.

INTEGRATING 3 AXIS FORCE SENSORS IN ROBOTICS AND AUTOMATION

INTEGRATION of 3 axis force sensors into robotic and automated systems is crucial for ensuring that these systems operate smoothly and safely. XJCSENSOR’s sensors are compatible with advanced robotics and automation platforms, enabling seamless integration and improving overall system performance. Our sensors provide consistent data that enhances the functionality of robotic systems and optimizes automated processes.

CUSTOMIZABLE SOLUTIONS FOR UNIQUE APPLICATIONS

CUSTOMIZATION is key in industries with unique requirements. XJCSENSOR offers customizable 3 axis force sensor solutions, designed to meet specific needs across various fields. Our sensors can be tailored for specific force ranges, dimensions, or environmental tolerances, providing a versatile solution for industries ranging from electronics to aerospace.

THE IMPORTANCE OF HIGH-ACCURACY SENSORS IN TESTING AND MEASUREMENT

ACCURACY is essential in testing and measurement applications, where precise data collection is crucial. XJCSENSOR’s 3 axis force sensors are crafted to provide high-accuracy force measurements, allowing users to conduct reliable tests and obtain consistent results. These sensors are ideal for applications in materials testing, product quality assessment, and research laboratories.

THE ROLE OF 3 AXIS FORCE SENSORS IN QUALITY CONTROL

QUALITY control processes rely on accurate data to ensure that products meet high standards. 3 axis force sensors from XJCSENSOR help monitor and control production processes by providing multi-dimensional force feedback. These sensors allow for the precise measurement of forces applied during manufacturing, ensuring that each product meets the required quality standards before it reaches the end user.

WHY XJCSENSOR IS A TRUSTED PROVIDER OF 3 AXIS FORCE SENSORS

TRUST is a crucial factor when selecting a supplier for industrial sensors. XJCSENSOR is recognized for its commitment to quality, precision, and customer satisfaction. As a leading manufacturer of 3 axis force sensors, we ensure our products meet the highest industry standards, offering robust, reliable, and accurate solutions for industrial and commercial applications.

CONCLUSION

3 axis force sensors are vital components in modern industry, enabling precise, multi-dimensional force measurements across a range of applications. XJCSENSOR’s advanced sensor solutions support industries in enhancing accuracy, improving automation, and ensuring quality control. With a reputation for high-quality, customizable products, XJCSENSOR stands out as a leading provider of 3 axis force sensors, trusted by businesses worldwide.

Whether for robotics, testing, or automation, XJCSENSOR’s 3 axis force sensors are engineered to deliver excellence, providing the data and reliability needed to drive industry forward.