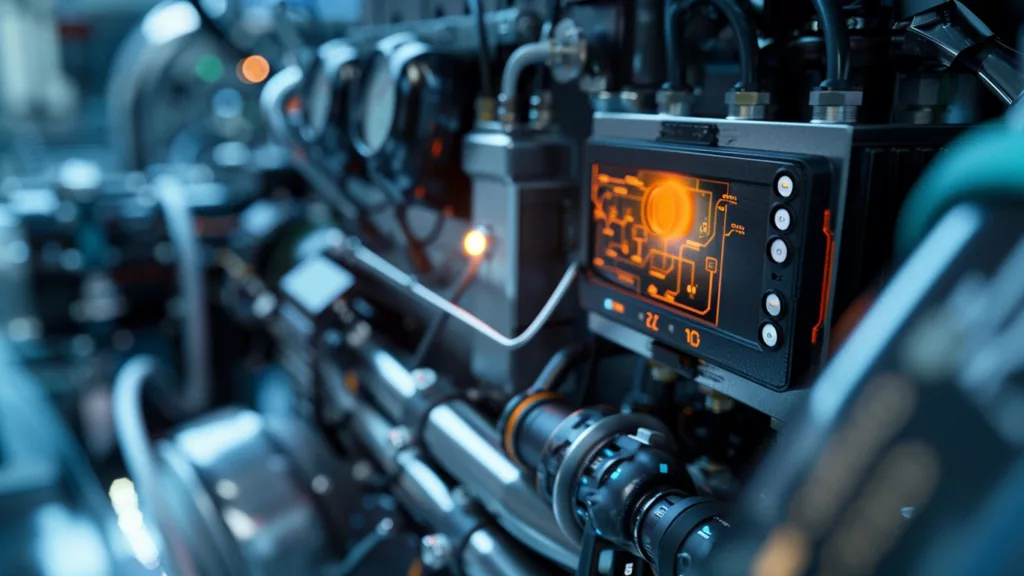

Precision Industrial Automation Sensor for Manufacturing

Enhancing Efficiency with Industrial Automation Sensors

Industrial automation sensors are transforming manufacturing and production lines, enhancing efficiency, safety, and control. XJCSENSOR, a leading manufacturer and supplier, offers advanced sensor solutions tailored for industrial automation applications, providing a competitive edge in today’s rapidly evolving industries.

UNDERSTANDING INDUSTRIAL AUTOMATION SENSORS

Industrial automation sensors are critical for monitoring and controlling automated processes. These sensors help collect real-time data on various parameters such as temperature, pressure, motion, and safety, optimizing factory operations and reducing downtime.

THE ROLE OF SMART SENSORS IN AUTOMATION

SMART sensors are designed to offer more than just basic data collection; they interpret and communicate information, often supporting predictive maintenance. XJCSENSOR provides smart sensors that help prevent costly breakdowns by alerting operators to potential issues before they occur.

Key Benefits of Smart Sensors:

- Predictive Maintenance: Reduce unplanned downtime

- Data Analytics: Generate actionable insights

- Improved Efficiency: Automate routine adjustments

By leveraging smart sensor technology, XJCSENSOR helps companies move toward more efficient, data-driven industrial processes.

SAFETY SENSORS FOR INDUSTRIAL ROBOTS

SAFETY sensors are essential for protecting workers in environments where robots and machinery operate in close proximity. These sensors detect the presence of humans or obstacles, enabling automated systems to halt or adjust their actions to prevent accidents.

INTEGRATING SENSORS FOR PREDICTIVE MAINTENANCE

PREDICTIVE maintenance relies on sensor data to monitor equipment condition, predicting failures before they happen. XJCSENSOR’s sensors for predictive maintenance track vibration, temperature, and other key metrics to identify early signs of wear.

MACHINE VISION SENSORS FOR QUALITY CONTROL

VISION sensors are invaluable for quality control in automated processes. XJCSENSOR’s machine vision sensors capture images and analyze products for defects, ensuring consistency in quality and reducing waste.

Industries like electronics, automotive, and pharmaceuticals benefit greatly from these sensors, which ensure that only high-quality products reach the end of the production line.

PRESSURE AND TEMPERATURE SENSORS FOR INDUSTRIAL APPLICATIONS

PRESSURE and TEMPERATURE sensors play a vital role in monitoring and maintaining optimal conditions in industrial processes. XJCSENSOR provides robust sensors that withstand harsh environments, making them suitable for industries such as oil and gas, chemical manufacturing, and power generation.

By integrating pressure and temperature sensors, manufacturers can ensure stable operations, reduce equipment strain, and enhance product quality.

THE IMPORTANCE OF SENSORS IN FACTORY AUTOMATION

FACTORY automation relies on an array of sensors to facilitate seamless communication between machines, systems, and operators. XJCSENSOR’s automation sensors streamline manufacturing processes by monitoring and adjusting operations in real-time.

These sensors play a critical role in:

- Reducing Errors: Through consistent monitoring and adjustments

- Increasing Throughput: Enabling machines to operate without manual intervention

- Energy Efficiency: Minimizing waste by optimizing resource usage

Factory automation sensors empower manufacturers to run more cost-effective and environmentally sustainable operations.

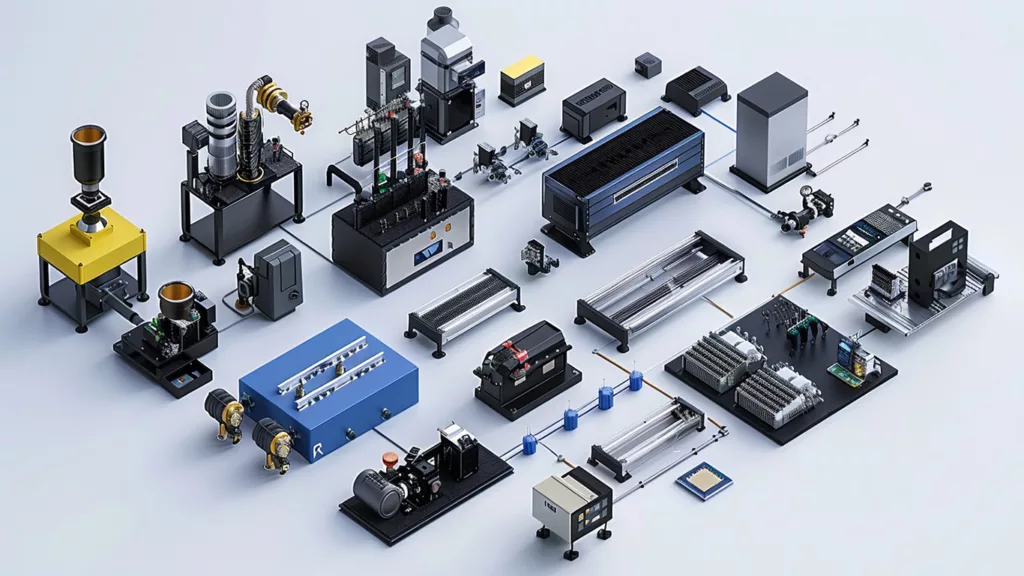

CUSTOM SENSOR SOLUTIONS FOR SPECIFIC INDUSTRY NEEDS

CUSTOMIZATION is essential for industries with unique requirements. XJCSENSOR offers customized sensor solutions to meet specific needs, whether for complex robotics in automotive manufacturing or sensitive instrumentation in pharmaceuticals.

With tailored sensors, manufacturers can ensure compatibility and optimal performance, reducing setup time and improving overall process efficiency. XJCSENSOR works closely with clients to design sensors that meet their specific industrial challenges.

HOW INDUSTRIAL IoT SENSORS ARE REVOLUTIONIZING AUTOMATION

The IoT (Internet of Things) is reshaping industrial automation, allowing equipment to communicate and share data for optimized performance. Industrial IoT sensors from XJCSENSOR collect and transmit data over networks, enabling remote monitoring and real-time insights.

Advantages of Industrial IoT Sensors:

- Remote Monitoring: Manage operations from anywhere

- Real-Time Data Collection: Immediate insights and adjustments

- Enhanced Decision Making: Data-driven strategies for improved efficiency

XJCSENSOR’s IoT sensors support smart factory transformations, enabling companies to leverage data for strategic decision-making.

WHY CHOOSE XJCSENSOR FOR INDUSTRIAL AUTOMATION SENSORS?

When it comes to TRUSTWORTHINESS and reliability, XJCSENSOR is a leader in industrial automation sensors. With a commitment to innovation, quality, and customer satisfaction, XJCSENSOR provides durable and accurate sensors that meet the demands of modern industries.

XJCSENSOR’s expertise, advanced sensor technology, and dedication to continuous improvement make them an ideal choice for businesses looking to enhance their automation capabilities.

CONCLUSION

Industrial automation sensors are key to optimizing manufacturing and production processes. XJCSENSOR’s wide range of sensors, including smart sensors, predictive maintenance sensors, safety sensors, and custom solutions, empower industries to operate safely, efficiently, and effectively. As a trusted manufacturer and supplier, XJCSENSOR is at the forefront of industrial sensor innovation, helping businesses around the world achieve their automation goals.

By partnering with XJCSENSOR, companies can leverage the power of sensor technology to create safer, more efficient, and data-driven operations.