Load cells are key in precision weighing and industrial force measurement. They are vital in many fields, from automation to medical devices. As demand for these technologies grows, finding top US manufacturers is key.

The load cell market has many companies, each with its own strengths. They focus on precision weighing solutions, industrial force measurement, and load sensor technology. These leaders serve sectors like manufacturing, healthcare, and more.

Exploring top load cell makers in the USA helps businesses find the best solutions. These companies offer top performance and great customer service. They are the best partners for improving force measurement systems.

Key Takeaways

- The USA is home to a diverse array of leading load cell manufacturers and suppliers.

- These companies offer innovative precision weighing solutions and industrial force measurement technologies.

- Reliable and high-performance load sensor technology is vital for many applications across various industries.

- Finding the right load cell supplier is key for organizations aiming to enhance their force measurement systems.

- Top manufacturers are known for their commitment to innovation, reliability, and competitive pricing in the load cell market.

Introduction to Load Cells

Load cells are key in modern weighing systems. They help measure force and weight accurately in many industries. These components use advanced technology to turn physical forces into electrical signals. This makes it possible to collect and analyze precise data.

What Are Load Cells?

Load cells are transducers that measure force or weight. They have a structural part, like a beam or platform, with strain gauges. When a load is applied, the gauges detect the deformation. They then send an electrical signal that the weighing system can understand.

Applications of Load Cells

- Industrial weighing and force measurement in manufacturing, mining, and logistics

- Precision weighing in the food, pharmaceutical, and chemical industries

- Structural health monitoring in construction and civil engineering

- Customized force measurement solutions for specialized applications

Importance of Load Cell Quality

The quality of load cells affects a weighing system’s accuracy and reliability. High-quality load cells, like those from XJCSENSOR, provide precise force measurement. This leads to efficient operations, improved safety, and enhanced productivity in various industries.

“Investing in reliable load cells is a strategic decision that can lead to long-term cost savings and operational excellence.”

Top Load Cell Manufacturers in the USA

We are proud to showcase the top load cell makers in the USA. These companies are leaders in creating custom load cells. They offer high-quality products for many industrial needs.

Overview of Key Players

Notable names in the US load cell market include XJCSENSOR, Omega Engineering, Vishay Precision Group, and Honeywell Sensing and Productivity Solutions. They are known for their expertise, reliable products, and excellent customer service.

Comparing Leading Manufacturers

- XJCSENSOR: Specializes in custom load cell design and manufacturing, with a wide range of products for various applications, including industrial weighing, force measurement, and process control.

- Omega Engineering: Offers a vast product range, including strain gauge load cells, hydraulic load cells, and precision instrumentation for industrial automation.

- Vishay Precision Group: Focuses on high-performance load cells and force measurement solutions for industries such as automotive, aerospace, and testing equipment.

- Honeywell Sensing and Productivity Solutions: Provides innovative load cell technologies and sensor systems for applications in transportation, logistics, and process control.

Notable Innovations in Load Cell Technology

These leading manufacturers have introduced groundbreaking innovations in load cell technology. They have enhanced accuracy, reliability, and connectivity. The latest advancements include wireless load cells with IoT integration and advanced digital signal processing.

| Manufacturer | Key Innovations | Industry Applications |

|---|---|---|

| XJCSENSOR | Custom load cell design, Integrated signal conditioning, Wireless load cell solutions | Industrial automation, Logistics, Transportation |

| Omega Engineering | Miniature load cells, Explosion-proof load cells, Integrated display and control modules | Process control, Material testing, Automotive manufacturing |

| Vishay Precision Group | High-accuracy load cells, Analog and digital output options, Modular design for easy integration | Aerospace, Defense, Heavy equipment manufacturing |

| Honeywell Sensing and Productivity Solutions | Intelligent load cells with built-in diagnostics, Rugged design for harsh environments, Seamless integration with industrial control systems | Transportation, Logistics, Warehousing |

As OEM load cell integrators and custom load cell design and manufacturing specialists, these leading US-based manufacturers continue to push the boundaries of innovation. They deliver cutting-edge solutions that meet the evolving needs of diverse industries.

How to Choose the Right Load Cell Supplier

Choosing the right load cell supplier is key for precision and industrial force measurement. The supplier’s quality can greatly affect your project’s success. To make a good choice, consider several important factors.

Factors to Consider

First, check the supplier’s technical know-how and experience in load cells. Choose a company known for quality and custom solutions. Also, look at their manufacturing process, quality checks, and ability to grow production.

Evaluating Supplier Credentials

Review the supplier’s credentials carefully. Check for certifications, industry approvals, patents, and innovations. This shows their dedication to quality and following standards. Also, consider their financial health and market presence for project support.

The Importance of Customer Service

Great customer service is essential when picking a load cell supplier. Look for a company that offers quick support, on-time delivery, and teamwork. Good customer service ensures a smooth project.

| Factors to Consider | Importance |

|---|---|

| Technical Expertise and Experience | Ensures high-quality products and customized solutions |

| Manufacturing Capabilities | Determines the supplier’s ability to meet production demands |

| Supplier Credentials | Reflects the supplier’s commitment to quality and innovation |

| Customer Service | Ensures a smooth and successful project implementation |

By looking at these factors, you can find the best load cell supplier. This will lead to better performance and success in your project.

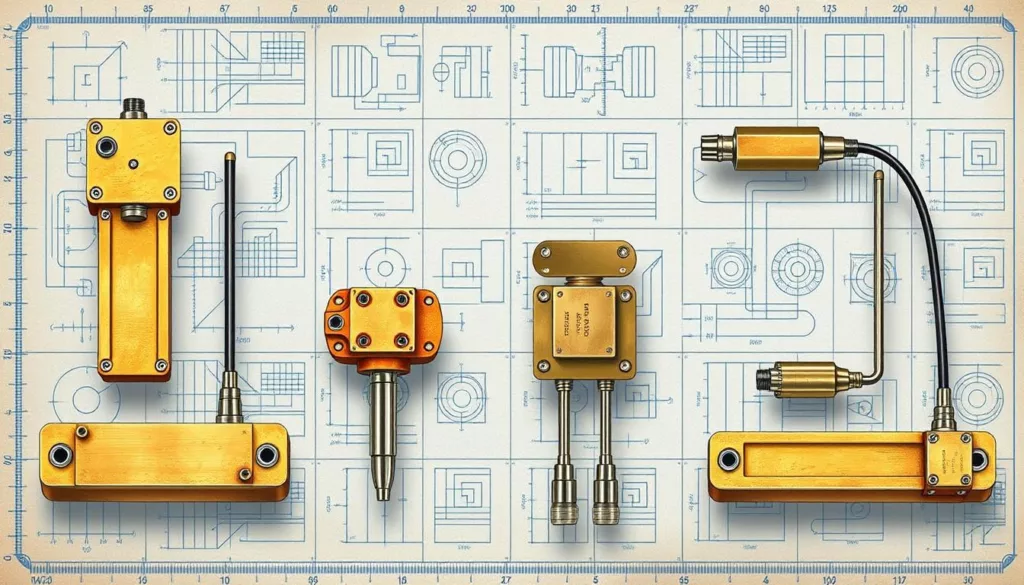

Popular Load Cell Types

There are many types of load cells for different needs in industries. Strain gauge, hydraulic, and pneumatic load cells are among the most used. Each has its own benefits and is best for certain tasks.

Strain Gauge Load Cells

Strain gauge load cells are the most common. They measure how much something bends when force is applied. They are accurate, reliable, and affordable, making them popular in many fields like manufacturing and logistics.

Hydraulic Load Cells

Hydraulic load cells use fluid pressure to measure force. They have a chamber filled with fluid and a diaphragm or piston that changes pressure with the load. They’re great for tough environments because they resist corrosion and can handle extreme conditions.

Pneumatic Load Cells

Pneumatic load cells use air pressure to measure force. They have an air-filled chamber with a flexible part that bends under load, changing air pressure. They’re safe for dangerous places because they don’t send out electrical signals.

Each load cell type has its own strengths and is best for different uses. When picking a load cell, think about how accurate you need it to be, the environment it will be in, and what your application needs.

| Load Cell Type | Principle of Operation | Key Advantages | Typical Applications |

|---|---|---|---|

| Strain Gauge Load Cells | Measure deformation or strain of a structural element | High accuracy, repeatability, and cost-effectiveness | Manufacturing, packaging, logistics |

| Hydraulic Load Cells | Utilize fluid pressure to measure applied force | Resistant to corrosion, can withstand harsh environments | Heavy-duty industrial applications, mining, construction |

| Pneumatic Load Cells | Rely on air pressure to measure applied force | Suitable for hazardous or explosive environments | Process control, safety-critical applications |

Industries Utilizing Load Cells

Load cells are key in many industries. They help measure forces and weights accurately. This is important in the automotive, aerospace, defense, and food and beverage sectors. They show how versatile and vital load cells are in different fields.

Automotive Industry

In the car world, load cells are used a lot. They check forces and stresses during car making, suspension tests, and brake checks. These sensors make sure cars are safe and work well.

Aerospace and Defense

The space and defense fields use load cells for many things. They measure forces and stresses in planes, rockets, and military gear. This helps keep these important items safe and reliable.

Food and Beverage Industry

In food and drink, load cells are key for quality and control. They help with packaging, portioning, and filling. They also check weights in storage and transport. Load cells help make production better, cut waste, and follow rules.

| Industry | Key Applications of Load Cells | Benefits of Using Load Cells |

|---|---|---|

| Automotive |

|

|

| Aerospace and Defense |

|

|

| Food and Beverage |

|

|

Load cells are vital in many areas. They help with industrial force measurement in cars and high-capacity weighing platforms in food. They give accurate data, making products better, processes more efficient, and operations smoother.

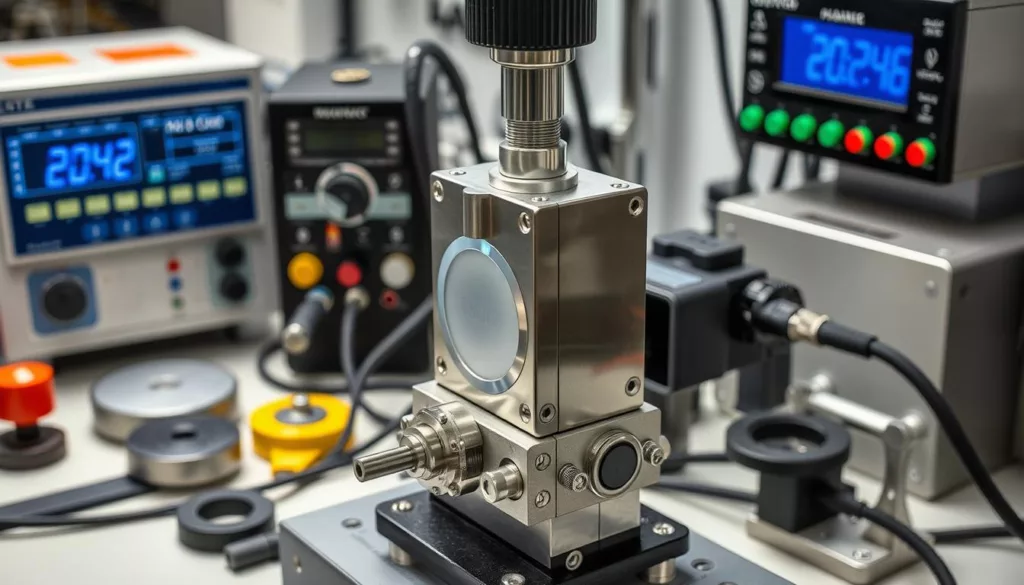

Load Cell Calibration and Maintenance

Precise weighing solutions need accurate and reliable load cells. Regular calibration and maintenance are key to keeping your system precise. Let’s look at why these practices are important and how they improve your load cell’s performance.

Importance of Regular Calibration

Calibrating your load cells regularly is vital for accurate measurements. Over time, factors like environment and use can affect their accuracy. Regular calibration keeps your precision weighing solutions reliable and consistent, protecting your weighing system components.

Best Practices for Maintenance

- Protect load cells from physical damage, such as impacts or overloading

- Keep load cell surfaces clean and free from debris or contaminants

- Properly secure load cells to minimize stress and strain

- Monitor load cell performance for any signs of deterioration

- Follow manufacturer-recommended maintenance schedules

Signs a Load Cell Needs Calibration

Knowing when to calibrate a load cell is key for its performance. Look out for these signs:

- Drift in measurement accuracy over time

- Increased hysteresis or non-linearity

- Fluctuating or unstable readings

- Visible damage or wear on the load cell

By being proactive with calibration and maintenance, you can make your precision weighing solutions last longer. This ensures your weighing system components keep giving you the accurate results you need.

Load Cell Pricing and Budgeting

Choosing the right load cell is important, and cost is a big factor. As experts in OEM load cell integrators and custom design, we know how to balance quality and price. We’ll look at what affects load cell prices, help you set a budget, and offer tips to save money.

Factors Influencing Cost

Several things can change a load cell’s price. These include the type of load cell, how much weight it can handle, and its accuracy. The materials used, any special features, and how it’s made also play a role. Buying in bulk can also lower the cost.

- Type of load cell (e.g., strain gauge, hydraulic, or pneumatic)

- Capacity and accuracy requirements

- Materials used in the construction

- Customization and special features

- Manufacturing processes and quality control measures

- Quantity ordered (larger orders often benefit from economies of scale)

Knowing these factors helps you understand what affects the price. This knowledge is key to budgeting wisely.

Setting a Realistic Budget

To set a budget, think about what you need and the costs involved. Consider the application, how long the load cell will last, and if you need extra accessories. Talking to OEM load cell integrators and custom load cell design and manufacturing experts can help you find a good price range.

Cost-Saving Tips for Purchase

To save money on load cells, try these tips:

- Look for bulk discounts to buy more at once

- Consider refurbished or reconditioned load cells for savings

- Focus on what you really need and avoid extra features

- Get advice from manufacturers and suppliers to find the best deal

Using these tips can help you buy a load cell that fits your budget without sacrificing quality.

“Choosing the right load cell supplier can have a significant impact on the overall cost of your project. It’s important to work with a partner who can provide customized solutions and cost-effective options to meet your specific needs.”

Innovations in Load Cell Technology

Load sensor technology is always getting better. New wireless load cells and IoT integration are changing the game. These advancements are making the industry more efficient and connected.

Wireless Load Cells

Wireless load cells are a big deal for hard-to-reach places. They send data through radio waves, no wires needed. This makes them perfect for construction, mining, and transportation where moving around is key.

IoT Integration in Load Cells

IoT is making load cells smarter. They can now send data in real-time and even do self-checks. This means smart manufacturing, better logistics, and more efficient processes, saving time and money.

Future Trends in Load Cell Development

Experts say we’re on the verge of even more amazing load cells. New materials, smaller sensors, and AI will make them more accurate and flexible. This is the future of load sensor technology and custom load cell design and manufacturing.

These new technologies will change how we measure and manage our work. By keeping up with these advancements, companies can offer top-notch solutions. These solutions will make operations better and more reliable.

Customer Support from Load Cell Suppliers

In the world of precision weighing solutions and industrial force measurement, good customer support is key. Reliable help is vital for the best performance and life of these parts.

Importance of Technical Support

Load cells are complex and need special knowledge for setup, calibration, and fixing problems. Suppliers with great technical support help customers get the most from their industrial force measurement systems. They guide users and solve issues quickly, showing they care about their customers.

Utilizing After-Sales Services

- Regular calibration keeps load cells precise and reliable. Suppliers that offer easy calibration services help customers keep their precision weighing solutions in top shape.

- When load cells break or wear out, quick repair or replacement is needed. Good after-sales support means less downtime for customers.

- Suppliers that let customers customize or upgrade their systems meet evolving needs. This extends the life and use of industrial force measurement equipment.

Resources for Troubleshooting

The best suppliers give more than just support when problems happen. They also give customers the tools and knowledge to avoid and fix common issues. This includes detailed manuals, videos, online help, and direct access to experts.

“Choosing a load cell supplier with a proven track record of exceptional customer support is vital for the long-term reliability and performance of your precision weighing solutions.”

By focusing on technical support, after-sales services, and troubleshooting resources, top industrial force measurement suppliers show they care about their customers. They aim to build strong, lasting relationships.

Conclusion: Choosing the Right Manufacturer

Choosing the right load cell manufacturer is key for accurate and reliable force measurement. Look at their technology, product quality, support, and experience. This helps you find the best fit for your needs.

Recap of Key Considerations

We’ve talked about the importance of a manufacturer’s skills, innovation, and focus on customers. Things like calibration, maintenance, and industry knowledge are vital. They affect how well your load cells work and last.

Future of Load Cells in Various Industries

The load cell industry is growing fast, thanks to new materials, electronics, and software. This means better accuracy and connection. As industries like manufacturing, aerospace, and robotics need more precise measurements, load cells will play a bigger role. They help improve performance, cut waste, and boost efficiency.

Making an Informed Decision

Know what you need, research top manufacturers, and check their skills. This way, you can choose wisely for your company’s success. Look for partners who offer custom solutions and great support. They’ll help meet your force measurement needs with precision and reliability.